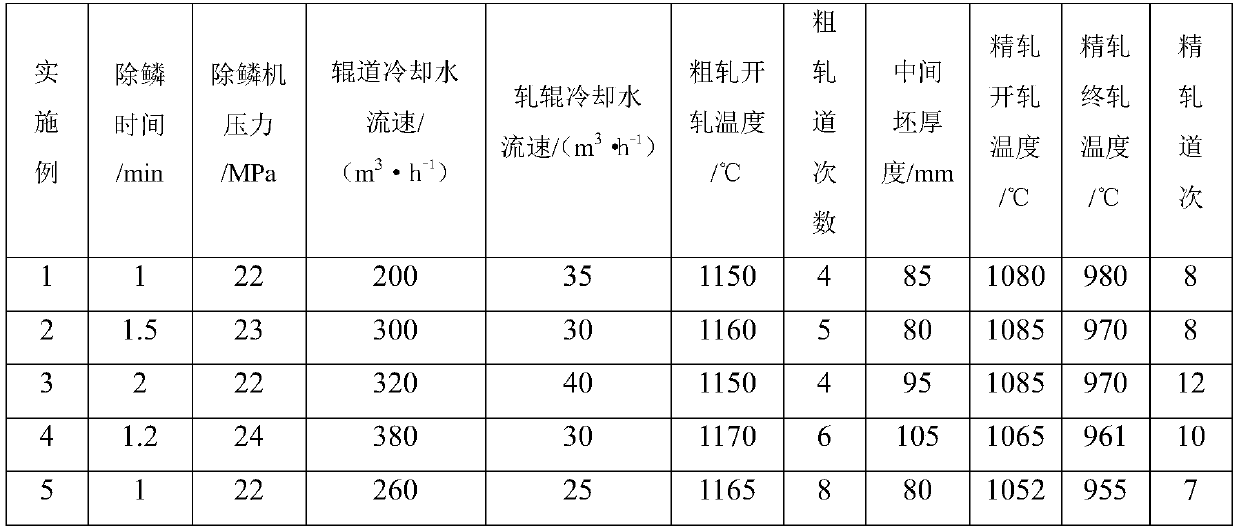

Patents

Literature

109results about How to "Increase equiaxed crystal ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

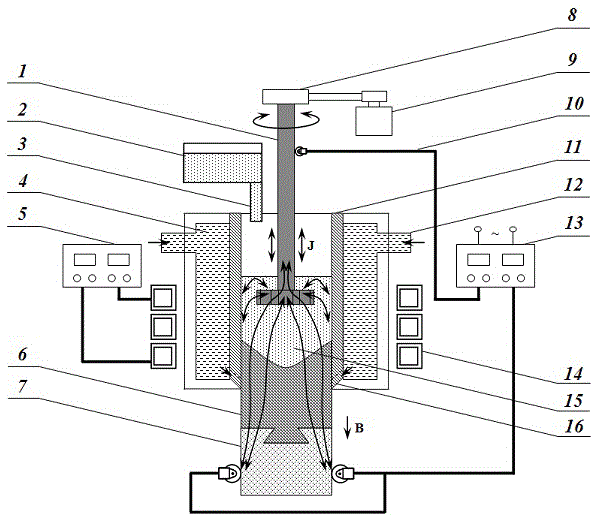

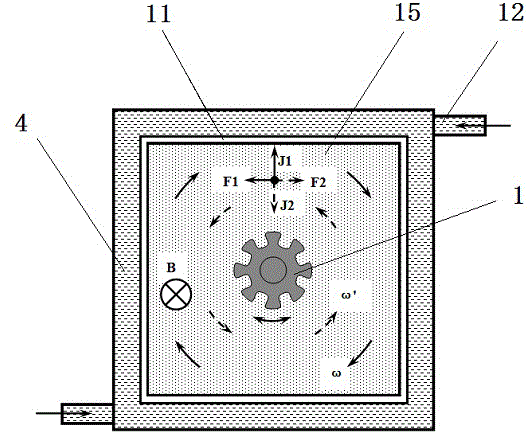

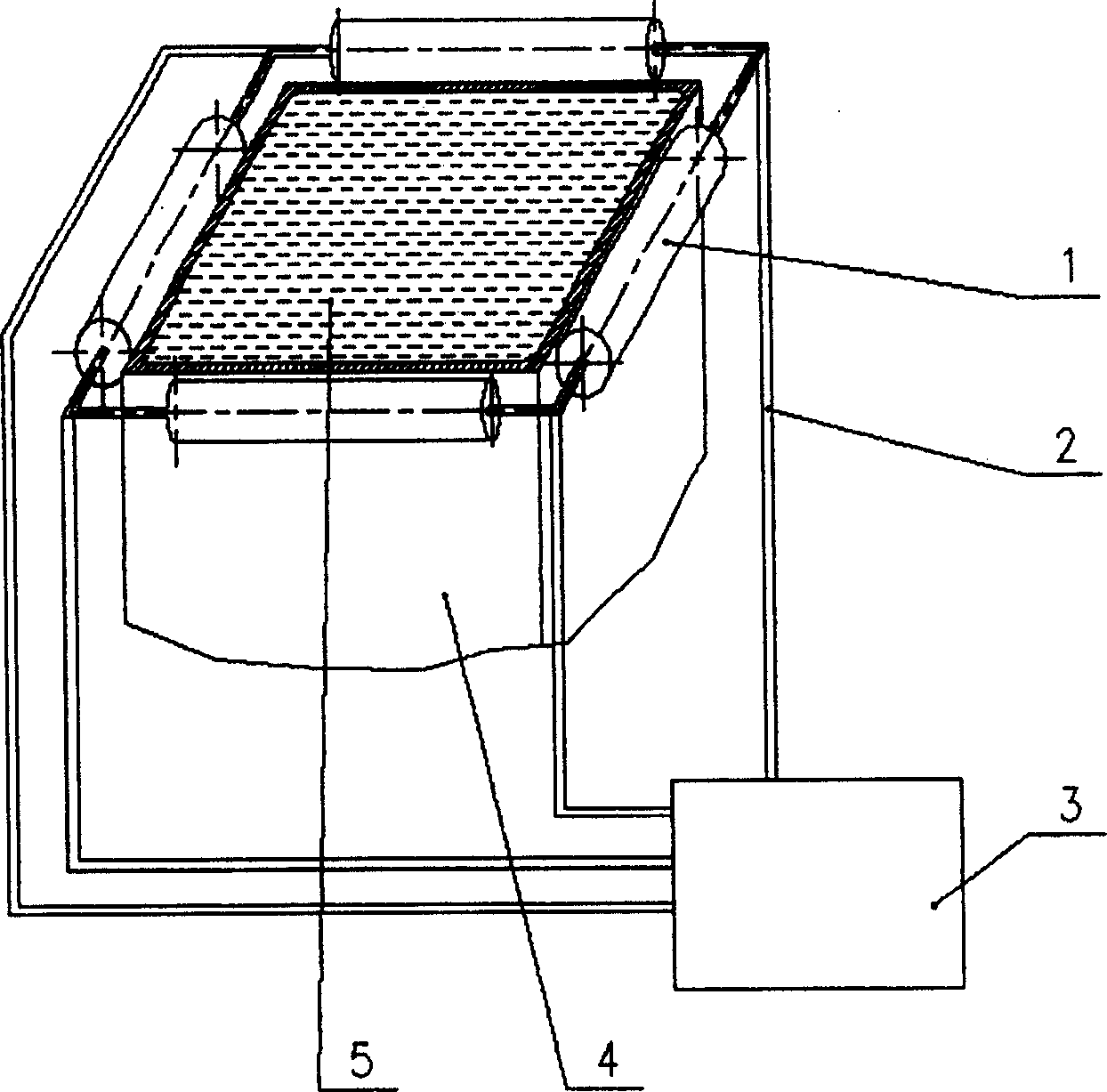

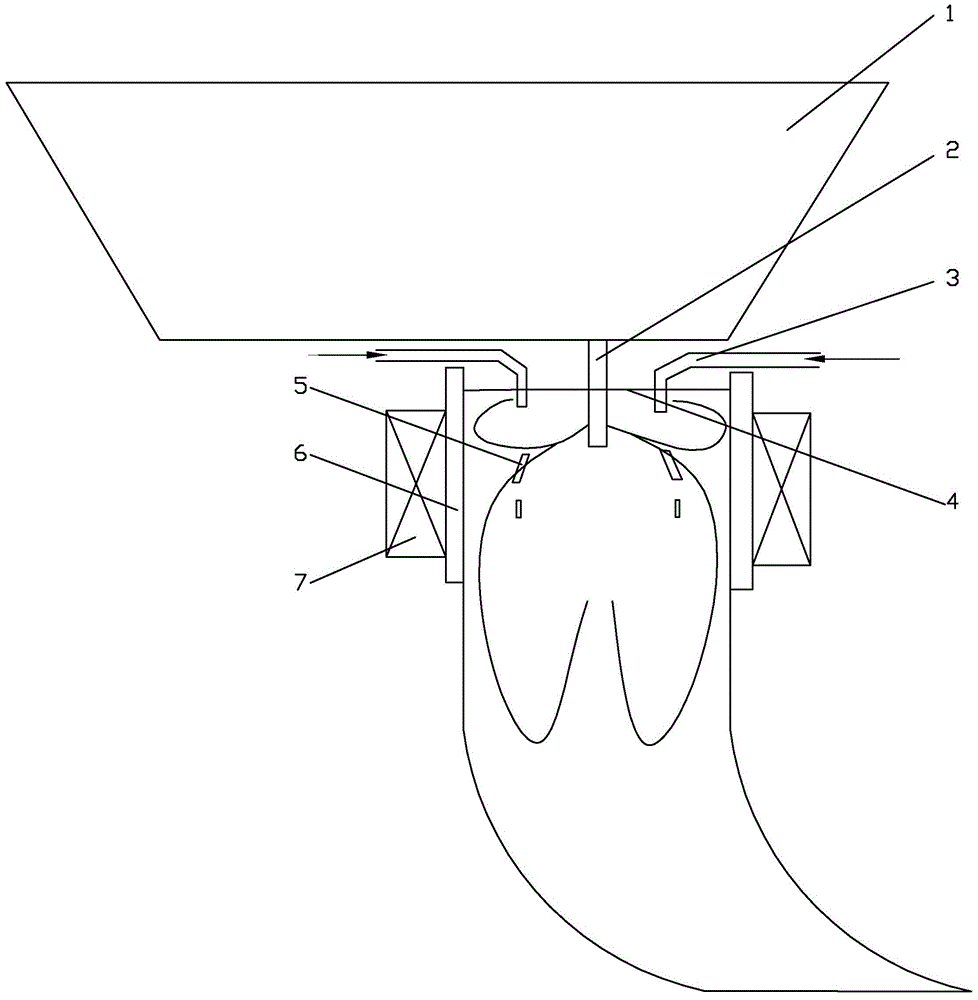

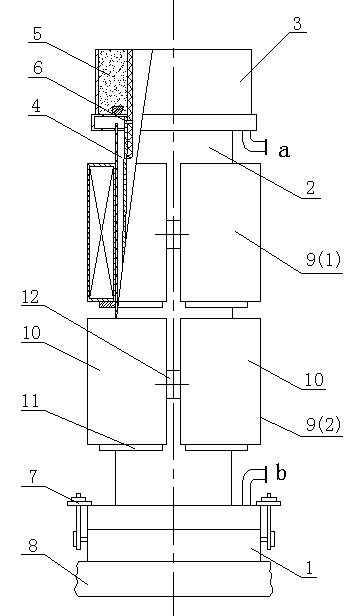

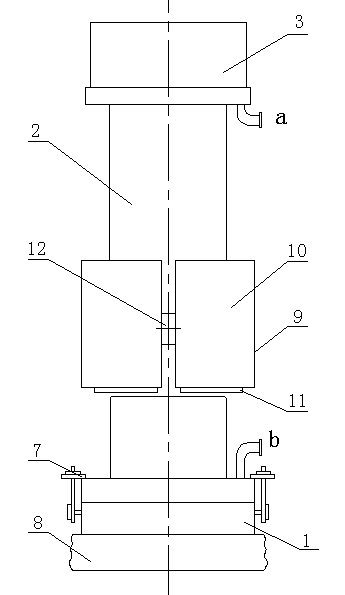

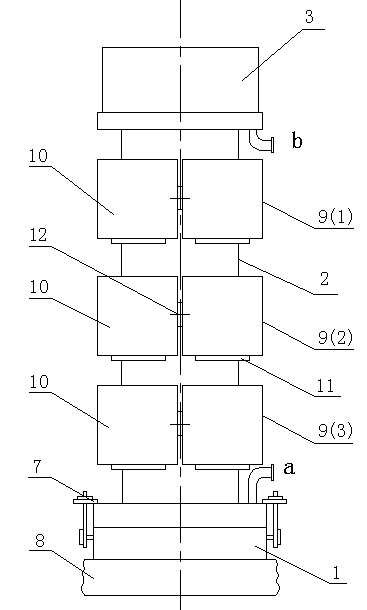

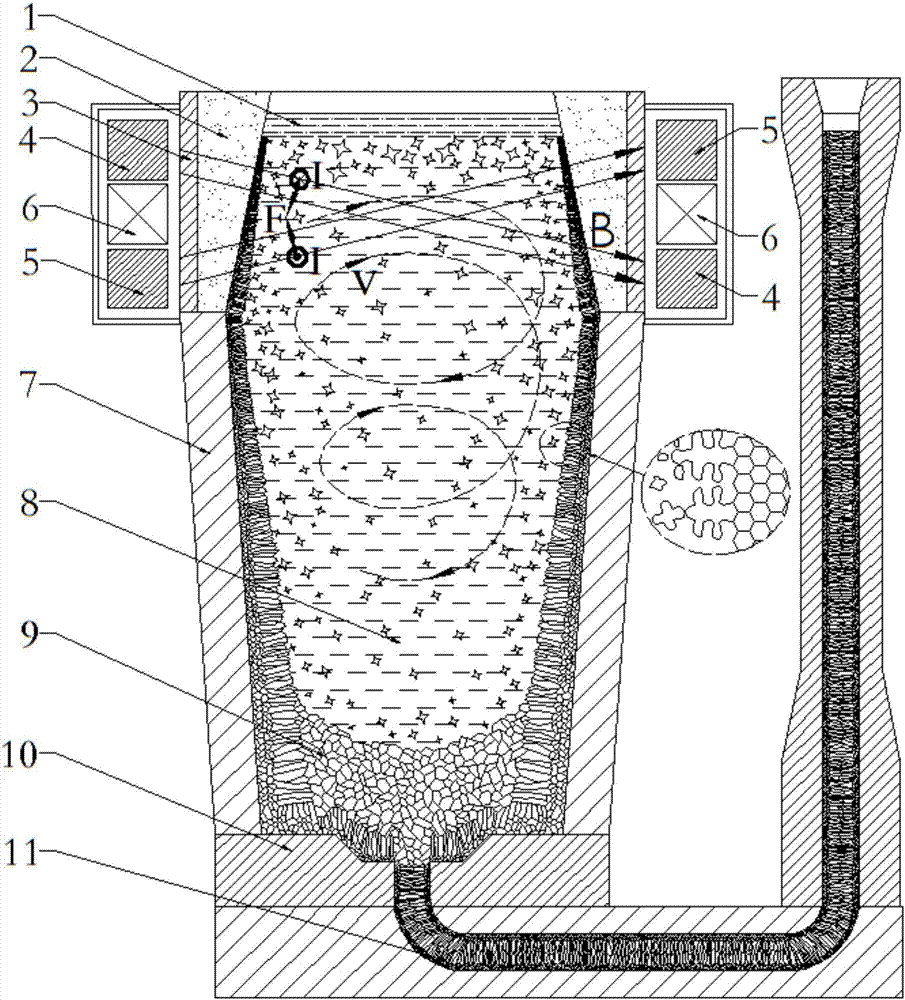

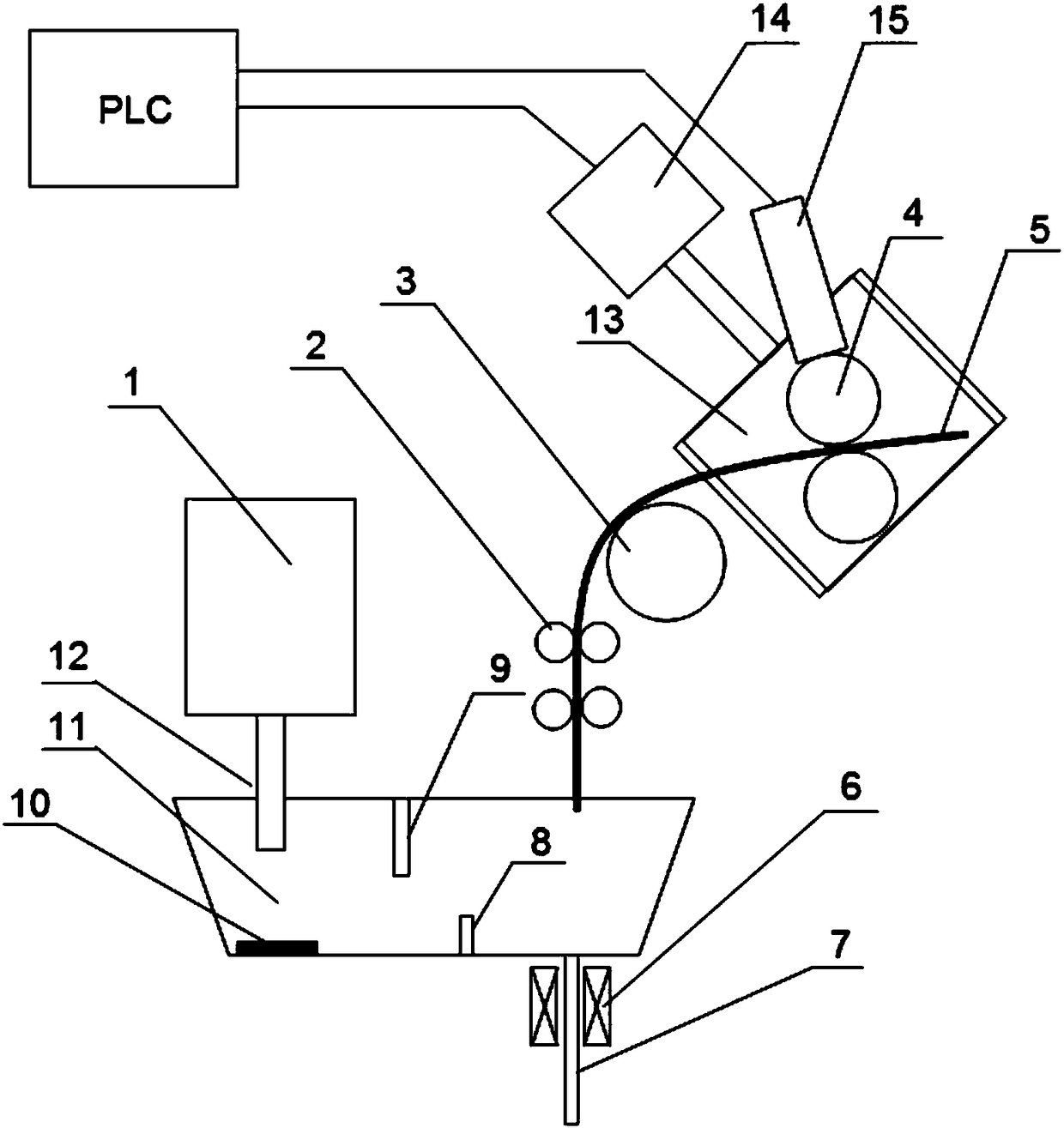

Continuous steel casting process and device with function of electromagnetic excitation compound mechanical stirring

