Patents

Literature

179results about How to "Reduce superheat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

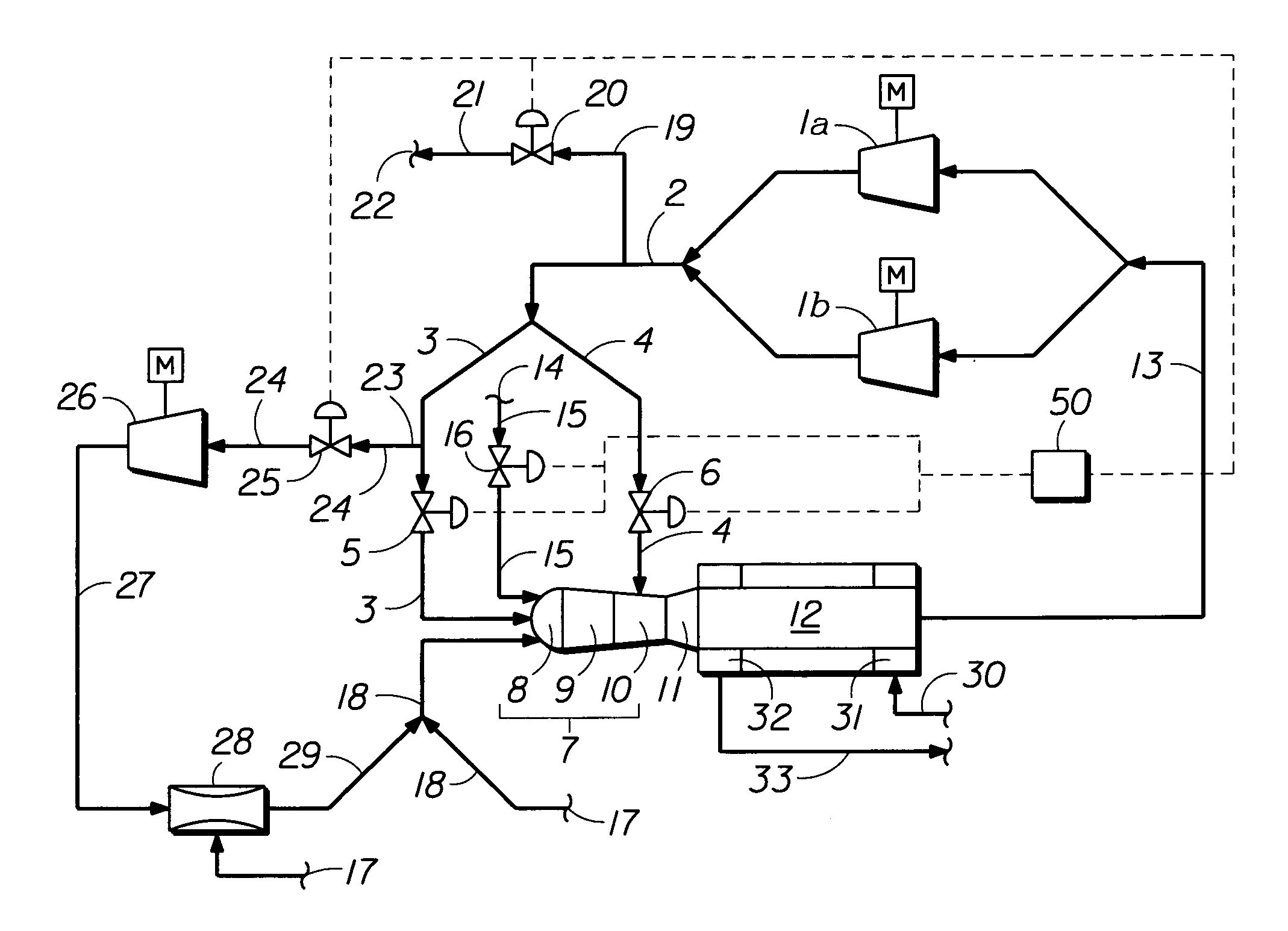

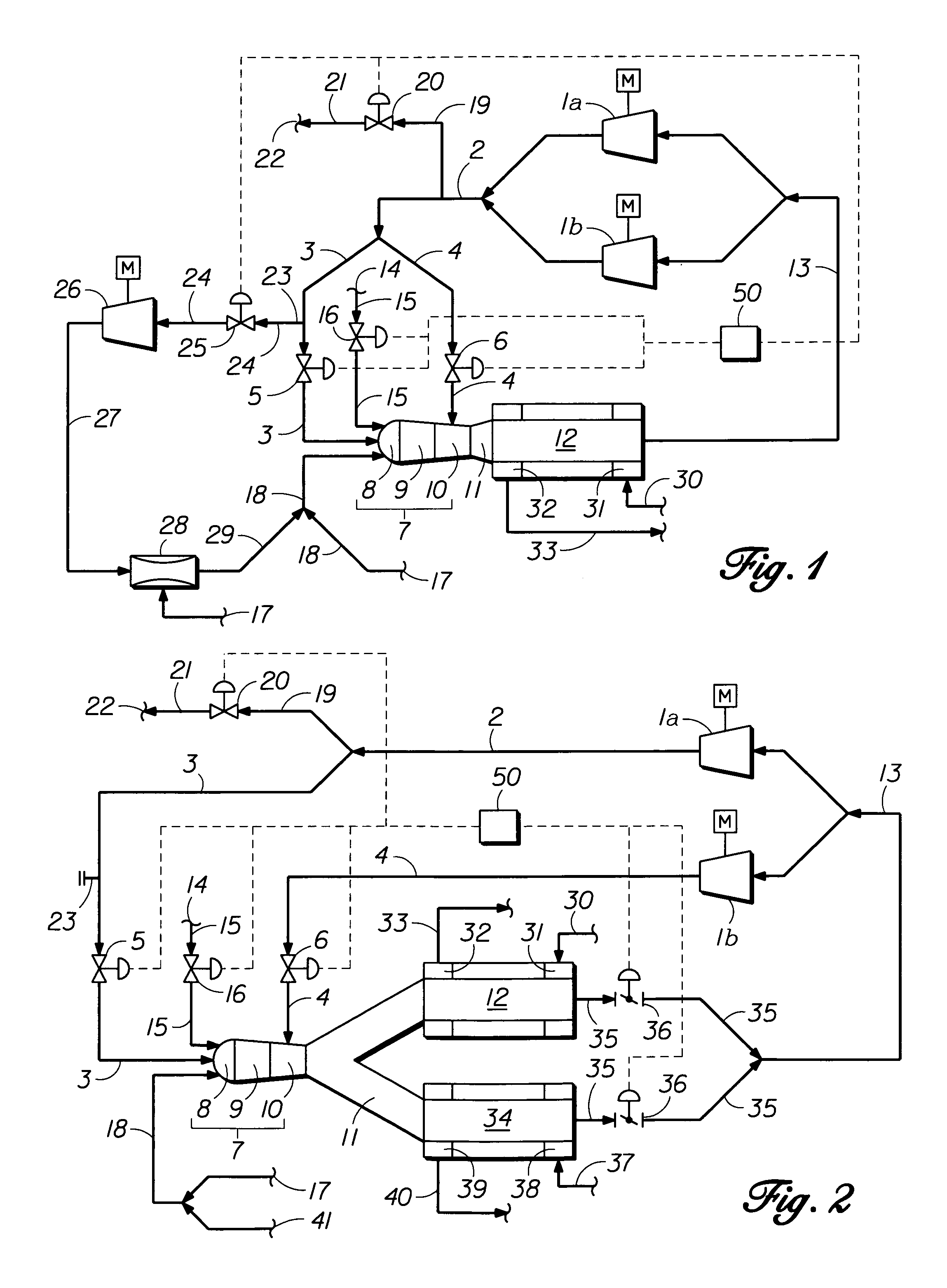

Partially-open fired heater cycle providing high thermal efficiencies and ultra-low emissions

InactiveUS7074033B2Long operate lifeLow operating temperatureFuel supply regulationGas turbine plantsNitrogen oxidesHeat transfer fluid

A partially open fired heater regenerative cycle wherein the fired industrial type heater cycle's heat transfer fluid replaces the air predominant nitrogen heat transfer fluid employed in a conventional air / fuel combustion heater. The heater cycle's method and apparatus means is susceptible to providing a 95 to 98 percent mass flow reduction of fugitive nitrogen oxide and carbon monoxide mass flow emissions as emitted by current art Low-NO.sub.x art heaters on a rated per million Btu per hour basis, and is further susceptible to developing steady-state heat transfer thermal efficiencies exceeding 124 percent.

