Developing device

A developing device and developing solution technology, which is applied in the processing of photosensitive materials, etc., can solve the problems of photoresist denaturation, increasing the amount of developing solution, and prone to defects, etc., and achieve the effects of reducing the number of defects, improving cleaning efficiency, and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

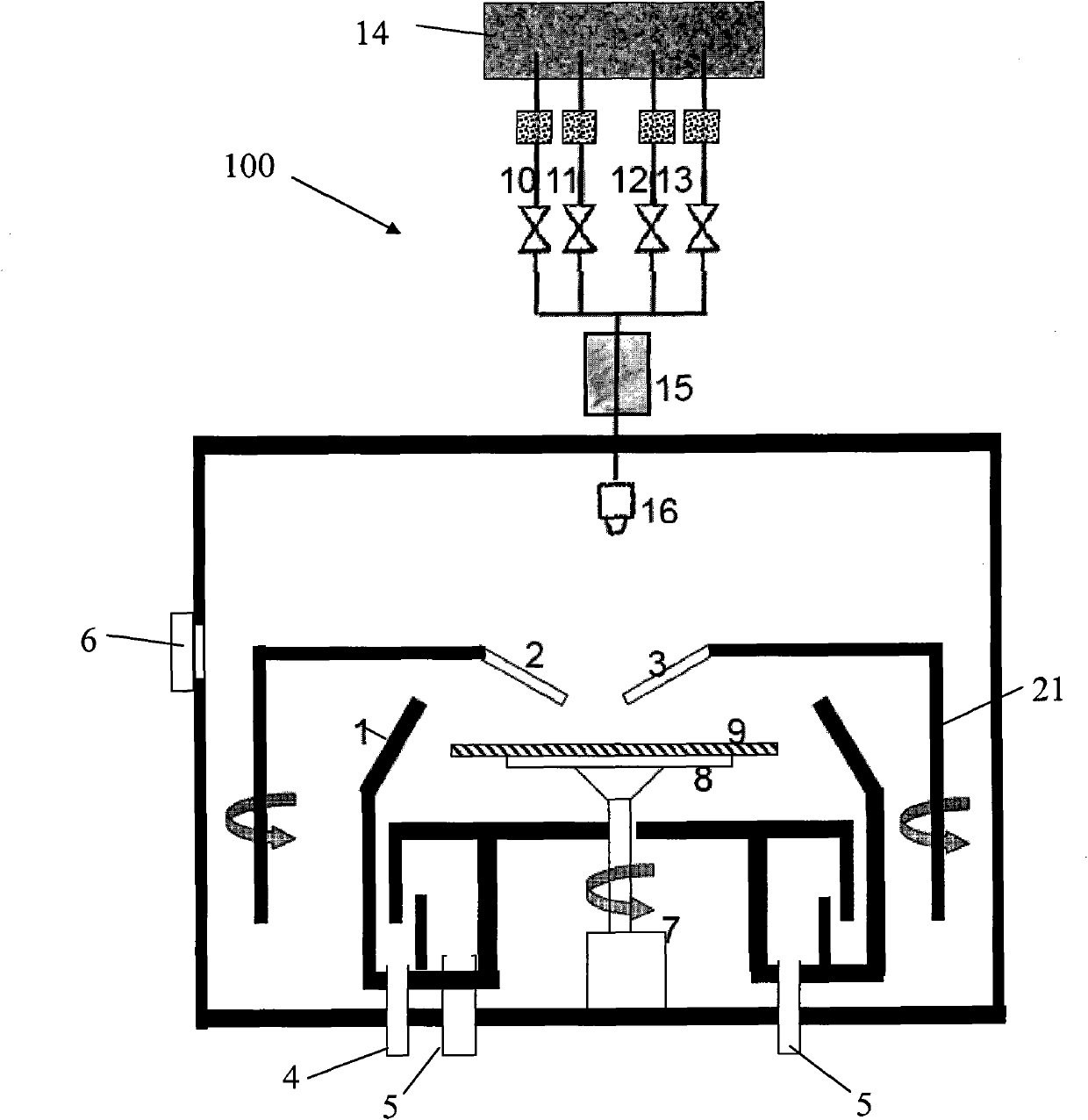

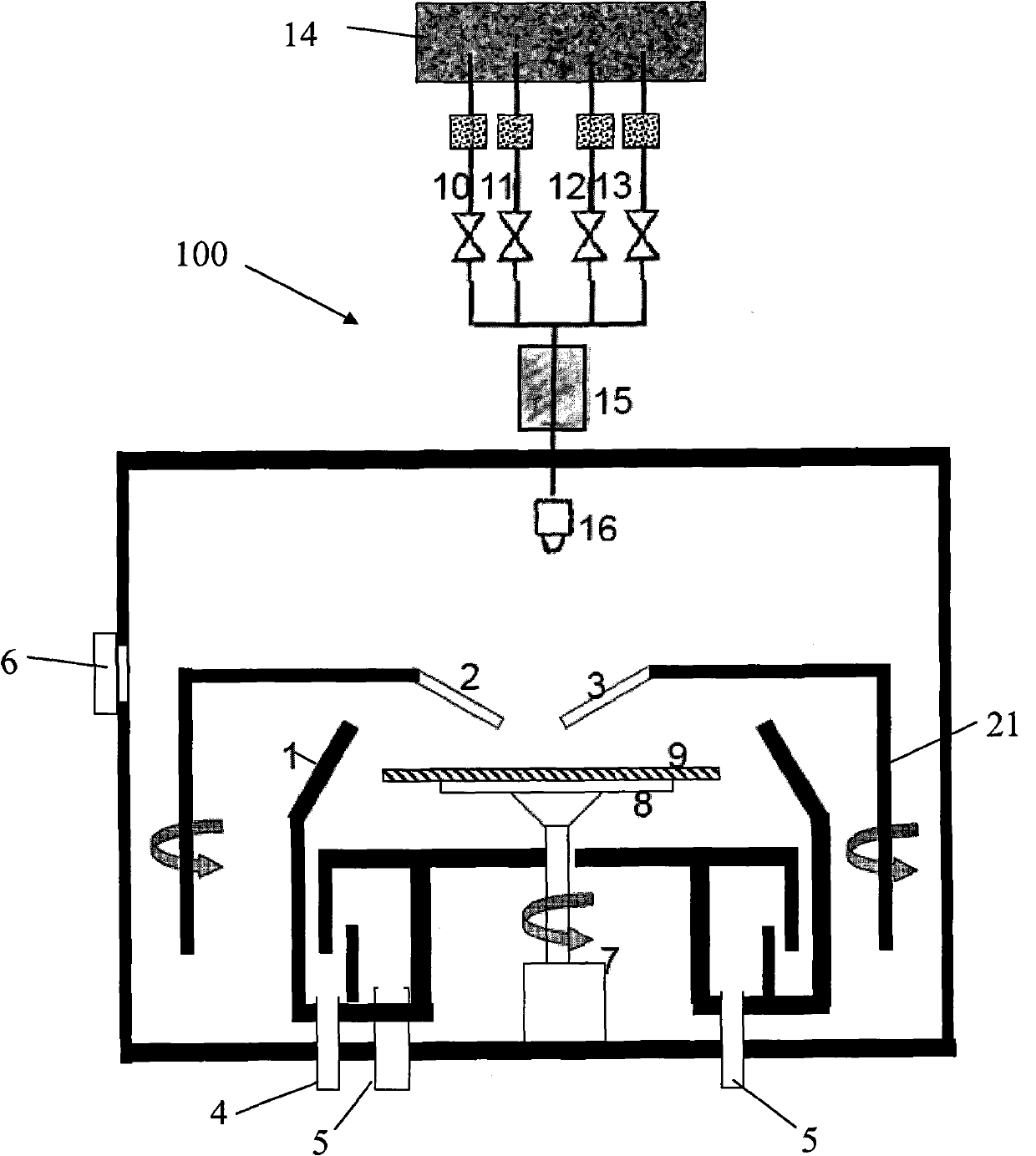

[0017] see figure 1 As shown, the present invention provides a developing device 100, which is used for photolithographic development in the semiconductor manufacturing process. The developing device 100 includes a developing chamber 1, a cleaning nozzle 2, a developing solution nozzle 3, a waste liquid discharge port 4, and a developing chamber exhaust. The control terminal 5 , the wafer 9 conveying the control port 6 , the motor 7 , the vacuum chuck 8 , the control module 14 , the atomizing device 15 and the mist nozzle 16 . In the photolithography development process described in the present invention, the development device 100 needs to use deionized water, a surfactant solution, an organic alcohol mixed solution mixed with an organic solvent such as ethanol, and a developer to process the wafer 9. Wetting, cleaning, and removing the photoresist on the wafer 9 to form the required circuit patterns on the wafer.

[0018] All main working components of the developing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com