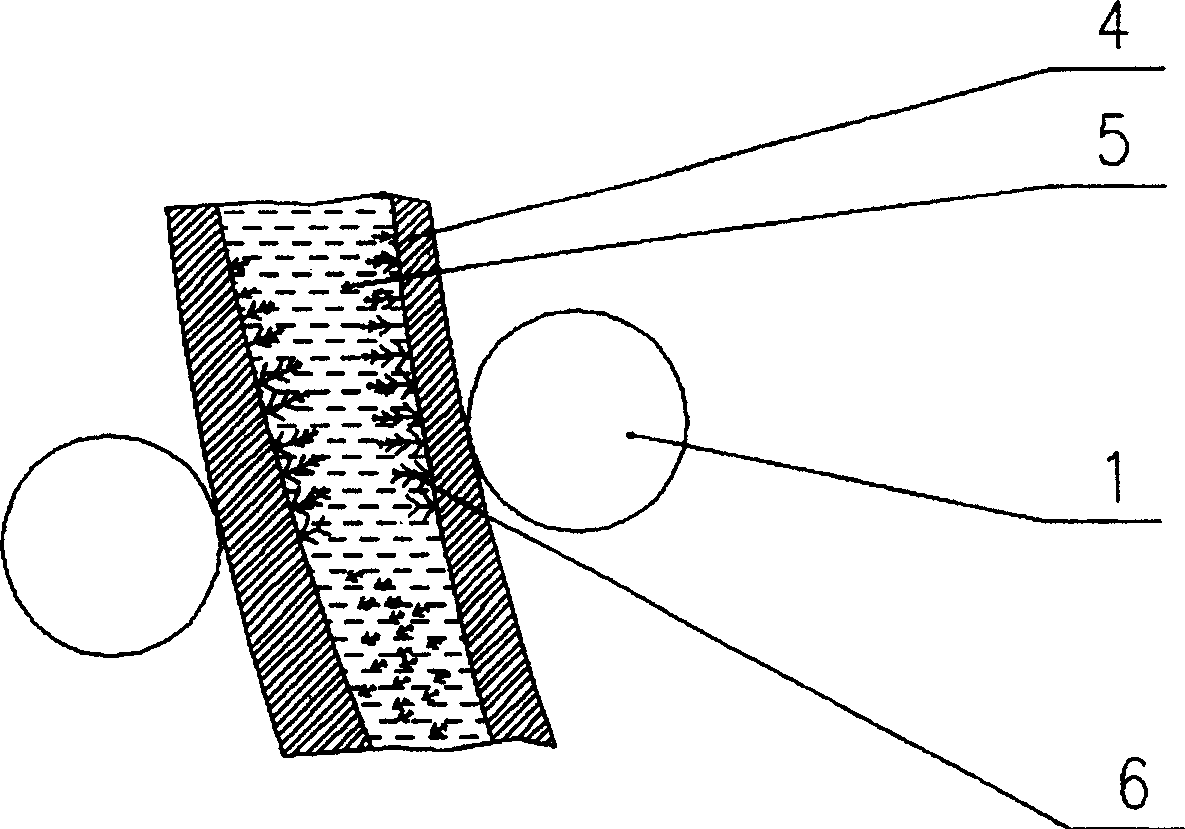

The invention discloses a continuous steel casting process with a function of electromagnetic excitation compound mechanical stirring. According to the process, when alloy melt solidifies, microscopic and macroscopic strong shear flows are generated to break dendritic crystal by the electromagnetic excitation compound mechanical stirring technology, and accordingly, solidification structure refinement, full-equiaxed crystallization and solute segregation reduction are achieved, and alloy properties are improved. The invention further provides a continuous steel casting device mainly comprising a crystallizer, a rotor stirring paddle, a wheel, a program control motor, a magnetic field generator, a coil, and a voltage-regulating frequency-modulating alternating current source. The microscopic flows generated by electromagnetic excitation and macroscopic flows generated by mechanical stirring form complex chaotic flows which form strong shear flows to brake the dendritic crystal, crystal nucleus proliferation is prompted, temperature gradient is reduced, and ultrafine full-equiaxed crystal structure is achieved; meanwhile, segregation of alloy elements is significantly reduced or completely suppressed. The continuous steel casting process and method has the advantages that the energy consumption is significantly lower than that of conventional electromagnetic stirring and energy conservation is significantly effective.

Owner:新兴发展集团有限公司

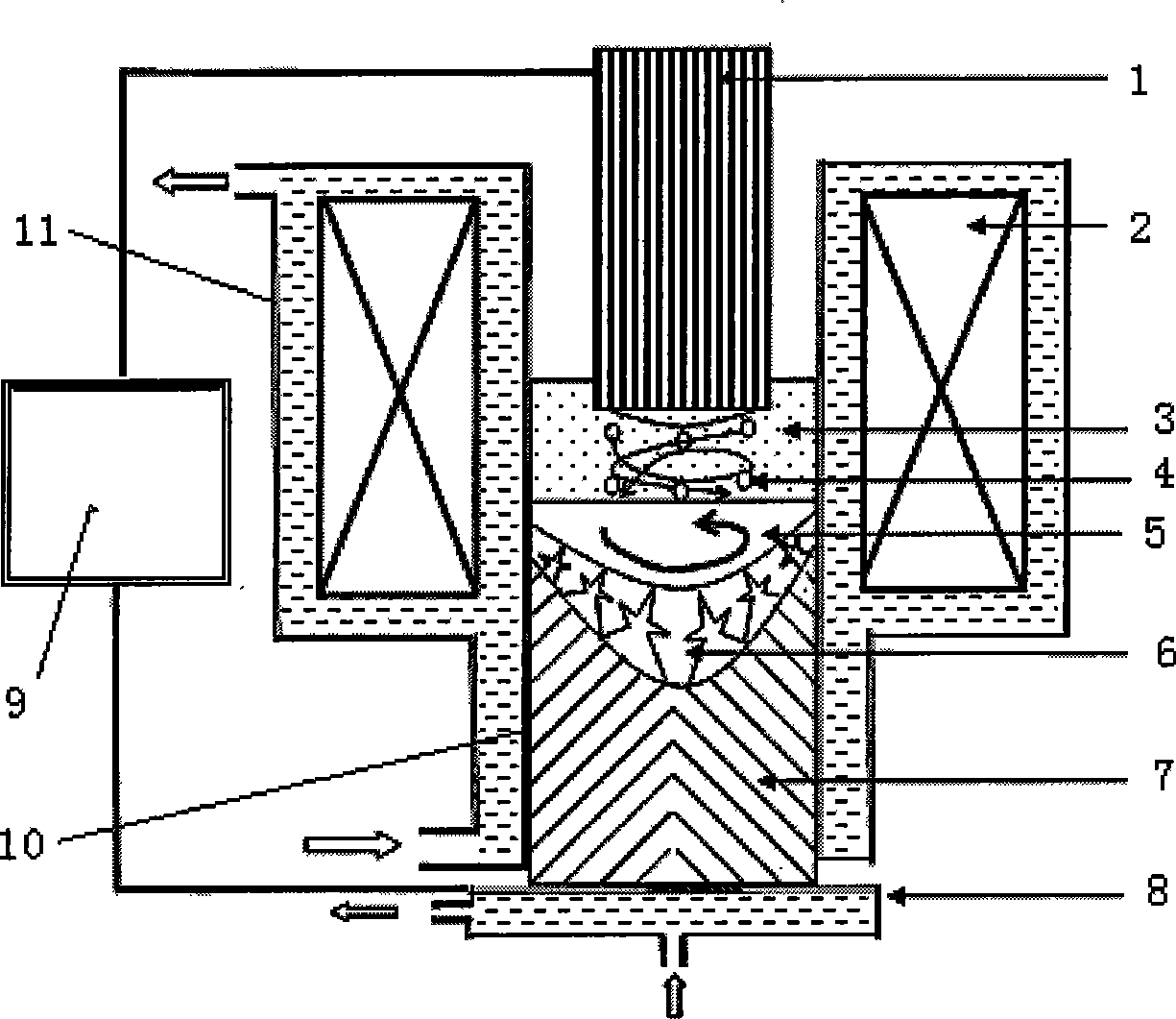

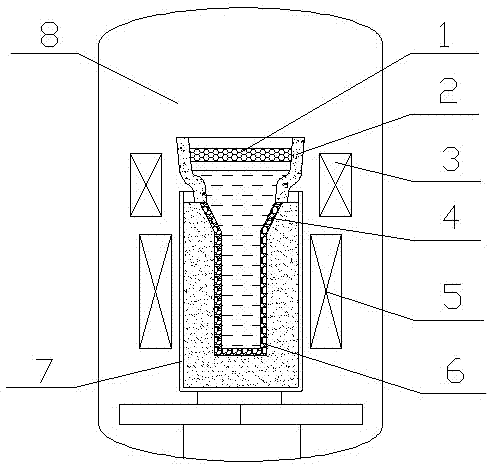

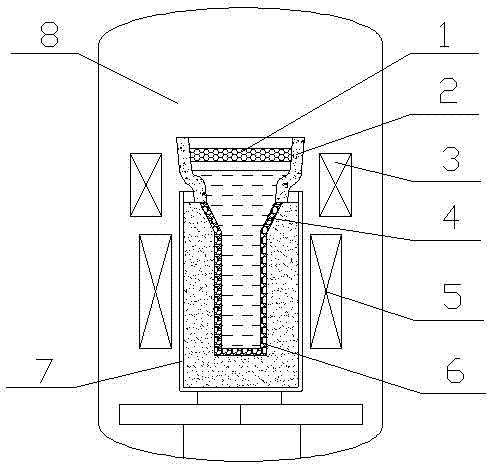

Electroslag smelting casting device with additional electromagnetic stirring and method

The invention relates to an electroslag casting device additionally provided with electromagnetic stirring and a method thereof. The electroslag casting device belongs to the technical field of special steel electroslag metallurgy and comprises a crystallizer, a crystallizer water jacket and an electromagnetic stirrer; an annular magnet is sleeved on the outer wall of the crystallizer and positioned at the middle-upper part of the crystallizer, a loop is wound on an iron core of the annular magnet, an electromagnetic stirrer water jacket is arranged at the periphery of the annular electromagnet, and the electromagnetic stirrer water jacket is communicated with the crystallizer water jacket; a melting consumable electrode forms molten steel drops which then enter a slag layer; the molten steel drops fall down in a spiral line way in the slag layer under the action of the rotary electromagnetic field and then enter a steel ingot liquid tank; the steel ingot liquid tank raises continuously and also enters into an effective magnetic field action region of the electromagnetic stirrer; and meanwhile, electric current in the molten steel is acted with the rotary magnetic field to produce the electromagnetic force which then drives the molten steel to rotate. The invention has simple equipment, and has the obvious functions of improving the surface quality, the subsurface quality and the solidifying tissue of a casting blank and the isometric crystal ratio, and lightening the internal defects, such as the center segregation, the center looseness, and the like.

Owner:NORTHEASTERN UNIV

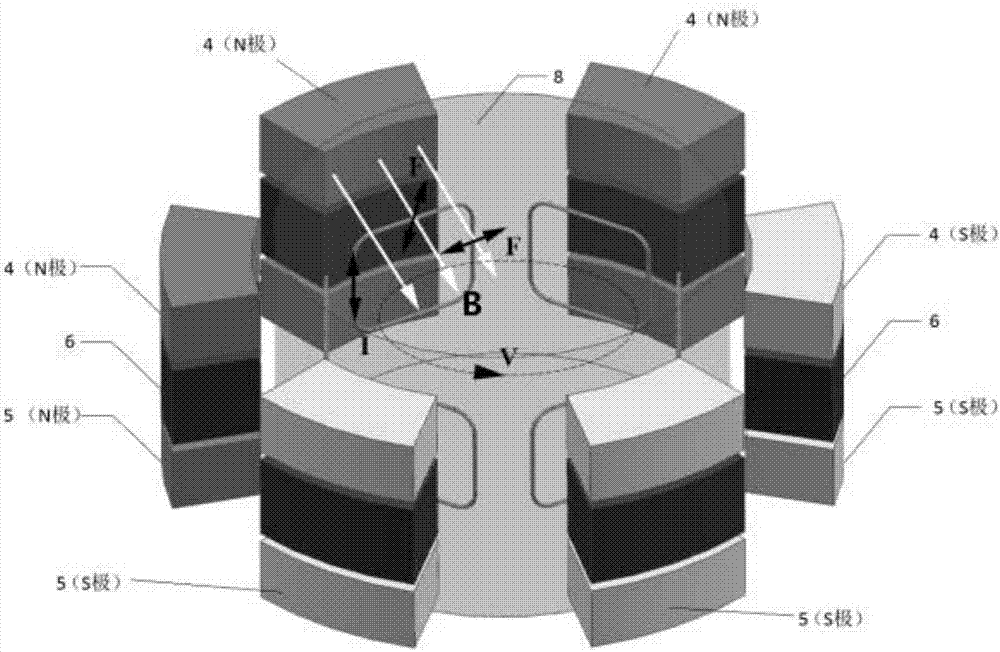

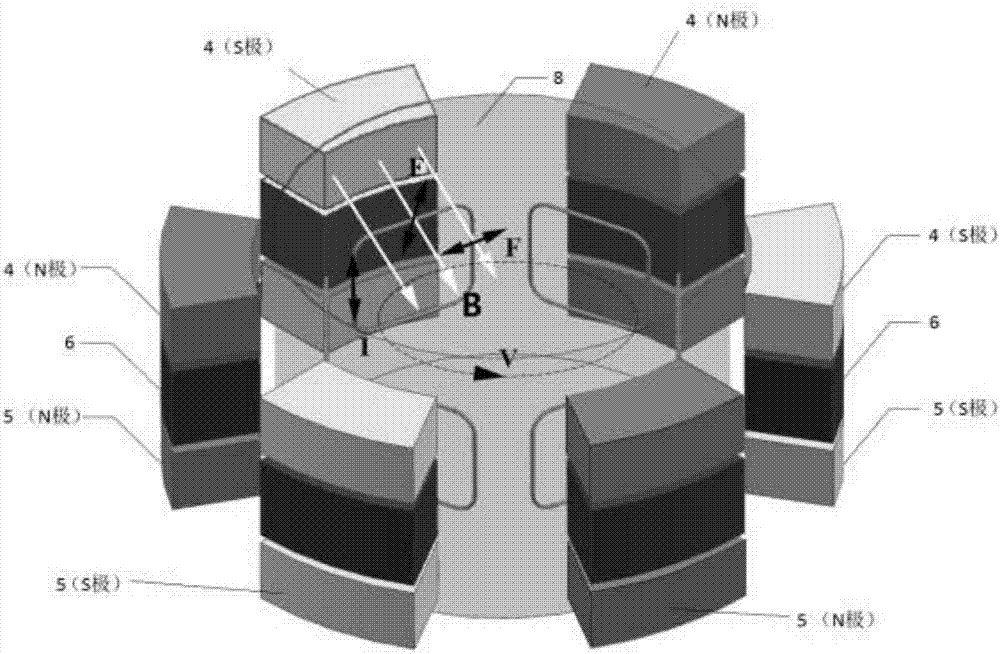

Process and device for high-temperature alloy fine-grain casting with composite electromagnetic fields

InactiveCN102528002AReduce wild swingsEliminates adverse effects of shrinkage cavity feedingSuperalloyAustenite

Disclosed are a process and a device for high-temperature alloy fine-grain casting with composite electromagnetic fields. The device is characterized in that two electromagnetic fields generators are arranged on the upper portion and the lower portion of the outside of an austenitic stainless steel sand box sequentially, wherein a steady direct-current electromagnetic field generator is arranged on the upper portion, and a bidirectional low-frequency alternating-current rotary electromagnetic field generator is arranged on the lower portion. A bidirectional rotary electromagnetic field is generated after bidirectional low-frequency alternating-current power is input into the bidirectional low-frequency rotary electromagnetic field generator on the lower portion of the austenitic stainless steel sand box, and grains of vacuum precision high-temperature alloy castings can be refined until the diameter of grains is 95 mu m and the section isometric crystal proportion reaches 100% under the bidirectional rotary electromagnetic stirring action generated in metal liquid. A steady direct-current electromagnetic field is generated by the steady direct-current electromagnetic field generator after the steady direct-current electromagnetic field generator is input with direct-current power, and electromagnetic brake power generated on the metal liquid level by the direct-current electromagnetic field suppresses sharp fluctuation of the metal liquid level caused by internal electromagnetic stirring action, and adverse affection of fluctuation of metal liquid level onto floating of inclusion and shrinkage cavity feeding during the solidification process of high-temperature alloy castings is eliminated.

Owner:LUOYANG INST OF SCI & TECH

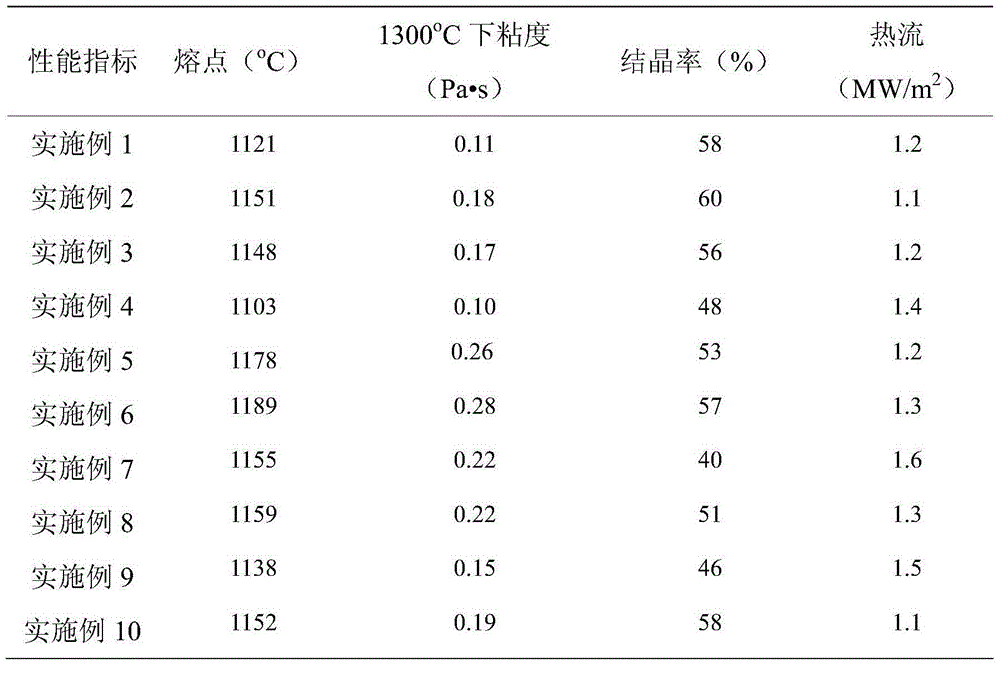

Novel medium manganese steel casting powder for automobile and application thereof

The invention relates to a novel medium manganese steel casting powder for an automobile and application of the novel medium manganese steel casting powder and belongs to the technical field of continuous casting of iron and steel. The casting powder comprises, by mass, CaO 29%-37%, Al2O3 16%-25%, SiO2 11%-15%, MgO 2%-7%, Na2O 10%-14%, Li2O 1%-5%, MnO 1%-7% and F- 9%-13%. The melting point of the casting powder is 1,100-1,200 DEG C; at 1,300 DEG C, the viscosity of the casting powder is 0.10-0.30 Pa*s, and the crystallizing rate is 40%-70%; the heat flow is 1.1-1.6 MW / m<2> in the continuous casting process. The designed casting powder can be well used in the medium manganese steel continuous casting process for the automobile with the mass percentage of Mn being 3.0%-15.0%.

