Preparation method of VW93M super-high-strength nano gradient magnesium alloy

A magnesium alloy, ultra-high-strength technology, applied in the field of ultra-high-strength nano-gradient magnesium alloy preparation, can solve the problems of lack of nano-gradient magnesium alloy methods, achieve high hydrostatic stress, high strain rate, and reduce the effect of cracking tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] a. The magnesium alloy used is Mg-8.0Gd-3.0Y-0.4Zr-0.05Ag-0.03Er, and the magnesium alloy ingot is prepared by a semi-continuous casting method and subjected to homogenization heat treatment;

[0018] b. Extruding and deforming the homogenized alloy billet;

[0019] c. The extruded bar was subjected to rotary forging deformation at 125°C. The deformation of each pass was 20%, 10%, 10%, and 5%, respectively, and the total deformation was 38%. The feeding speed was controlled at 4mm / min. During the deformation process The feeding direction remains unchanged, and the grain size of the obtained nanogradient magnesium alloy rod gradually increases from the center to the edge. The size is 20mm in diameter and 2000mm in length;

[0020] d. The swaged bar is subjected to aging heat treatment.

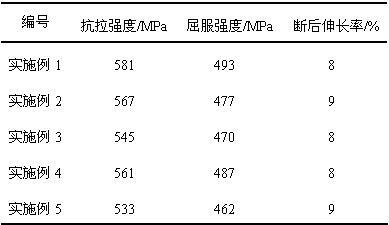

[0021] According to GB / T228-2002, the mechanical properties of the obtained nano-gradient magnesium alloy were tested, and the results are shown in Table 1.

Embodiment 2

[0023] a. The magnesium alloy used is Mg-8.0Gd-3.0Y-0.4Zr-0.05Ag-0.03Er, and the magnesium alloy ingot is prepared by a semi-continuous casting method and subjected to homogenization heat treatment;

[0024] b. Extruding and deforming the homogenized alloy billet;

[0025] c. The extruded bar is subjected to rotary forging deformation at 150°C, the deformation of each pass is 15%, 10%, 10%, and the total deformation is 31%, the feeding speed is controlled at 4mm / min, and the feeding direction during the deformation process is Keeping the same, the grain size of the obtained nanogradient magnesium alloy rod gradually increases from the center to the edge, the grain size of the center is 50-100nm, the grain size of the edge is 1-2μm, and the finished rod size is diameter 30mm, length 2000mm;

[0026] d. The swaged bar is subjected to aging heat treatment.

[0027] According to GB / T228-2002, the mechanical properties of the obtained nano-gradient magnesium alloy were tested...

Embodiment 3

[0029] a. The magnesium alloy used is Mg-8.0Gd-3.0Y-0.4Zr-0.05Ag-0.03Er, and the magnesium alloy ingot is prepared by a semi-continuous casting method and subjected to homogenization heat treatment;

[0030] b. Extruding and deforming the homogenized alloy billet;

[0031] c. The extruded bar was subjected to rotary forging deformation at 200°C, the deformation of each pass was 20%, 10%, 10%, 5%, and the total deformation was 38%, and the feeding speed was controlled at 2mm / min. During the deformation process The feeding direction remains unchanged, and the grain size of the obtained nanogradient magnesium alloy rod gradually increases from the center to the edge. The size is 14mm in diameter and 1000mm in length;

[0032] d. The swaged bar is subjected to aging heat treatment.

[0033] According to GB / T228-2002, the mechanical properties of the obtained nano-gradient magnesium alloy were tested, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com