External oil filling type shield hob

An oil-filled hob technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as seal failure, hob failure, and damaged bearings, so as to prevent hob failure, reduce damage, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

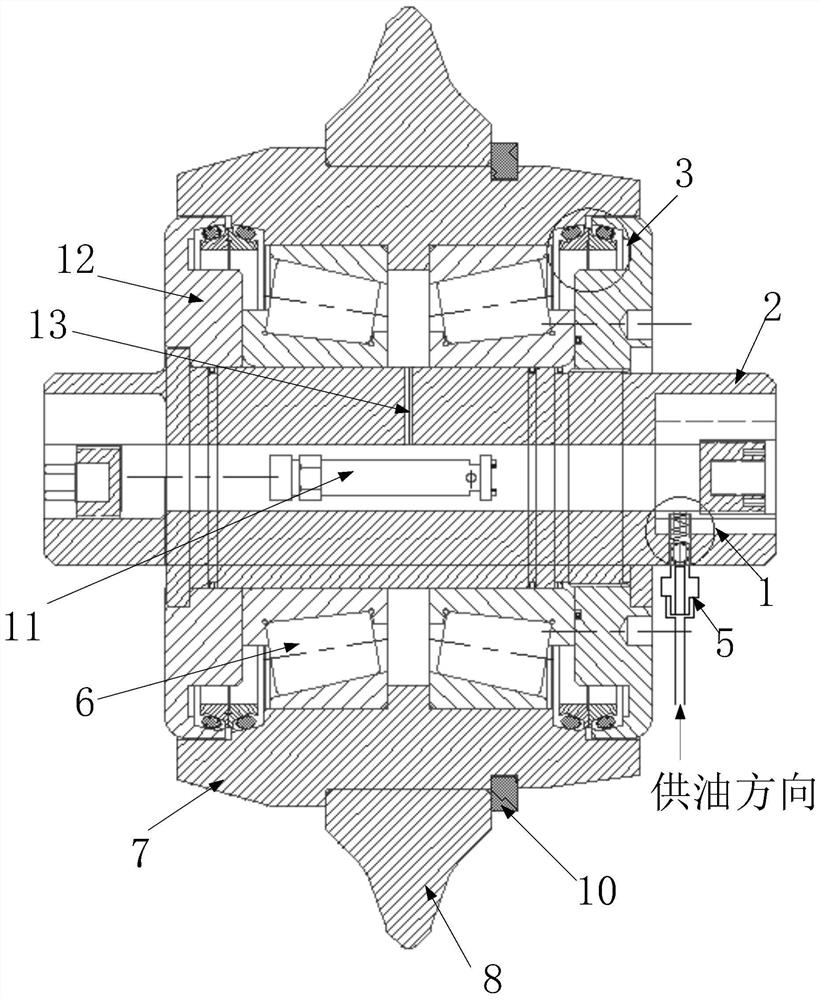

[0030] Such as Figure 1 to Figure 4 As shown, Embodiment 1 of the present invention provides an external oil-filled shield hob, the external oil-filled shield hob is an external oil-filled single-blade hob, specifically a 17-inch external oil-filled single-blade hob The knife is suitable for shield tunneling construction, especially for tunneling construction in composite ground. The outer oil-filled single-edged hob comprises: a cutter hub 7, two bearings 6 are arranged inside the cutter hub 7, a hollow cutter shaft 2 is arranged inside the bearing 6, end caps 12 are arranged at both ends of the cutter hub 7, and the hollow cutter shaft The two ends of 2 pass through the end cover 12, and the outside of the cutter hub 7 is provided with a cutter ring 8.

[0031] Specifically, the inner ring of the bearing 6 is mounted on the hollow cutter shaft 2 with an interference fit, the outer ring of the bearing 6 is installed in the cutter hub 7 through an interference fit, and the c...

