Static magnetic field-laser coaxial composite fusion covering method and device

A static magnetic field and laser technology, applied in the coating process of metal materials, coatings, etc., can solve the problems that it is difficult to effectively control the solidification and crystallization process of the cladding layer, and the cladding layer is prone to residual inclusions, porosity, and inability to apply to parts at the same time. , to achieve the effect of simple device, low cost and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

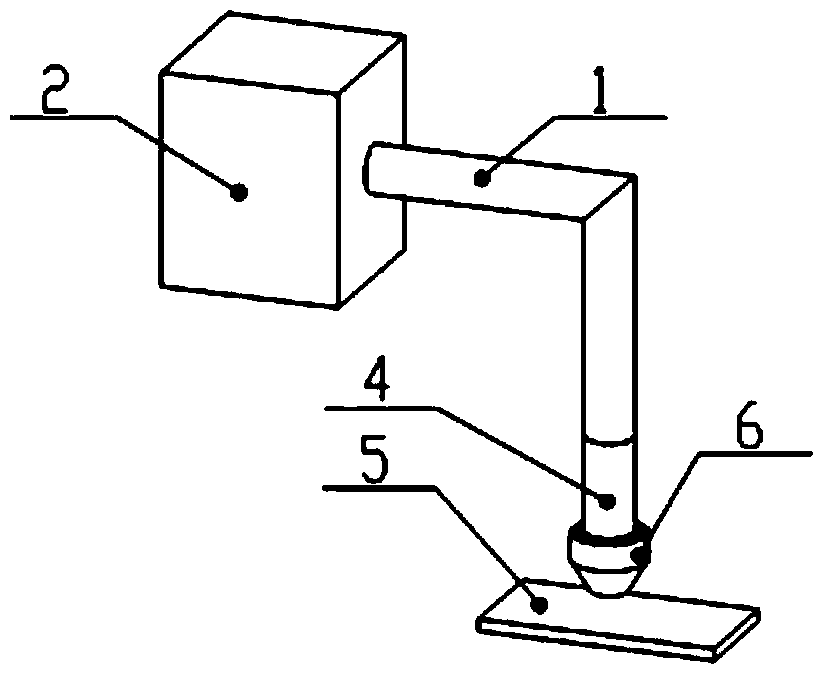

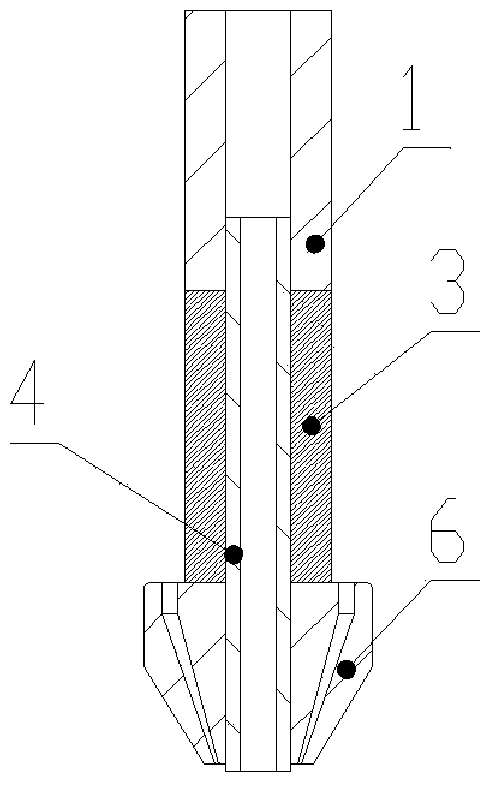

[0025] like figure 1 , a device for applying a static magnetic field-laser coaxial composite cladding, including a laser generator 2 connected in sequence, a laser transmission channel 1, a magnetic core 4, and a coaxial powder feeder 6, and the magnetic core 4 is equipped with The excitation coil 3 and the gas protection device are connected to the laser transmission channel 1, wherein the excitation coil 3 is coaxially combined with the magnetic core 4, the magnetic core 4 is coaxially combined with the coaxial powder feeder 6, and the coaxial powder feeder 6 is combined with the laser transmission channel coaxial 1 combination (as figure 2 As shown), the laser generator 2 and the laser transmission channel 1 can be connected through a flexible optical fiber or a flying optical path, the cladding substrate 5 is placed on the workbench, and the gas protection device is connected to the laser transmission channel 1.