Owner:CENT SOUTH UNIV

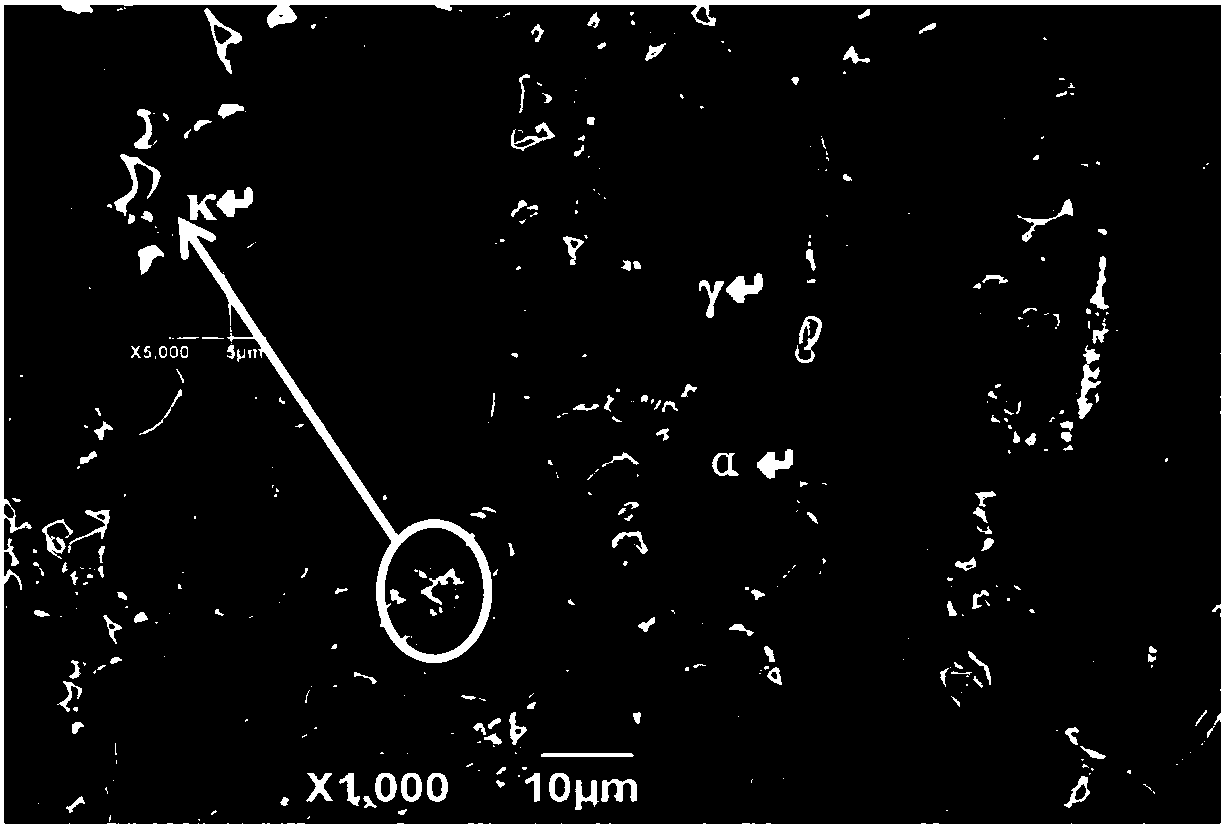

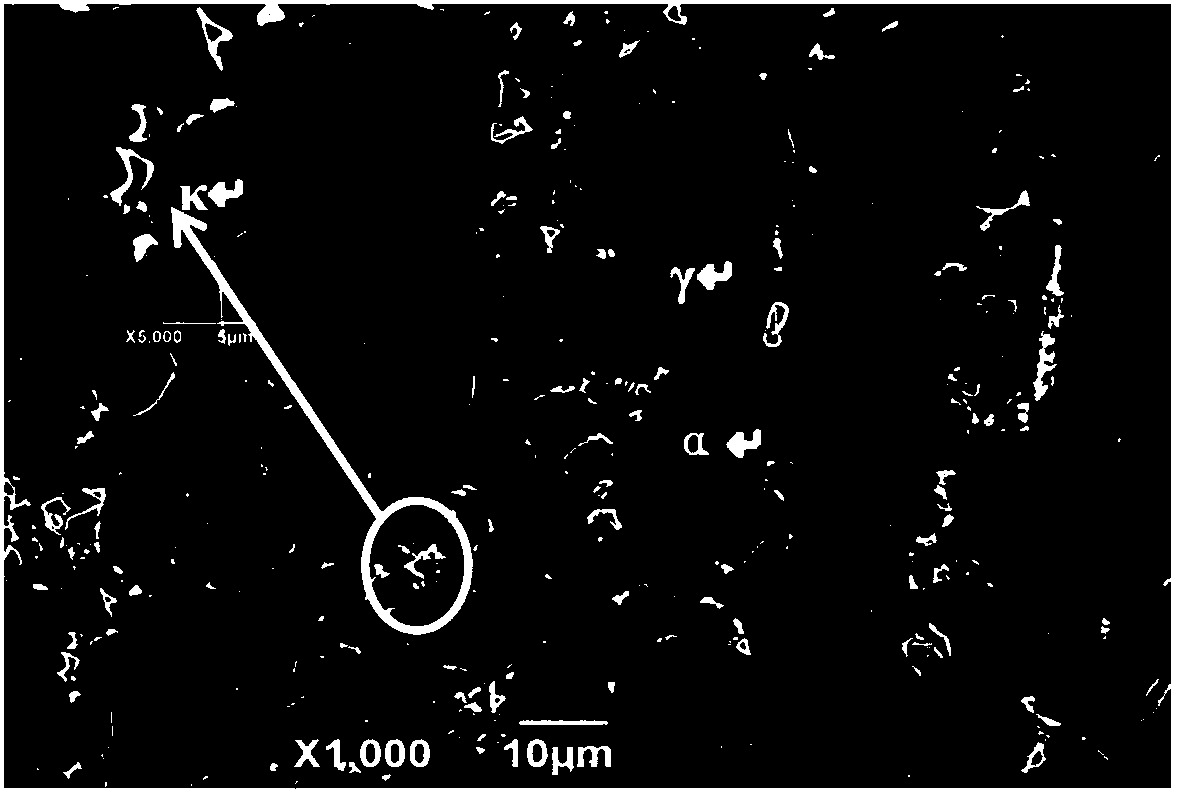

Low-density high manganese steel with high product of strength and elongation

InactiveCN107641763AHigh strengthImprove plasticityProcess efficiency improvementSolution treatmentCarbide

The invention provides low-density high manganese steel with high product of strength and elongation, and belongs to the field of low-density steel. The sum of the mass percents of Mn and Al in low-density steel exceeds 28%. The low-density high manganese steel is prepared through the following steps: smelting, namely, smelting on the basis of the alloy component system; casting; hot rolling, namely, heating a casting blank to be 1150-1250 DEG C; maintaining the temperature; then performing hot rolling at least twice; performing solution treatment, namely, maintaining the temperature of 1000-1100 DEG C of the casting blank, and then quenching; cold rolling, namely, performing cold rolling on the obtained low-density steel at least twice; annealing and then cooling to obtain the low-densitysteel. According to the low-density high manganese steel with high product of strength and elongation, a certain amount of Al is added to the steel, and the alloy component and the processing technology are adjusted, so as to obtain Fe-Mn-Al-C series low-density steel; the low-density steel is of an appearance of an austenite, ferrite and k carbide multi-phase structure, so that the low-density steel is high in strength and high in plasticity.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

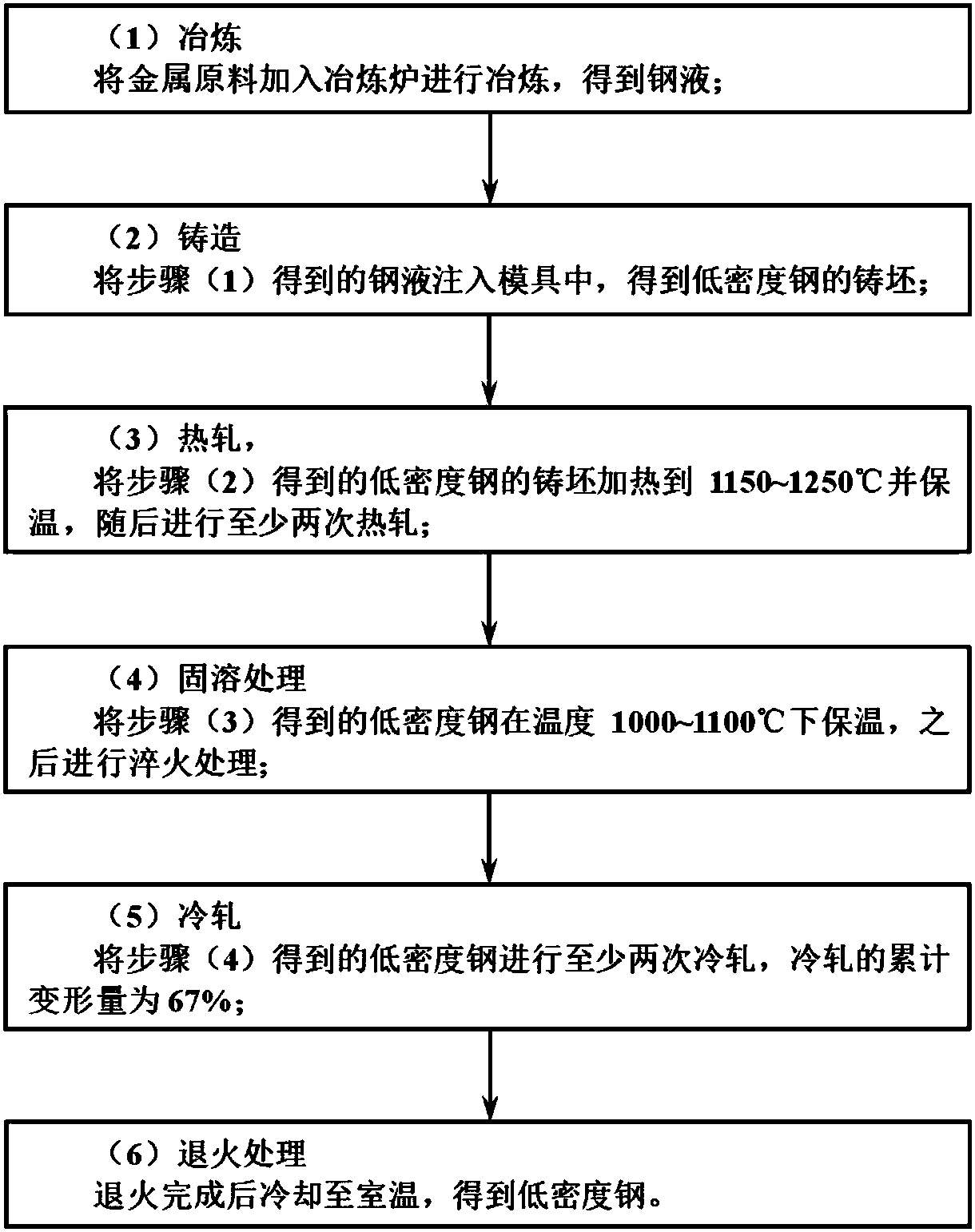

Preparation method for low-density steel with strength and elongation product larger than 50 GPa.%

The invention relates to a preparation method for low-density steel with the strength and elongation product larger than 50 GPa.%, and belongs to the field of low-density steel. The preparation methodincludes the following steps of smelting, specifically, raw materials are put into a smelting furnace for smelting; casting, specifically, obtained molten steel is poured into a mold, and low-densitysteel ingots are obtained after cooling; hot rolling, specifically, the obtained low-density steel ingots are heated to 1150-1250 DEG C, heat preservation is carried out, and then at least two timesof hot rolling are carried out; solution treatment, specifically, the obtained low-density steel is subjected to heat preservation at the temperature of 1000-1100 DEG C, and quenching treatment is carried out; cold rolling, specifically, the obtained low-density steel is subjected to at least two times of cold rolling; and cooling after annealing treatment. In this way, the low-density steel is obtained. Through regulation of alloy elements and the machining process, the Fe-Mn-Al-C system low-density steel is obtained, and the morphology of the low-density steel is of a multi-phase structure including austenite, ferrite and kappa carbide, so that the low-density steel has high strength and good plasticity, and the strength and elongation product is larger than 50 GPa.%.

Owner:马鞍山学院

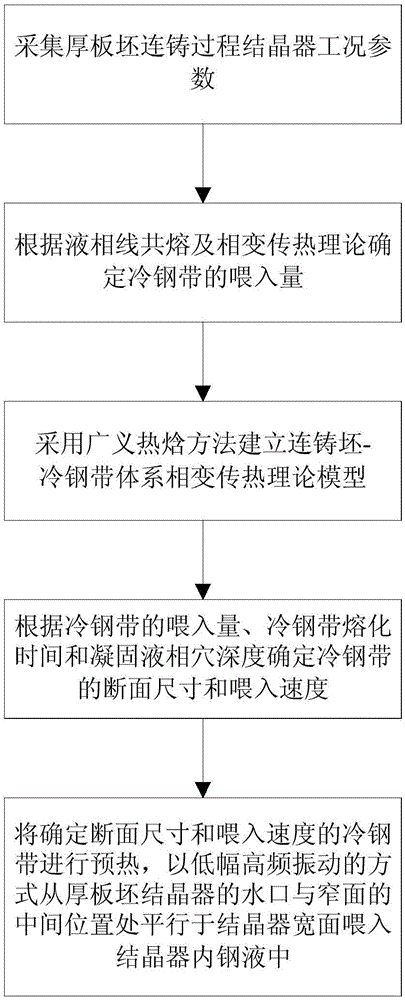

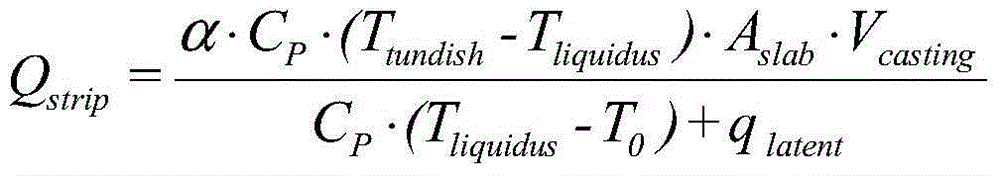

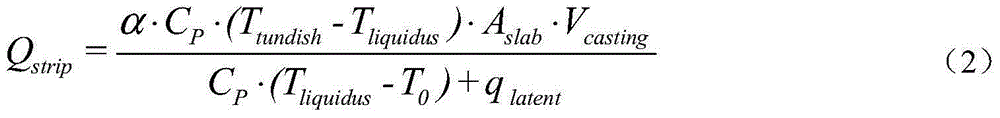

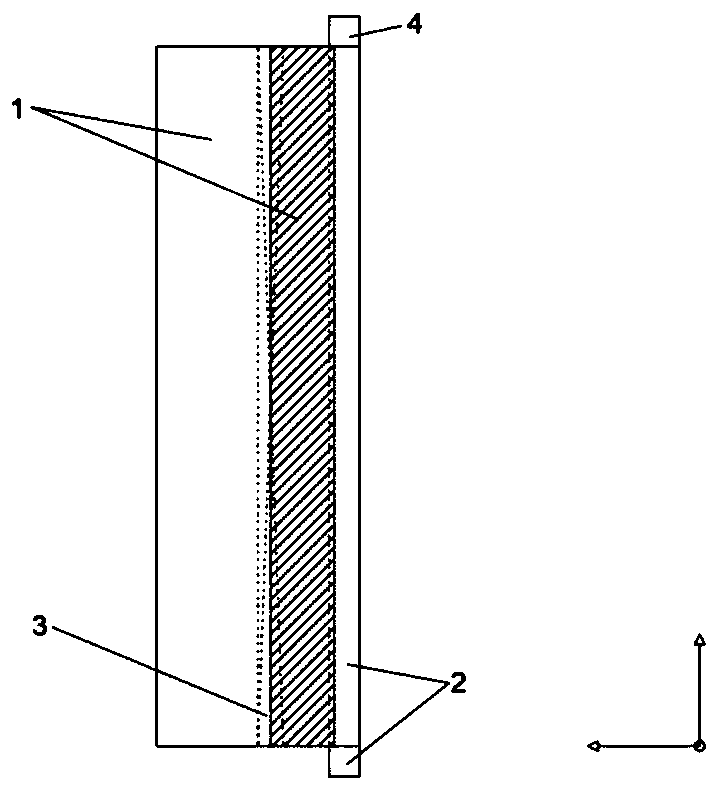

Method for determining steel belt feeding process parameter of crystallizer in thick slab continuous casting process

ActiveCN105033216AReduce macro segregationIncrease equiaxed crystal ratioLiquid coreCongruent melting

The invention relates to a method for determining the steel belt feeding process parameter of a crystallizer in the thick slab continuous casting process. The method comprises the steps the work condition parameter of the crystallizer in the thick slab continuous casting process is collected, and the feeding quantity of a cold steel belt is determined through the work condition parameter of the crystallizer in the thick slab continuous casting process based on the liquidus congruent melting and phase change heat transfer theory; a continuous casting slab-cold steel belt system phase change heat transfer theoretical model is built through a generalized enthalpy method, namely, a relation model among the melting time and feeding thickness of the cold steel belt, the superheat degree of casting molten steel and the initial temperature of the cold steel belt; the section size and feeding speed of the cold steel belt are determined through the continuous casting slab-cold steel belt system phase change heat transfer theoretical model according to the feeding quantity and melting time of the cold steel belt and the depth of a solidified liquid core; and the cold steel belt with the determined section size and feeding speed is preheated and fed into molten steel in the crystallizer through the position between a water opening and a narrow face of the thick slab crystallizer parallel to the wide face of the crystallizer in a low-amplitude high-vibration manner.

