Friction inserting type clutch and its mfg. method

A manufacturing method and technology of clutches, applied to clutches, mechanically driven clutches, clutches that mesh with each other, etc., can solve the problems of burnt friction surface separation, unclear separation, easy slipping, etc., and achieve the effect of non-slip separation and smooth combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

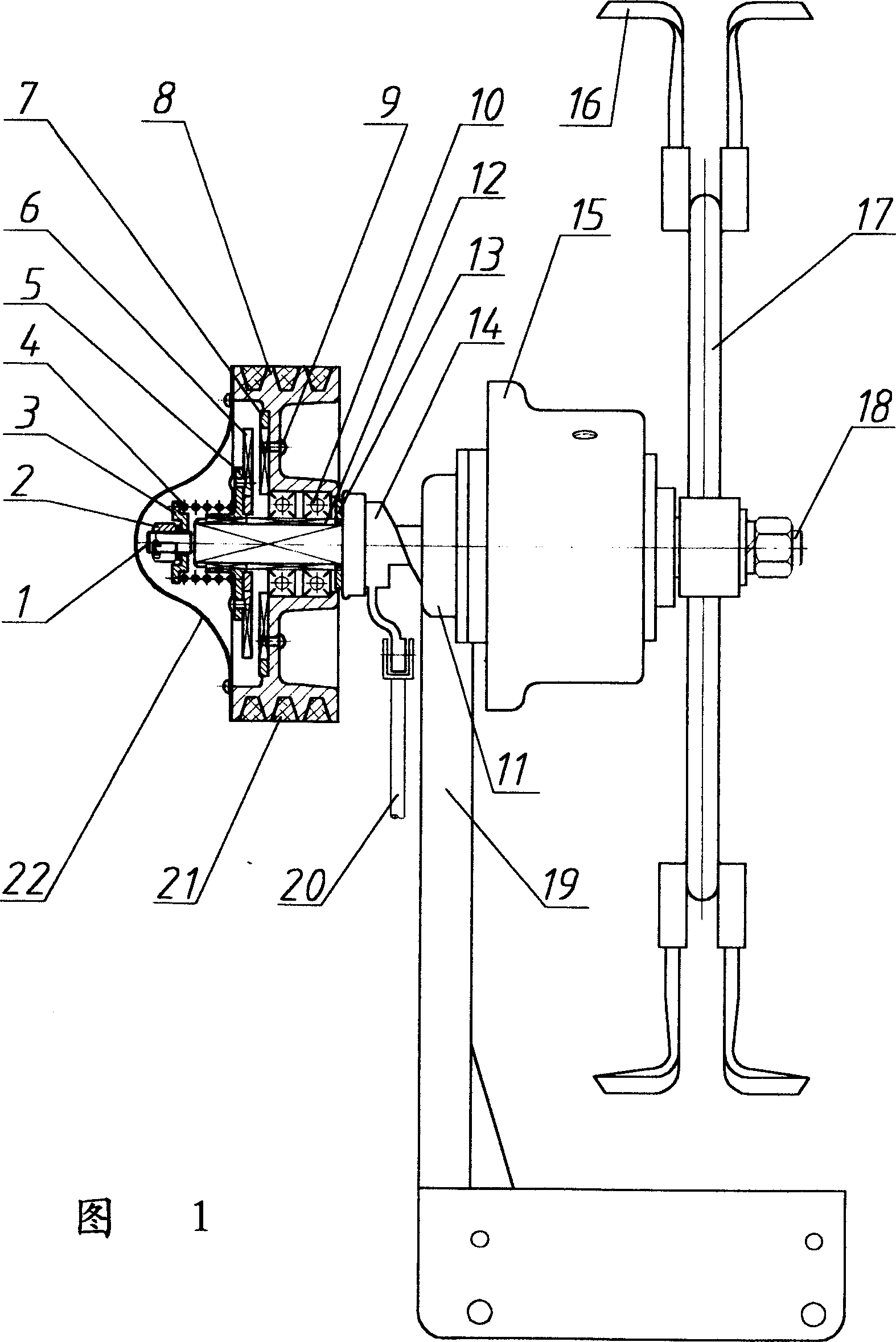

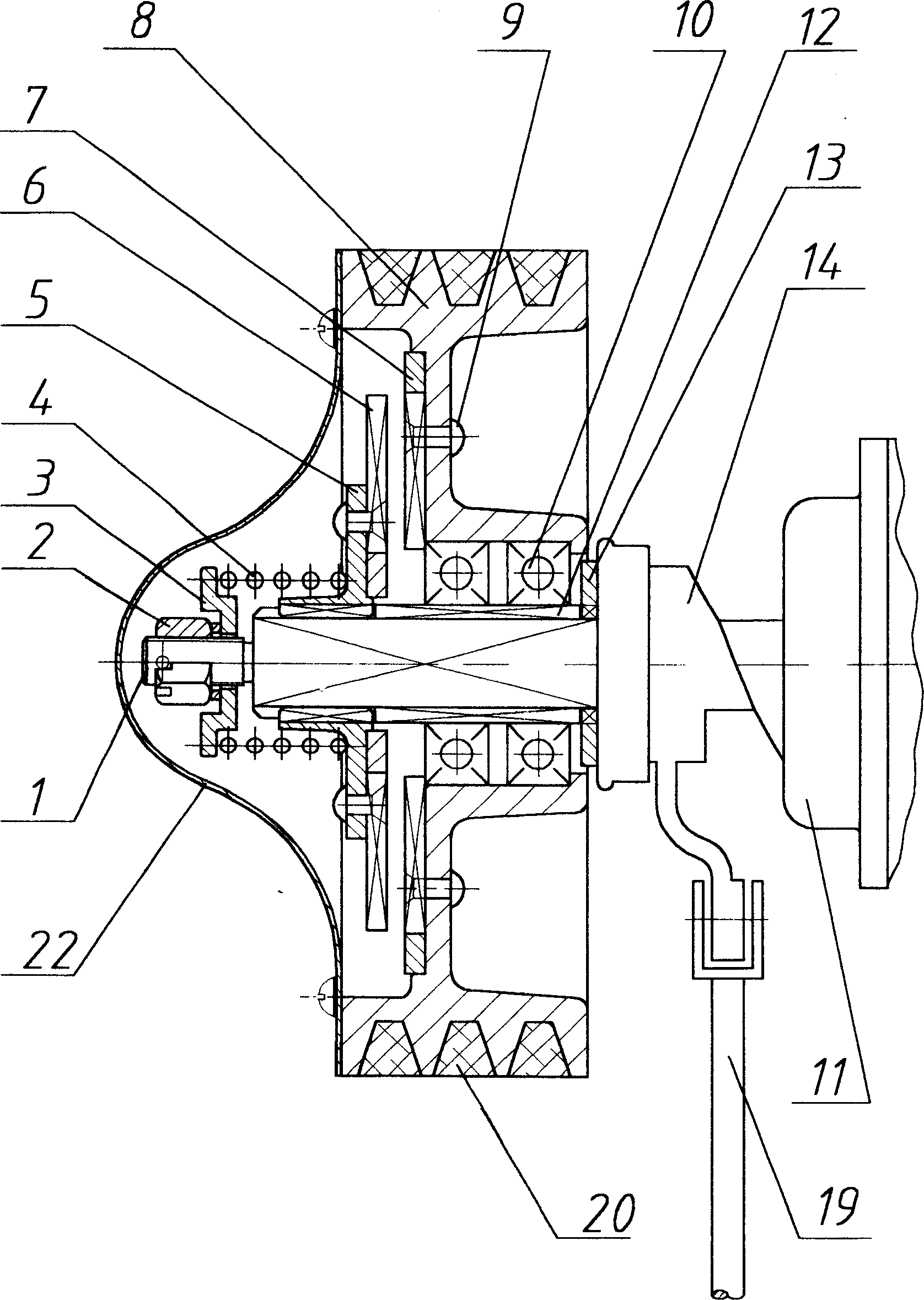

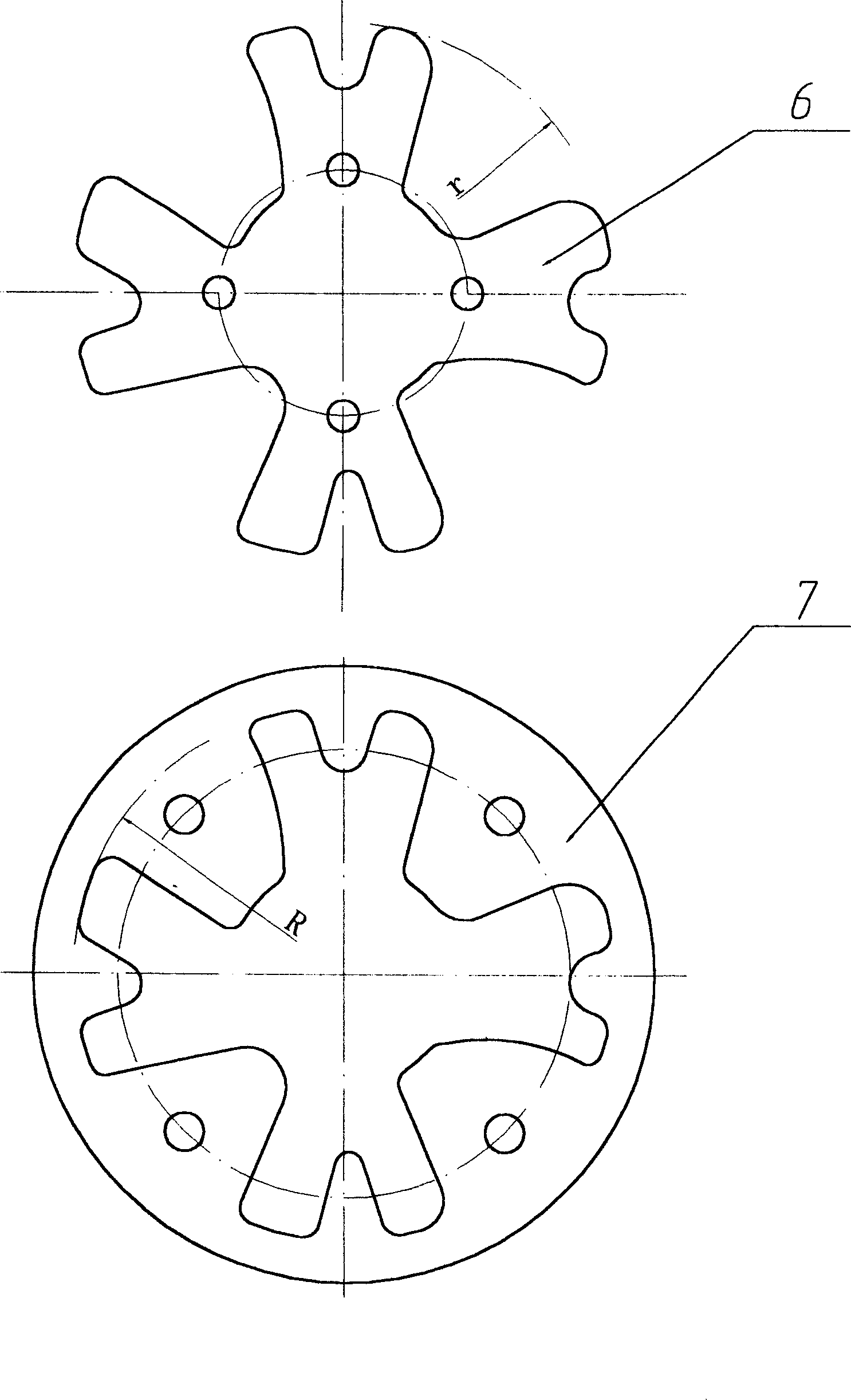

[0035]Embodiment 1, a front-mounted ditching machine using a friction clutch: Referring to Figures 1 and 2: a gear box 15 is mounted on the ditching machine frame 19, and a cutter head is mounted on the