Continuous casting permanent magnet spiral magnetic field stirrer

A helical magnetic field and stirrer technology, which is applied in the direction of mixer accessories, chemical instruments and methods, mixers, etc., can solve the problems of high design and production costs of hydraulic motors and gear transmission mechanisms, low control precision of axial force and circumferential force, and overall problems of mixers. Complicated structure and other issues, to save materials and maintenance costs, reduce production costs, and achieve significant water-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

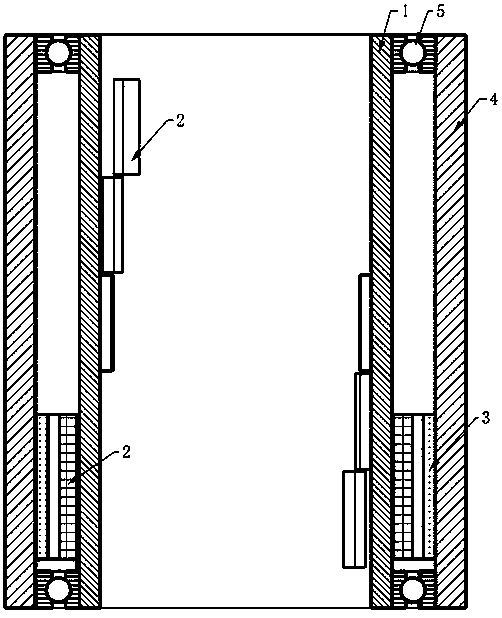

[0035] Such as Figure 5 As shown, in the present invention, the bearing 5 can also be replaced with a roller as a support position when the steel cylinder 1 rotates, and the wheels are installed on the fixed shaft through the fixed handle-type fixed shaft at equal intervals on the edge of the steel cylinder 1. The wheel surface is attached to the inner wall of the shell 4 to form a support for the steel cylinder 1, and ring-shaped baffles are fixed at both ends of the shell. This design forms a relatively open space between the steel cylinder 1 and the shell 4 at both ends. , so the heat dissipation will be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com