Owner:AES DEV CO

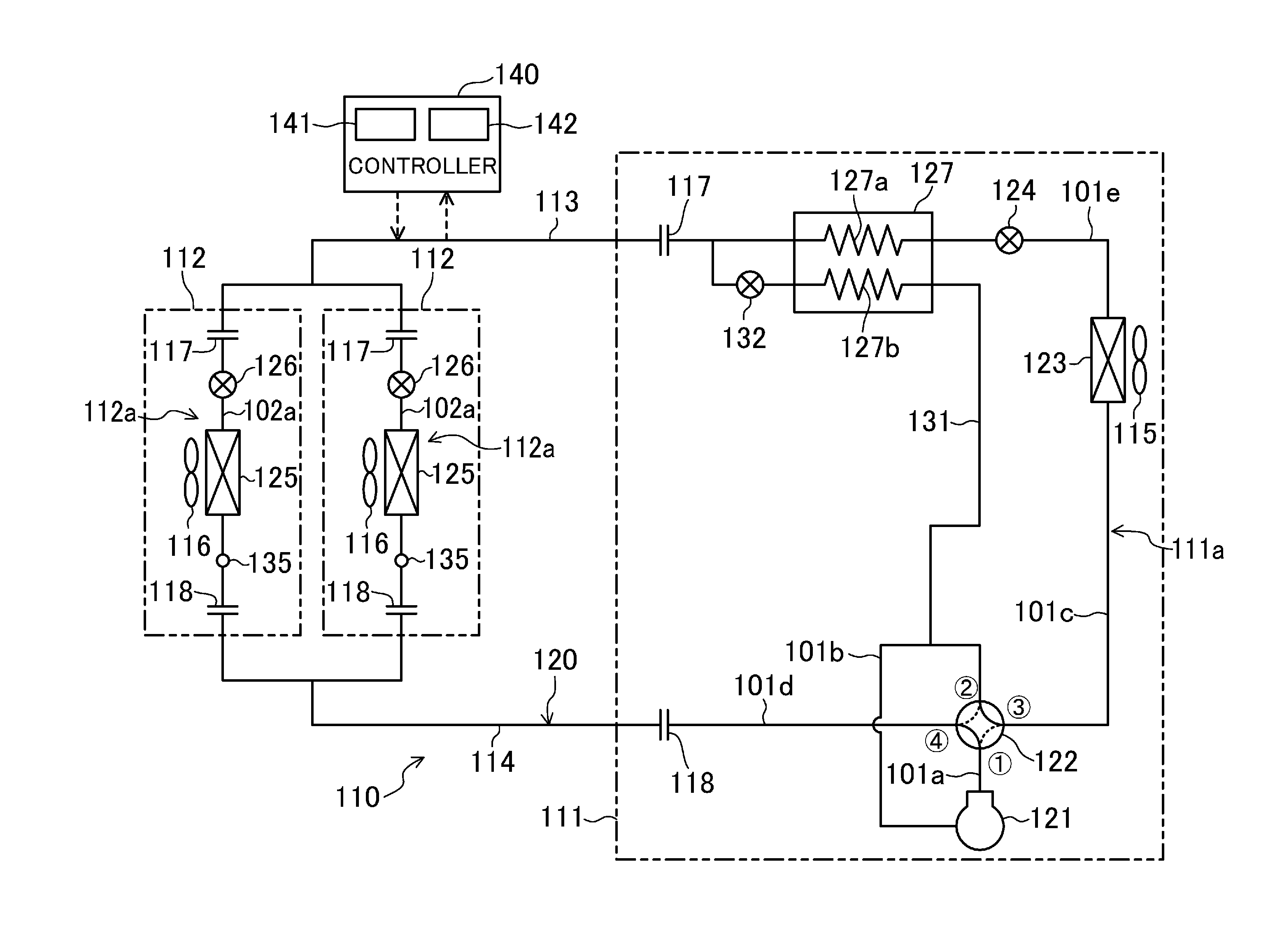

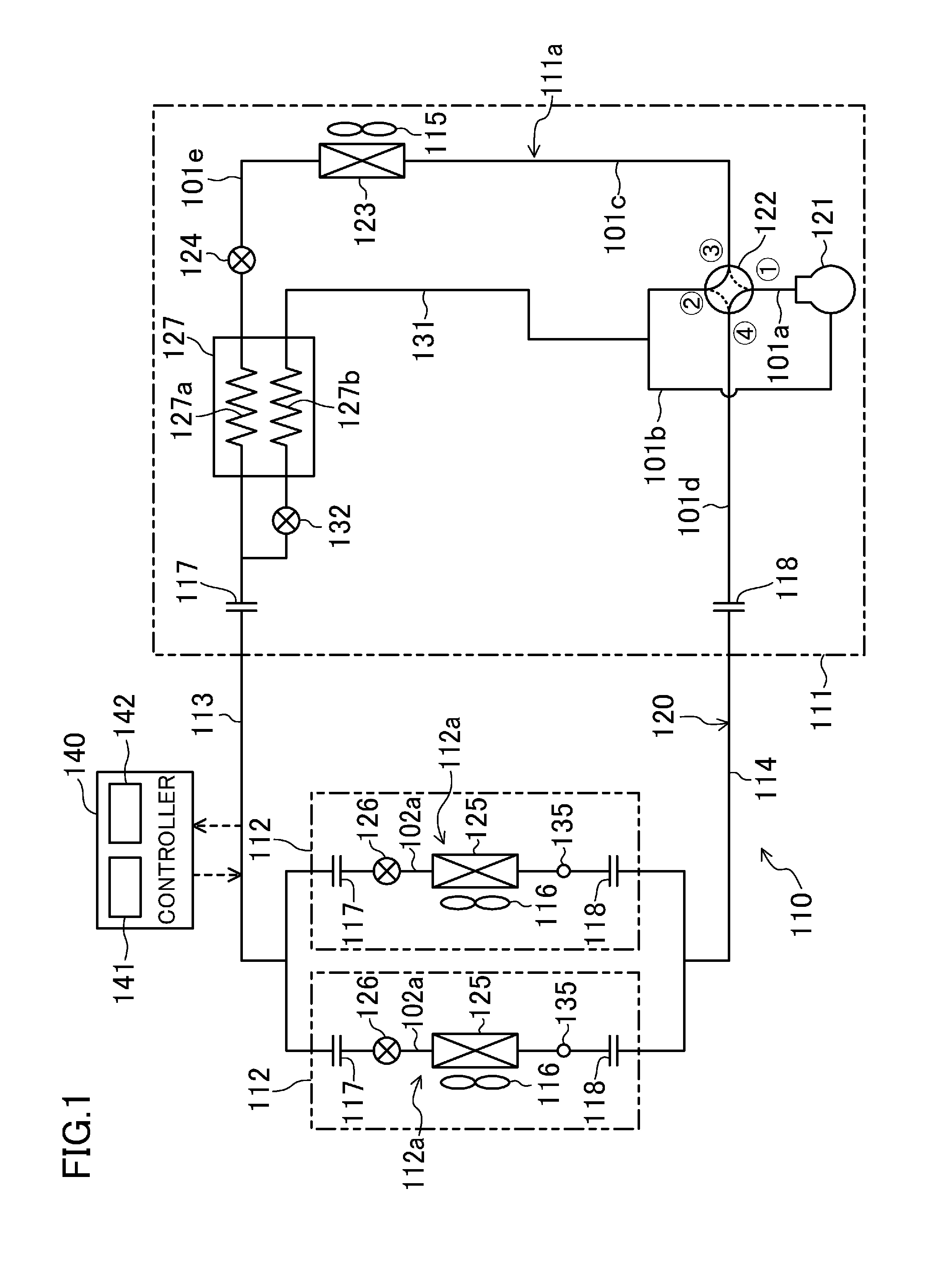

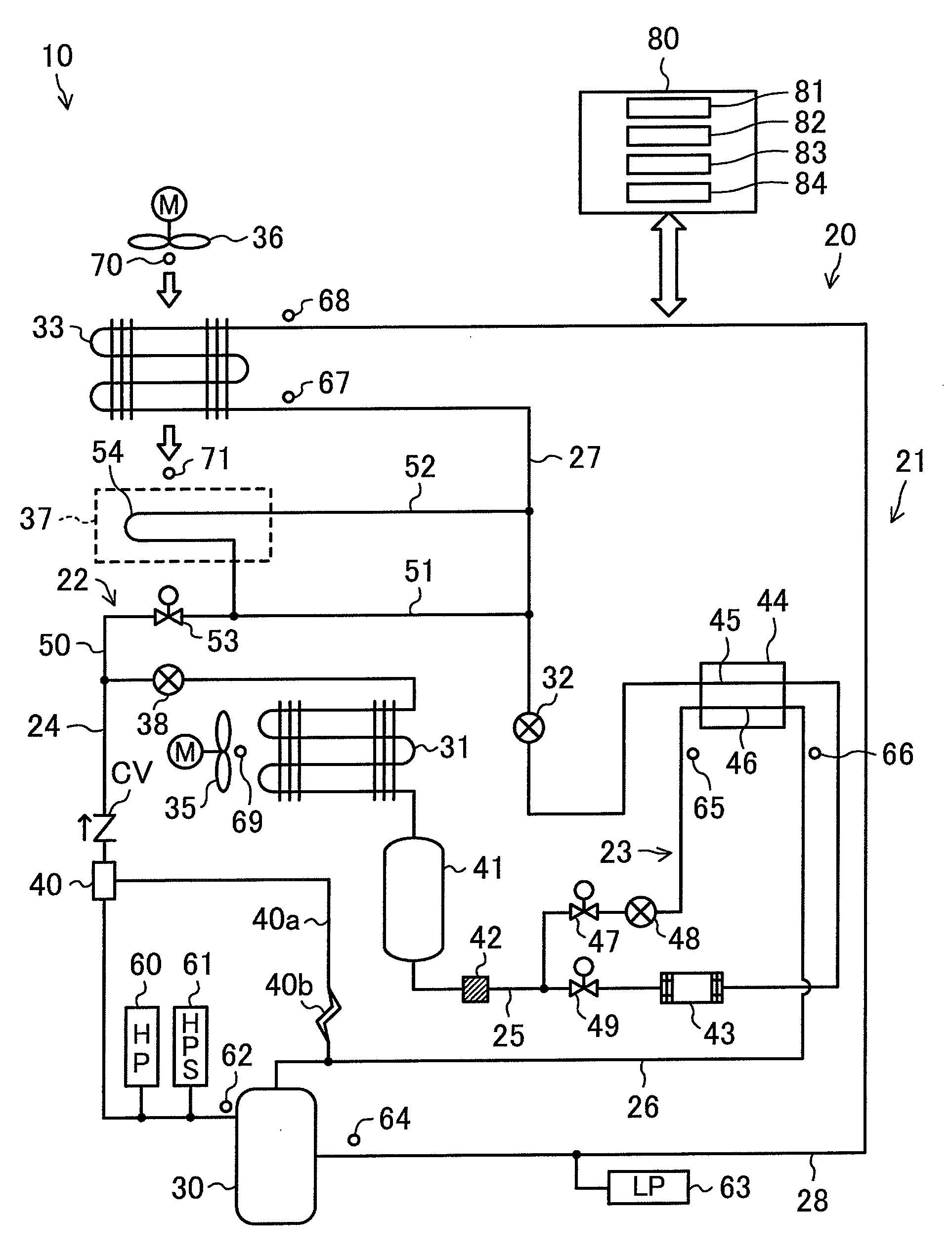

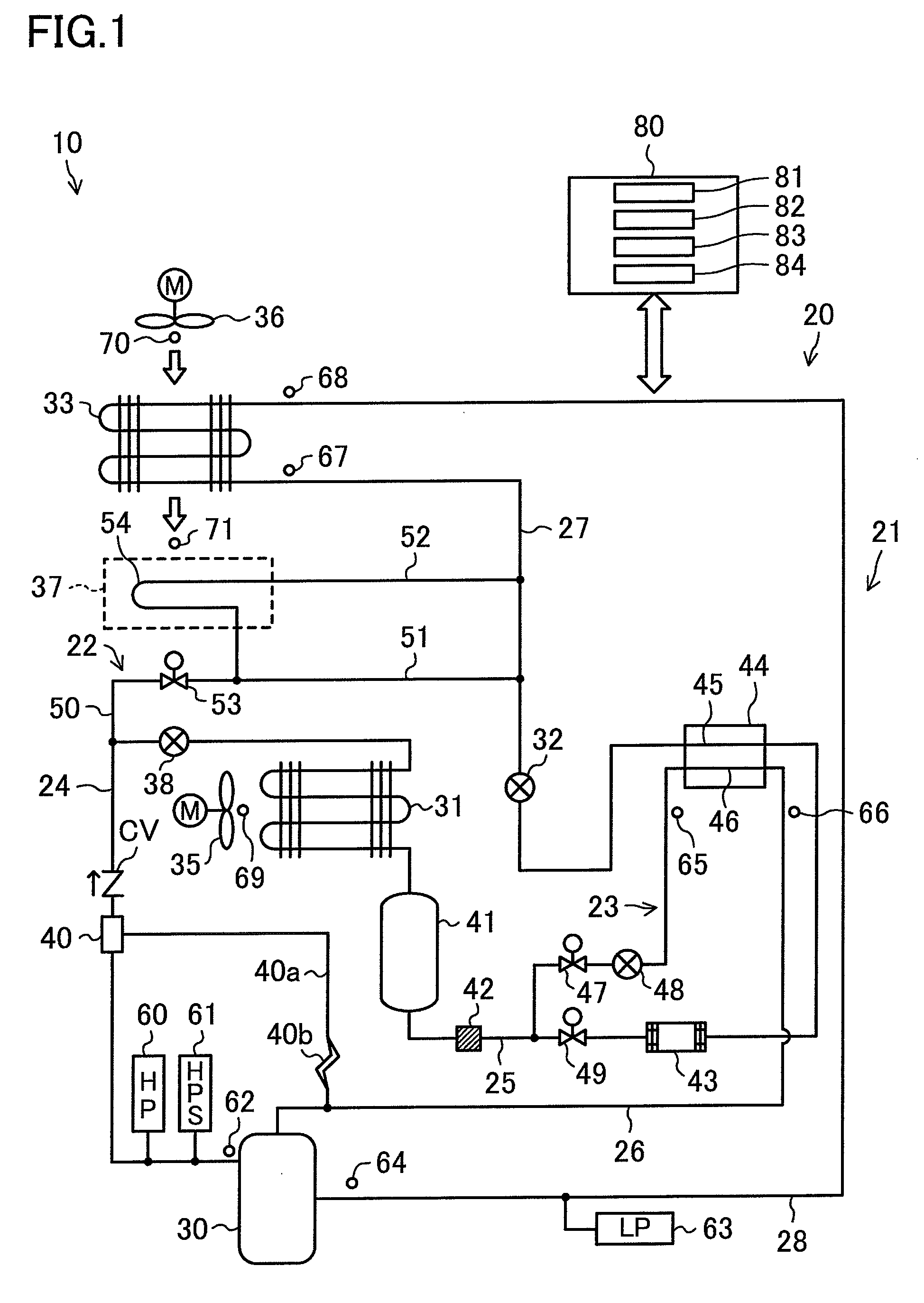

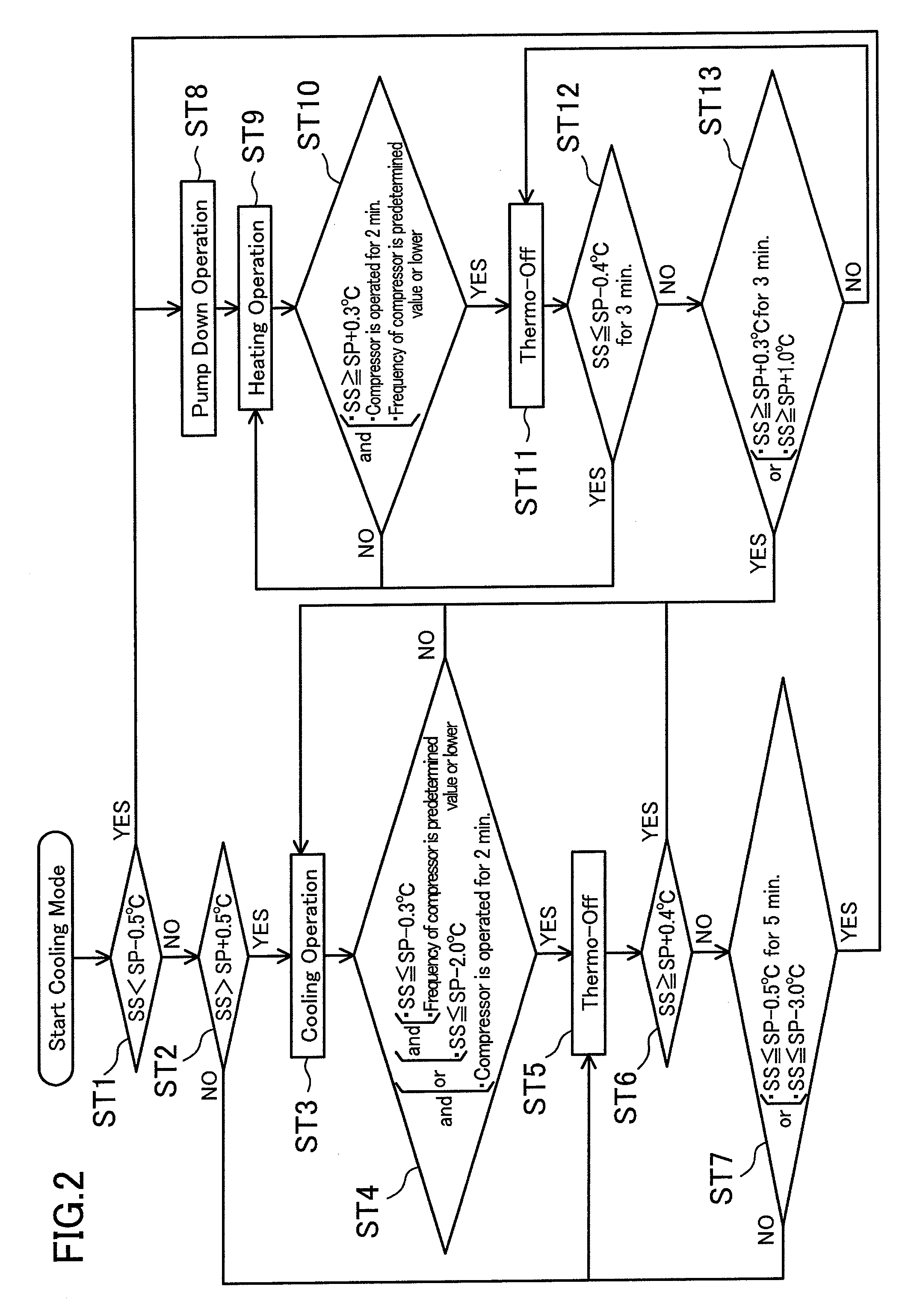

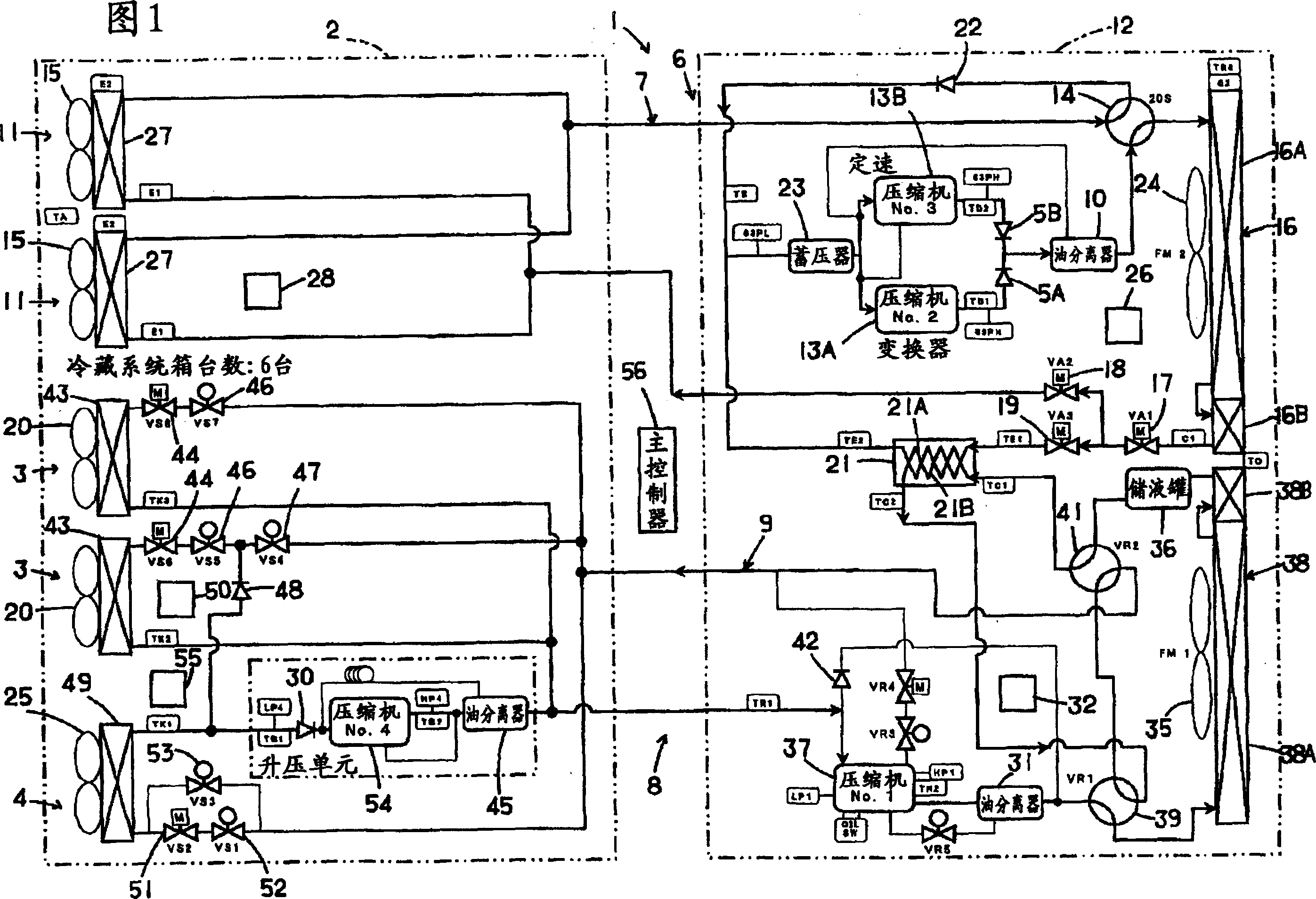

Refrigeration apparatus

ActiveUS20150233622A1Reduce the differenceReduce leak rateMechanical apparatusCompression machines with reversible cycleEngineeringRefrigerant

An air conditioner includes a refrigerant circuit which connects an outdoor circuit and a plurality of indoor circuits connected in parallel. The air conditioner includes a leak detection section which detects leak of a refrigerant from the indoor circuits, and a control section which circulates the refrigerant to perform a refrigeration cycle when the leak detection section detects leak of the refrigerant such that the refrigerant in the indoor circuits of the refrigerant circuit is at a low pressure. Providing the control section in the air conditioner can reduce the leak of the refrigerant from the indoor circuit at low cost.