Owner:NORTHEASTERN UNIV

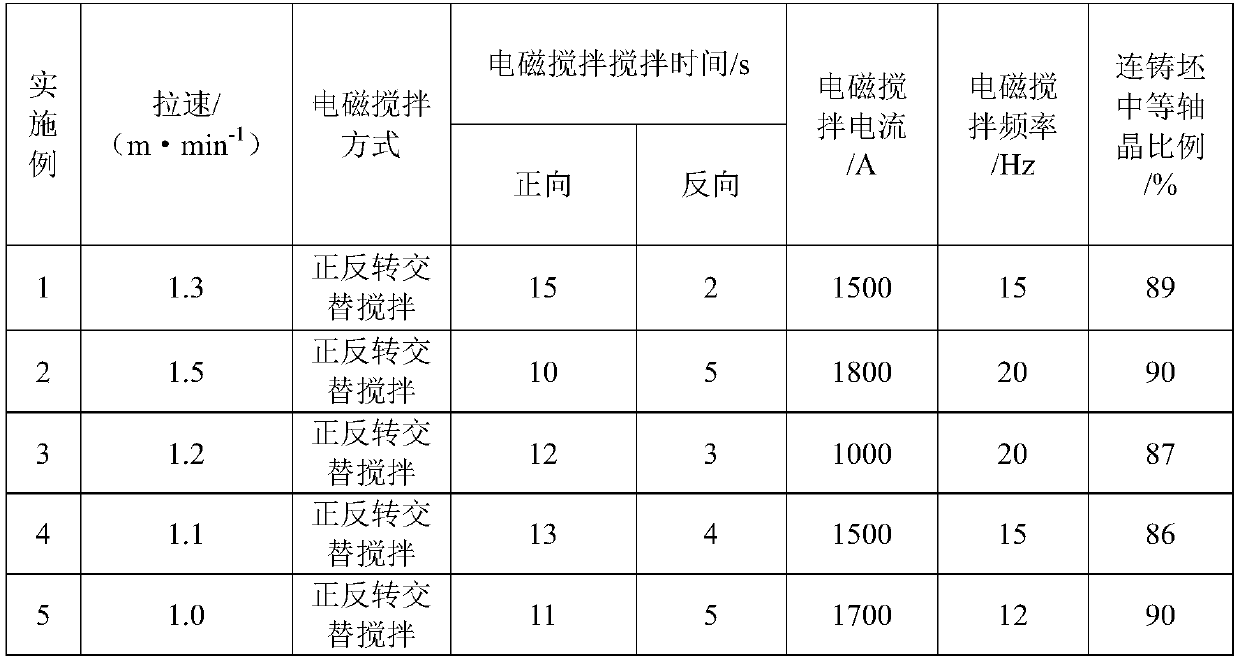

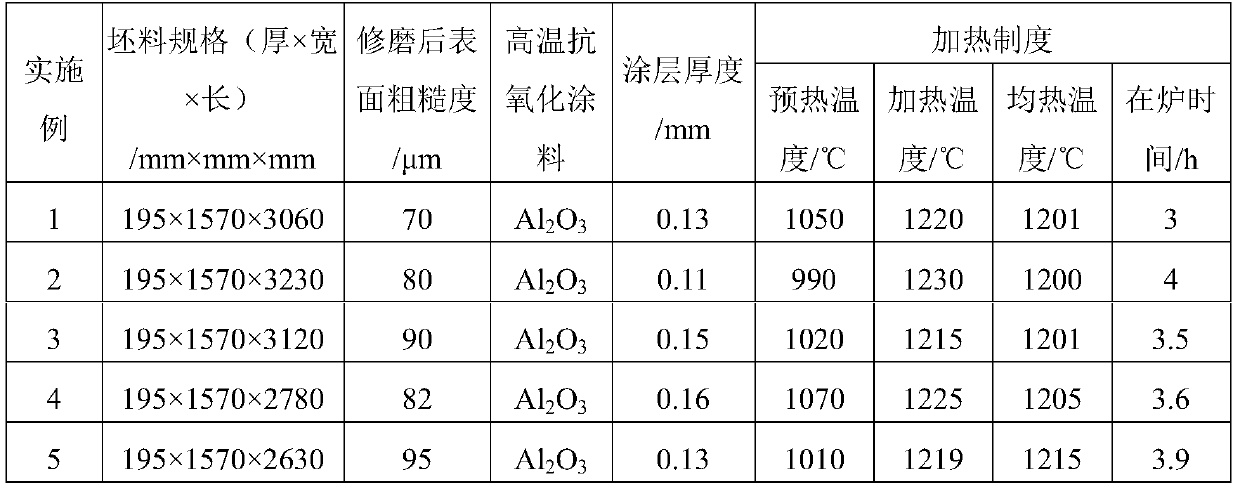

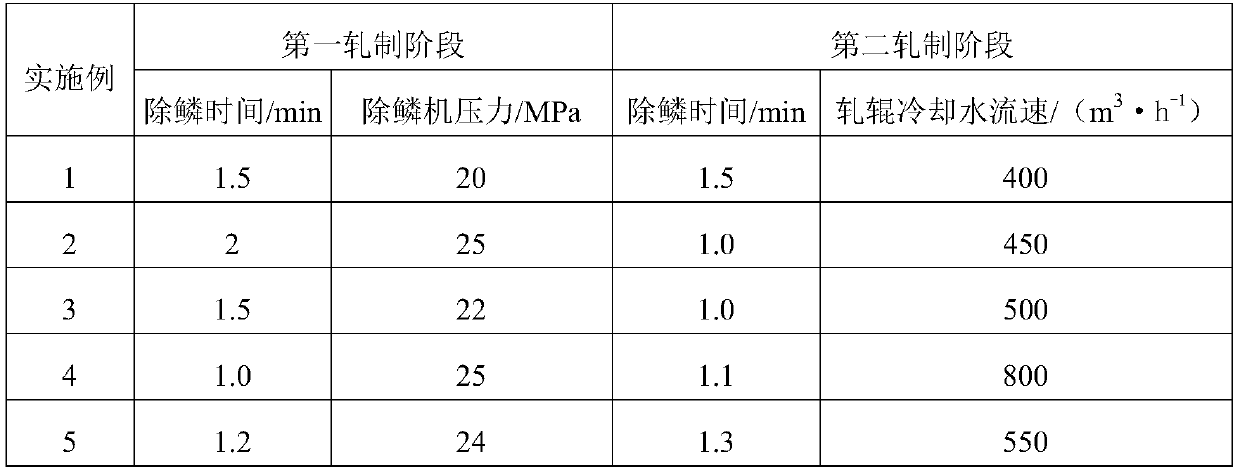

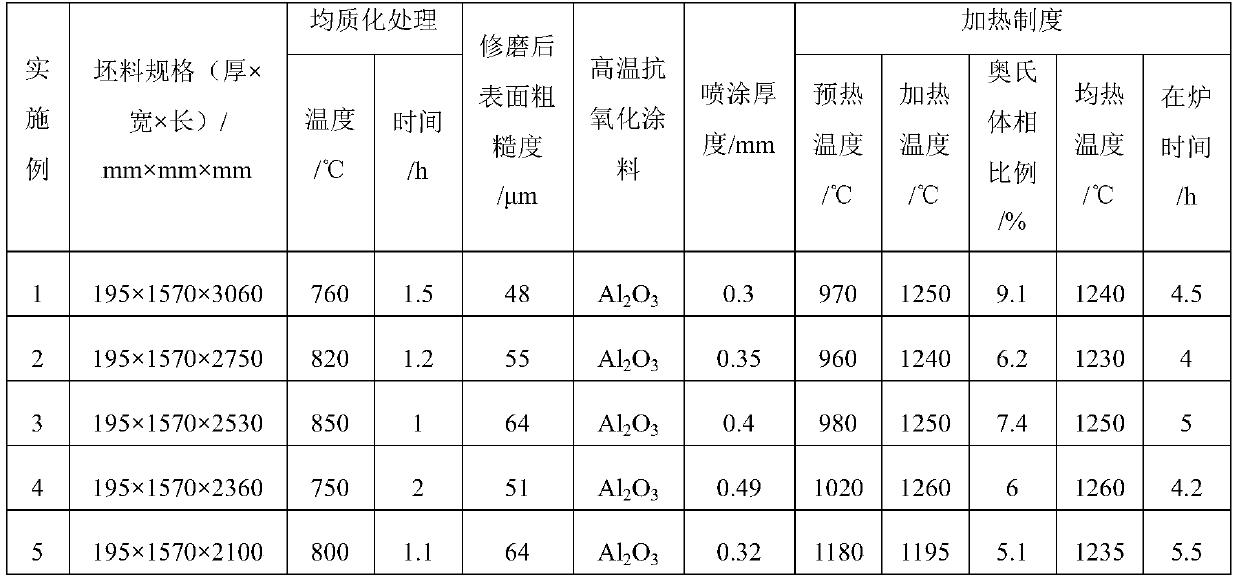

Method for eliminating surface cracks of ultra-wide high-nitrogen austenitic stainless steel medium thick plate

ActiveCN110438416AIncrease equiaxed crystal ratioImprove surface qualityProcess efficiency improvementWork heating devicesAustenitic stainless steelHigh nitrogen

The invention discloses a method for eliminating surface cracks of an ultra-wide high-nitrogen austenitic stainless steel medium thick plate. The isometric crystal proportion in a continuous casting blank is not lower than 85%; the surface roughness degree Ra of the casting blank after being subjected to repairing grinding is smaller than or equal to 100 microns, and high-temperature anti-oxidizing coating is sprayed; after being treated through a pre-heating segment at a temperature of 980-1100 DEG C, a heating segment at a temperature of 1100-1230 DEG C, and a soaking zone at a temperature of 1200-1230 DEG C in sequence, the casting blank is discharged out of a furnace, and the in-furnace time is 3-4 h; the initial rolling temperature in the first stage is larger than or equal to 1150 DEG C, and the final rolling temperature is larger than or equal to 950 DEG C; and the initial rolling temperature in the second stage is larger than or equal to 1120 DEG C, the final rolling temperature is larger than or equal to 950 DEG C, a high-temperature solid solution temperature is 980-1050 DEG C, the in-furnace time is 2-5 min / mm, and water cooling is performed till a room temperature is achieved. A product width is 2200-4000 mm, and the thickness is 20-60 mm. A surface crack rejection ratio is lowered to be 2% or below from 10% or above. A product is suitable for a structural part highin toughness and high in strength and bearing an impacting load.

Owner:ANGANG STEEL CO LTD

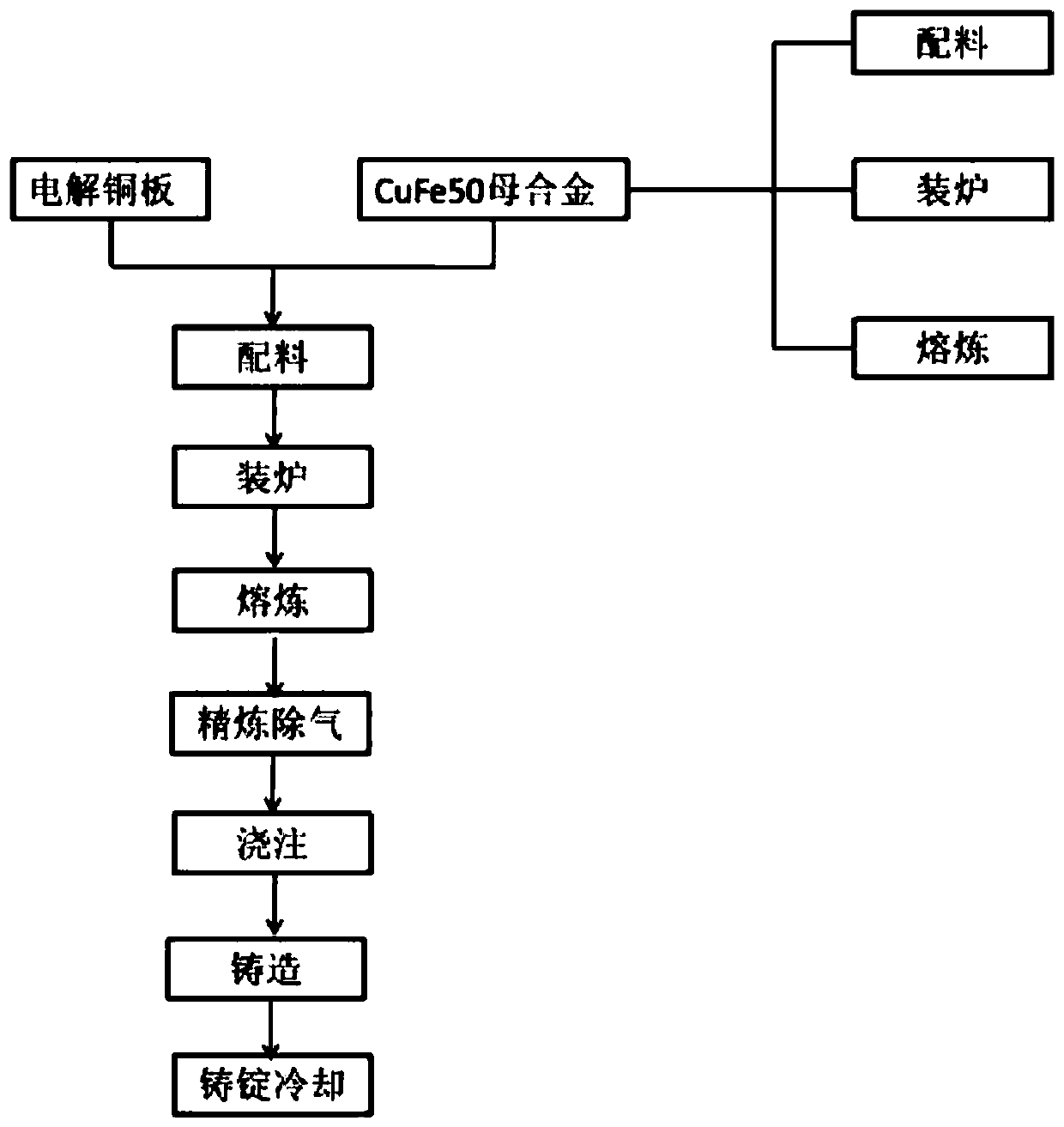

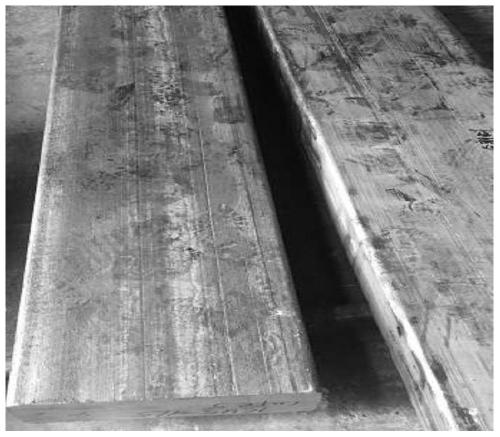

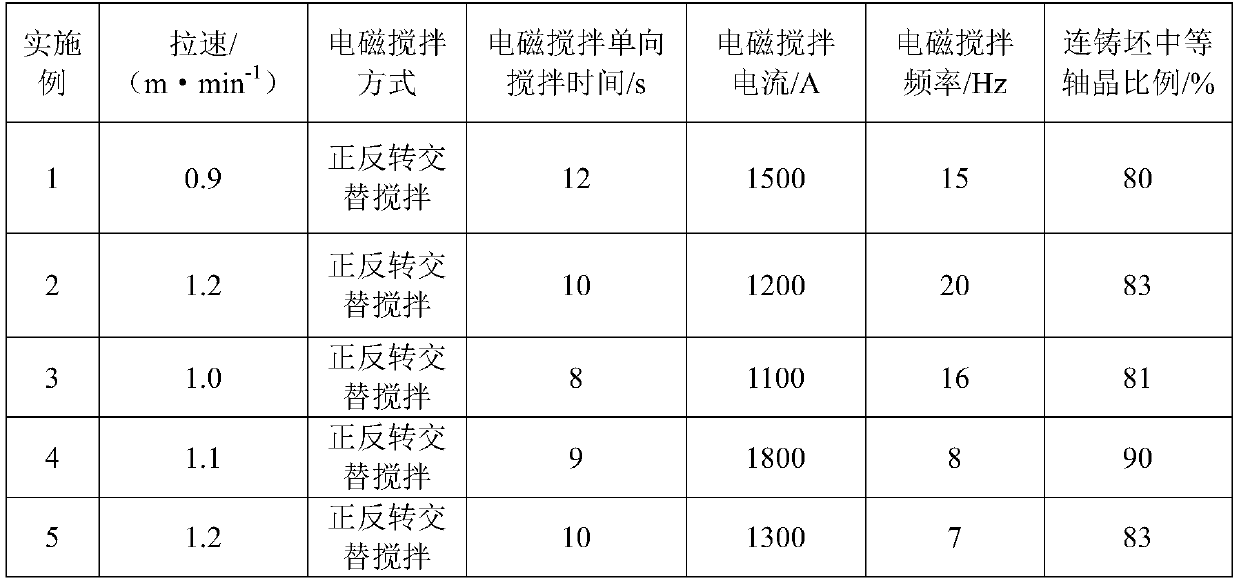

Production process of non-vacuum downwards-drawing continuous casting copper-iron alloy slab ingot

The invention discloses a production process of a non-vacuum downwards-drawing continuous casting copper-iron alloy slab ingot. The production process mainly comprises the following steps of burdening, charging, smelting, refining degassing, pouring, casting and ingot casting, wherein the copper-iron alloy slab ingot is successfully prepared by using an electrolytic copper plate and a CuFe50 master alloy as smelting raw materials through a non-vacuum downwards-drawing continuous casting process, and compared with a traditional vacuum casting process, the equipment requirement is low; inert gasprotection is adopted in the casting process, appropriate measures such as iron content are adjusted, and the alloy composition and the oxygen content are effectively controlled; the process has theadvantages of being stable in process, simple and convenient to operate, low in casting production cost and capable of realizing industrial production of the copper-iron alloy slab ingot.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

Method for eliminating surface cracks of ultra-wide ferrite stainless steel middle-thick plate

ActiveCN110438414AIncrease equiaxed crystal ratioShorten the forming intervalProcess efficiency improvementWork heating devicesSingle passThick plate

The invention discloses a method for eliminating surface cracks of an ultra-wide ferrite stainless steel middle-thick plate. The proportion of the medium axis crystal of a continuous cast blank is notlower than 75%; the homogenization temperature of the cast blank is 750-850 DEG C, the duration in the furnace is 1-2 hours, and water cooling is carried out to the room temperature; the surface roughness Ra of the cast blank after grinding is less than or equal to 70 microns, and high-temperature antioxidant coating is sprayed; the cast blank is processed by a preheating section, a heating section and a soaking section in sequence, and then is discharged from the furnace; the temperature of the preheating section is 950-1180 DEG C, the temperature of the heating section is 1180-1260 DEG C, the temperature of the soaking section is 1220-1250 DEG C, and the furnace time is 4-5.5 hours; the rough rolling temperature is larger than or equal to 1150 DEG C; the finish rolling temperature is larger than or equal to 1150 DEG C, the final rolling temperature is larger than or equal to 950 DEG C, the rolling single-pass pressing rate is less than or equal to 20%, the annealing temperature is 750-880 DEG C, the furnace time is 2-5 min / mm, and air cooling is carried out. The product width is 2500-4000 mm and the thickness is 8-30 mm. The rejection rate of the surface cracks is reduced from 6% or above to 0.5% or below.

