Chemical mechanical polishing solution for processing optical surface of Ge-As-Se chalcogenide glass

A ge-as-se, chalcogenide glass technology, applied in polishing compositions containing abrasives, etc., can solve problems such as multiple microscopic surface defects on optical surfaces, and achieve the effect of reducing the number of surface defects and facilitating preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

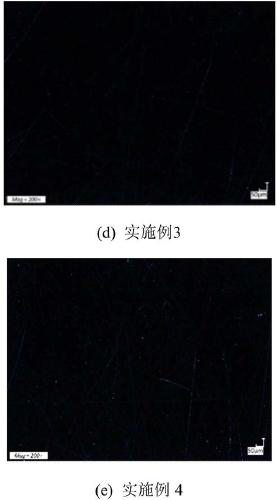

[0039] Weigh 50g of alumina polishing powder with a particle size of W0.3 and add it into 852.24ml of deionized water while stirring, and ultrasonically disperse for 5-10min;

[0040] Weigh 1g sodium hexametaphosphate and add the above solution while stirring;

[0041] Measure 0.27ml of sulfuric acid stock solution with a concentration of 98%, and add it into the above solution along the container wall until the pH value is about 2;

[0042] Measure 147.49ml of 30% hydrogen peroxide stock solution, and add it into the solution while stirring.

[0043] Implementation effect analysis:

