Horizontal measuring device for axial static rigidity of ball screw pair and method thereof

A ball screw pair and measuring device technology, applied in the field of measurement, can solve the problems of single form, low versatility, inability to measure, etc., and achieve the effects of accurate and reliable data value, stable and reliable loading, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

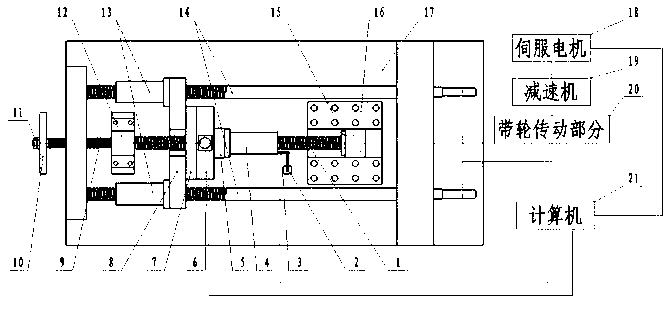

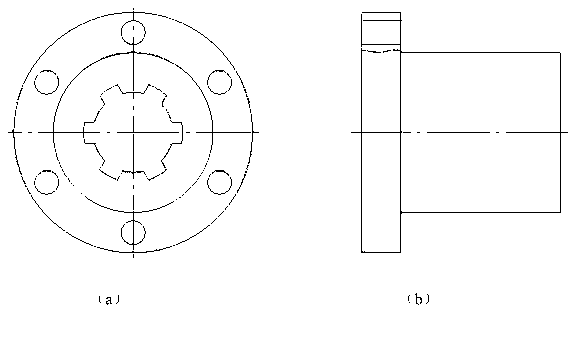

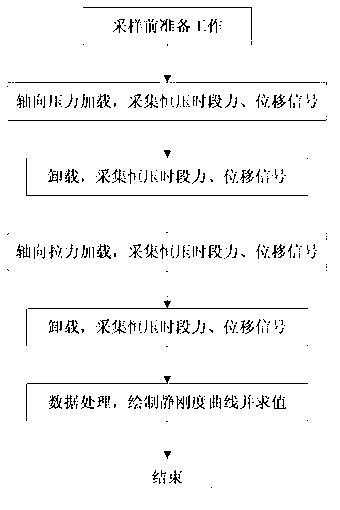

[0013] The present invention adopts the loading mode of fixing the screw to be tested and exerting force on the nut to be tested, and uses a pressure sensor and a displacement sensor to sample the axial load and micro-displacement of the nut to be tested respectively, wherein the pressure sensor and the nut to be tested are fixed Even, the displacement sensor is installed on the bed through the displacement sensor fixture to measure the vertical displacement of the right end face of the nut under test. By processing the sampled data, the axial static stiffness curve of the ball screw under the tension and compression state can be drawn respectively, and the value can be finally calculated, so as to realize the measurement of the axial static stiffness of the ball screw. The specific content is as follows.

[0014] to combine figure 1 , the horizontal static stiffness measuring device of the ball screw pair of the present invention includes a loading assembly, an anti-rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com