Bismuth ferrite lead titanate-based functional ceramic material and preparation method thereof

A bismuth ferrite lead titanate-based, functional ceramic technology, applied in the field of ferrofunctional ceramic materials, can solve the problems of inability to obtain a saturated hysteresis loop, cannot be put into use, and high process cost, so as to improve the breakdown field strength and Ferroelectric properties, reduced lattice stress, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of bismuth ferrite lead titanate-based functional ceramic material, comprising the following steps:

[0033] Step 1, take required raw material by stoichiometric ratio, each raw material molar ratio is: Fe 2 o 3 :X 2 o 3 :TiO 2 :PbO:Bi 2 o 3 =x:0.1x:(1-x):(1-x):0.9x, 0.6≤x≤0.9, X 2 o 3 It is the rare earth oxide used for modification, and the raw material is fully mixed and ground to a smaller particle size to obtain the raw material;

[0034] Step 2. Pre-press the homogeneously mixed raw material obtained in Step 1 in a mold with a pressure of 100 MPa-500 MPa, and then place it in a high-temperature reaction furnace and heat it up to 700°C-950°C for pre-sintering. Compared with traditional In terms of a heating rate of 5°C / min, the present invention adopts a heating rate as high as 10°C / min-20°C / min, and keeps the temperature for 60min-200min to obtain a pre-sintered sample;

[0035] Step 3. Put the pre-sintered sample obtained in Step 2 i...

