Annealing method to reduce defects of epitaxial films and epitaxial films formed therewith

An epitaxial thin film, low-defect technology, applied in chemical instruments and methods, from chemically reactive gases, crystal growth, etc., can solve the problem that the defect density of epitaxial thin films cannot be further reduced, and achieve the goal of reducing defect density and reducing lattice stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

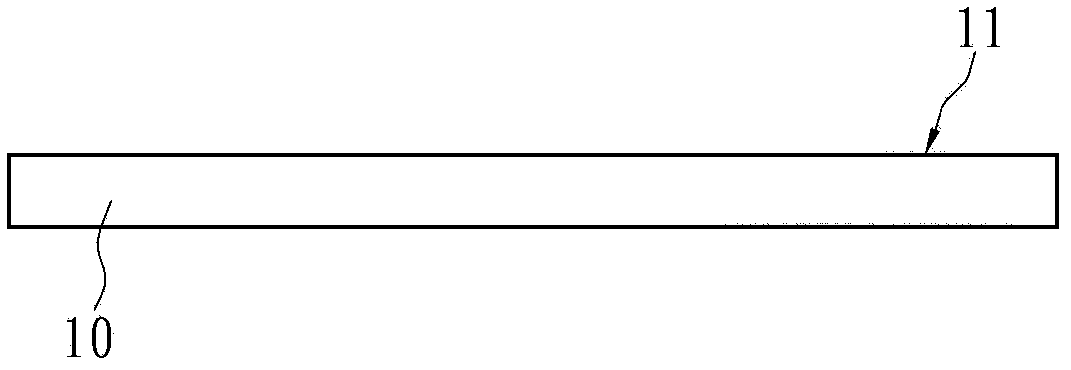

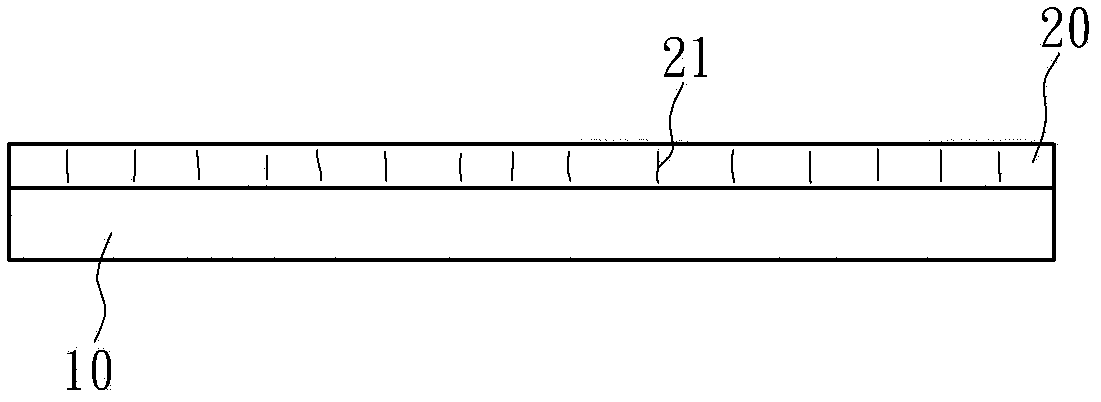

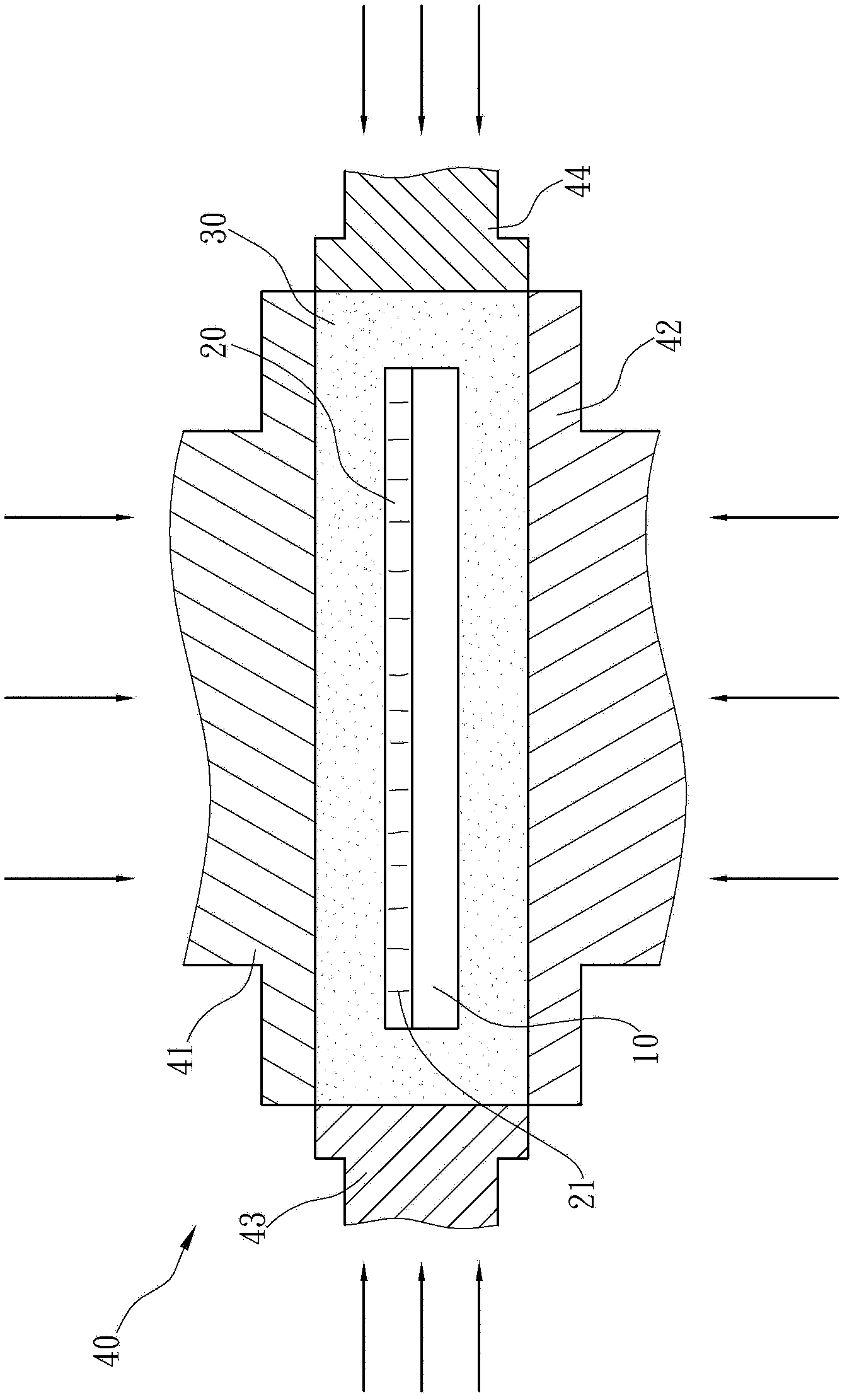

[0037] The present invention relates to an annealing method for reducing the defects of epitaxial film, and the epitaxial film obtained by using the annealing method, please refer to Figure 1A to Figure 1D , is a schematic diagram of the manufacturing process of an embodiment of the present invention, such as Figure 1A As shown, a substrate 10 is first provided. In this embodiment, the substrate 10 has a thickness between 420 μm and 440 μm. The obtained sheet substrate, the upper surface 11 of the substrate 10 is the (0001) lattice plane (also called C-plane) of alumina, but the present invention is not limited to the (0001) lattice plane of alumina as the For the upper surface 11 , according to practical applications, a (1-102-) lattice plane (also called R-Plane) or a (0001) lattice plane (also called M-Plane) can also be selected as the upper surface 11 . In addition, in this embodiment, the sapphire ingot can be grown by Czochralski (Czochralski, CZ for short) method, Ed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com