Owner:ANGANG STEEL CO LTD

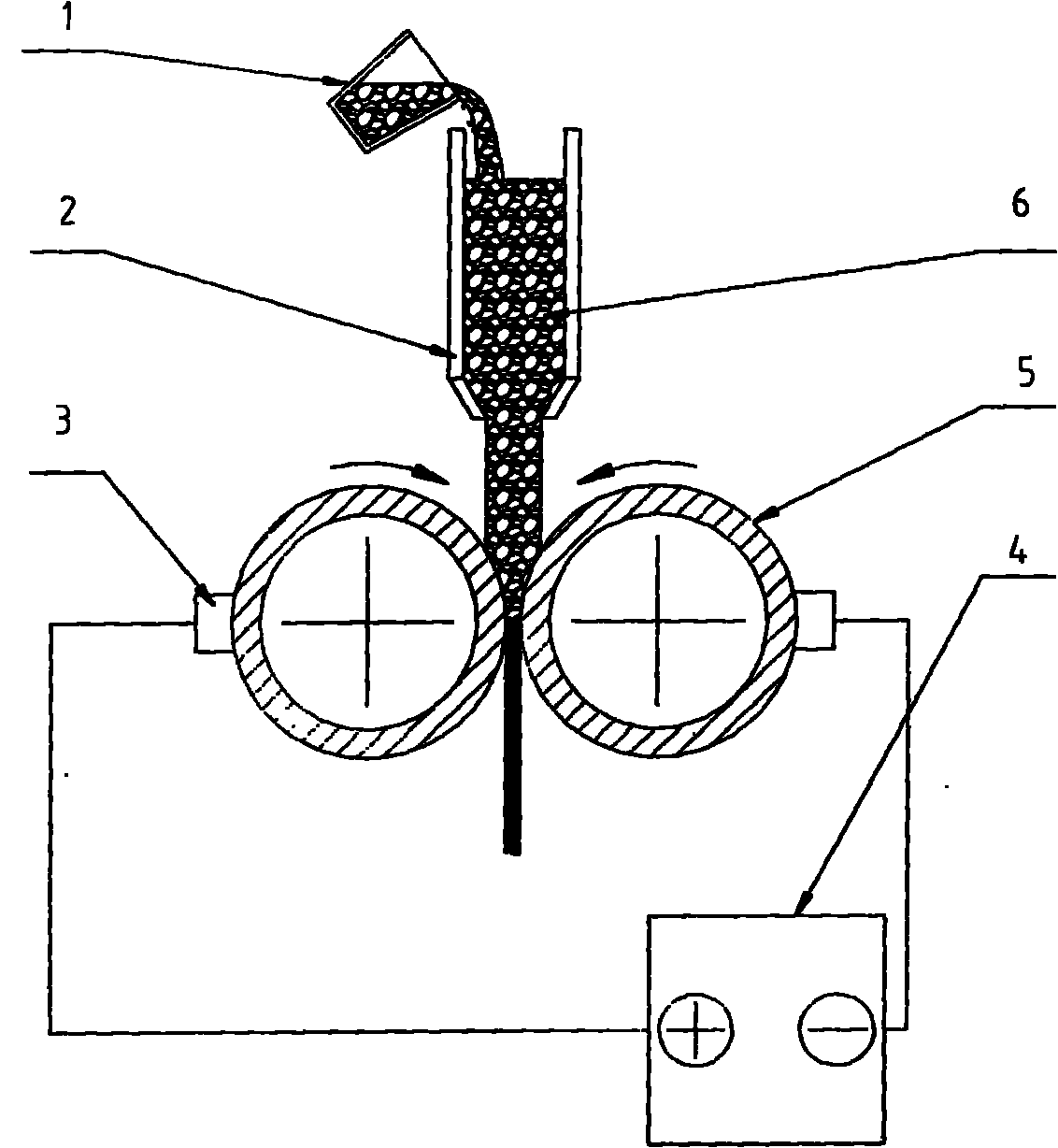

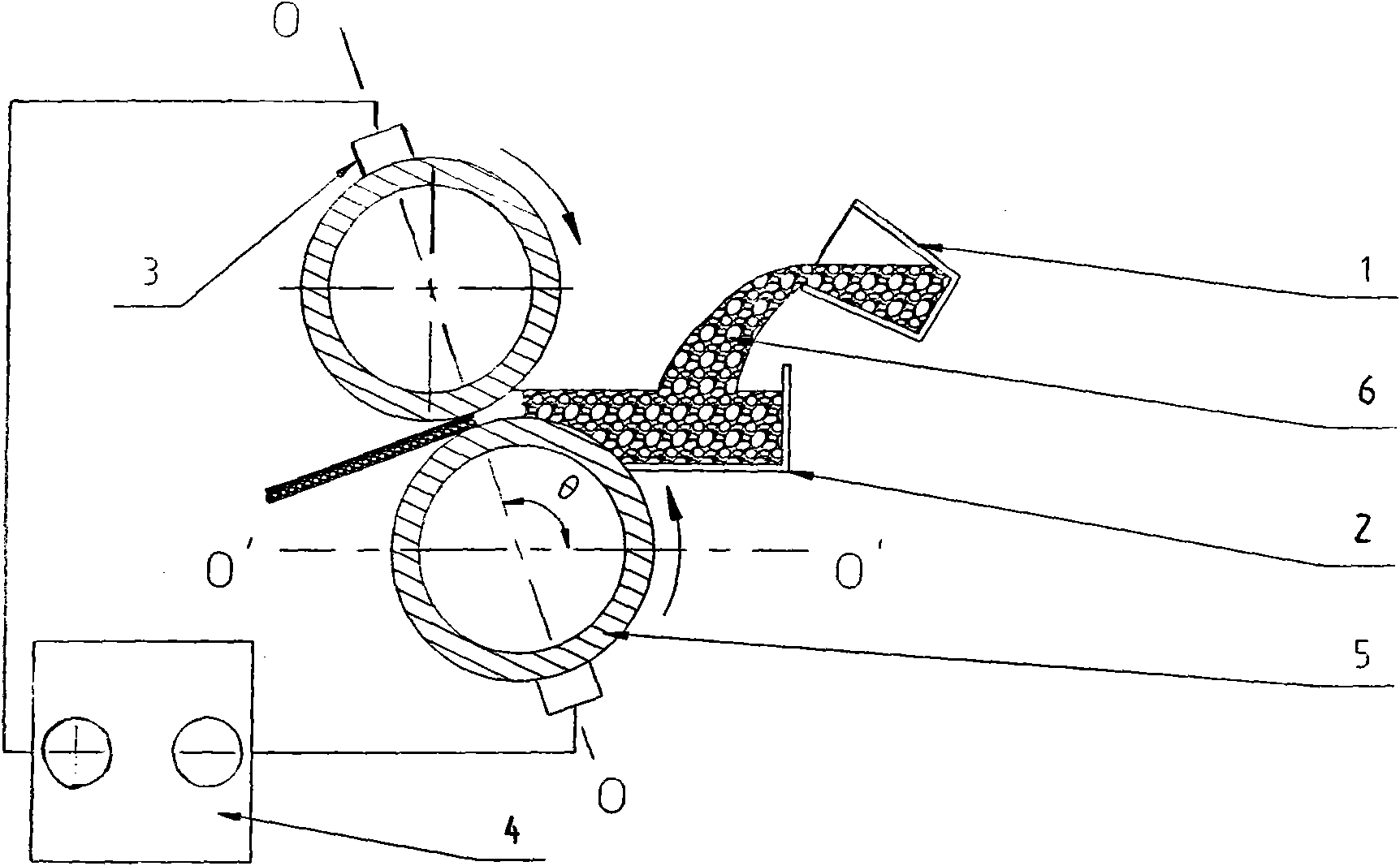

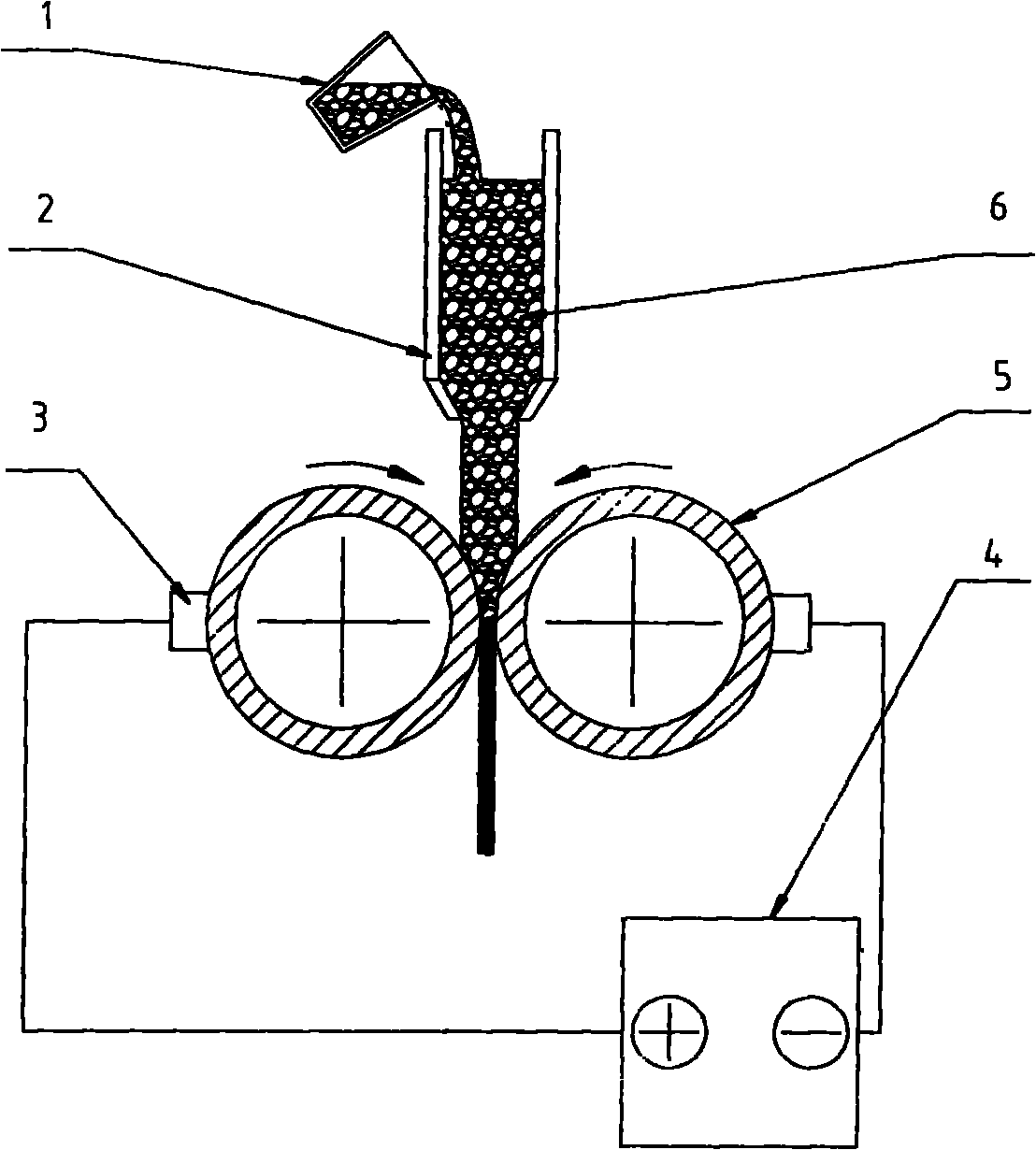

Electric pulse casting and rolling method of semi-solid alloy

The invention relates to an electric pulse casting and rolling method of a semi-solid alloy. In the method, semi-solid alloy slurry is filled between two rollers rotating in reverse directions, and is subject to flash set and plastic deformation under the action of pulse currents, thus obtaining alloy plates, thin alloy materials, alloy bars or alloy wires. The method can remarkably eliminate the segregation, refines the grains, and enhances the plastic deformation capability of the metal material, thereby improving the comprehensive mechanical properties of the material.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

CrNiMo round steel for wind power gear and preparation method

InactiveCN112522615AImprove purityReduce and stabilize superheatProcess efficiency improvementElectric furnaceGear wheelContinuous caster

The invention discloses CrNiMo round steel for a wind power gear and a preparation method. The CrNiMo round steel comprises the following ingredients in parts by weight: 0.15%-0.21% of C, 0.17%-0.37%of Si, 0.50%-0.90% of Mn, 1.50%-1.80% of Cr, 1.40%-1.70% of Ni, smaller than or equal to 0.20% of Cu, smaller than or equal to 0.025% of P, smaller than or equal to 0.025% of S, 0.25-0.35% of Mo, smaller than or equal to 0.0020% of O, 0.025-0.040% of Al and 0.0080-0.0120% of N. The preparation method comprises the steps of electric furnace smelting, LF refining, VD vacuum degassing, five-machine five-flow arc-shaped continuous casting machine and rolling, the preparation method is easy to operate and high in production efficiency, the prepared round steel has the advantages of being low in oxygen content, narrow in through hardening band, high in purity, accurate in component control, light in strip shape, excellent in surface quality and the like, and various technical requirements of steel for wind power gears are completely met.

Owner:ZENITH STEEL GROUP CORP +1

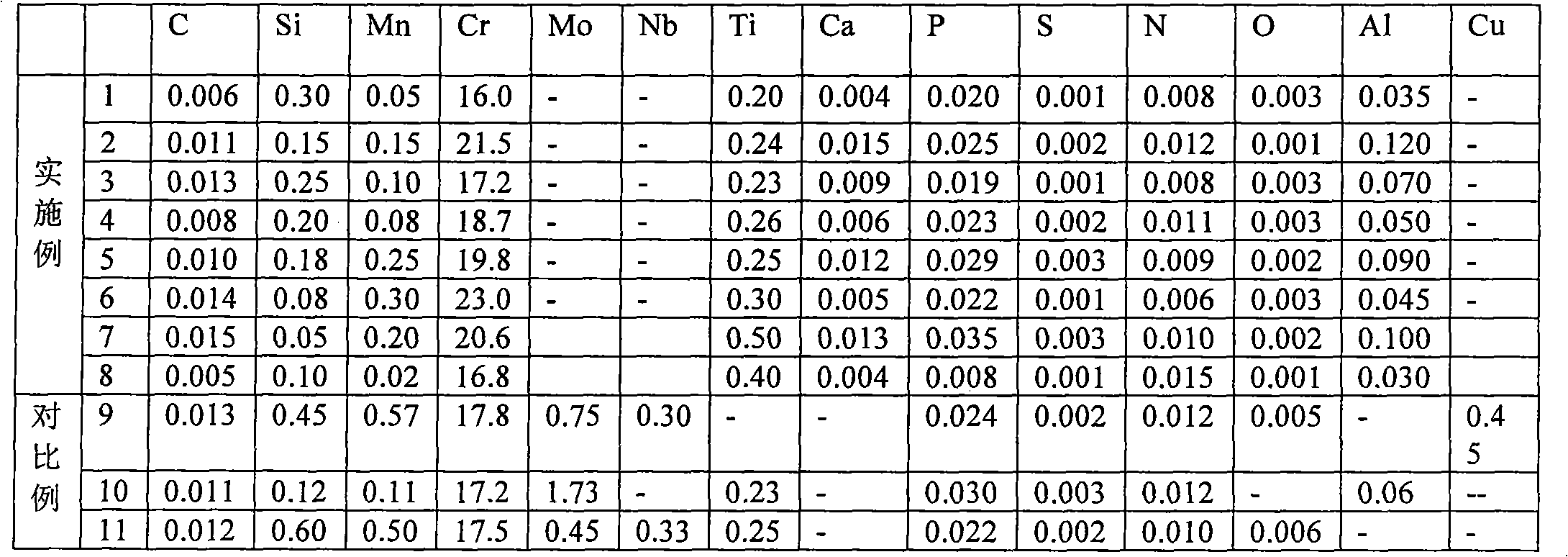

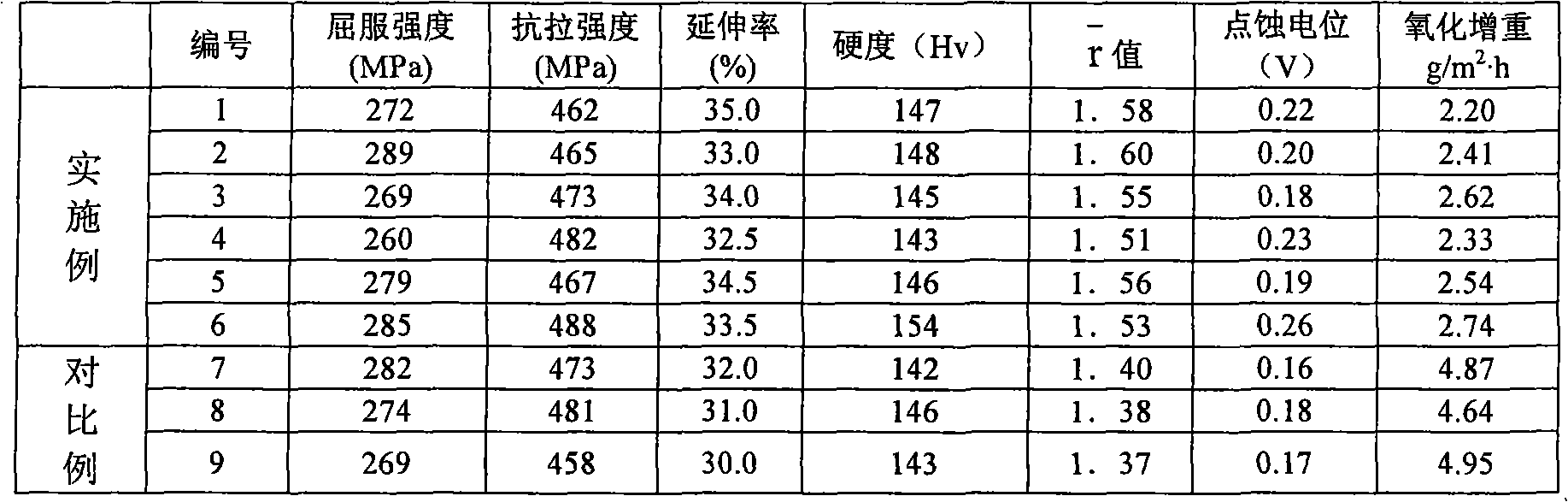

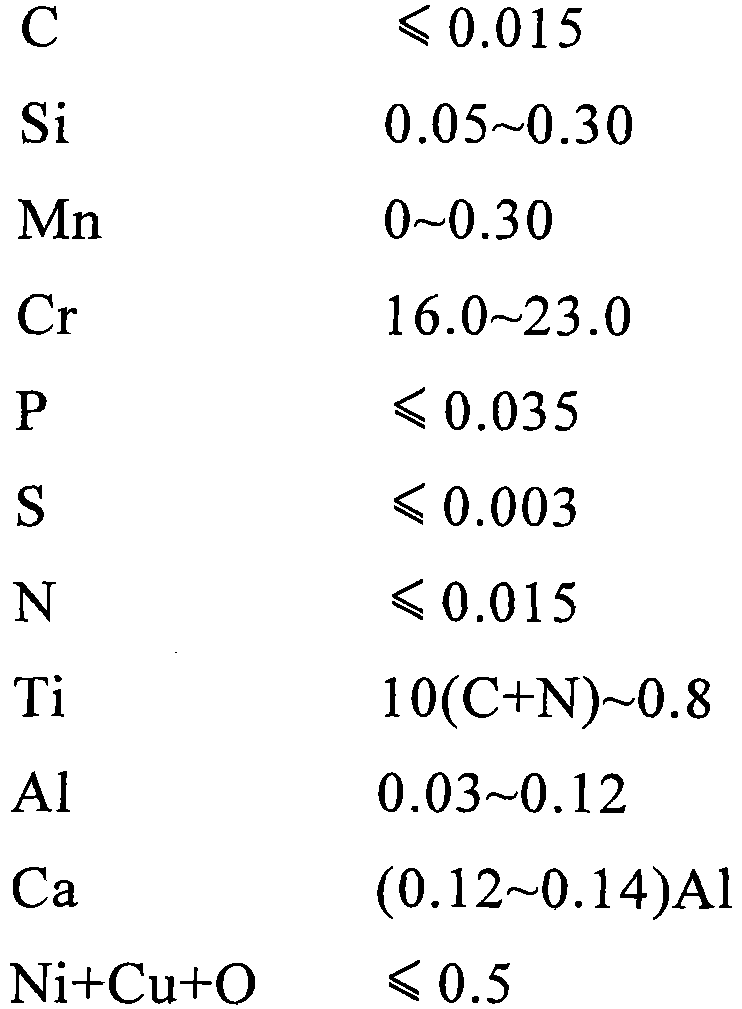

Stainless steel for heat exchanger welded pipe and manufacturing method thereof

ActiveCN102041455AImprove corrosion resistanceImprove mechanical propertiesRoll force/gap control deviceTemperature control devicePlate heat exchangerWater vapor

The invention relates to a stainless steel for a heat exchanger welded pipe and a manufacturing method thereof. The stainless steel for the heat exchanger welded pipe comprises the following components in mass by percent: less than or equal to 0.015 percent of C, 0.05-0.30 percent of Si, 0-0.30 percent of MnO, 16.0-23.0 percent of Cr, less than or equal to 0.035 percent of P, less than or equal to 0.003 percent of S, less than or equal to 0.015 percent of N, Ti, 0.03-0.12 percent of Al, Ca, Ni, Cu and O, and the balance of Fe and inevitable impurity, wherein the C and the N are totally less than or equal to 0.025 percent, the Ti is 10 times the total mass of the C and the N or 0.8 percent at most, the Ca is 0.12-0.14 times the mass of the AL, and the Ni, the Cu and the O are totally less than or equal to 0.5 percent. Through reasonable design of type and content of elements, the stainless steel has the characteristics of large heat conductivity, little expansion coefficient, excellentresistance to oxidation, excellent stress corrosion resistance, and the like, and is suitable for manufacturing parts for resisting atmosphere, steam, water and oxidability acid corrosion.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

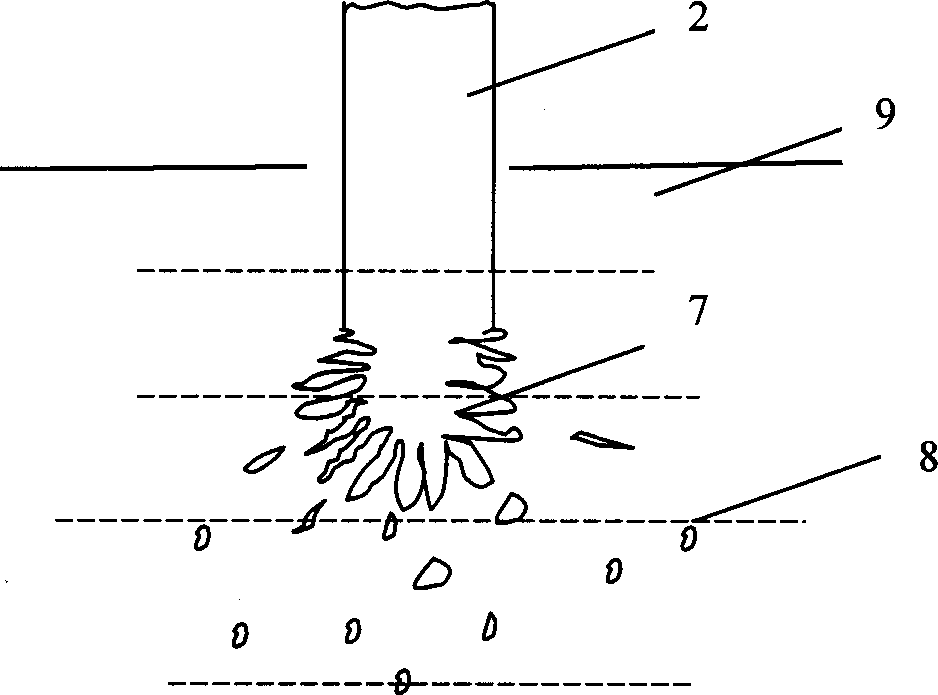

Improved method of vibration exciting metal liquid shape crystal nucleus and its device

An improved method for vibration excitation of the nucleuses in molten metal includes such steps as immersing at least one crystal nucleus ejector with high-frequency low-amplitude in molten metal, quickly generating a lot of crystal nucleuses in the front of said ejector, and ejecting them in the molten metal to form a lot of crystal nucleuses of equiaxed crystals. It features that said crystal nucleus ejector is a consumable cold metal material.