cutter shaft 18 of the gear box 15 17. The blade 16 is installed on the cutter head 17, and the driven shaft 1 on the other side of the gear box 15 corresponding to the cutter head 17 is equipped with a driving wheel 8, in order to reduce wear and tear between the driven shaft 1 and the driving wheel 8 The bearing 10 is assembled; the driving piece 7 and the driving wheel 8 are connected and fixed by screws or rivets 9; the driven piece 6 and the spline sleeve 5 are fixed by screws or rivets 9, and the spline sleeve 5 and the driven shaft 1 are splined. It cannot rotate, but it can slide axially on the driven shaft 1. The nut 2 and the large washer 3 at the shaft end press the spring 4 to the spline sleeve 5; there is a sealing cover 22 on the outside of the nut 2 to cover the d...

Embodiment 2

[0042] Embodiment 2, with reference to Figure 4 : Embodiment 2 is a notch-type friction-embedded clutch, punching out more than 2 notches with different geometric shapes on the circular plate, as the driven plate, and the material punched out from the notch is assembled to the driving wheel as the active plate superior;

Embodiment 3

[0043] Embodiment 3, referring to Figure 5: 2 to 6 through holes with different geometric shapes are punched out on a circular plate as driven pieces or active pieces, and the materials punched out from the through holes are assembled to the corresponding active pieces. piece or driven piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com