Owner:DAIKIN IND LTD

Steam engine

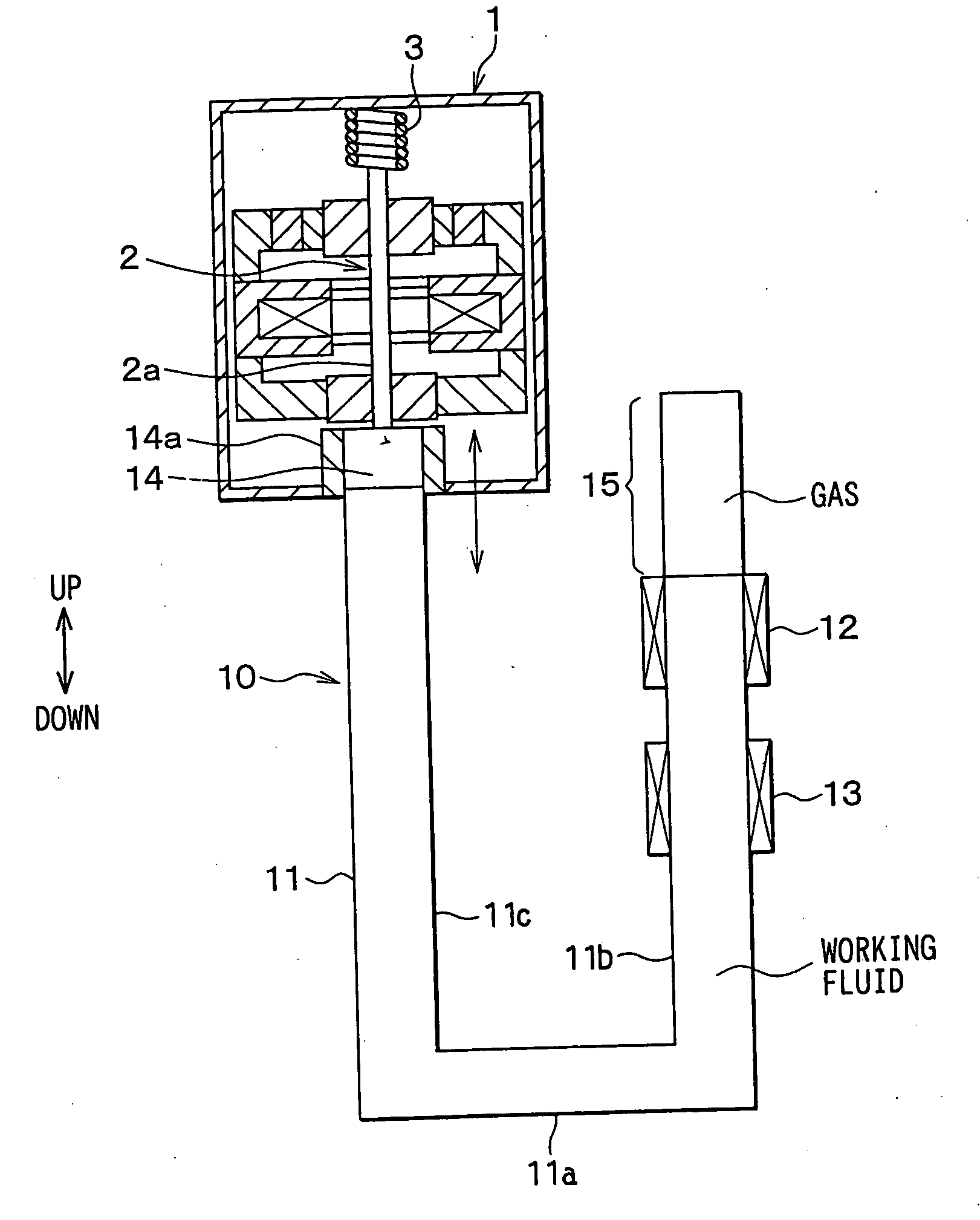

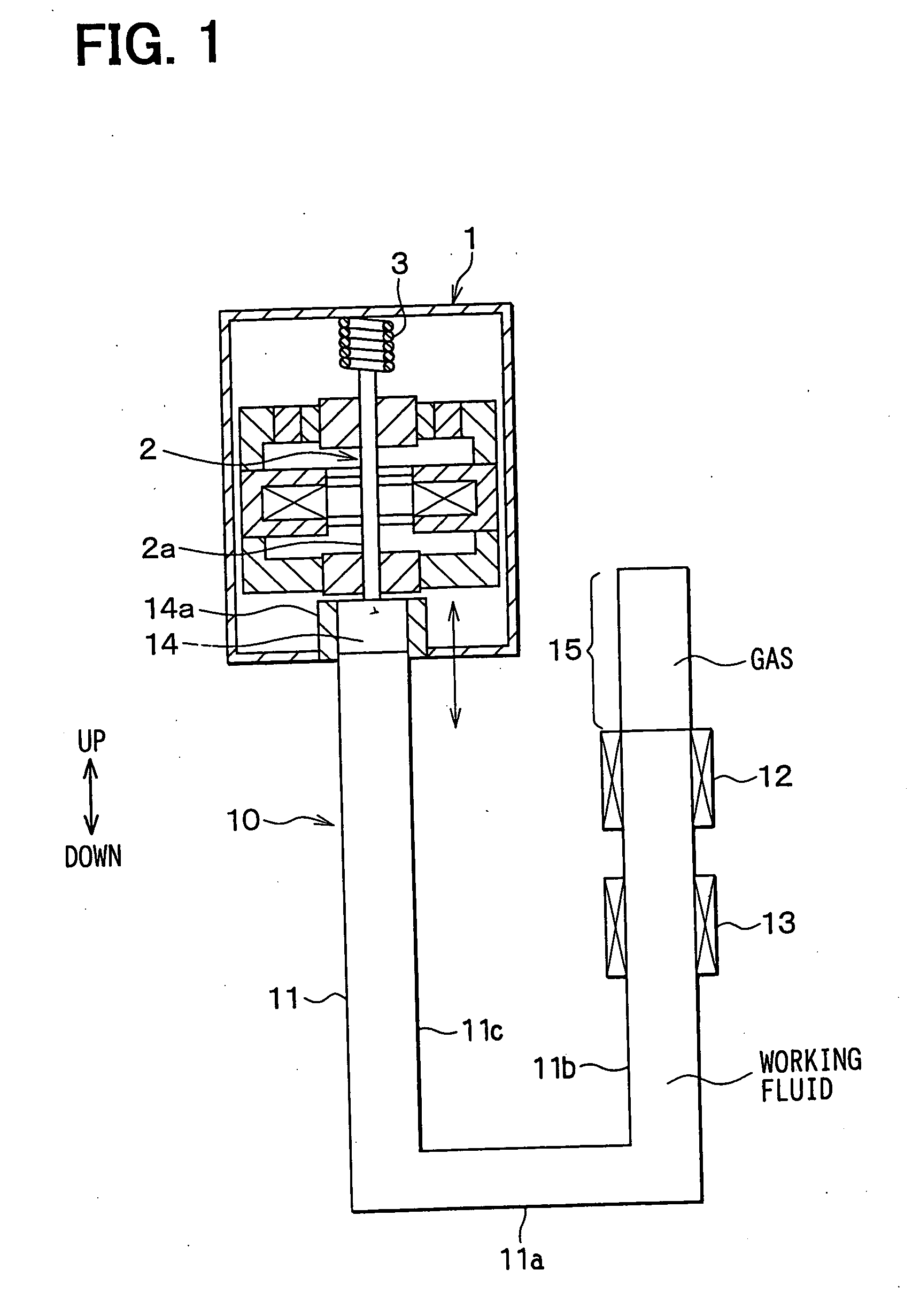

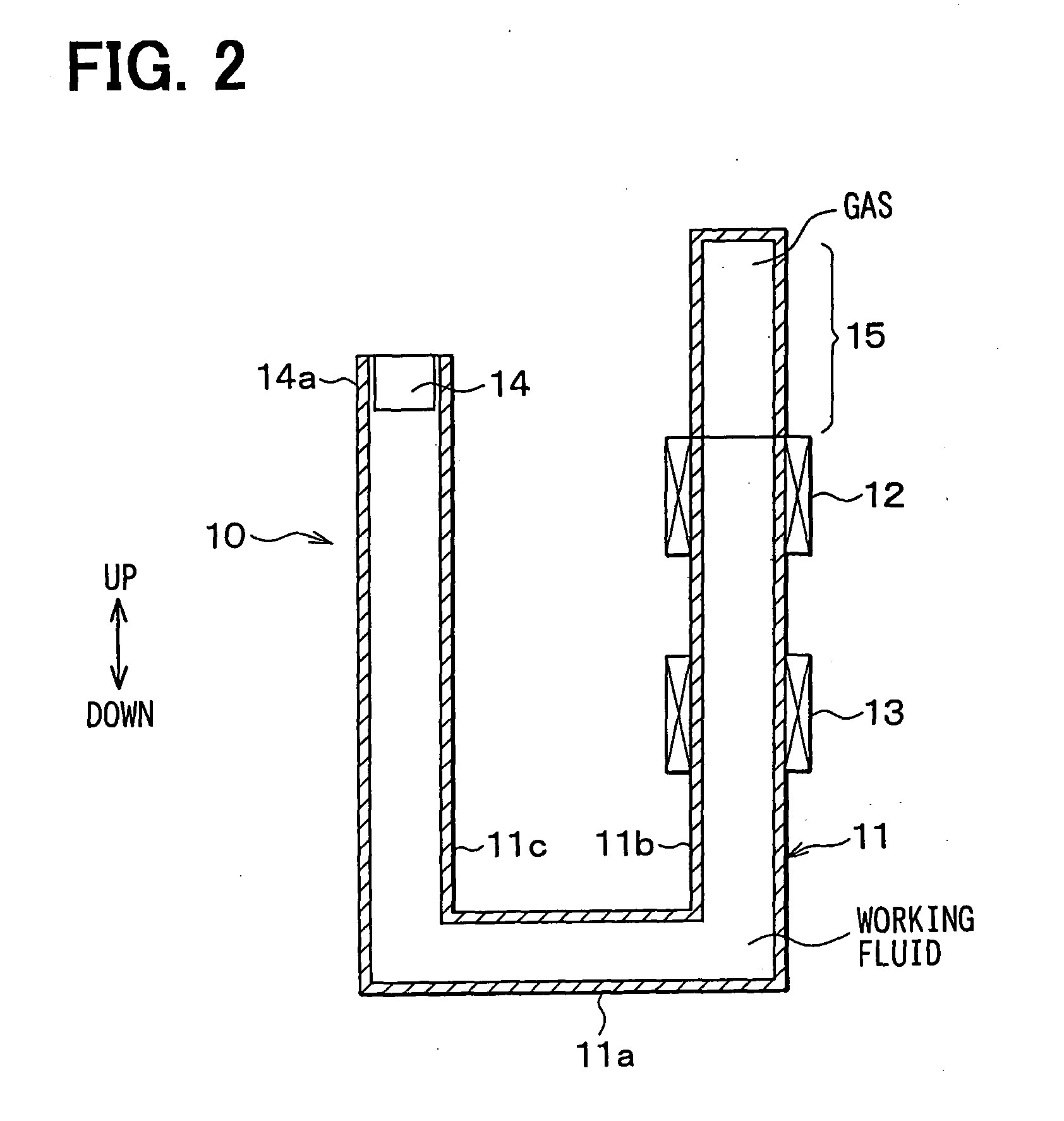

ActiveUS20040060294A1Avoid it happening againAvoid abrasionsSteam accumulatorsEngine componentsSteam pressureWorking fluid

A steam engine increases efficiency and prevents corrosion, abrasion, and the like in a part receiving steam pressure. A heater and a cooler are provided on one side of a U-shaped fluid container, and a piston for output is provided on its other side. The heater heats working fluid to vaporize the fluid. The expansion pressure of steam of the working fluid depresses a fluid level in a first vertical pipe. The liquid component of the working fluid flows from the first vertical pipe into a second vertical pipe, thereby applying pressure to the piston in an upward direction. Then, the liquid component of the working fluid functions as a liquid piston directly receiving the expansion pressure of the steam, so that it is possible to prevent the occurrence of corrosion, abrasion and the like in the part receiving steam pressure.

Owner:DENSO CORP

Continuous casting method of continuous-cast round billets

ActiveCN104259415AReduce temperature gradientIncrease the ratio of axial crystalsSteelmakingPorosity

The invention discloses a continuous casting method of continuous-cast round billets. The method comprises the steps of 1) obtaining high-purity molten steel through steel-making; 2) pouring the obtained molten steel into a tundish under large-tundish long-nozzle argon blowing protection, controlling the degree of superheat of the molten steel inside the tundish to be 15-30 DEG C; 3) pouring the molten steel into a crystallizer through a tundish integrated type submerged nozzle, controlling the depth of the a crystallizer submerged nozzle inserted into the surface of the molten steel to be 100-120 mm; (4) perform constant-speed continuous casting, control the casting speed to be 0.16-0.22 m / min for different kinds of steel; 5) utilizing an air-water atomizing cooling mode in a secondary cooling area at a specific water flow rate of 0.12-0.22 L / kg; 6) performing dynamic soft reduction through a withdrawal and straightening machine to obtain the continuous-cast round billets. The continuous casting method of the continuous-cast round billets effectively reduces the temperature gradient of molten steel from a billet shell to a casting core and the degree of superheat of the molten steel in the center, improves the proportion of isometric crystal of the cast billets, enhances the structural density of the cast billets and significantly improves the effects of center porosity, center segregation and contraction of large continuous-cast round billets.

Owner:SHANDONG IRON & STEEL CO LTD

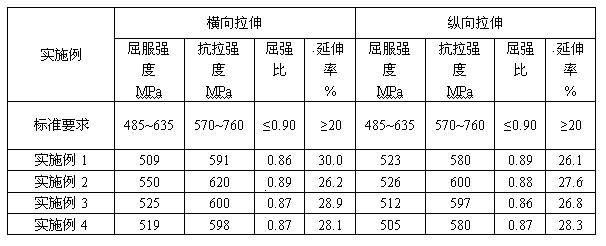

Super-thick X70 pipeline steel and manufacturing method thereof

The invention discloses super-thick X70 pipeline steel and a manufacturing method thereof, wherein the pipeline steel is 30-32mm thick, and the pipeline steel comprises the following chemical ingredients in percentage by mass: 0.03-0.06% of C, 0.1-0.30% of Si, 1.30-1.60% of Mn, less than or equal to 0.010% of P, less than or equal to 0.0050% of S, 0.030-0.050% of Nb, 0.008-0.020% of Ti, 0.10-0.30% of Ni, 0.l0-0.30% of Cr, 0.10-0.30% of Cu and the balance being Fe and inevitable impurity elements. smelting raw materials are sequentially subjected to KR molten iron pretreatment, converter smelting, LF refining and RH vacuum degassing to obtain molten steel which is relatively high in purity, and then the pipeline steel, which is high in thickness, high in strength, narrow in strength interval, excellent in low-temperature toughness, and excellent in both low-temperature resistant aging performance and HIC resistance, is obtained through a controlled rolling and controlled cooling process.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