Owner:CENT IRON & STEEL RES INST

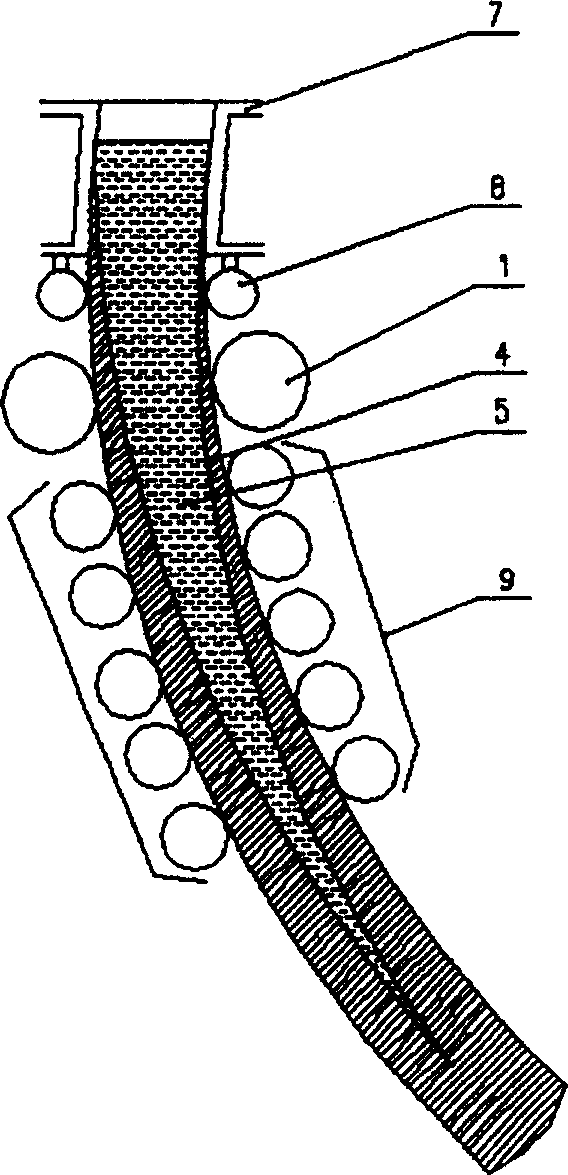

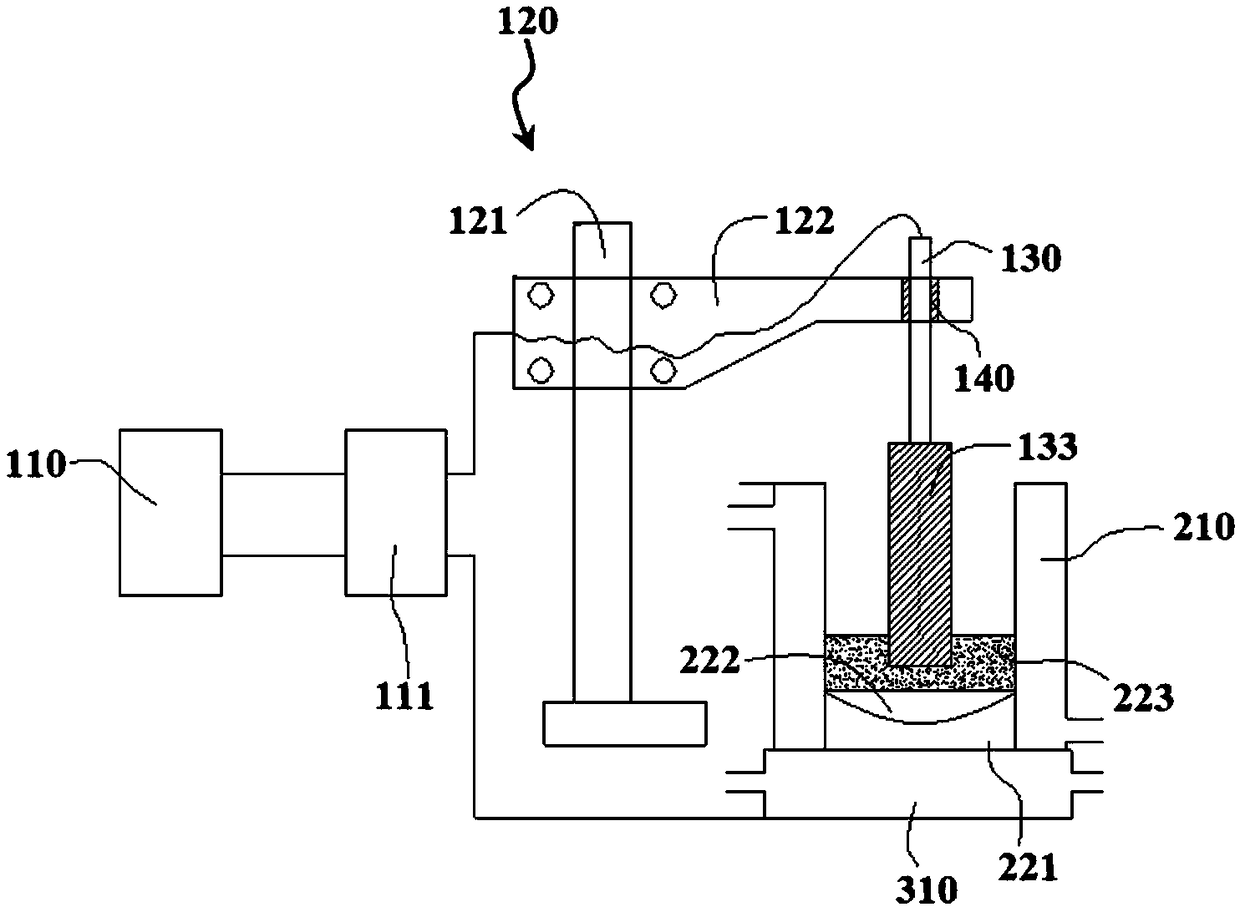

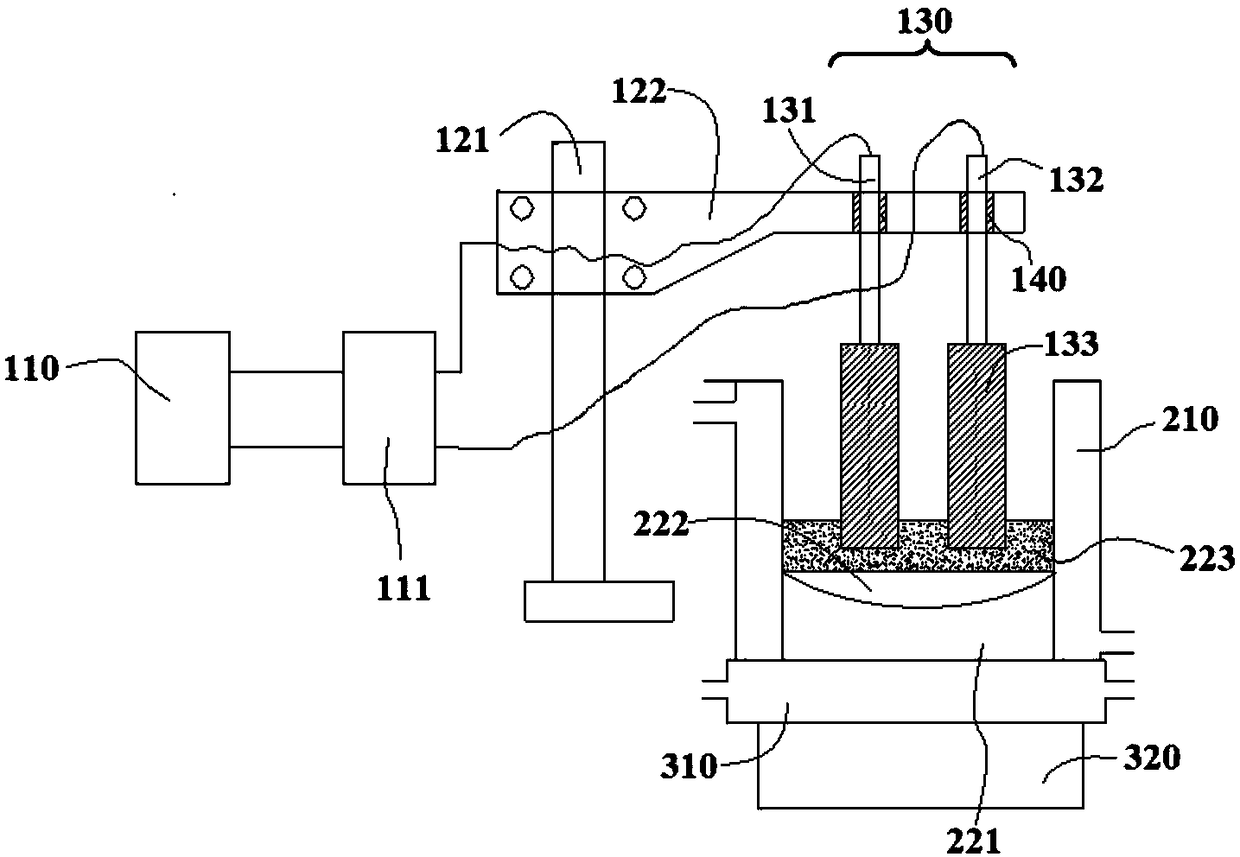

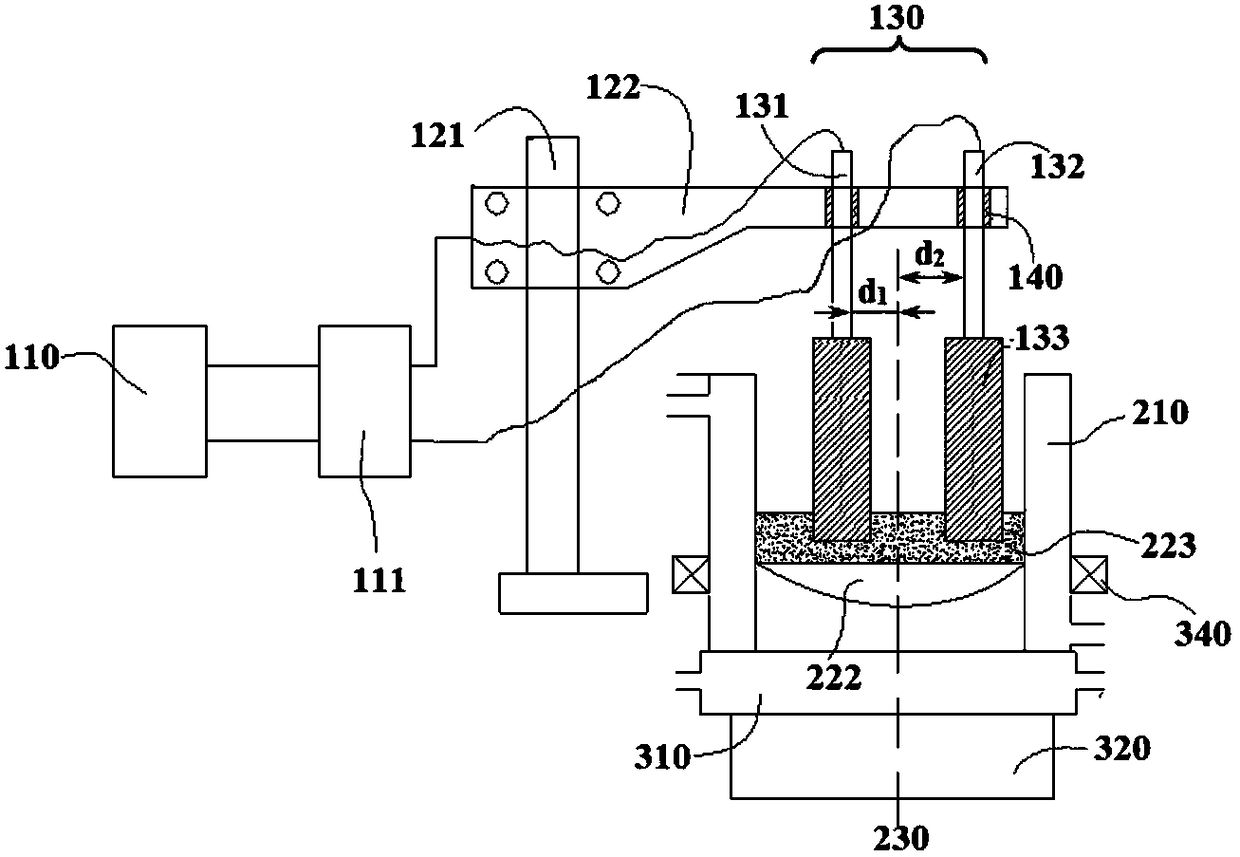

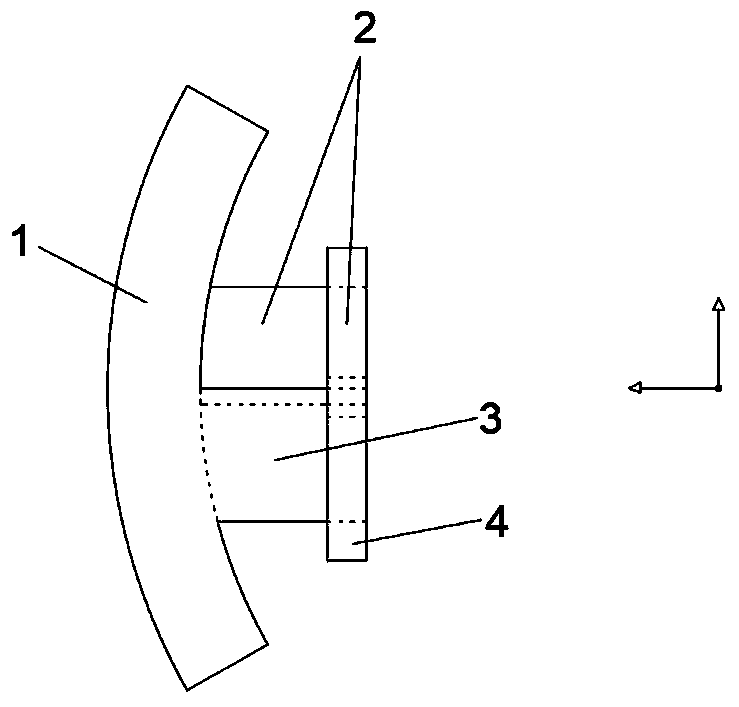

Method for improving continuous casting blank quality and vibration support roller device

The invention belongs to the field of continuous casting of metals, in particular to a method for improving the quality of continuous casting slabs and a vibrating support roller device. In this method, the vibrating support rollers that are closely attached to the outer wall of the continuous casting slab shell maintain synchronous rotation with the surface of the continuous casting slab, and at the same time, under the drive of the vibration source, vibrate perpendicular to the thickness direction of the slab or parallel to the casting direction, and This vibration is transmitted to the solidified shell with a liquid core by contact. The vibration support roll device used in the above method is composed of the vibration support roll closely attached to the outer wall of the continuous casting slab, the vibration transmission pipeline connected with it and the vibration generation source. Compared with the prior art, the present invention has the advantages of increasing the equiaxed grain rate in the center of the continuous casting slab through the vibrating support roller device with simple structure and easy control, so as to significantly improve the shrinkage cavity and porosity in the center of the continuous casting slab, reduce segregation and effectively avoid the use of The advantage of improving the quality of continuous casting slabs is the generation of rolling cracks caused by light pressure at the end of solidification.

Owner:CENT IRON & STEEL RES INST

Production method of non-oriented electrical steel

The invention discloses a production method of non-oriented electrical steel. The method includes the steps of adopting roller type electromagnetic stirring on a secondary cooling section, opening all rollers for electromagnetic stirring, starting the electromagnetic stirring when the casting length is 7-9m and stopping the electromagnetic stirring after a casting machine stops casting, and controlling the water flow rate to be not less than 9 <3> / h and the pure water conductivity to be not more than 50mu in the electromagnetic stirring process. According to the method for improving the equiaxial crystal ratio of the non-oriented electrical steel, the roller type electromagnetic stirring is adopted in the secondary cooling section, the carbon content and nitrogen content of the non-oriented electrical steel are controlled, and therefore the equiaxial crystal ratio of non-oriented electrical steel products can be improved.