[0026] Firstly, the surface of the low-carbon alloy steel...

Embodiment 2

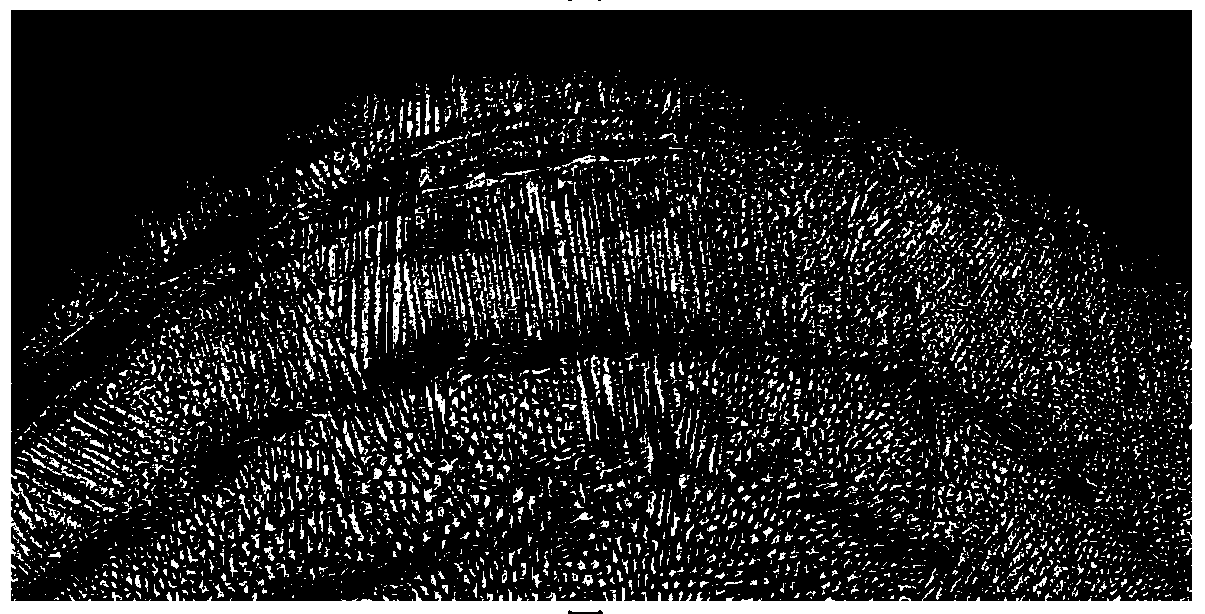

[0028] In this example, the static magnetic field in Example 1 (that is, the coil does not flow through) is removed, while other process parameters remain the same. The results of this example show that, under the effect of no static magnetic field, there are only a small amount of columnar crystals growing perpendicular to the interface of the cladding layer near the substrate interface, and the rest of the interface are uniform equiaxed crystals (such as Figure 4 As shown), combined with Example 1 and Example 2, it is proved that the static magnetic field can effectively regulate the grain growth form of the laser cladding layer.

Embodiment 3

[0030] The device for static magnetic field-laser coaxial composite cladding is the same as that of Embodiment 1.

[0031] After grinding the surface of the low-carbon alloy steel to be fused, wash it repeatedly with acetone, then put it in a drying oven and dry it at 100°C for 30 minutes, and place the pretreated sample on the workbench. 1A direct current is passed into the excitation coil to control the mechanical arm, adjust the laser focal length, and adjust the magnetic core at the same time, so that the distance between the magnetic core and the substrate is as close as possible. At this time, the magnetic induction generated on the surface of the substrate under the permeable core is about 200mT. Turn on the laser generator (power 1800W, spot diameter 4mm), gas protection device (argon gas flow rate 4L / h), turn off the powder feeder (powder feeding volume 0), and use the scanning speed of 300mm / min according to the preset The melting track is fused, and the excitation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com