Backlight module

A backlight module and backplane technology, applied in the field of direct-type backlight modules, can solve problems such as damage to the diffuser plate, and achieve the effect of reducing the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

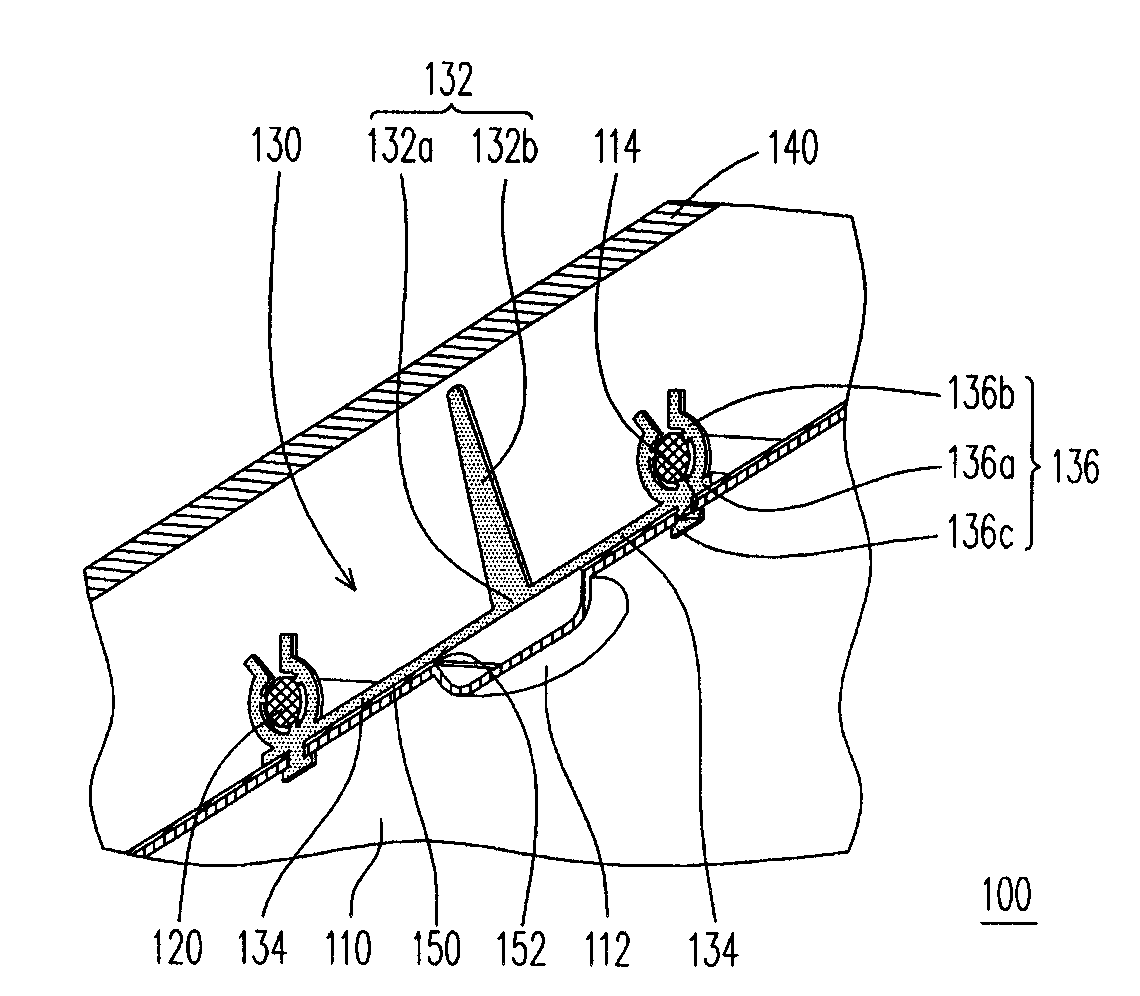

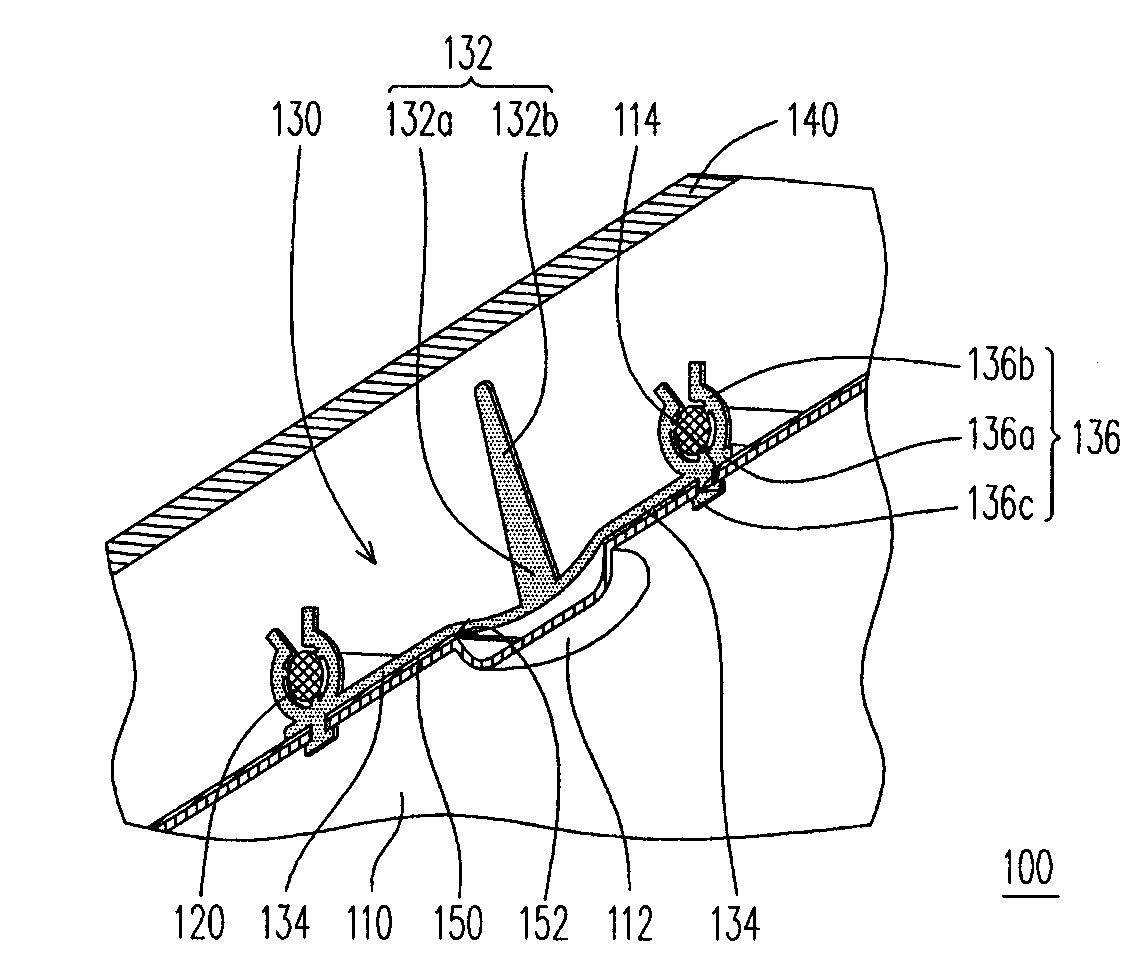

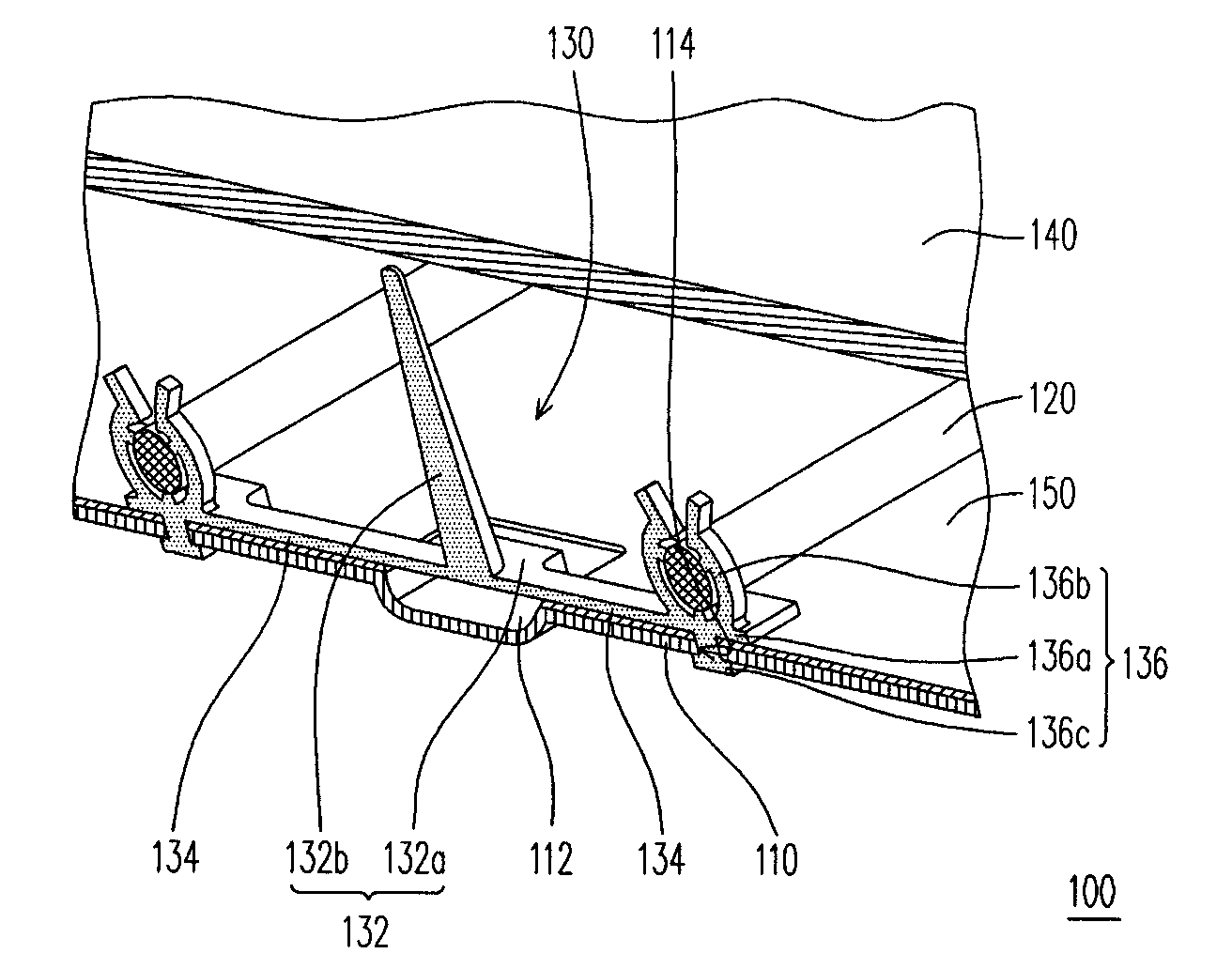

[0050] figure 1 It is a three-dimensional cross-sectional view of a backlight module according to an embodiment of the present invention. figure 2 for figure 1 The three-dimensional cross-sectional view of elastic deformation of the supporting part. Please refer to figure 1 , the backlight module 100 of this embodiment includes a backplane 110 , a plurality of lamp tubes 120 (two are shown in the figure), a lamp tube fixing base 130 and a diffuser plate 140 . The back plate 110 has a recess 112, the lamp tube 120 is arranged on the back plate 110 and the lamp tube fixing seat 130, the lamp tube fixing seat 130 for fixing the lamp tube 120 is also arranged on the back plate 110, and the diffuser plate 140 is arranged on the back plate 110. Above the board 110 , the lamp tube 120 and the lamp tube fixing seat 130 .

[0051] The lamp fixing seat 130 has a support portion 132 extending away from the back plate 110 for supporting or resisting the diffuser plate 140 . The vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com