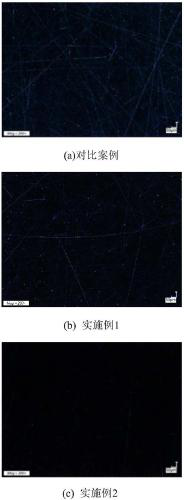

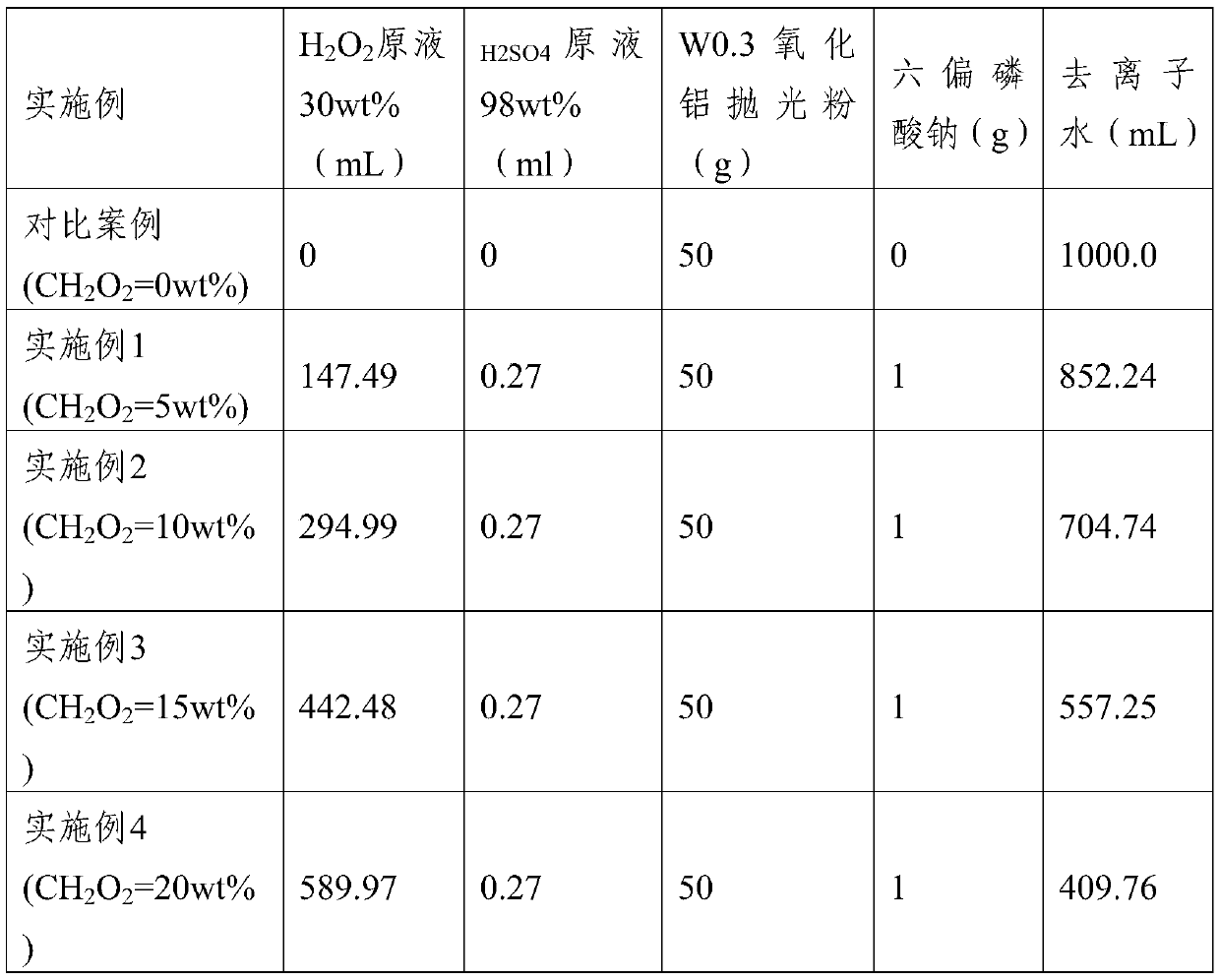

[0044] The Φ40mm wafer-shaped Ge 10 As 40 Se 50The chalcogenide glass sample is placed on a polishing machine, the spindle speed is controlled at 37rpm, the swing speed of the pendulum shaft is 25rpm, the eccentricity is 10mm, and the polishing time is 30min. figure 1 -As shown in (b), the surface roughness is shown in the attached table 2.

Embodiment 2

[0046] Weigh 50g of alumina polishing powder with a particle size of W0.3 and add it into 704.74ml of deionized water while stirring, and ultrasonically disperse for 5-10min;

[0047] Weigh 1g sodium hexametaphosphate and add the above solution while stirring;

[0048] Measure 0.27ml of sulfuric acid stock solution with a concentration of 98%, and add it into the above solution along the container wall until the pH value is about 2;

[0049] Measure 294.99ml of 30% hydrogen peroxide stock solution, and add it into the solution while stirring.

[0050] Implementation effect analysis:

[0051] The Φ40mm wafer-shaped Ge 10 As 40 Se 50 The chalcogenide glass sample is placed on a polishing machine, the spindle speed is controlled at 37rpm, the swing speed of the pendulum shaft is 25rpm, the eccentricity is 10mm, and the polishing time is 30min. figure 1 -As shown in (c), the surface roughness is shown in the attached table 2.

Embodiment 3

[0053] Weigh 50g of alumina polishing powder with a particle size of W0.3, add it into 557.25ml of deionized water while stirring, and ultrasonically disperse for 5-10min;

[0054] Weigh 1g sodium hexametaphosphate and add the above solution while stirring;

[0055] Measure 0.27ml of sulfuric acid stock solution with a concentration of 98%, and add it into the above solution along the container wall until the pH value is about 2;

[0056] Measure 442.48ml of 30% hydrogen peroxide stock solution, and add it into the solution while stirring.

[0057] Implementation effect analysis:

[0058] The Φ40mm wafer-shaped Ge 10 As 40 Se 50 The chalcogenide glass sample is placed on a polishing machine, the spindle speed is controlled at 37rpm, the swing speed of the pendulum shaft is 25rpm, the eccentricity is 10mm, and the polishing time is 30min. figure 1 -As shown in (d), the surface roughness is shown in the attached table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com