Novel chalcogenide easily cut steel and iron material

A steel material, easy-cutting technology, applied in the field of metallurgical materials, can solve the problems of segregation of easy-cutting elements, which have not been solved well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The above-mentioned and other technical features and advantages of the present invention will be described in more detail below in conjunction with the embodiments.

[0012] The components of each embodiment are listed in Table 1, and the inclusion morphology and distribution statistics of each embodiment are shown in Table 2.

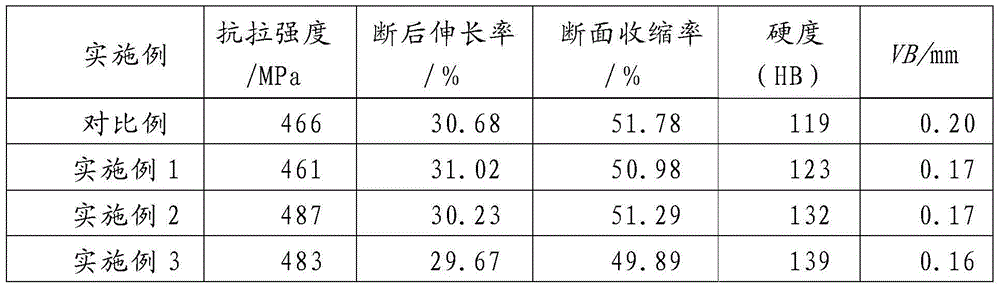

[0013] The mechanical properties and cutting properties of each embodiment are shown in Table 3.

[0014] Each embodiment composition of table 1 (mass percentage / %)

[0015] Example

C

mn

P

S

Si

Zr

comparative example

0.15

1.35

0.08

0.30

0.7

-

Example 1

0.14

1.29

0.11

0.28

0.10

0.04

Example 2

0.15

1.33

0.10

0.29

0.09

0.07

Example 3

0.14

1.31

0.09

0.29

0.09

0.11

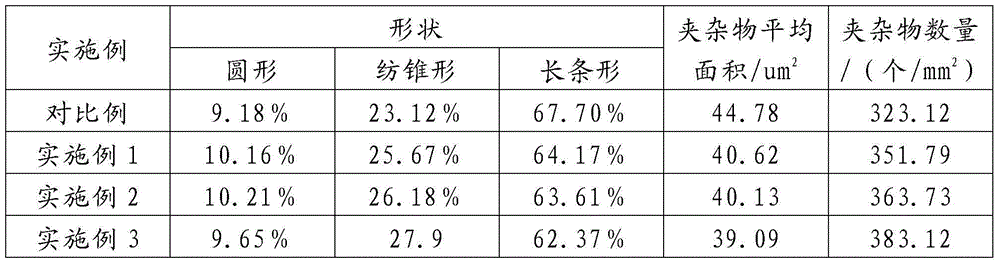

[0016] Table 2 The morphology and distribution statistics of inclusions in each example

[0017]

[0018] The mechanica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com