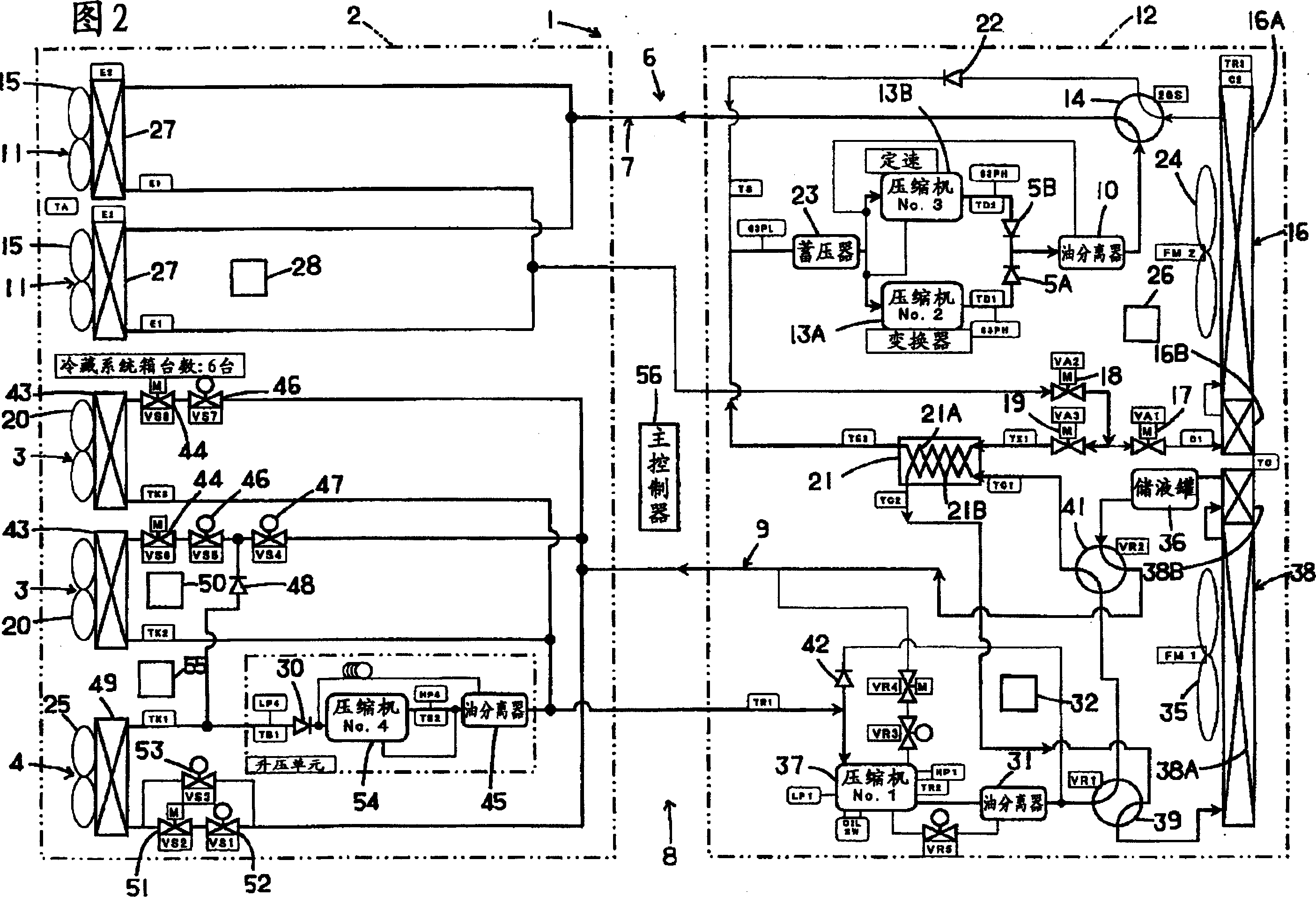

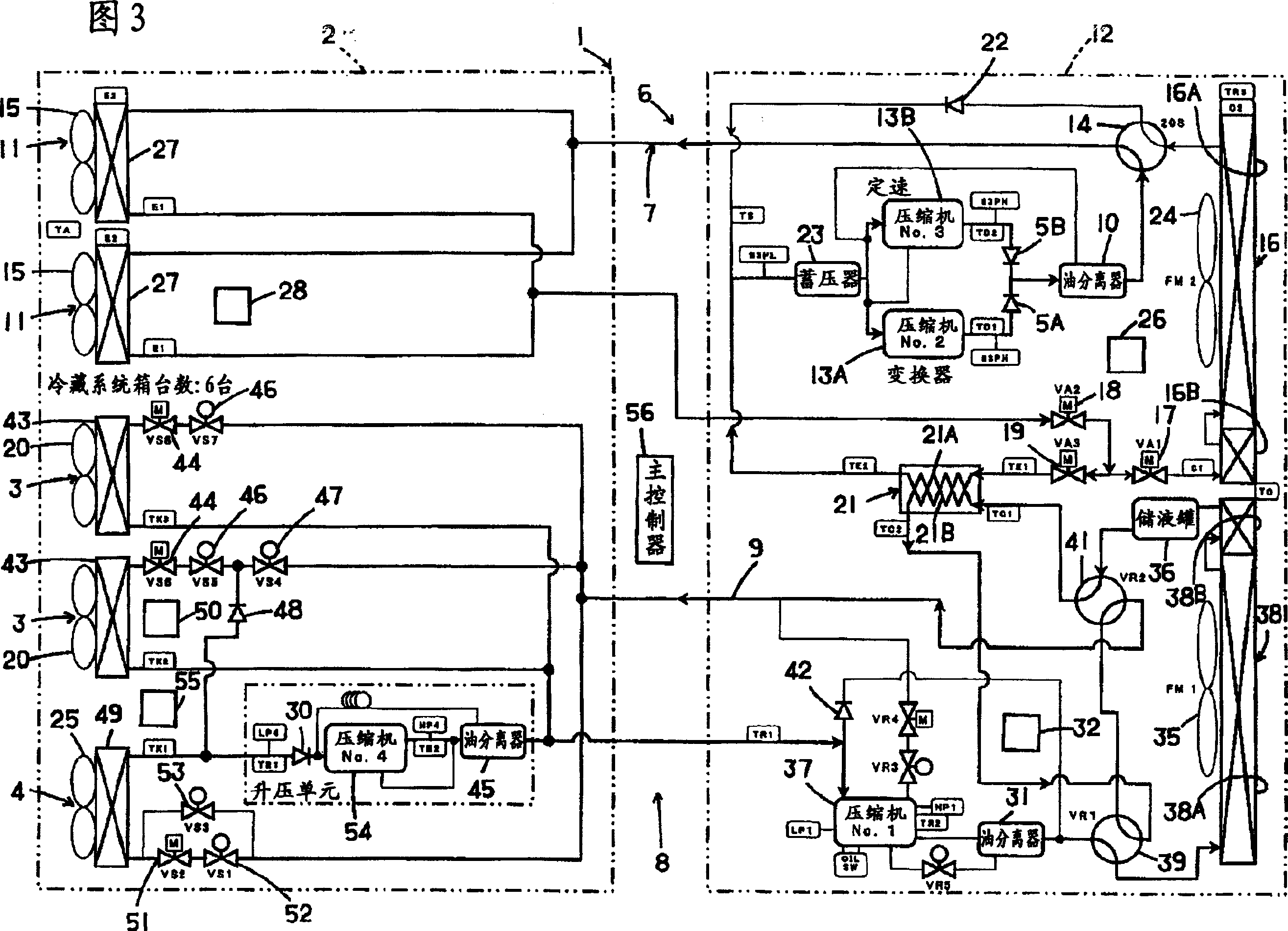

Container refrigeration apparatus

ActiveUS20120272673A1Reduce amountIncrease degreeMechanical apparatusCompression machines with non-reversible cycleEvaporatorOperating speed

A container refrigeration apparatus includes: a refrigerant circuit which performs a refrigeration cycle, and includes a main circuit sequentially connecting a compressor, a condenser, a main expansion valve and an evaporator, and a hot gas bypass circuit through which a refrigerant compressed in the compressor bypasses the condenser and the main expansion valve to flow into the evaporator; and a compressor control section which controls operating speed of rotation of the compressor during heating operation for heating inside of a container by the evaporator while returning the compressed refrigerant from the compressor to the compressor through the hot gas bypass circuit and the evaporator so that a temperature inside the container reaches a target temperature.