Embodiment 2

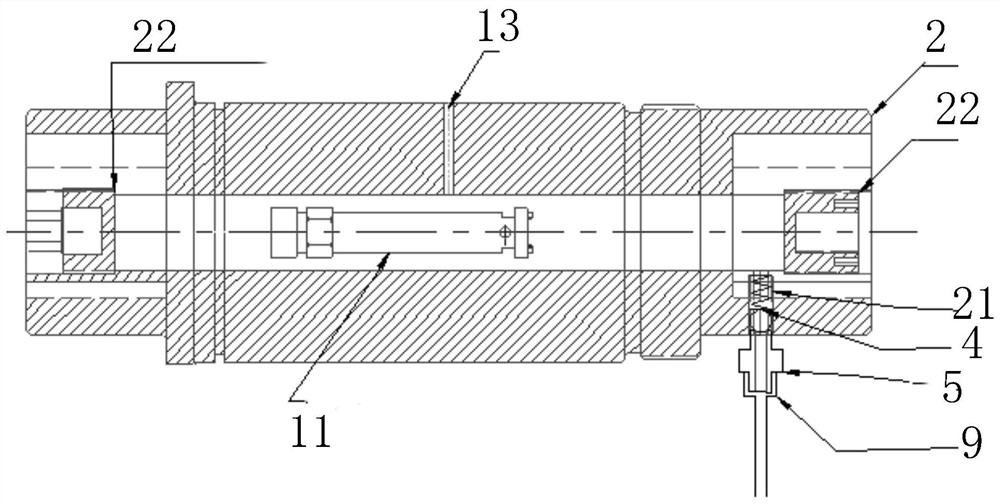

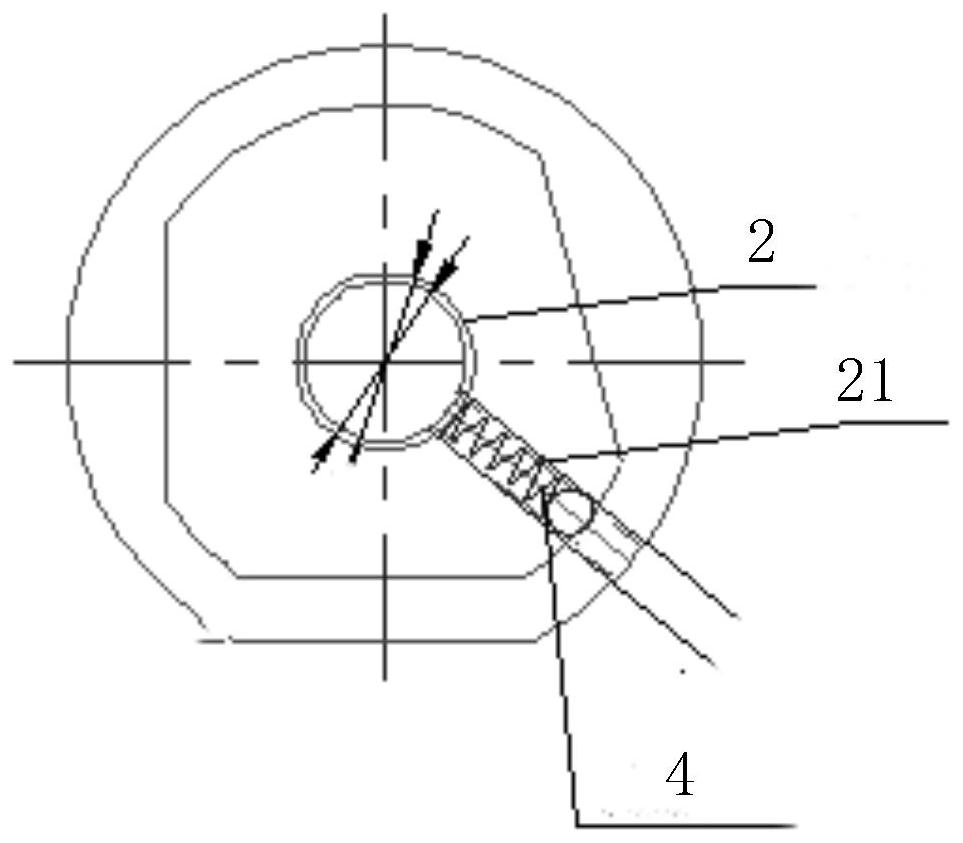

[0039] see Figure 5 to Figure 7 , Embodiment 2 of the present invention also provides an external oil-filled shield hob, the external oil-filled shield hob is an external oil-filled central double hob, specifically a 17-inch external oil-filled central double The hob, the outer oil-filled center duplex hob includes: two cutter hubs 7, the two cutter hubs 7 are arranged side by side, each cutter hub 7 is provided with two bearings 6, and the bearings 6 are provided with a hollow cutter shaft 2 , the outer end of the cutter hub 7 is provided with an end cover 12, and an intermediate block 14 is arranged between the two cutter hubs 7; the two ends of the hollow cutter shaft 2 extend to the outer end surface of the end cover 12, and each cutter hub 7 is set There are 8 knife rings.

[0040] Specifically, the inner ring of the bearing 6 is mounted on the hollow cutter shaft 2 with an interference fit, the outer ring of the bearing 6 is installed in the cutter hub 7 through an int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com