Lithium ion battery positive electrode precursor material with low crystal lattice stress and preparation method thereof

A lithium-ion battery, lattice stress technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problem of affecting the cycle stability and rate performance of electrode materials, the high lattice stress of ternary positive electrode materials, and the generation of lattice stress and other issues, to achieve the effect of low material cost, small stress, and reduced lattice stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

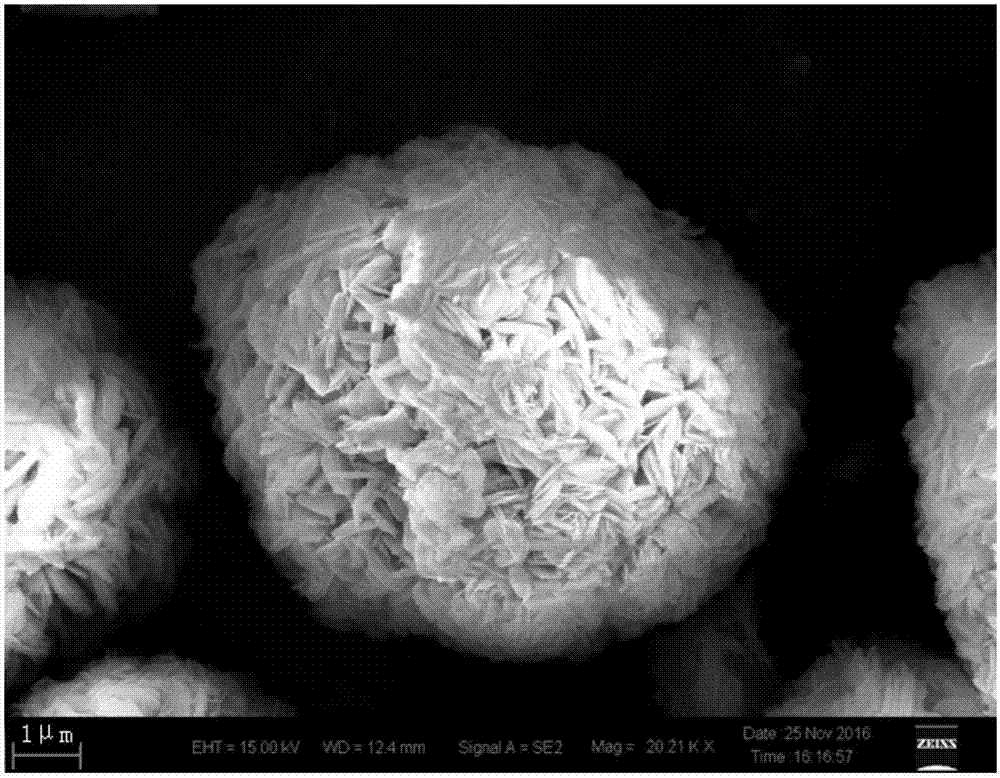

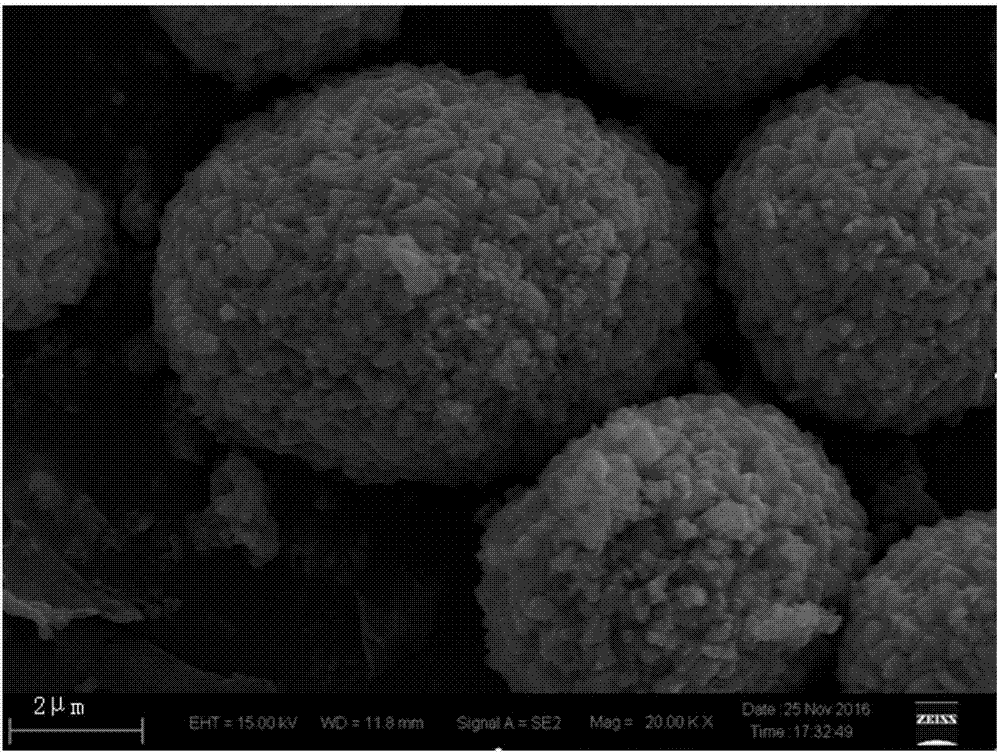

specific Embodiment approach 1

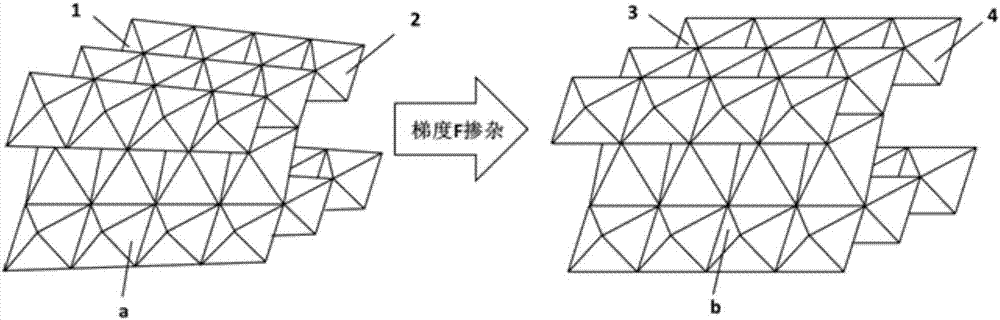

[0034] Specific embodiment one: the chemical formula of a kind of lithium-ion battery anode precursor material with low lattice stress of this embodiment is Ni x co y mn z m 1-x-y-z (OH) 2-n f n or Ni x co y mn z m 1-x-y-z (CO 3 ) 1-0.5n f n ; Wherein the Ni content x decreases from the inside to the outside, and the F content n increases from the inside to the outside, 0<x≤1, 0<y≤1, 0<z≤1, 0<x+y+ z≤1, 0<n≤0.15.

specific Embodiment approach 2

[0035] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the change gradient of the content x of Ni and the change gradient of the content n of F satisfy 5≤Δ x / Δ n ≤7; where Δ x is the difference of Ni content x at different distances from the center of the sphere, Δ n is the difference of the content n of F at the position corresponding to the content x of Ni. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0036] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: said M is Li, Zr, Fe, Sm, Pr, Nb, Ga, Zn, Y, Mg, Al, Cr, Ca, Na , Ti, Cu, K, Sr, Mo, Ba, Ce, Sn, Sb, La and Bi or a mixture of several. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com