Owner:DAIKIN IND LTD

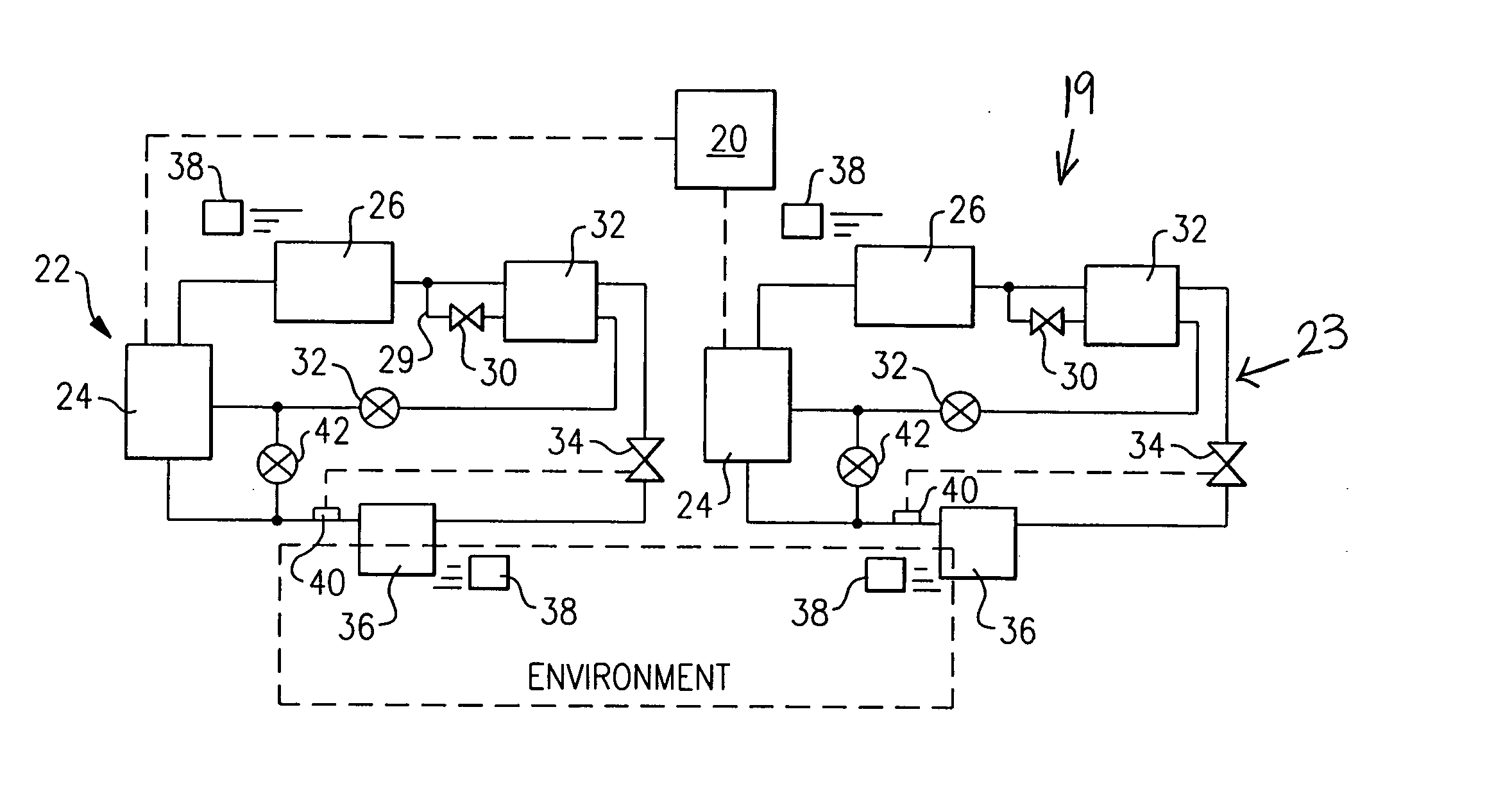

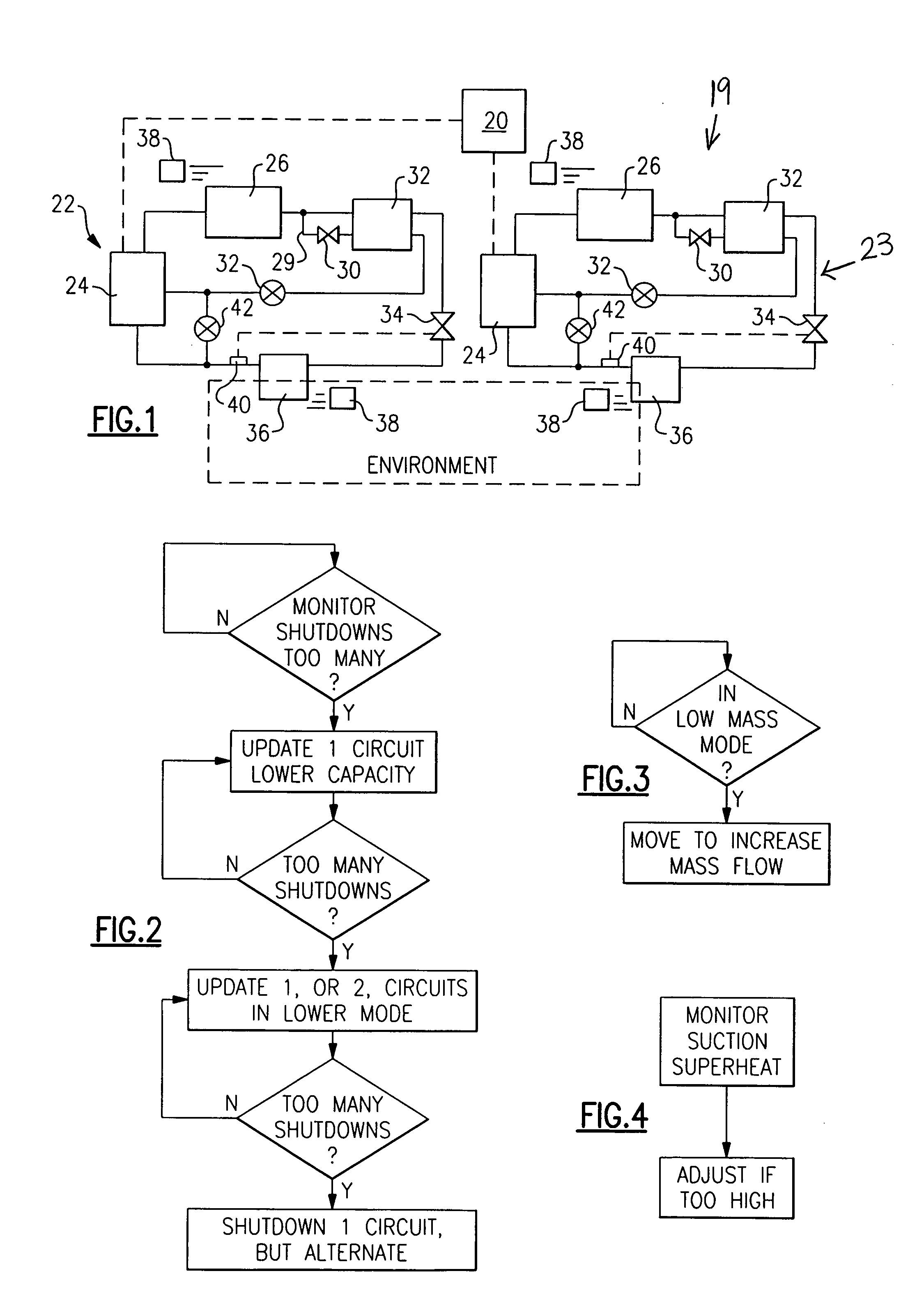

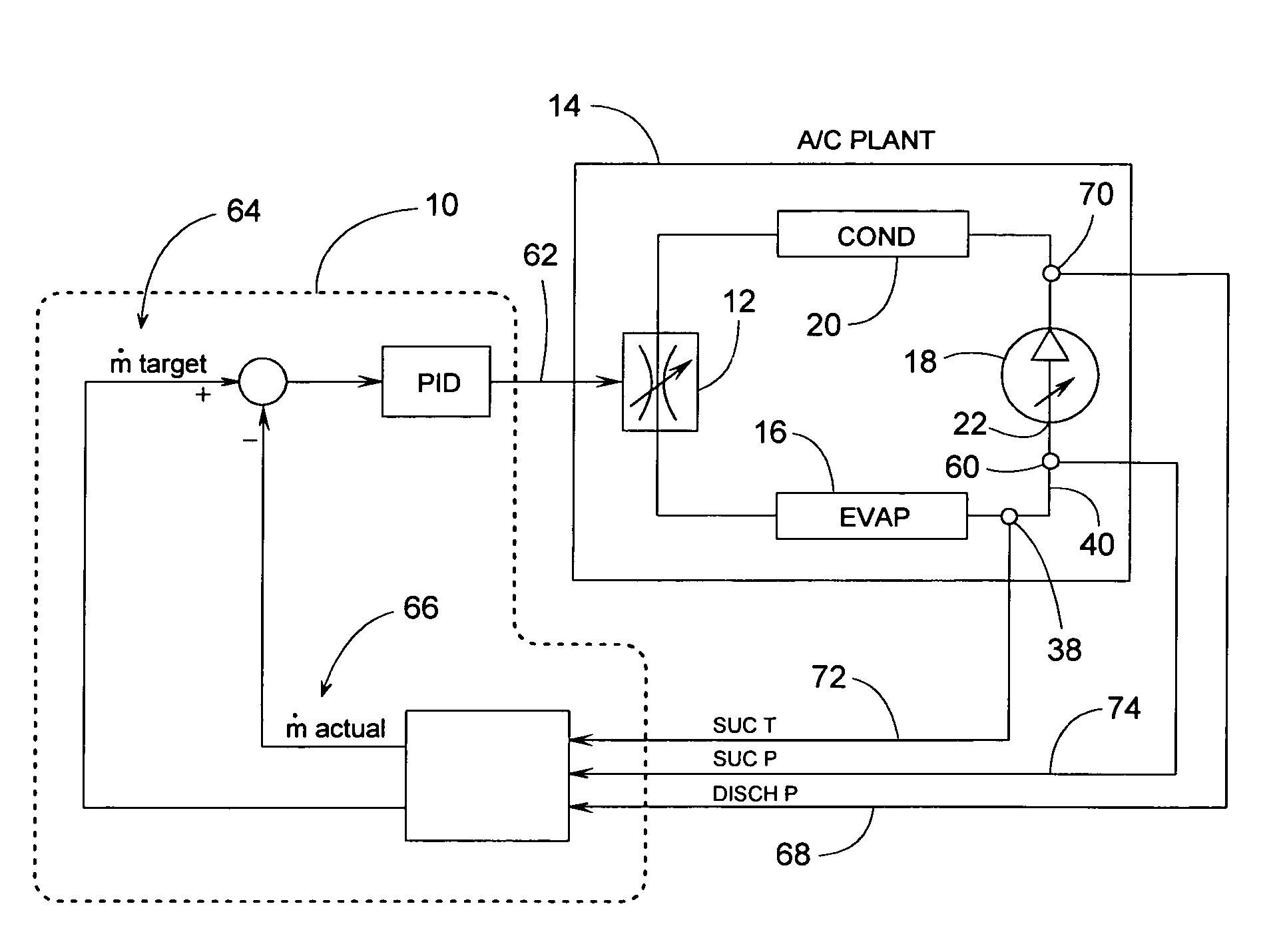

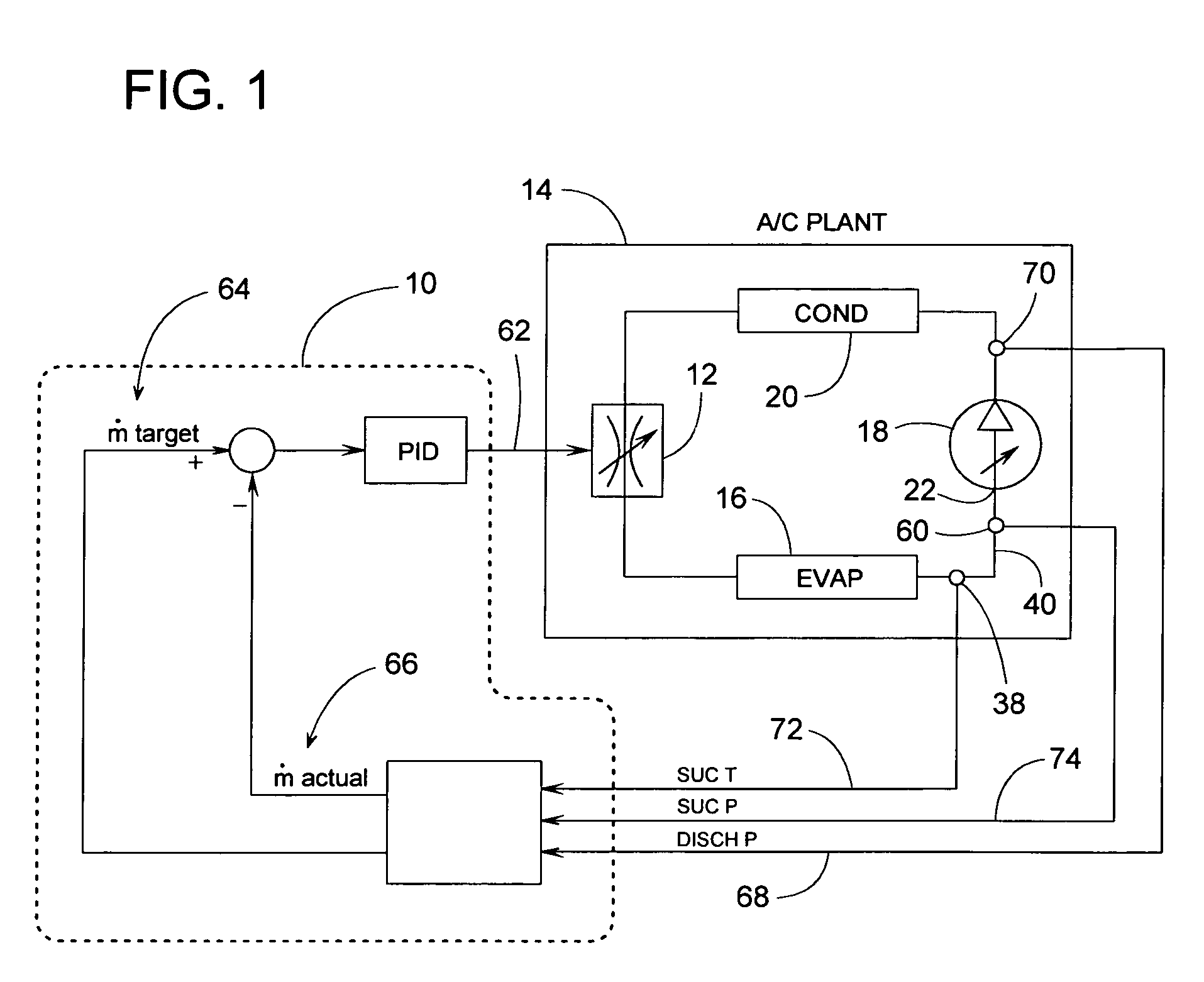

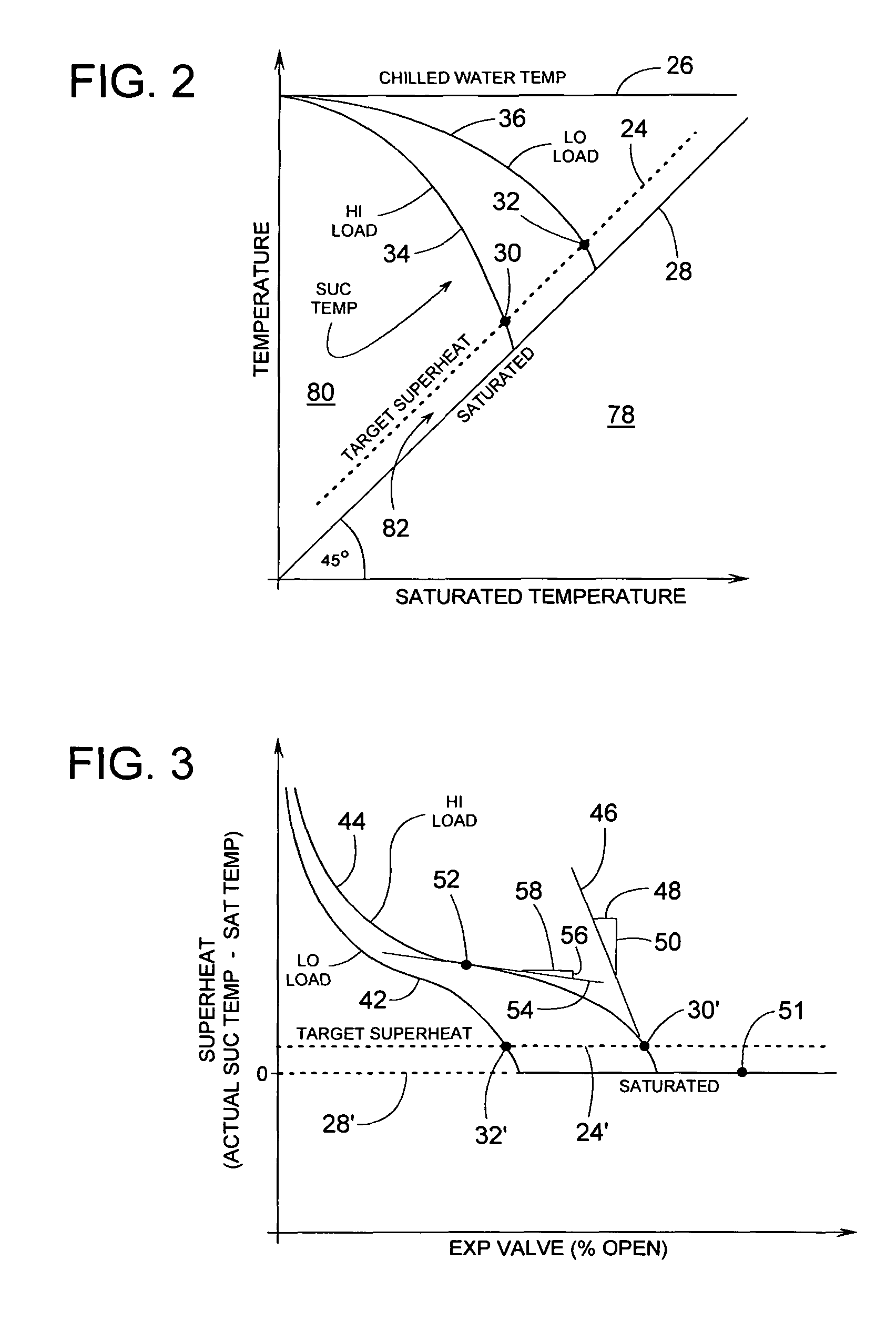

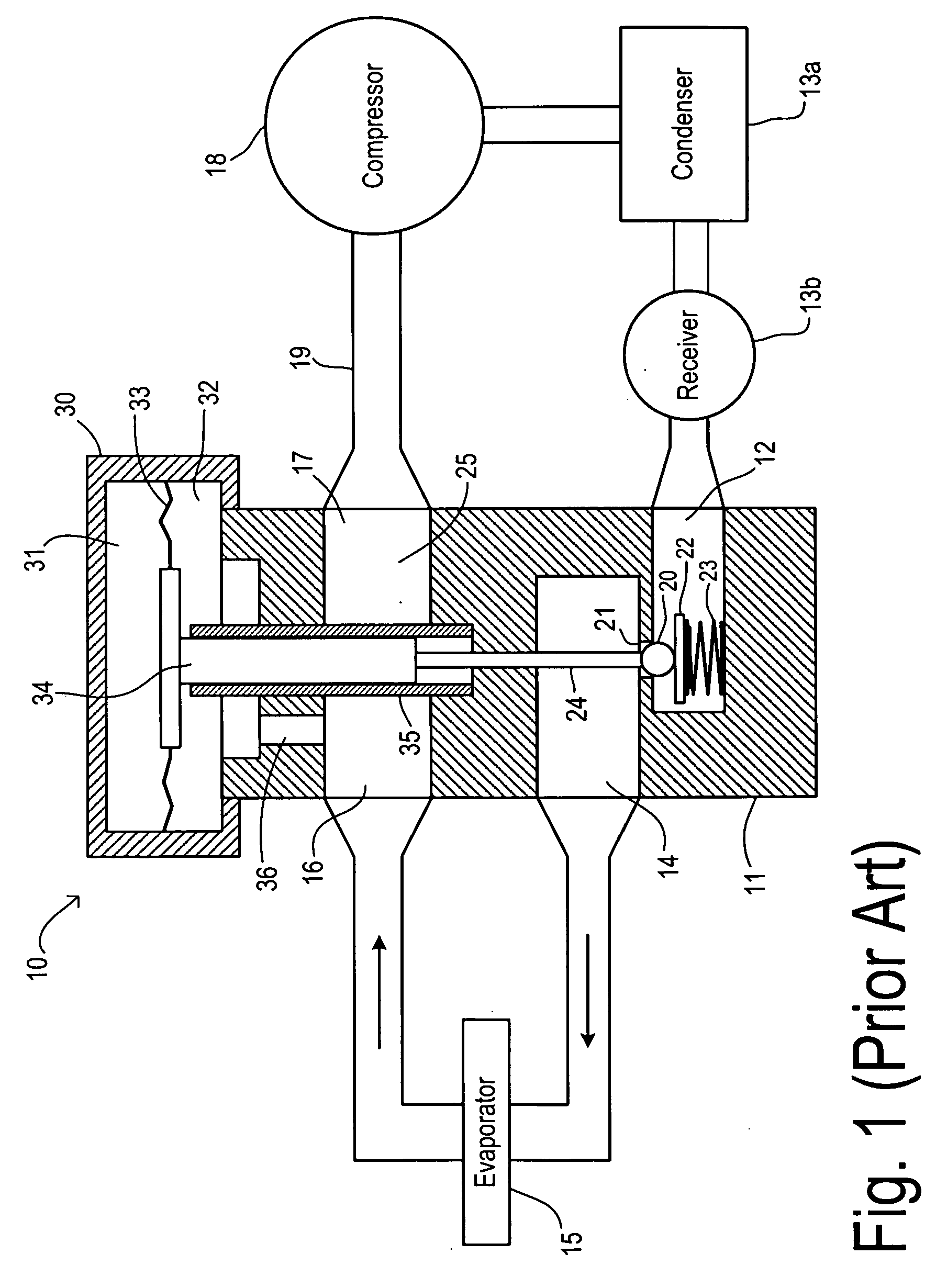

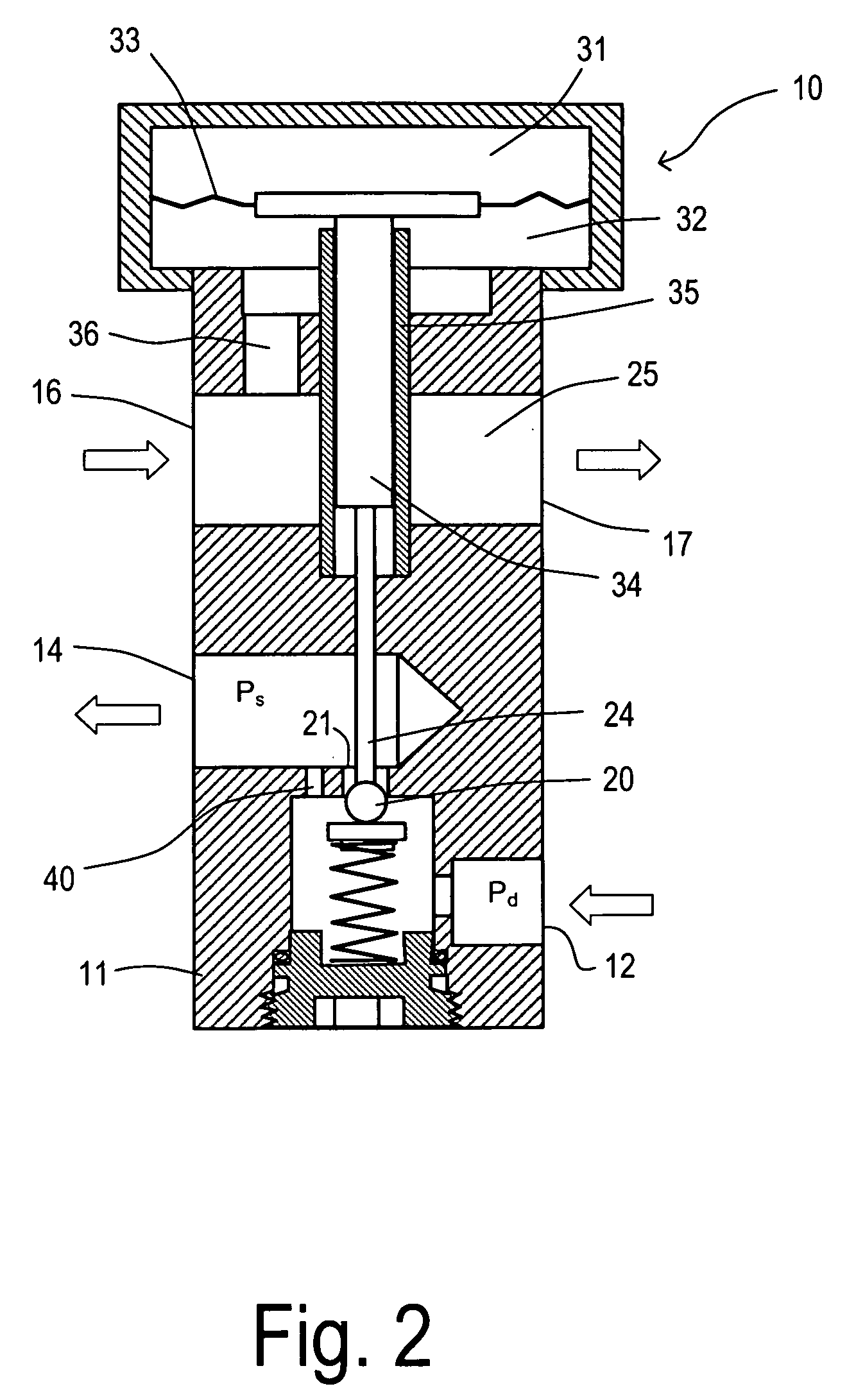

Oil return control in refrigerant system

InactiveUS20050126193A1High viscosityReduce superheatCompressorCompression machines with non-reversible cycleTraffic volumeRefrigerant

Several control algorithms reduce the likelihood of insufficient oil return to the compressor. One algorithm is useful in a multi-circuit refrigerant system. A control reduces the cooling capacity of one of the circuits if the number of compressor start / stop cycles becomes excessive. By reducing the capacity, the control will reduce the number of compressor start / stop cycles for a circuit. In this manner, the oil continues to circulate through the circuit, and is more efficiently returned to the compressor. Another problem area associated with a poor oil return back to the compressor is when there is low mass flow rate of refrigerant circulating through the system. Various ways of increasing the refrigerant mass flow rate are disclosed to ensure proper oil return to the compressor. Also, if oil return problems are likely due to an undesirably high oil viscosity at the vapor portion of the evaporator or suction line, then steps are taken to reduce oil viscosity. Overall, the present invention discloses three distinct algorithms that may be utilized, either separately or in combination, to ensure better flow of oil back to the compressor. The invention enhances system and compressor reliability and performance as well as prevents the compressor damage.

