Hot-rolled titanium coil and surface quality control method thereof

A surface quality and control method technology, applied in metal rolling, profile control, metal rolling, etc., can solve problems such as poor surface quality of hot-rolled titanium coils, and achieve product quality improvement, labor cost saving, and surface quality improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0029] According to a preferred embodiment of the present invention, the velocity of the water sprayed from the nozzle is 20-30m / s, preferably 24-26m / s. If the speed of the water sprayed by the nozzle is less than 20m / s, the spatter generated by the scraping and falling on the titanium slab cannot be completely blown away; if the speed of the water sprayed by the nozzle is greater than 30m / s, it will Seriously affect the service life of the nozzle.

[0030] In the present invention, preferably, the nozzle is installed before the finishing roll used in the finishing rolling process. The adoption of this preferred embodiment is more conducive to blowing away the spatter generated by scraping and falling on the titanium slab during the finish rolling process, so as to avoid the formation of indentation defects.

[0031] In the present invention, there is no special requirement on the shape of the nozzle, and it may be a commonly used nozzle shape in the field, for example, fan-s...

Embodiment 1-5

[0047] This embodiment is used to illustrate the hot-rolled titanium coil and its surface quality control method of the present invention.

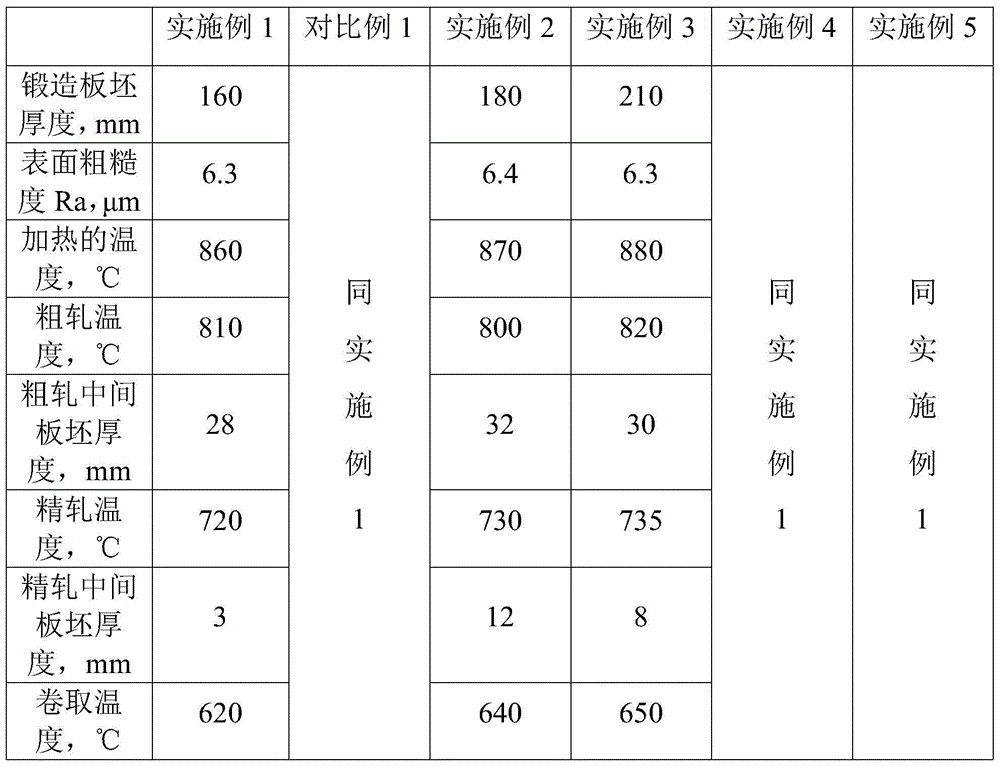

[0048]Sponge titanium was smelted twice in a 10t vacuum consumable furnace. After smelting, it was forged to form a titanium slab. The thickness of the forged titanium slab is shown in Table 1. The forged titanium slab was milled, Heating, rough rolling (3 times), finish rolling (1 time) and coiling to produce hot-rolled titanium coils. Among them, the surface roughness Ra, heating temperature, intermediate slab thickness, rough rolling temperature, finish rolling temperature and coiling temperature of the titanium slab obtained by milling are shown in Table 1, respectively.

[0049] Wherein, in the finishing rolling process, the nozzle is installed before the finishing roll, and water is sprayed to the surface of the titanium slab through the nozzle, the shape of the nozzle, the angle between the opening direction of the nozzle and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com