Owner:BEIJING SHOUGANG CO LTD

Method for refining metal structure in oxide metallurgy by utilizing pulsed magnet field

InactiveCN103341617AImprove performanceIncrease equiaxed crystal ratioAlloy elementPowder metallurgy

The invention relates to a method for refining metal structure in oxide metallurgy by utilizing a pulsed magnet field, and belongs to a metal solidification and crystallization technology. The method comprises the following steps of: fusing a metal material, wherein the degree of superheat is 100-150 DEG C, and insulating for 5-15 minutes; adding compound alloy elements which induce transgranular ferrite into the metal liquid, wherein the metal liquid comprises the following chemical components: 0.25-0.6% of C, 0.1-0.4% of Si, 0.5-1.5% of Mn, less than or equal to 0.045% of S, less than or equal to 0.045% of P, 0-0.05% of Ti, 0-0.1% of V and 0-0.01% of N; applying the pulsed magnet field to the metal liquid, wherein the magnetic induction intensity is 0-5T, and the pulse period is 0-30s; cooling and condensing the metal liquid to room temperature at a cooling speed of 50-150 DEG C / min. The method provided by the invention organically combines treatment of the pulsed magnet field and oxide metallurgy, so that grains and tissues in the steel liquid are double-refined in the whole condensing process, thereby, optimizing the performance of the steel material.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for improving internal quality of casting blank by composite intervention

Provided is a method for improving internal quality of casting blank by composite intervention. The method comprises following steps: 1), machining pure iron or steel with the approximate content of steel grades to be an easily-melted cold bodies moving with molten steel and then drying; 2), baking feeding guide pipes which are made by refractory material and immersing them into a crystallizer below the molten steel surface; aligning feeding guide pipe openings to the center of steel streams as for round and square billets; utilizing two guide pipes for plate blank and distributing them on two sides of a wide surface of the crystallizer; 3), continuously injecting the dried cold bodies into a high-temperature region of a molten pool of the crystallizer, adding the cold bodies in the amount of 0.8-1.3% of casting blank; adopting the crystallizer to electromagnetically stir during the continuous casting process. The method for improving internal quality of casting blank by composite intervention has following beneficial effects: cold bodies are fed into the crystallizer such that superheat and temperature gradient of molten steel during mass production of continuous casting; the solidification structure of casting blank is improved; quality flaws of the internal quality of the casting blank is reduced; the temperature field of the crystallizer is improved; and therefore the purposes of increasing equiaxial crystal ratio and improving internal quality of the casting blank are fulfilled.

Owner:BAOSHAN IRON & STEEL CO LTD

Electromagnetic stirring water-cooled mold and method for pouring steel ingot

The invention discloses an electromagnetic stirring water-cooled mold and a method for pouring a steel ingot, belonging to the field of steel and iron smelting. The electromagnetic stirring water-cooled mold consists of a base plate, an auxiliary plate, a mold body and a heat preservation cap, wherein the heat preservation cap is embedded and inserted into an upper port of the mold body; an annular gap of the upper port of the heat preservation cap is filled with filler sand; a heat insulating plate of the heat preservation cap is provided with a reinforcing hole; a cooling water jacket is arranged along the circumference of the mold body; the gap of the cavity of the jacket is increasingly expanded from bottom to top; and an electromagnetic stirrer is arranged along the circumference of the mold body. The method for pouring the steel ingot of the electromagnetic stirring water-cooled mold comprises the following steps of: filling casting powder at the bottom of the mold; opening a cooling water system; controlling pouring speed of molten steel of the ingot body to be (10-50) cm / min; when the liquid level rises to over 2 / 3 of the height, turning on the electromagnetic stirrer; and when the liquid level rises to the space above the reinforcing hole and below a hanger structure, stopping pouring. By using the device, the electromagnetic stirrer is turned on during pouring and crystallization of the molten steel, and the molten steel is dynamically crystallized into solid. Compared with the original technology, the equiaxed crystal ratio of the steel ingot is further improved, the stirring strength and the micro-adjustment stirring method are properly set according to different steel types, and an ideal equiaxed crystal ratio can be achieved; and a finished product of the steel ingot is uniform in composition and the grain is refined, so that the quality of the steel ingot is greatly improved.

Owner:孙柏良

Method and device for homogenizing large ingot solidification structure by combining static magnetic field with rotating magnetic field

The invention discloses a method and device for homogenizing a large ingot solidification structure by combining a static magnetic field with a rotating magnetic field. Through the electromagnetic oscillation effect generated by a combined magnetic field and the rotational flow induction stirring effect of the rotating magnetic field, nucleation is promoted, dendritic crystal tips are crushed, crystal grains are refined, the solidification structure is homogenized, macroscopic segregation is reduced, and therefore the method and the device are used for the large ingot casting process. When metal melt is solidified, the static magnetic field and the rotating magnetic field are exerted to a heat preservation riser in a combined mode according to the characteristics that metal liquid at an ingot mould riser is solidified lastly, the riser wall and the metal liquid surface are easy to nucleate first, and the rotating magnetic field and the static magnetic field can easily permeate a riser material, the metal liquid in the heat preservation riser is effectively oscillated and stirred, and the metal liquid in the riser is delivered into the metal liquid at the center of an ingot mould through oscillating and rotational flow stirring; the dendritic crystal tips are crushed, the crystal grains are refined, the solidification structure is homogenized, macroscopic segregation is reduced, a compact, homogenized and crystal grain-refined large ingot is obtained, and therefore the subsequent machining performance and service performance of the large ingot are improved.

Owner:SHANGHAI UNIV

Production method capable of effectively controlling quality of 37Mn round pipe billet steel casting blank

ActiveCN105586531AGood and stable quality controlIncreased low-magnification rating quality levelsManufacturing convertersPower flowWater flow

The invention belongs to the field of metallurgy and particularly discloses a production method capable of effectively controlling the quality of a 37Mn round pipe billet steel casting blank. The production method aims at solving the problems that when a 37Mn round pipe billet casting blank large in section size is produced through an existing production method, the equiaxial crystal ratio is commonly low. The production method capable of effectively controlling the quality of the 37Mn round pipe billet steel casting blank includes the steps of smelting performed in a converter, refining performed in an LF furnace, RH vacuum processing and continuous casting, and in the continuous casting step, according to electromagnetic stirring parameters of a crystallizer, stirring current is 300-400 A, and frequency is 2-4 Hz; according to electromagnetic stirring parameters at the final stage of solidification, stirring current is 100-250 A, and frequency is 4.0-7.0 Hz; overheat degree is controlled to be 20-35 DEG C; pulling speed is controlled to be 0.75-0.90 m / min; cooling of the crystallizer is controlled to be 2400-2500 L / min; secondary cooling specific water flow is controlled to be 0.21-0.30 L / kg steel. According to the method, by means of combined electromagnetic stirring of electromagnetic stirring of the crystallizer and electromagnetic stirring at the final stage of solidification, casting blank solidification heat transfer is optimized, the large-specification 37Mn round pipe billet casting blank solidification structure is controlled, and the equiaxial crystal ratio of the casting blank solidification structure is improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Nitrogen-containing high-carbon steel for grinding balls and low-cost smelting process thereof

ActiveCN112553528AImprove purityImprove quality uniformityElectric furnaceProcess efficiency improvementSmelting processSolid solution strengthening

The invention belongs to the technical field of iron and steel smelting, and particularly relates to nitrogen-containing high-carbon steel for grinding balls and a low-cost smelting process thereof. The steel comprises the components in percentage by weight: 1.00-1.10% of C, 0.30-0.55% of Si, 1.05-1.15% of Mn, less than or equal to 0.025% of P, less than or equal to 0.035% of S, 0.65-0.75% of Cr,0.015-0.030% of Al, 0.010-0.025% of Ti, 60-100ppm of N and the balance Fe and inevitable impurities. According to the nitrogen-containing high-carbon steel for the grinding balls and the low-cost smelting process thereof, by properly increasing the carbon content, adding a certain amount of Al, Ti, N and other elements for microalloying and designing process parameters, the purposes of grain refinement and solid solution strengthening are achieved, the smelted grinding ball steel is uniform in chemical component, high in purity and fine in grain, the technical indexes such as abrasion resistance, hardness and toughness of the steel are effectively improved, and the use requirements of users for high-end grinding ball steel are completely met.

Owner:ZENITH STEEL GROUP CORP +1

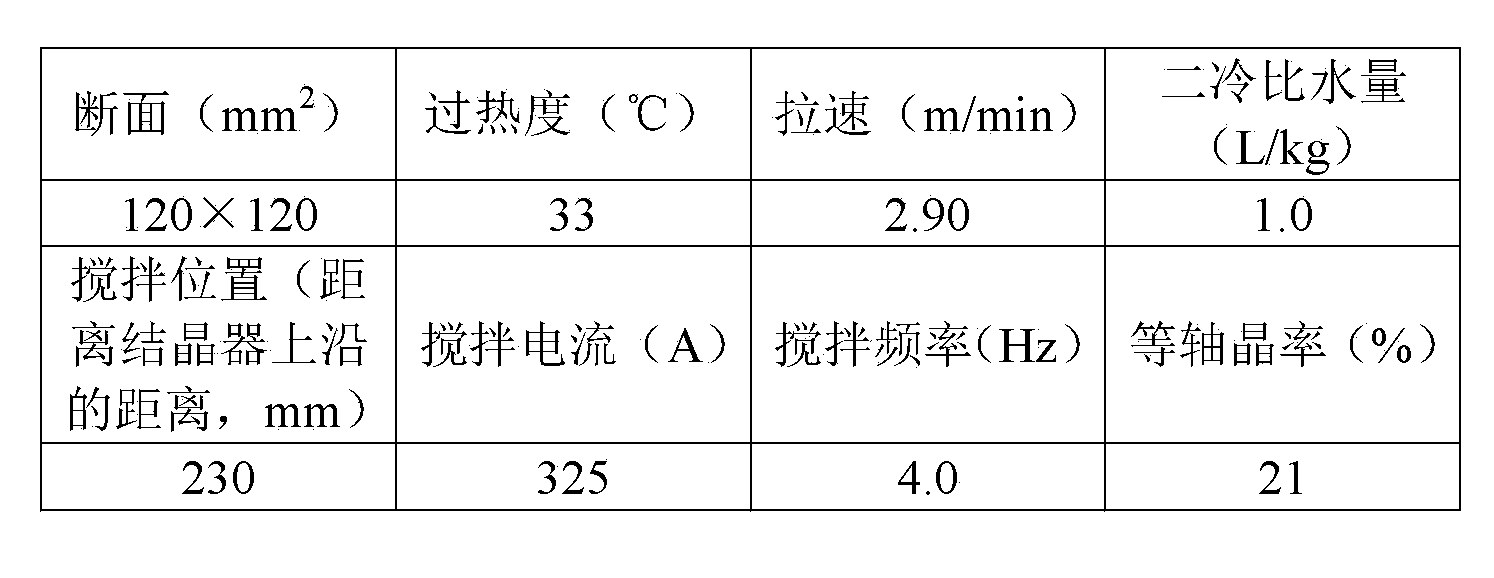

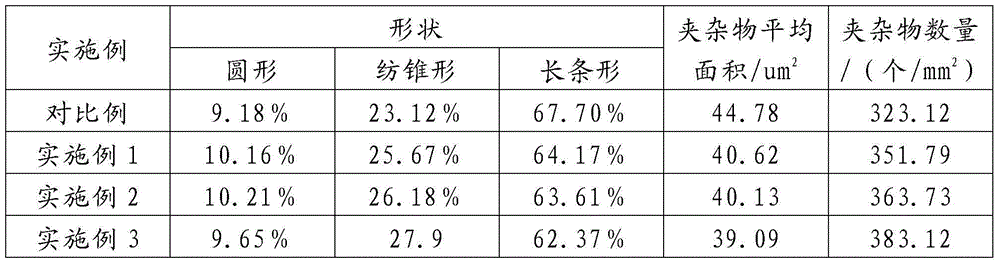

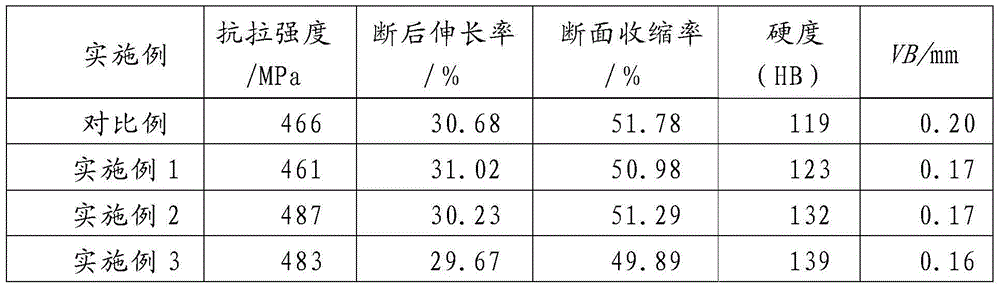

Method for improving isometric crystal ratio of high-carbon steel billet

ActiveCN103506589AIncrease equiaxed crystal ratioIncrease productivityPower flowChemical composition

The invention provides a method for improving the isometric crystal ratio of a high-carbon steel billet. The high-carbon steel comprises, by weight, 0.57%-0.65% of C, 0.17%-0.37% of Si, 0.4%-0.8% of Mn, 0.025% of P, 0.025% of S, and the balance Fe and inevitable impurities. The degree of superheat of molten steel is 25-35 DEG C. The blank casting speed is 2.5-2.9m / min. The secondary cooling specific water flow is 0.9-1.2L / kg. An electromagnetic stirrer is placed at a position 18-22mm away from the lower edge of a crystallizer, the current intensity of the electromagnetic stirrer is 290-330A, and electromagnetic stirring frequency is 4.0-4.6Hz. According to the method for improving the isometric crystal ratio of the high-carbon steel billet, the isometric crystal ratio of a 60# billet can be stably improved to 20%, and the high casing speed enables production efficiency to be improved. Therefore, high-efficiency production is guaranteed, defects of loosening and shrinkage caused by insufficient isometric crystal ratio in the prior art are overcome or eliminated, and the defects are prevented from being passed onto the steel rolling procedure.

Owner:ANGANG STEEL CO LTD

Novel chalcogenide easily cut steel and iron material

The invention relates to a novel chalcogenide easily cut steel and iron material. The novel chalcogenide easily cut steel and iron material consists of the following ingredients in percentage by mass: 0.13-0.16 percent of C, 0.9-1.35 percent of Mn, 0.06-0.12 percent of Si, 0.07-0.11 percent of P, 0.28-0.33 percent of S, 0.04-0.11 percent of Zr, not larger than 0.006 percent of Al, not larger than 0.005 percent of N and the rest of Fe based on the 100% total mass percentage. The easily cut steel and iron material is provided and prepared with economical advantage, and the cutting performance is improved under the condition of ensuring mechanical performance.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Method for improving solidification quality of electroslag remelting steel ingot

InactiveCN108411120AImprove solidification qualityUniform temperature fieldLiquid stateSmelting process

The invention discloses a method for improving solidification quality of an electroslag remelting steel ingot and relates to the technical field of electroslag remelting. The method for improving thesolidification quality of the electroslag remelting steel ingot. When a smelting device is adopted for smelting, consumable metal of a metal electrode is inserted into liquid state slag of a smeltingcrystallizer, a positive pole of a pulse power source is connected with the metal electrode, a negative pole of the pulse power source is connected with a bottom water tank, the pulse power source iselectrified and an electric circuit is formed, and the consumable metal of the metal electrode is re-smelted and re-solidified, so that the steel ingot is obtained. When the smelting device is adoptedfor smelting, the metal electrode leads pulse current of the pulse power source to the smelting process, the pulse power source is electrified and an electric circuit is formed, and the consumable metal of the metal electrode is re-smelted and re-solidified, so that the steel ingot is obtained.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

Cryogenic treatment process for improving toughness of magnesium alloy

The invention discloses a cryogenic treatment process for improving the toughness of magnesium alloy, and belongs to the technical field of metal materials. The process comprises the following steps that (1), a die is preheated to 100-400 DEG C; (2), magnesium alloy melt is poured into the preheated die, and the alloy is solidified, wherein a rotating magnetic field with the magnetic field intensity of 0.5-5 T can be applied at the same time in the whole process, and the mode is that the magnetic field can not be applied or applied in the pouring process, and the magnetic field is applied in the solidification process; (3), the solidified magnesium alloy undergoes solution treatment, wherein the temperature of the solution treatment is 390-420 DEG C, the heat preservation time of the solution treatment is 6-48 hours; (4), the magnesium alloy subjected to the solution treatment undergoes quenching treatment; and (5), the magnesium alloy subjected to the quenching treatment is placed inliquid nitrogen to undergo cryogenic treatment to obtain the magnesium alloy, wherein the temperature of the cryogenic treatment ranges from minus 196 DEG C to minus 209 DEG C, and the time of the cryogenic treatment is 24-48 hours. According to the process, the magnesium alloy is poured under the condition of the rotating magnetic field, so that the mechanical property of the alloy is increased,and after the magnesium alloy undergoes the solution treatment and the cryogenic treatment, the toughness of the magnesium alloy is greatly improved; and the process method is simple in technologicalprocess and is beneficial to practical application.