Owner:CARRIER CORP

High speed steel finishing roll of wire bar mill and manufacturing method of high speed steel finishing roll

ActiveCN104384193AEvenly distributedImprove bindingRollsMetal rolling arrangementsCrack resistanceChemical composition

The invention discloses a high speed steel finishing roll of a wire bar mill and a manufacturing method of the high speed steel finishing roll, belonging to the technical field of machining and casting. The finishing roll consists of a roll neck and a roll body comprising a working layer, a primary core and a core part; the working layer comprises the following chemical components: 1.50-2.50 percent of C, 0.40-1.00 percent of Si, 0.40-0.80 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, 4.0-8.0 percent of Cr, 0.50-1.00 percent of Ni, 5.00-8.00 percent of Mo and 5.00-8.00 percent of V. In the casting process, the casting temperature and the rotating speed of a centrifuge can be controlled by adopting manners of high-temperature discharge from a furnace, low-temperature casting, high-speed mold filling and slow-down solidification. According to the high speed steel finishing roll and the manufacturing method of the high speed steel finishing roll, the adaptability of high speed steel materials on bar rolling can be effectively solved by reasonable design of alloy components and the processing technology, and the wear resistance and the millimeter rolling quantity of the roll are improved; in addition, the high speed steel finishing roll has favorable thermal crack resistance, and the working efficiency of a heavy and medium plate mill can be greatly improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

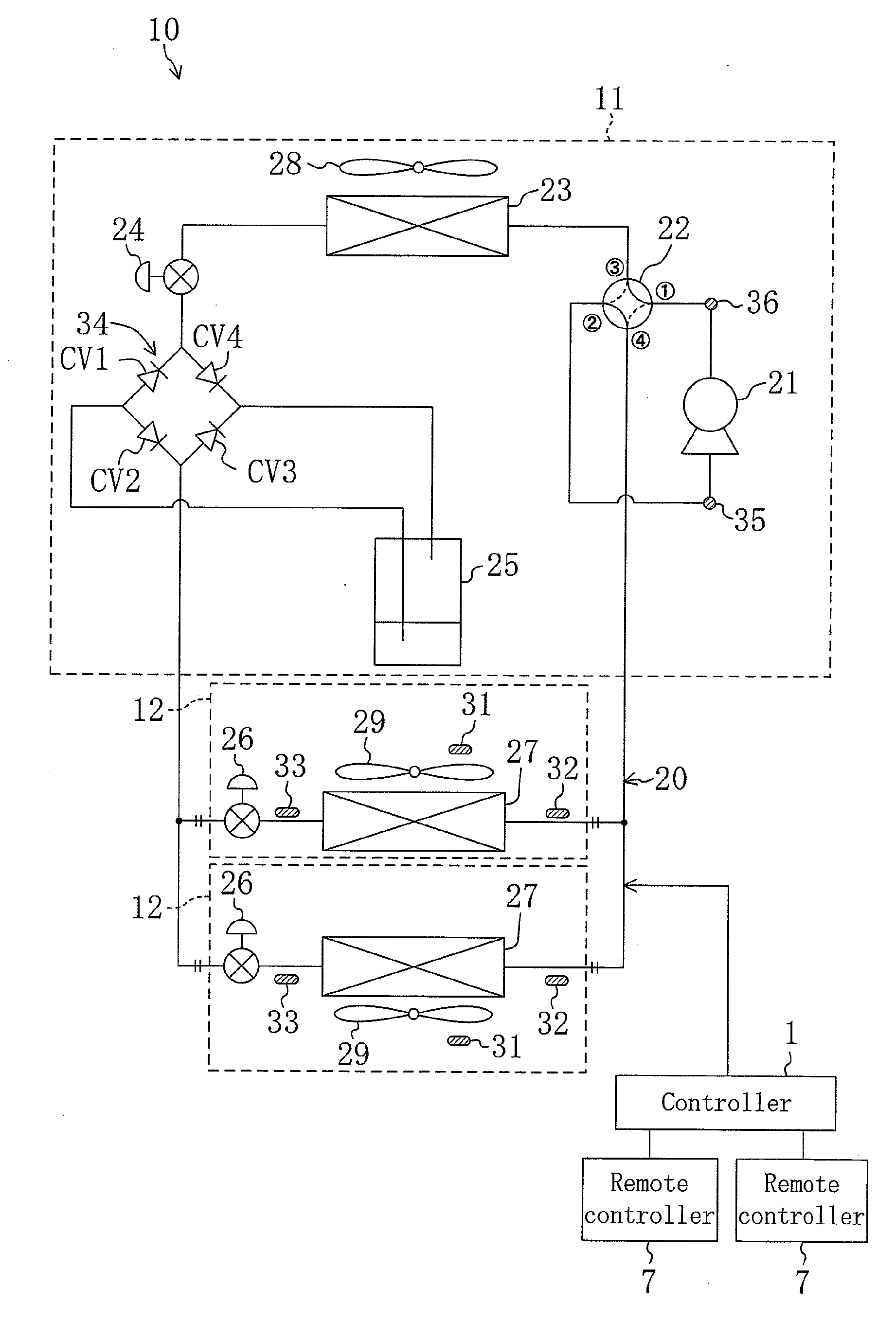

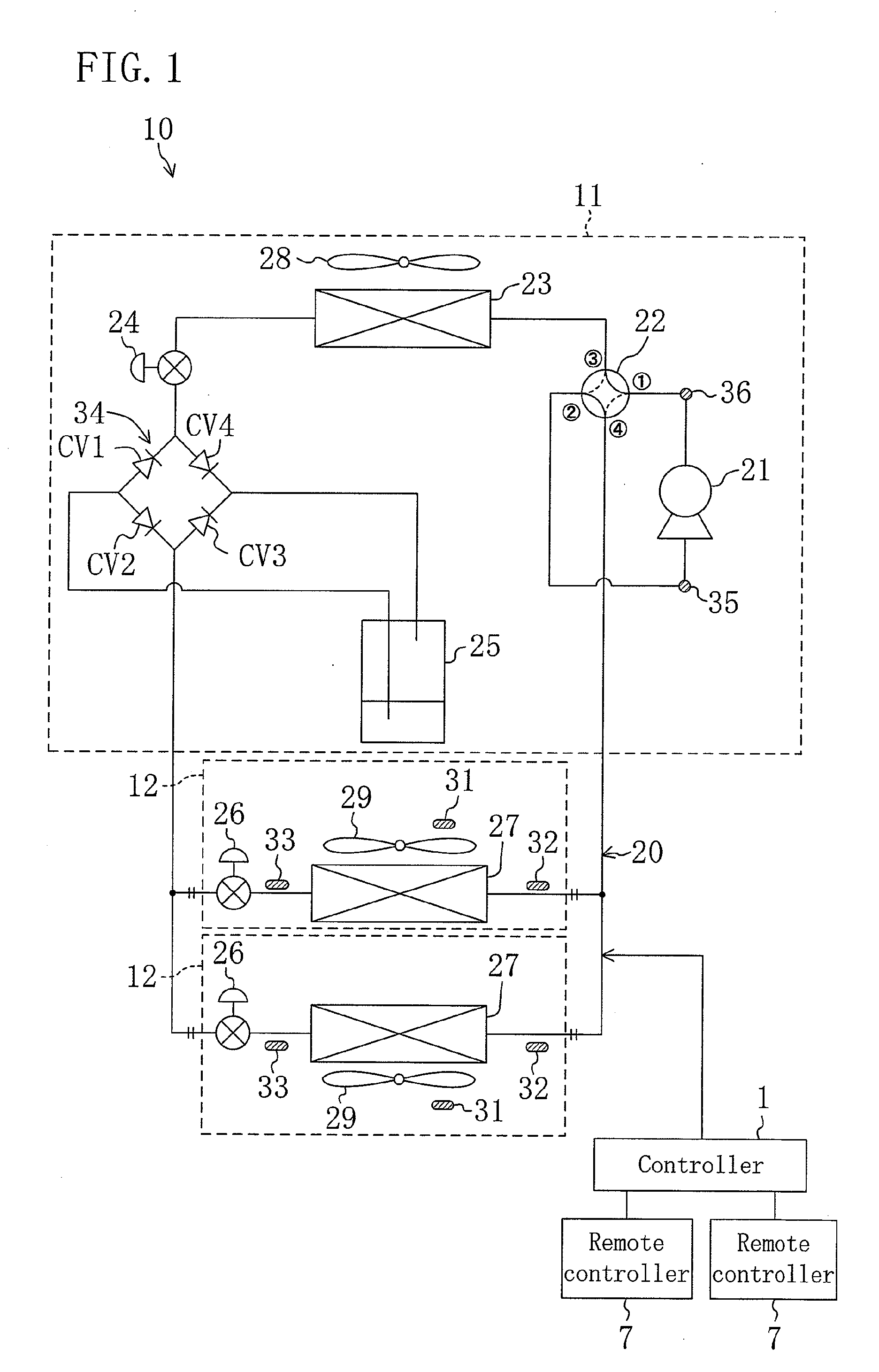

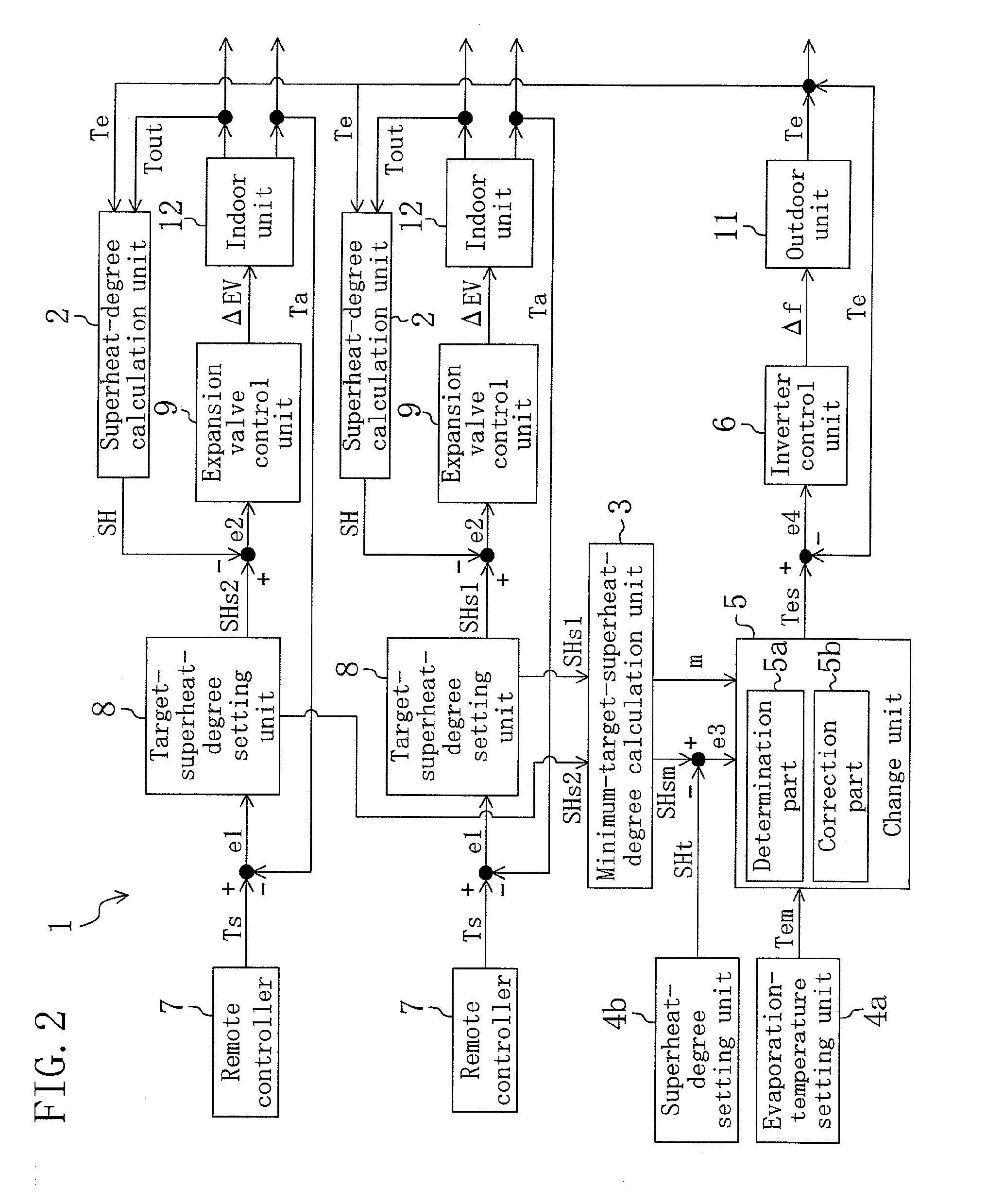

Refrigeration system

ActiveUS20110023534A1Reduce power consumptionReduction factorCompression machines with non-reversible cycleCompression machines with several evaporatorsProcess engineeringRefrigeration

An air conditioner (10) includes a refrigerant circuit (20) including a plurality of indoor heat exchangers (27). A controller (1) for controlling operation of the air conditioner (10) includes a change unit (5) configured to change a set temperature Tem to a value larger than a current value when the minimum target superheat degree SHsm of target superheat degrees SHs determined for the respective indoor heat exchangers (27) is higher than a predetermined value SHt.

Owner:DAIKIN IND LTD

Method for casting and forming TiAl-based alloy vent valve

The invention provides a method for casting and forming a TiAl-based alloy vent valve, and relates to casting methods for the TiAl-based alloy vent valve. The technical problems that gravity casting of an existing TiAl-based alloy vent valve can not enable mold filling to be conducted smoothly, inner quality can not be guaranteed, a centrifugal casting method is complex in process, the material utilization rate is low, the casting process is too complex, and the surface quality is poor are solved. The method mainly comprises the steps that first, the prior art is used for manufacturing a metal mold of the vent valve; second, the metal valve of the vent valve in the first step is placed in a suction casting chamber of a smelting furnace, and the metal mold of the vent valve is mounted on a mold seat; third, a graphite suction port is mounted on a water cooling crucible; fourth, a TiAl-based alloy pig which is smelted in advance is placed in a suction casting crucible of a vacuum arc melting furnace, and overheating melt is obtained by smelting; fifth, a vacuum system of a suction casting chamber of the vacuum arc melting furnace is opened, a suction casting button is opened, suction casting, mold filling and cooling are conducted, and a casting is obtained. The method is used for preparing TiAl-based alloy vent valve castings.

Owner:HARBIN INST OF TECH

Low-alloy high-strength steel and its manufacturing method

The high strength low alloy steel comprises: C 0.06-0.09 wt%, Mn 1.30-1.40 wt%, Si 0.195-0.305 wt%, P not more than 0.015 wt%, S not more than 0.006 wt%, V 0.025-0.035 wt%, Nb 0.015-0.025 wt%, Ti 0.010-0.020 wt%, Al 0.020-0.035 wt%, and Ca 0.0015-0.0045 wt%, except Fe and inevitable impurity. The making process includes: a. smelting in converter with C content in blowoff not less than 0.04 wt% and free oxygen controlled in 550-650 ppm; b. RH vacuum deairing for over 6 min; c. calcifying treatment at the overheat temperature controlled in 10-20 deg.c higher than liquid phase line temperature; and d. casting at temperature of 10-20 deg.c higher than liquid phase line and casting speed of 1.1-1.3 m / min. The present invention has lowered Nb content for avoiding edge crack, reasonable V content for required strength, and calcification for pure steel content and stable quality.

Owner:BAOSHAN IRON & STEEL CO LTD

Production process for lightening 22CrMoH gear steel banded structure

InactiveCN110093474ARaise the ratioShorten the lengthManufacturing convertersProcess efficiency improvementLiquid coreChemical composition

The invention relates to a production process for lightening 22CrMoH gear steel banded structure. The production method includes converter smelting, LF refining, RH refining, continuous casting, heating and rolling processes. In the converter smelting process, The end point P content is controlled below 0.008 wt%. In the RH refining process, soft blowing time is more than or equal to 12 min afterthe RH refining to ensure that inclusions float up and chemical components are even and reduce segregation caused by uneven chemical components. The continuous casting process ensures that molten steel casting superheat rate is less than or equal to 30 DEG C. The production process of the invention effectively controls the center segregation of a gear steel casting blank and increases a ratio of equiaxed crystals. Low superheat rate and low casting speed shorten the length of a liquid core and solidification time and reduce element segregation, thereby reducing a grade of a banded structure.

