Sealing structure for rotary shaft of flue gas valve

A shaft sealing and valve technology, applied in shaft sealing, engine sealing, valve details, etc., can solve problems such as shaft end leakage, and achieve the effect of small instantaneous impact force, good convenience, and improved convenience.

Active Publication Date: 2014-10-22

江苏明江阀业有限公司

View PDF10 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0033] Embodiment 2 is different from Embodiment 1 in that: the area of the high temperature end of the thermoelectric tube is 80% of the area of the door panel.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

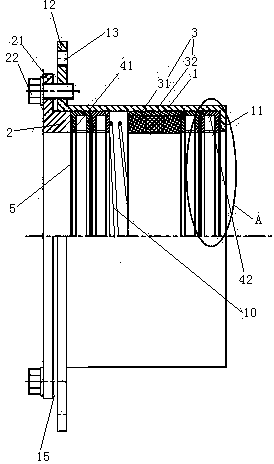

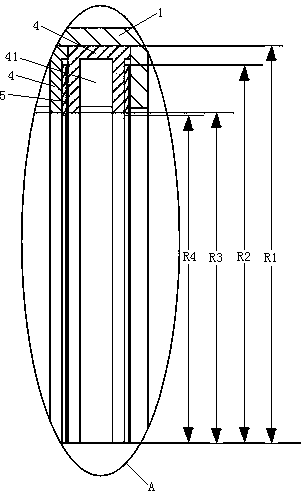

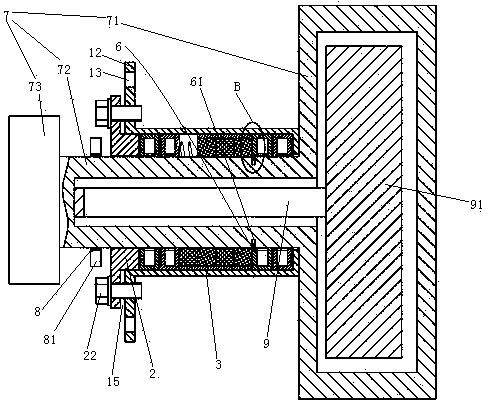

The invention relates to a flue gas valve, and discloses a sealing structure for a rotary shaft of a flue gas valve. The sealing structure comprises a packing pipe. A pressing ring, first buffering rings, a compression spring, a graphite sealing ring and second buffering rings which are sequentially butted to one another are arranged in the packing pipe, an inner rib is arranged at one end of the packing pipe, an outer rib is arranged at the other end of the packing pipe, an outer flange is arranged at the end, which is far away from the first buffering rings, of the pressing ring and is connected with the outer rib by assembling bolts, an adjusting gap is reserved between the outer flange and the outer rib, the second buffering rings are butted to the inner rib, the outer peripheral surface of the graphite sealing ring is hermetically connected with the inner peripheral surface of the packing pipe, the flue gas valve comprises the rotary shaft, the rotary shaft is penetratingly arranged in the graphite sealing ring and is hermetically butted to the graphite sealing ring, matching surfaces of the rotary shaft and the graphite sealing ring are conical surfaces, and small-diameter ends of the conical surfaces are close to the inner rib. The sealing structure for the rotary shaft of the flue gas valve has the advantages that a shaft end of the rotary shaft of the flue gas valve can be sealed by the sealing structure, and sealing effects can be adjusted; the problem of leakage at a shaft end of an existing flue gas valve can be solved by the aid of the sealing structure.

Description

technical field [0001] The invention relates to a flue gas valve, in particular to a shaft sealing structure of the flue gas valve, which belongs to the technical field of gas turbine power generation. Background technique [0002] The flue gas valve is a device connected to a gas turbine (also known as a gas turbine) and a waste heat boiler. The temperature of the flue gas inside is between 500 ° C and 700 ° C, and the pressure is 5000 ~ 6500 Pa. When used, it is driven by an external hydraulic cylinder or a motor. Drive the shaft of the flue gas valve to rotate, so as to realize the rotation of the valve plate from 0 to 90°. A flue gas valve and a sealing structure are disclosed in a patent document with a Chinese application number of 2007101646590, a publication date of July 9, 2008, and a title of "smoke baffle door and sealing device". The existing flue gas valves only solve the sealing problem when the valve plate and the flue are closed, and the sealing between ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16J15/16F16K41/02

Inventor 危金兰

Owner 江苏明江阀业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com