Owner:SHENYANG POLYTECHNIC UNIV

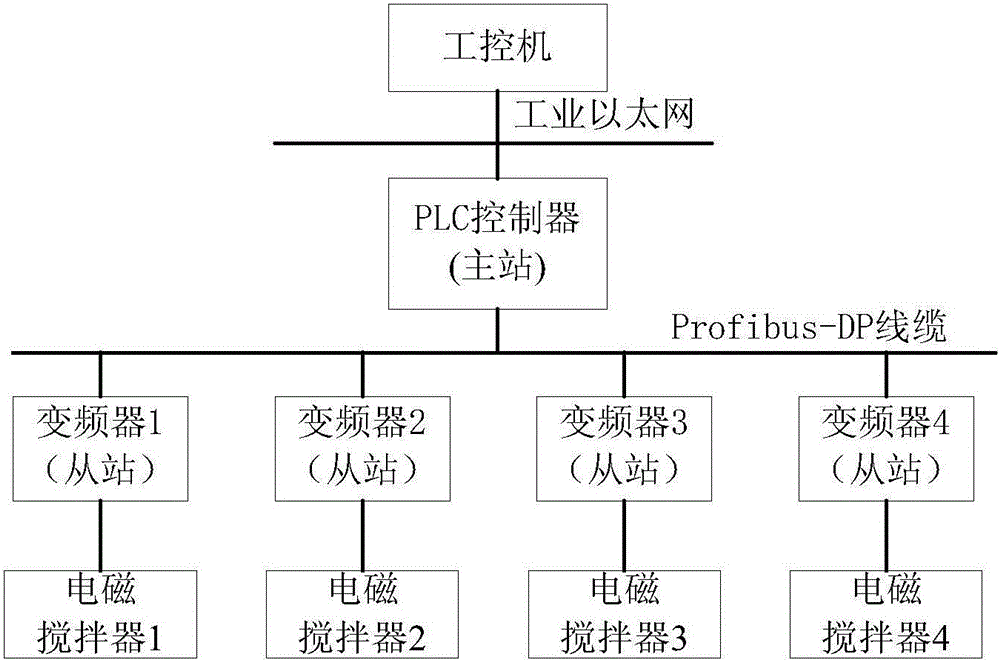

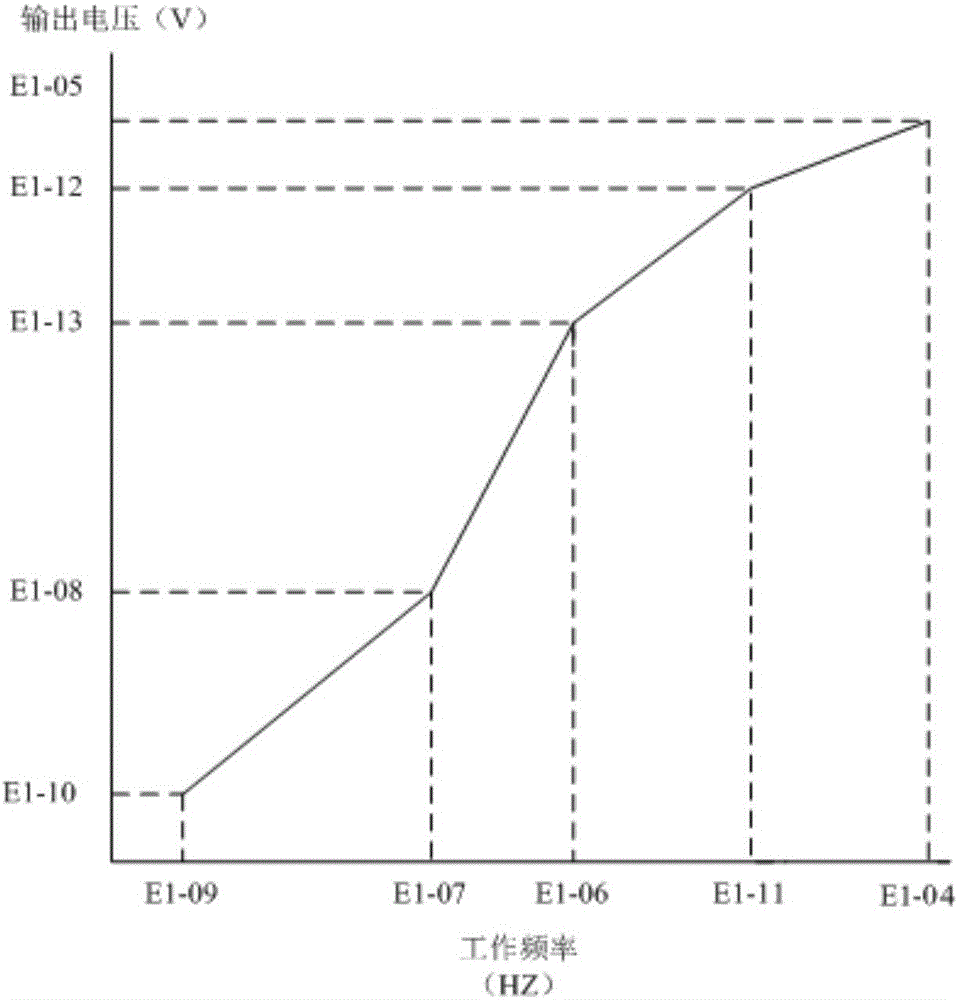

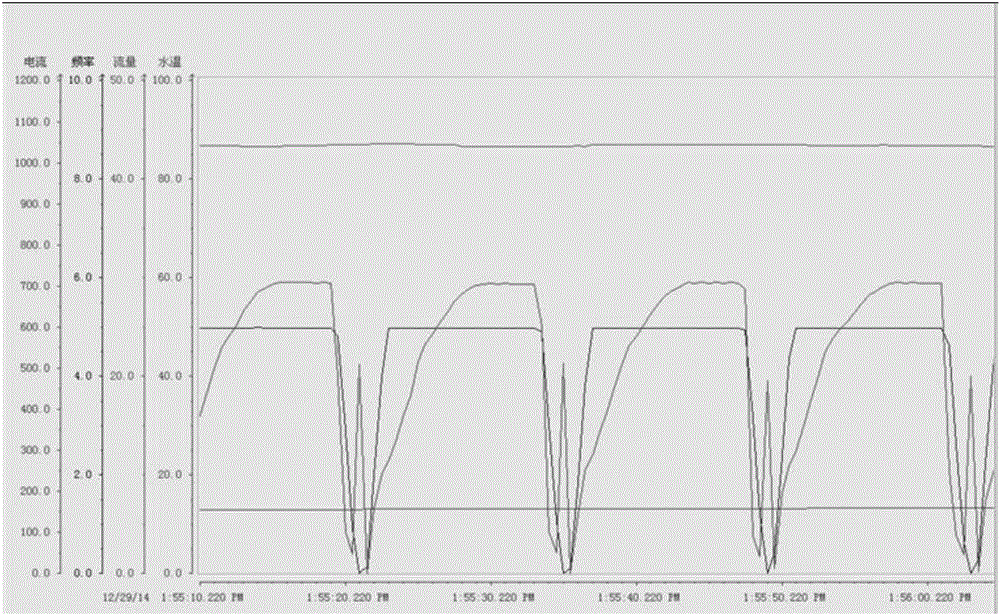

Circular blank continuous casting terminal electromagnetic stirring control system

InactiveCN106077548AQuality improvementIngenious structural designFrequency changerElectromagnetic shielding

The invention relates to a circular blank continuous casting terminal electromagnetic stirring control system. The system comprises an industrial controller, a PLC, a frequency converter and an electromagnetic stirrer; the industrial controller and the PLC are communicated through a network; the data interaction is performed between the PLC and the frequency converter through a scene bus; and the frequency converter and the electromagnetic stirrer are connected through a control cable. As control parameters of the frequency converter for controlling the electromagnetic stirrer in the system are intelligently controlled, the high matching of the operation current curve of the electromagnetic stirrer and the ideal curve is realized, the problems of short effective time of electromagnetic stirring at terminal and influence on peak current are effectively solved, the higher effect on improvement of the internal quality of circular blanks is achieved, and the requirements on quality by a production process are satisfied.

Owner:JIANGSU LIANFENG ENERGY EQUIP

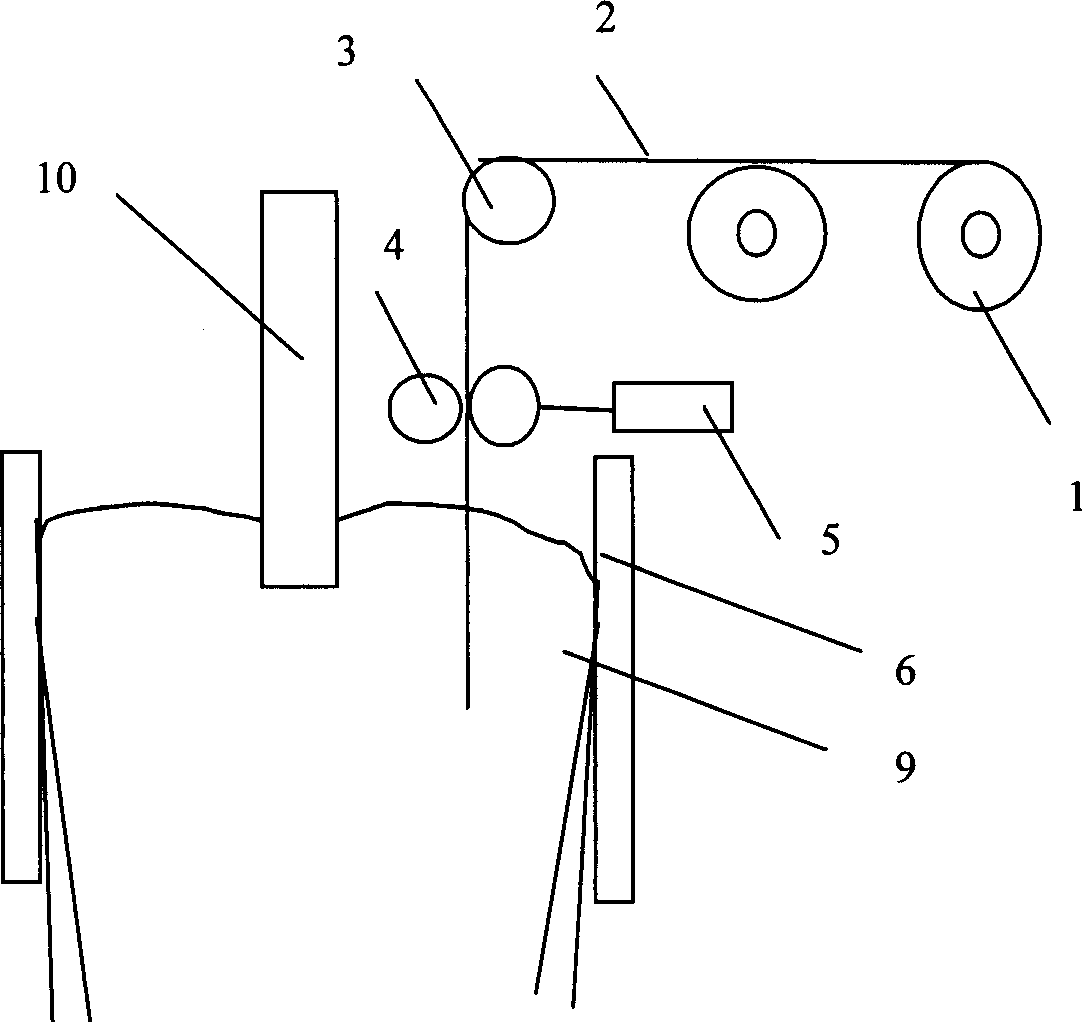

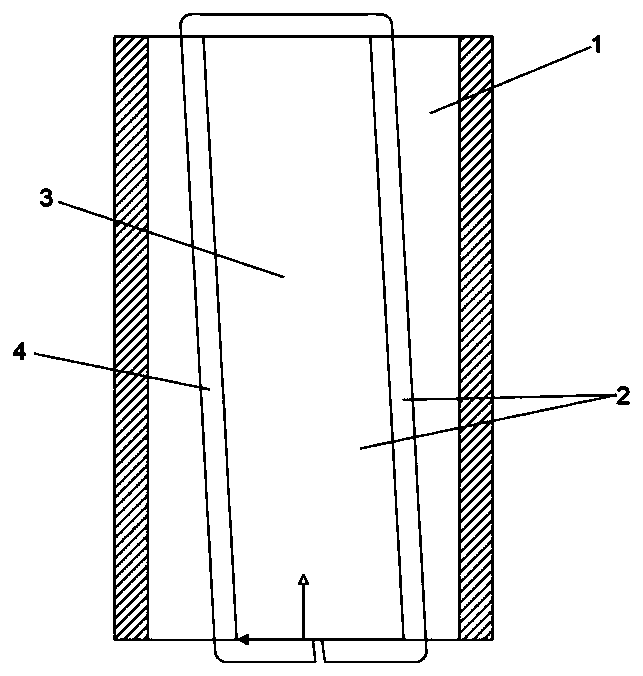

Tundish steel strip feeding device and method

The invention provides a tundish steel strip feeding device and method. The steel strip feeding device comprises guide rolls, a supporting roll, drive rolls, a speed reducer, a motor, a compression hydraulic cylinder and a PLC; and induction heaters are arranged at the outer part of a submersed nozzle. A steel ladle is opened to inject molten steel into a tundish, and when the amount of the moltensteel reaches the requirement, the temperature of the molten steel above the submersed nozzle is measured, and the steel strip feeding device is started after a molten steel superheat degree value and a steel strip feeding quantity are obtained; the temperature of the molten steel above the submersed nozzle is measured at fixed times, and the steel strip feeding quantity is regulated according toa temperature change; and once the flocculating flow phenomenon occurs in the steel strip feeding process, the electromagnetic induction heaters are started immediately, and the molten steel in a submersed nozzle region is heated until the flocculating flow phenomenon is eliminated. The steel strip feeding device provided by the invention is simple in structure and convenient to operate, can control the superheat degree of the molten steel at 5-10 DEG C, and enables the equiaxial crystal ratio of a casting blank to be increased by 15-30 percent, thereby lowering composition segregation and shrinkage holes of a continuous casting blank and improving the quality of the casting blank.

Owner:ANGANG STEEL CO LTD

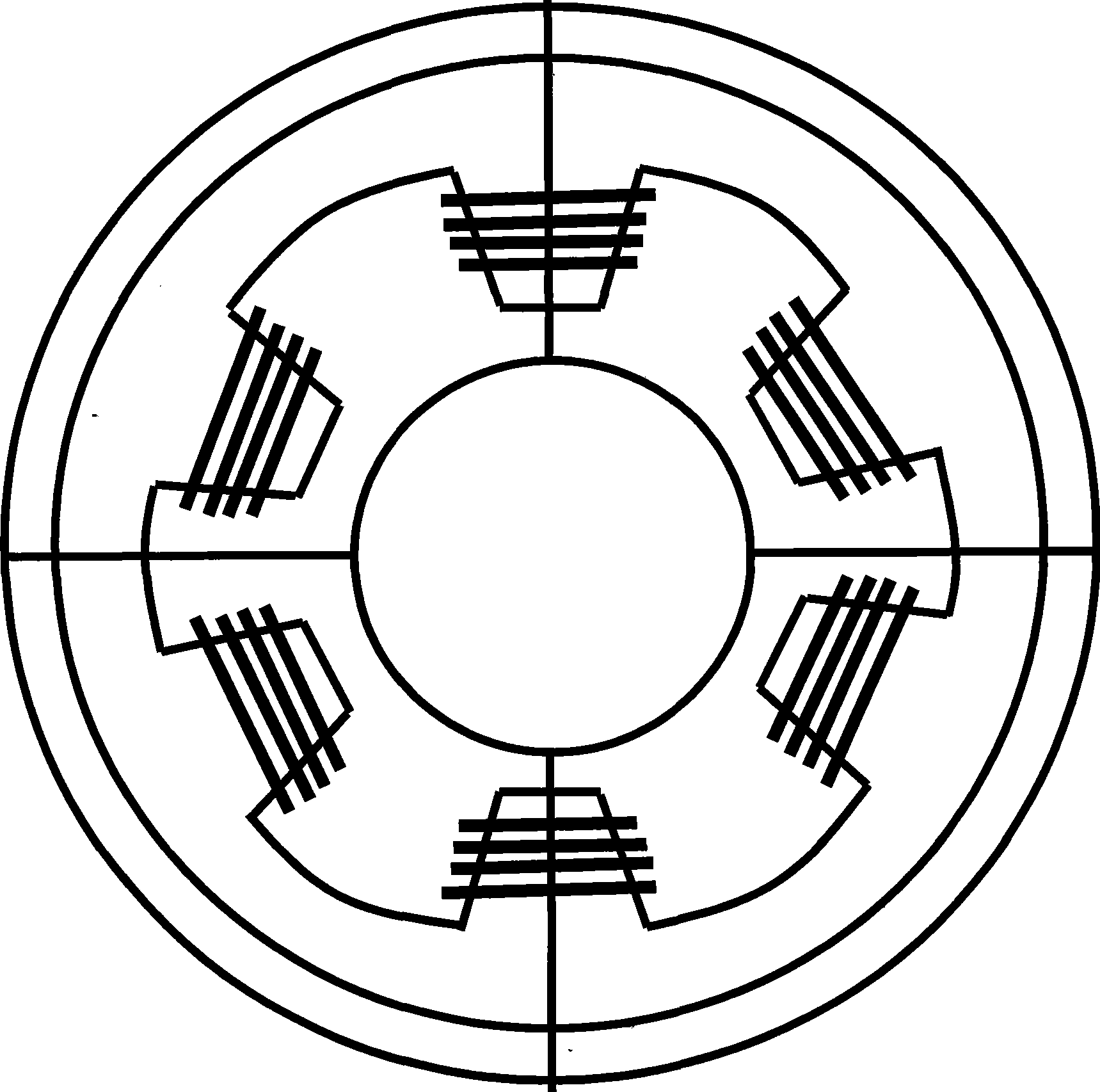

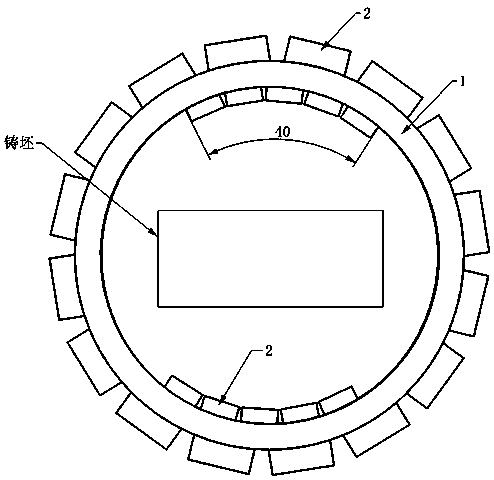

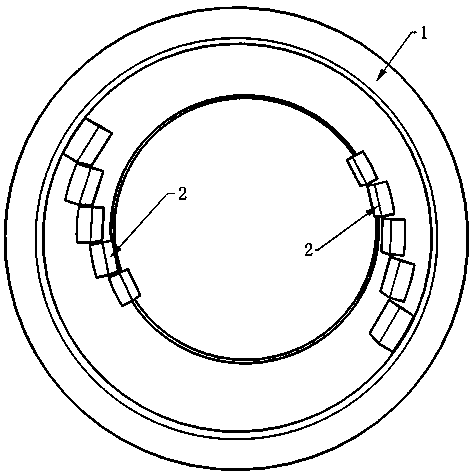

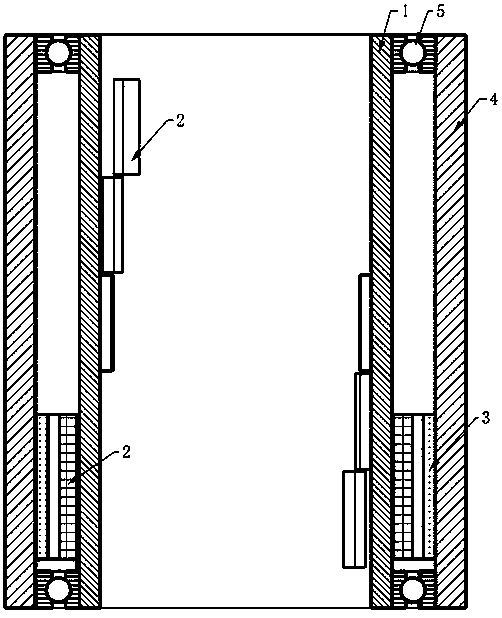

Oblique pole type crystallizer electromagnetic stirring device

The invention provides an oblique pole type crystallizer electromagnetic stirring device. The device comprises annular yoke iron and a magnetic field generating device. The annular yoke iron is located on the outer side of the crystallizer and keeps a certain distance away from the crystallizer, six rotary magnetic field generating devices are annularly installed on the inner wall of the annular yoke iron, each rotary magnetic field generating device is composed of a deflection iron core and a rotary magnetic field coil, and the rotary magnetic field coil winds the deflection iron core in thedirection parallel to the flowing direction of molten steel. According to the stirring device, a three-phase alternate current enters the rotary magnetic field generation device to generate a rotary magnetic field, molten steel components are allowed to be distributed in the crystallizer more uniformly under the action of electromagnetic force to reduce the temperature gradient, reduce the segregation of a casting blank and improve the quality of the casting blank.

Owner:YANSHAN UNIV

Continuous casting permanent magnet spiral magnetic field stirrer

ActiveCN110152545AReduce volumeReduce weightTransportation and packagingMixer accessoriesMetallurgyMagnetic poles

The invention discloses a continuous casting permanent magnet spiral magnetic field stirrer which comprises a steel cylinder, magnetic steel, a stator iron core and a shell. The continuous casting permanent magnet spiral magnetic field stirrer is characterized in that the shell is of a topless bottomless tubbish structure; the steel cylinder is of a topless bottomless tubbish structure; the steelcylinder is sleeved by the shell in a concentric manner; the stator iron core is fixed on the inner wall of the shell; a coil is embedded into the stator iron core to form a stator winding; the magnetic steel is fixed on the outer wall of the steel cylinder in a manner of surrounding the steel cylinder to form a rotor magnetic pole; two pieces of magnetic steel arranged in a spiral line are fixedon the inner wall of the steel cylinder; the two pieces of magnetic steel arranged in the spiral line mutually form an angle of 180 degrees in symmetry with the steel cylinder as a center; an includedangle of 40 degrees is formed by a head block and a tail block of each piece of magnetic steel to form an internal spiral magnetic field; and both ends of the stator iron core are assembled inside the shell through bearings. The stirrer is small in size, light in weight, simple in transmission, flexible to control, stable in performance, low in energy consumption, good in practicability and easyto popularize.

Owner:包钢集团电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com