Owner:HANDAN IRON & STEEL GROUP +1

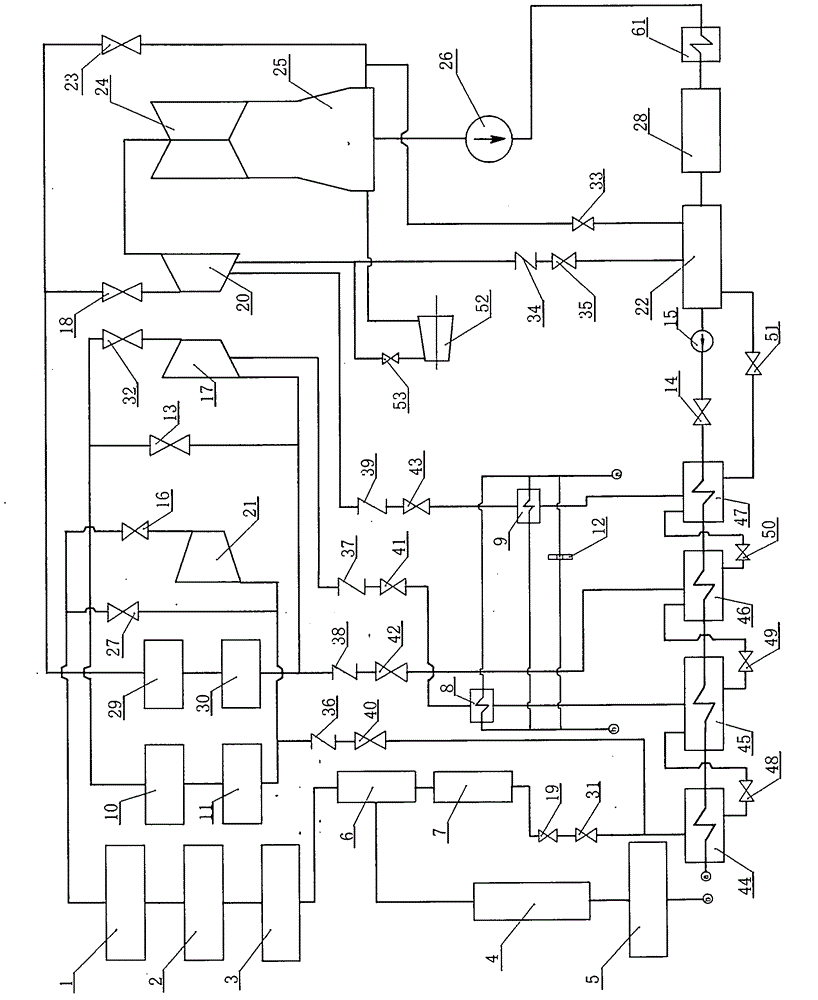

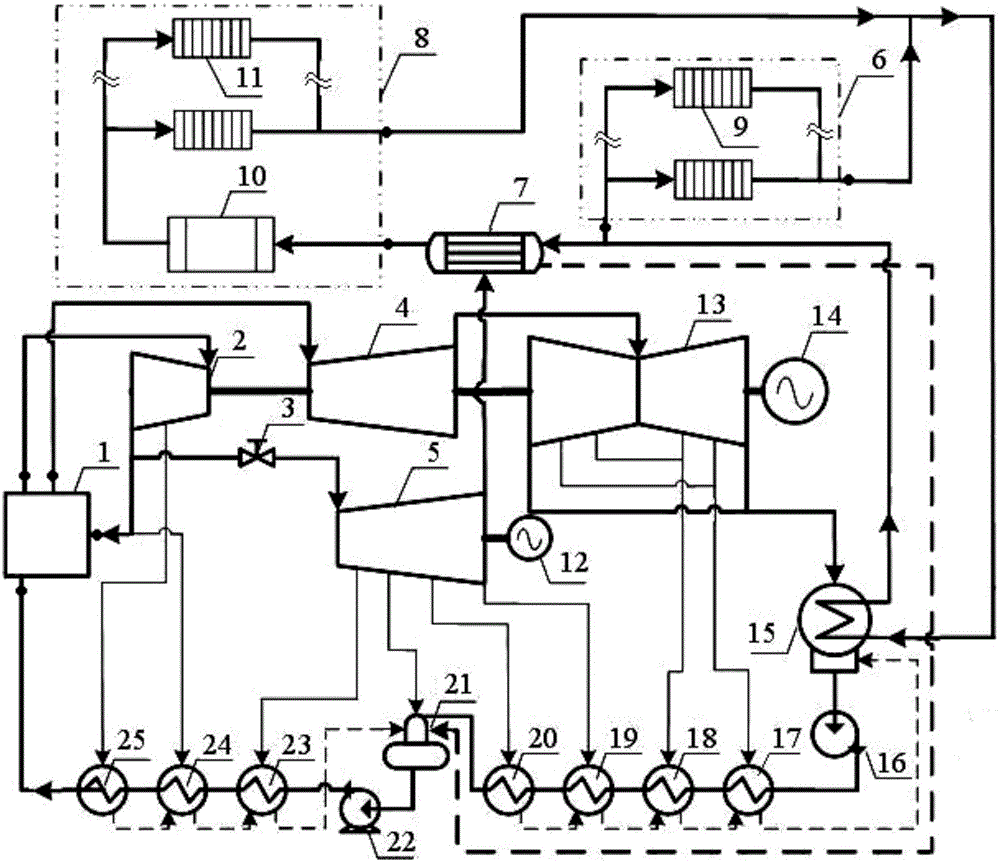

Optimum scheme of ultra-supercritical secondary reheating unit

ActiveCN104806308AIncrease output powerReduce heat consumptionSteam engine plantsUltra high pressureEngineering

The invention discloses an optimum scheme of an ultra-supercritical secondary reheating unit, and refers to a secondary reheating unit of a coal-fired power plant after optimization of a back heating system, parameter optimization of main steam, primary reheating steam, and secondary reheating steam, and structural optimization of a turbine body. The optimum scheme of the ultra-supercritical secondary reheating unit can obviously reduce the heat loss of the secondary reheating unit, and significantly decrease greenhouse gas emission and decreases cost of the ultra-supercritical secondary reheating unit obviously. By taking a 1200 MW grade unit as an example, four mono-axial cylinders are used for gas exhausting, the ultra-supercritical secondary reheating unit is composed of a single-flow ultra-high pressure cylinder capable of completely supplying water, back-heating and pumping gas, a dual-flow high and medium pressure cylinder, and two dual-flow middle and low pressure cylinders; there is no middle pressure cylinder and a middle low pressure linking pipe; no gas pumping opening is arranged on the high middle pressure cylinder and the middle low pressure cylinder; the water supply and back heating are provided by a first pump, a new second pump, a new third pump, and a new fourth pump; a ultra-low temperature coal economizer, and a heat primary wind condensing water heater replace a seventh pump, an eighth pump, a ninth pump, and a tenth pump to heat the condensed water; all low-pressure heaters are canceled.

Owner:章礼道

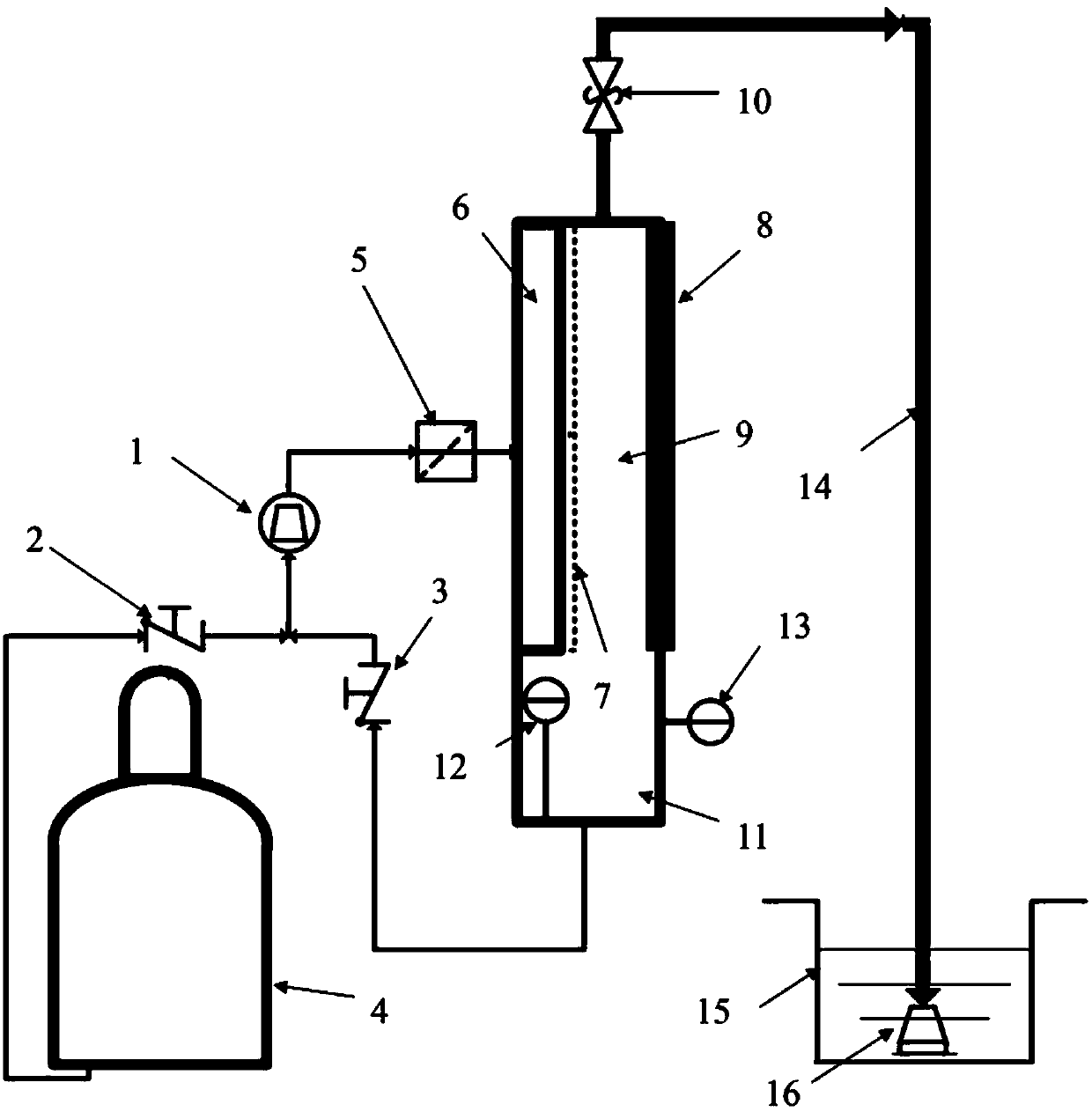

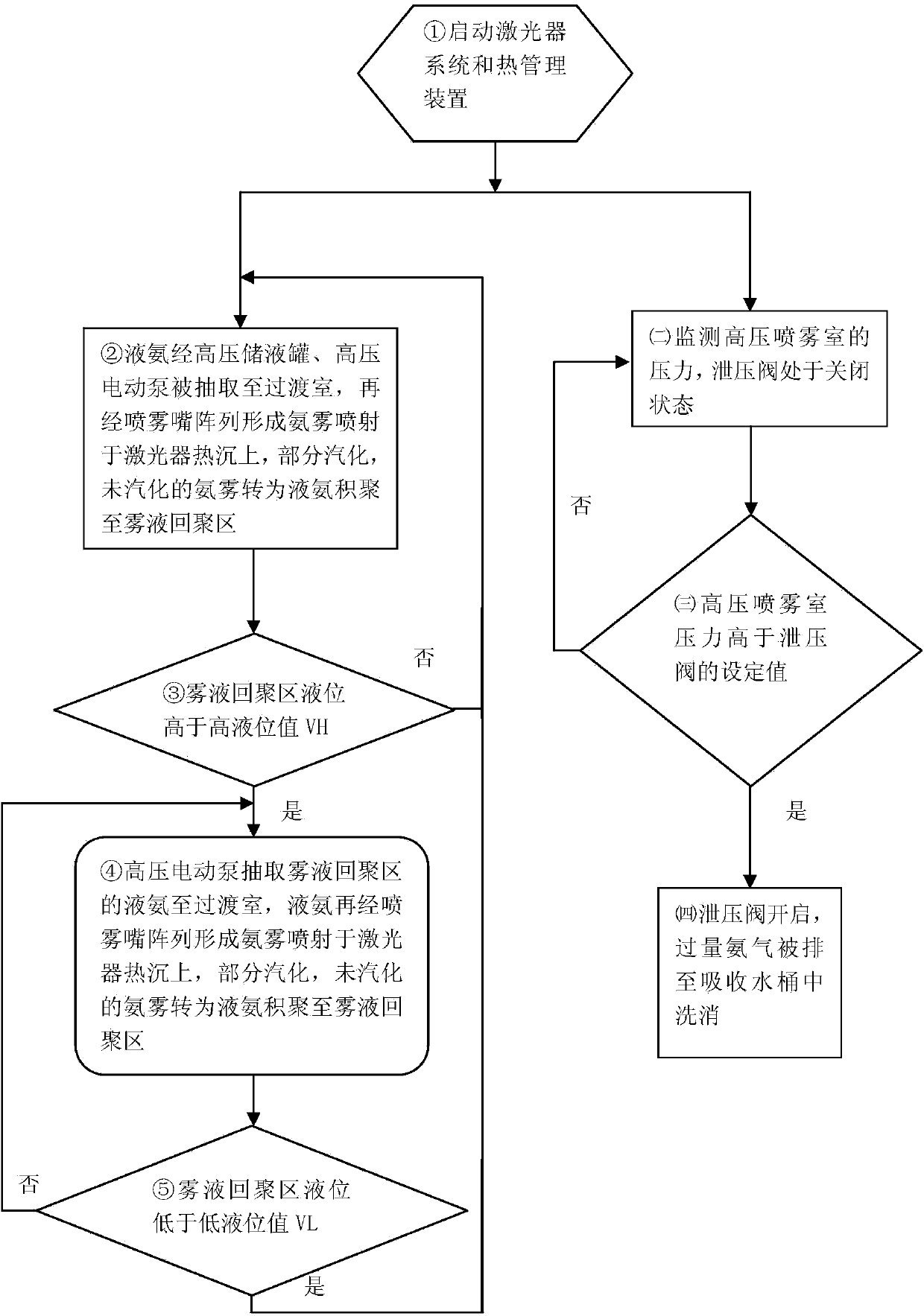

Device and method for high-power laser heat management based on spray evaporation

ActiveCN103441422AOverall small sizeSmall weightLaser detailsSemiconductor lasersHigh power lasersLiquid storage tank

The invention discloses a device and method for high-power laser heat management based on spray evaporation. The device for the high-power laser heat management comprises a high-pressure spray chamber arranged on a laser heat sink, a spray nozzle array and an air pressure sensor are arranged in the high-pressure spray chamber, the high-pressure spray chamber is adjacent to a transitional chamber, the transitional chamber is connected with a high-pressure liquid storage tank through a high-pressure electric pump, a spray liquid returning and accumulating area on the bottom portion of the high-pressure spray chamber is connected with the transitional chamber through the high-pressure electric pump, the high-pressure spray chamber is further connected with an exhaust pipe, and a decompression valve is arranged on the exhaust pipe. The method for the high-power laser heat management is achieved through the device for the high-power laser heat management, and the method is used for maintaining the pressure of gas refrigerants in the high-pressure spray chamber to be constant, and therefore temperature is maintained to be constant to achieve constant temperature control over the laser heat sink. The device is simple and reliable in structure, high in compactness, accurate in temperature control and stable in operation, and the method is simple and easy to implement, high in efficiency and environmentally friendly.

Owner:NAT UNIV OF DEFENSE TECH

Superheat control by pressure ratio

ActiveUS8096141B2Slow down increaseRapid responseMachines using electric/magnetic effectsFluid circulation arrangementControl theoryElectronic expansion valve

Owner:TRANE INT INC

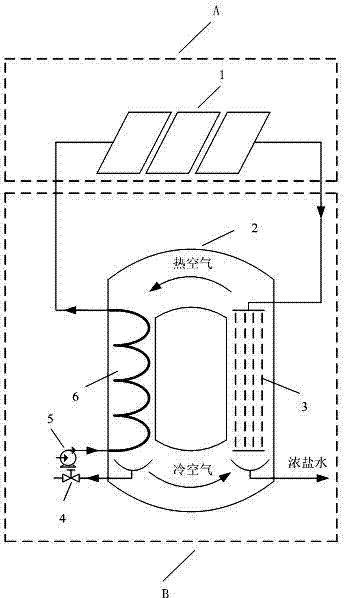

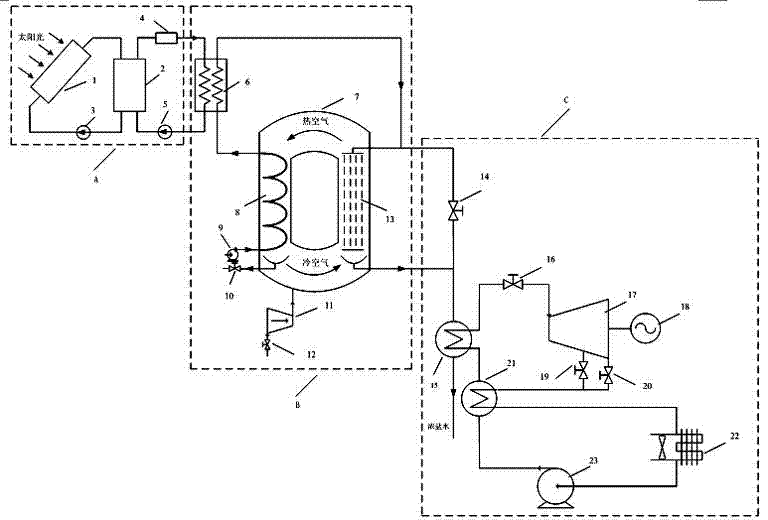

Water-power cogeneration system for recovering waste heat of concentrated seawater of desalination and method of system

ActiveCN103925024AReduce superheatImprove heat transfer coefficientGeneral water supply conservationSeawater treatmentOrganic Rankine cycleCogeneration

The invention relates to a water-power cogeneration system for recovering waste heat of concentrated seawater of desalination and a method of the system, and belongs to the fields of energy and power. The system is characterized by comprising an organic Rankine cycle subsystem; the organic Rankine cycle subsystem comprises a waste heat recoverer for recovering heat carried by the concentrated seawater discharged by a desalination system, an organic turbine regulating valve connected with an outlet of the waste heat recoverer, an organic turbine connected with an outlet of the regulating valve, a steam exhaust regulating valve connected with an outlet of the organic turbine, a heat regenerator connected with the outlet of the steam exhaust regulating valve, and an air cooling condenser connected with an outlet of the heat regenerator; the air cooling condenser is connected with a liquid phase inlet of the waste heat recoverer through an organic working medium pump. The heat carried by the concentrated seawater discharged by the desalination system is fully utilized, so that comprehensive utilization efficiency of heat energy is increased; the turbine cooling an organic working medium with air is adopted to exhaust steam, so that cooling water is saved greatly; the system follows the principle of gradient utilization of energy, and is in line with national objectives of energy conservation and emission reduction and sustainable development strategy of water resources.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