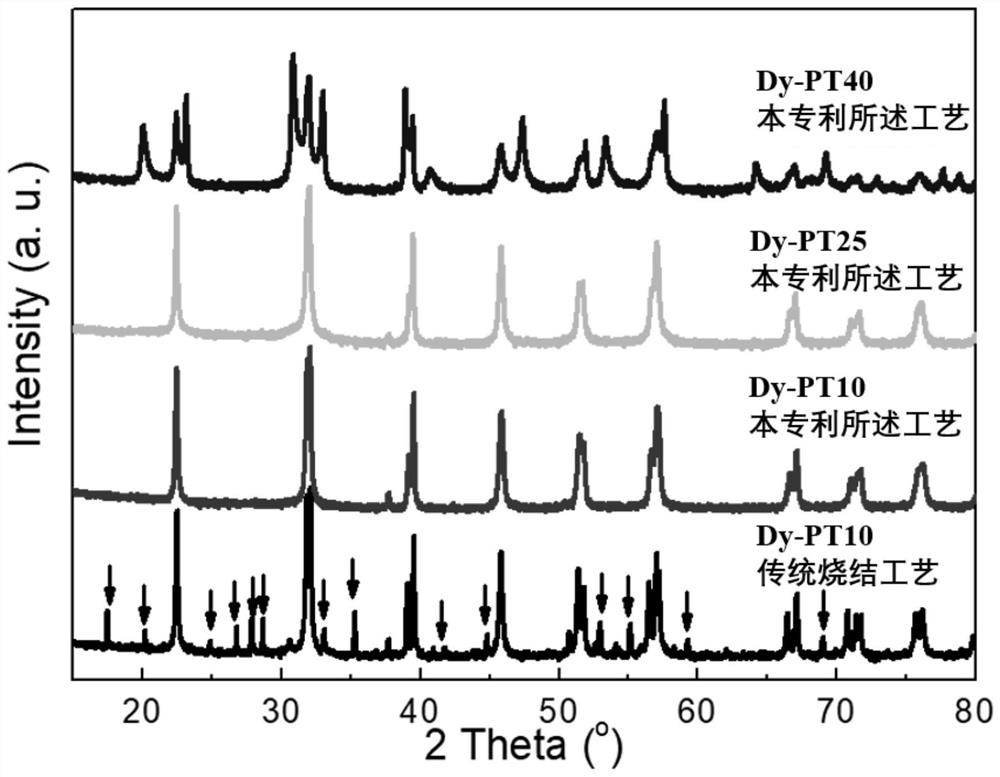

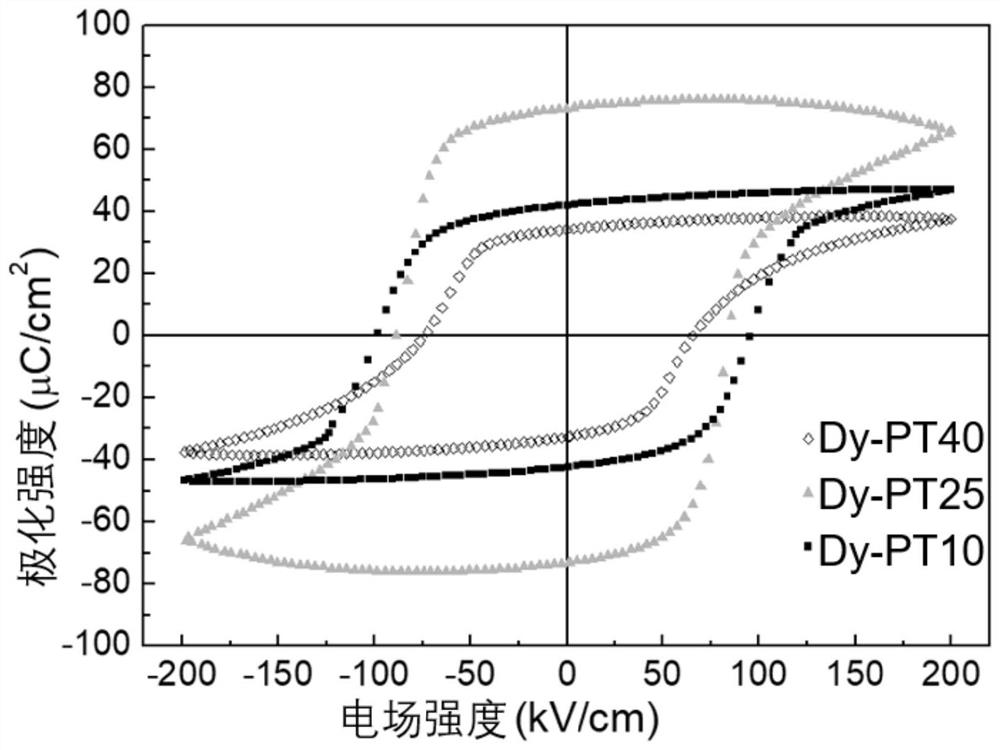

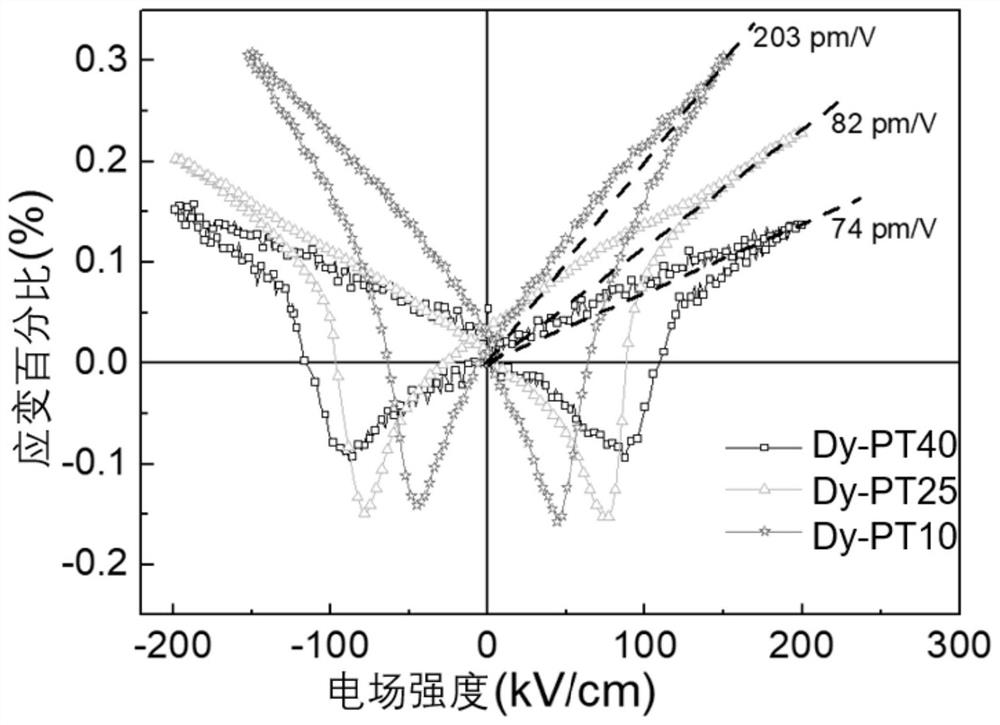

Embodiment 1

[0039] A Dy (dysprosium)-doped 0.9BiFeO prepared by an improved solid-state sintering process 3 -0.1PbTiO 3 Functional ceramic material, the chemical composition is 0.9Bi 0.9 Dy 0.1 FeO 3 -0.1PbTiO 3 , referred to as Dy-PT10. Including the following steps:

[0040] Step 1: Take the required raw materials according to the stoichiometric ratio: the molar ratio of each raw material is: Fe 2 o 3 : Dy 2 o 3 : TiO 2 :PbO:Bi 2 o 3 :=0.9:0.09:0.2:0.2:0.81, fully mix the raw materials and grind them to obtain the raw materials.

[0041] Step 2: The uniformly mixed raw material obtained in step 1 is pre-pressed in a mold with a pressure of 100 MPa, and then placed in a high-temperature reaction furnace to raise the temperature to 700°C and then held for 200 minutes for pre-sintering to obtain a pre-sintered sample. Compared with the traditional process, a higher heating rate is adopted here: 10°C / min;

[0042] Step 3: Put the pre-sintered sample obtained in step 2 into a m...

Embodiment 2

[0046] A Dy-doped 0.75BiFeO prepared by an improved solid-state sintering process 3 -0.25PbTiO 3 Functional ceramic material, the chemical composition is 0.75Bi 0.9 Dy 0.1 FeO 3 -0.25PbTiO 3 , referred to as Dy-PT25. Including the following steps:

[0047] Step 1: Take the required raw materials according to the stoichiometric ratio: the molar ratio of each raw material is: Fe 2 o 3 : Dy 2 o 3 : TiO 2 :PbO:Bi 2 o 3 :=0.75:0.075:0.5:0.5:0.675, fully mix the raw materials evenly and grind to obtain the raw material.

[0048] Step 2: Pre-press the homogeneously mixed raw material obtained in Step 1 in a mold with a pressure of 200 MPa, and then place it in a high-temperature reaction furnace to raise the temperature to 800°C. Compared with the traditional process, a higher heating rate is adopted here. It can reach 12°C / min, keep warm for 100min, and obtain pre-sintered samples.

[0049] Step 3: Put the pre-sintered sample obtained in step 2 into a mortar for second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com