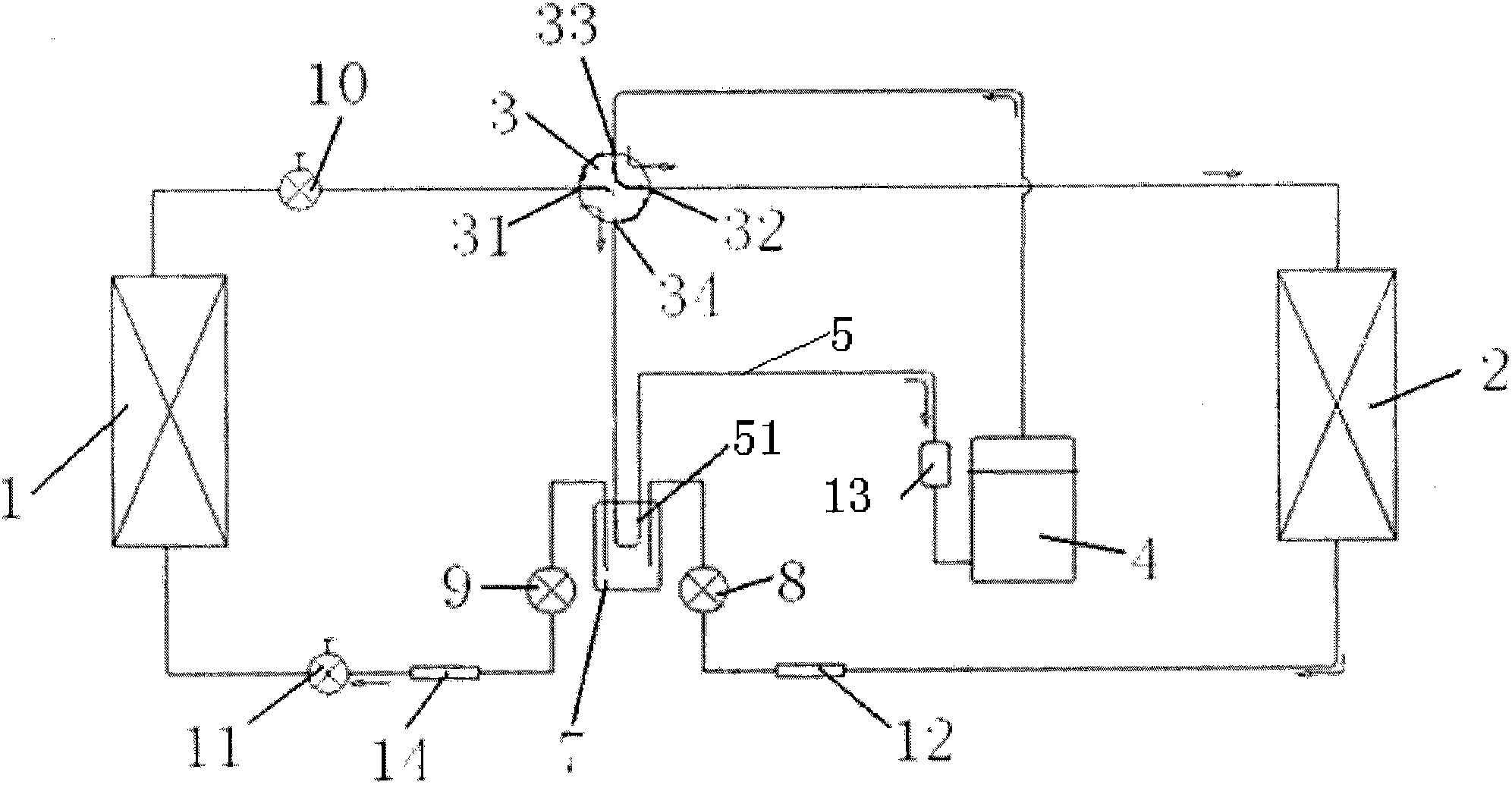

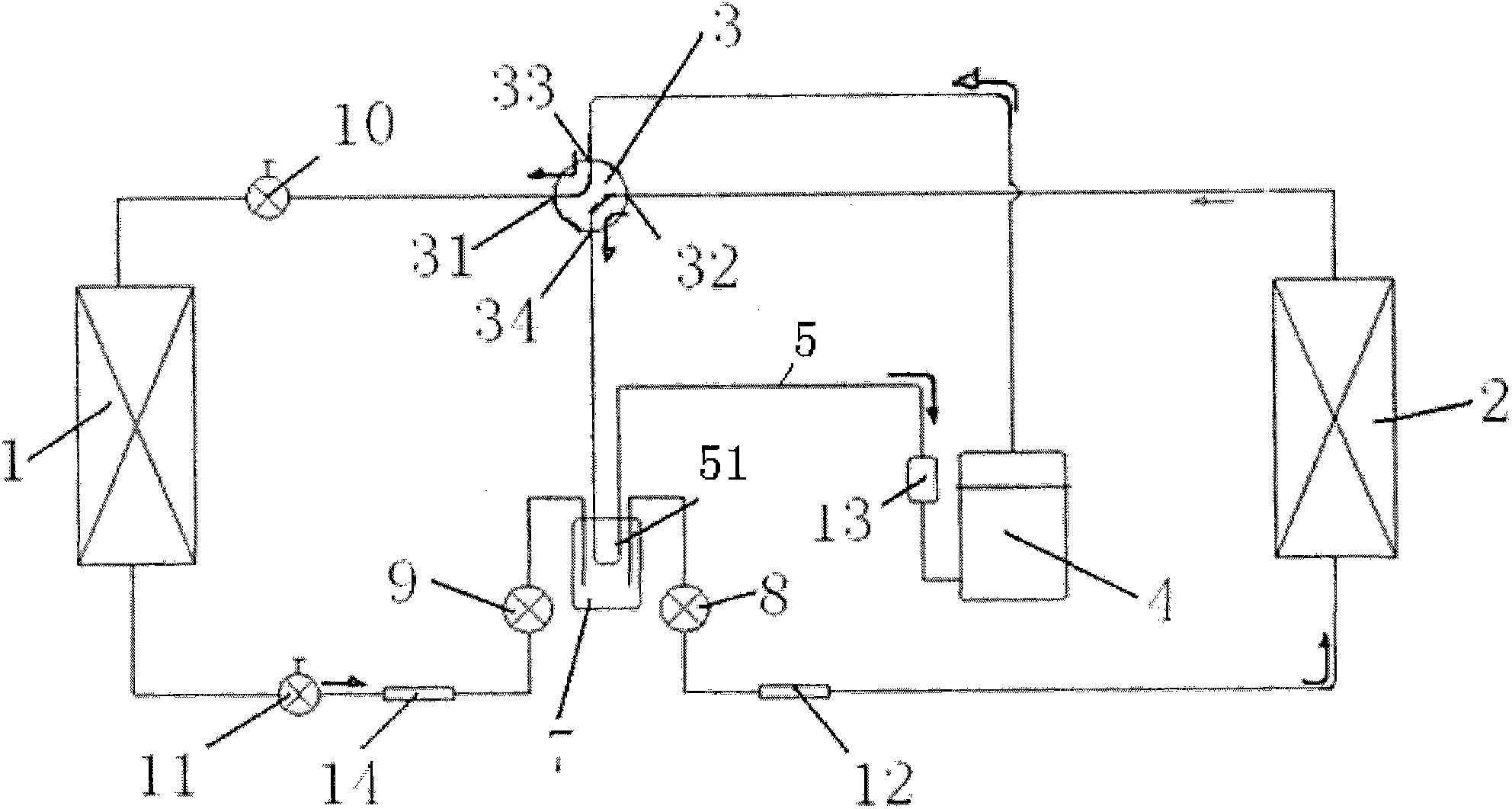

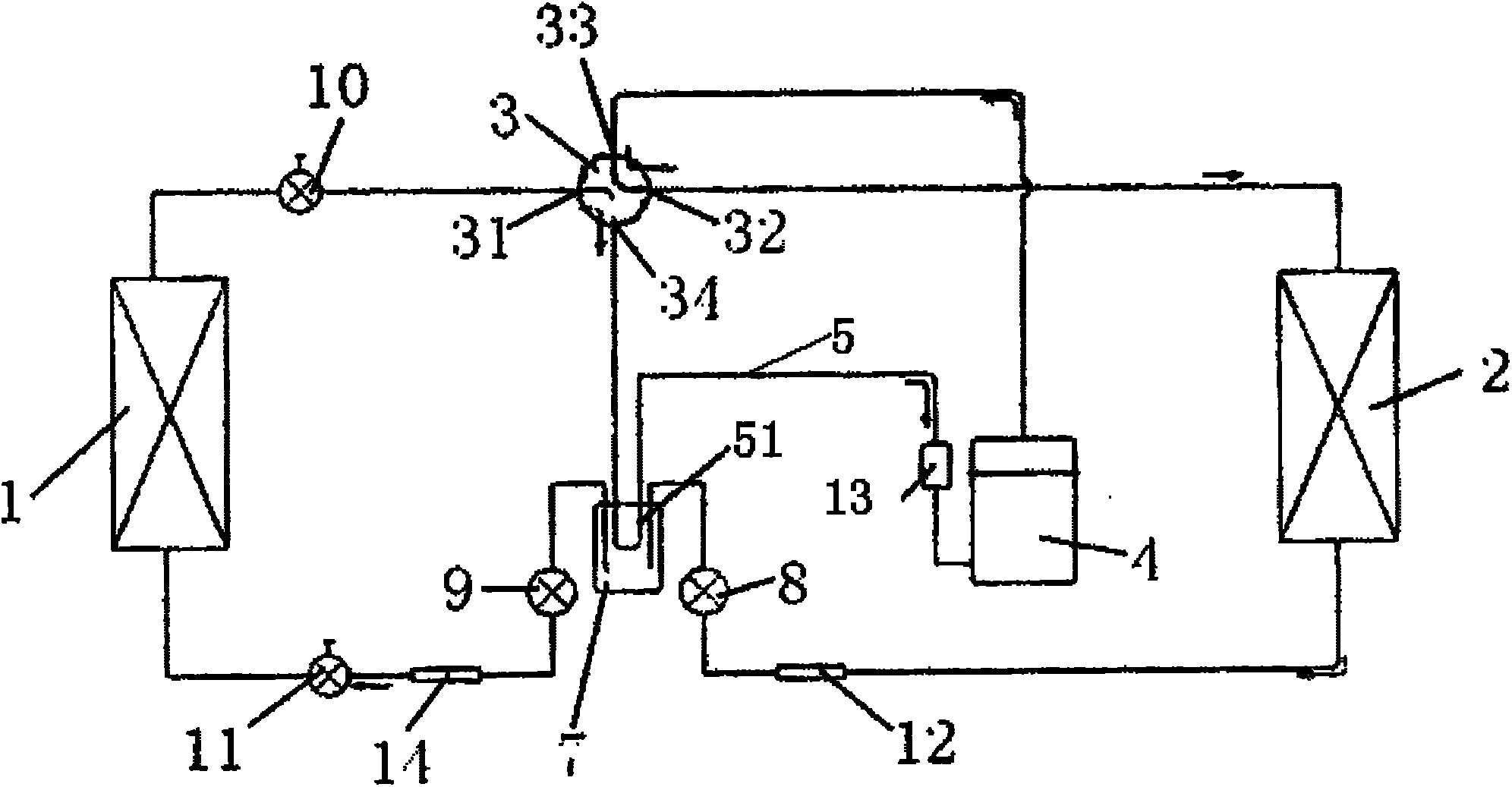

Air conditioner system

InactiveCN102022853AIncrease subcoolingReduce subcoolingEfficient regulation technologiesFluid circulation arrangementFour-way valveEngineering

The invention provides an air conditioner system comprising an indoor heat exchange device, an outdoor heat exchange device, a four-way valve, a first throttle device, a liquid reservoir and a second throttle device, wherein the indoor heat exchange device and the outdoor heat exchange device are respectively provided with a first and a second refrigerant ports, and the first refrigerant port of the indoor heat exchange device is communicated with the first refrigerant port of the outdoor heat exchange device by a first refrigerant pipe; the first port of the four-way valve is connected with the second refrigerant port of the indoor heat exchange device, the second port is connected with the second refrigerant port of the outdoor heat exchange device, the third port is connected with the exhaust port of a compressor, and the fourth port is connected with the air suction port of the compressor by a second refrigerant pipe; and the first throttle device, the liquid reservoir and the second throttle device are orderly connected to the first refrigerant pipe in series, the second refrigerant pipe is provided with a first pipe section held in the liquid reservoir, and the first pipe section is immersed in refrigerant coming from the first refrigerant pipe in the liquid reservoir, so refrigerant in the second refrigerant pipe exchanges heat with refrigerant in the liquid reservoir. The air conditioner system can simultaneously increase the degree of supercooling and the degree of superheating of cold media in one circulation.

Owner:HAIER GRP CORP +1

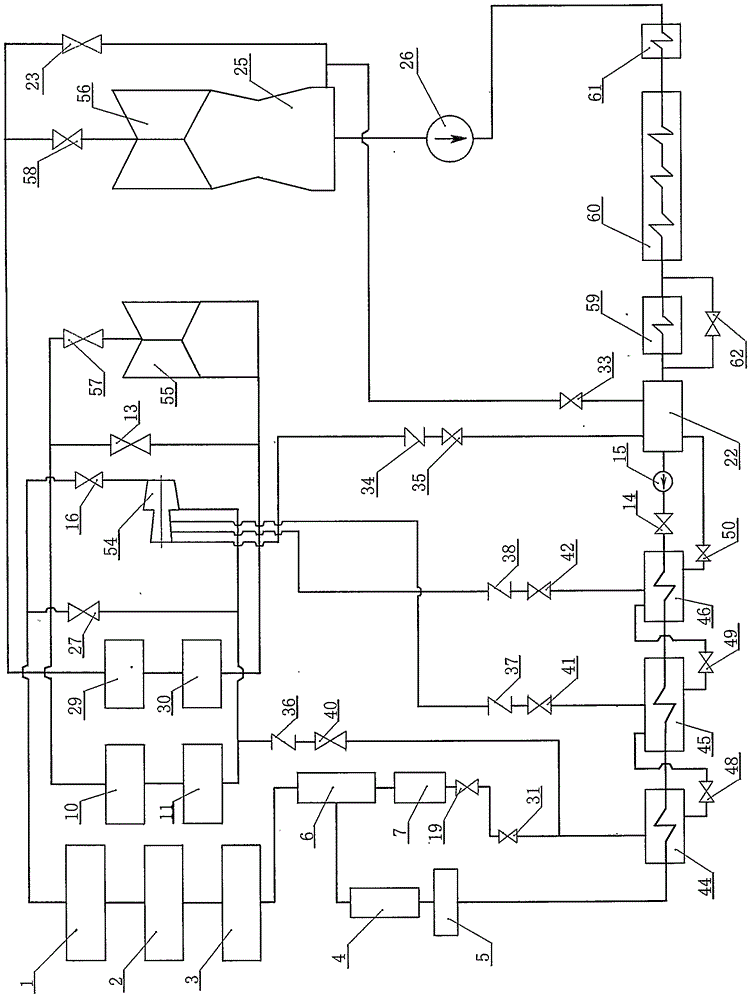

High-back pressure combined heat and power generation system coupled with exhaust steam and supply heat of non-reheat steam turbine

InactiveCN105736068AReduce superheatImprove the flow structureCombination enginesSteam useProcess engineeringDynamo

The invention belongs to the technical field of thermoelectricity, and relates to a high back pressure heat and power cogeneration system coupled with exhaust steam heat supply of a non-reheat steam turbine. A non-reheat medium-pressure steam turbine and generator II are added to the power generation system, and the heating system mainly includes a high backpressure heating condenser, a non-reheat medium-pressure steam turbine, a heat network heater, a remote heat network and a short-range heat network. The exhaust steam from the low-pressure cylinder of the main steam turbine enters the heating condenser to condense and release heat. The circulating water in the condenser absorbs heat and enters the short-distance heating network or heating network heater. The exhaust steam from the steam turbine is further heated and enters the remote heating network, and the return water from the remote and short-range heating networks is mixed and then enters the condenser. The invention utilizes the waste heat of the exhaust steam of the steam turbine to reduce the loss of the cooling source; the return water of the short-range and remote heating network is mixed, so that the temperature of the return water of the heating network entering the condenser is reduced, and the utilization efficiency of waste heat is improved. The invention is suitable for the heat supply transformation of 300MW and above large-capacity units with short-range low-temperature heat demand.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

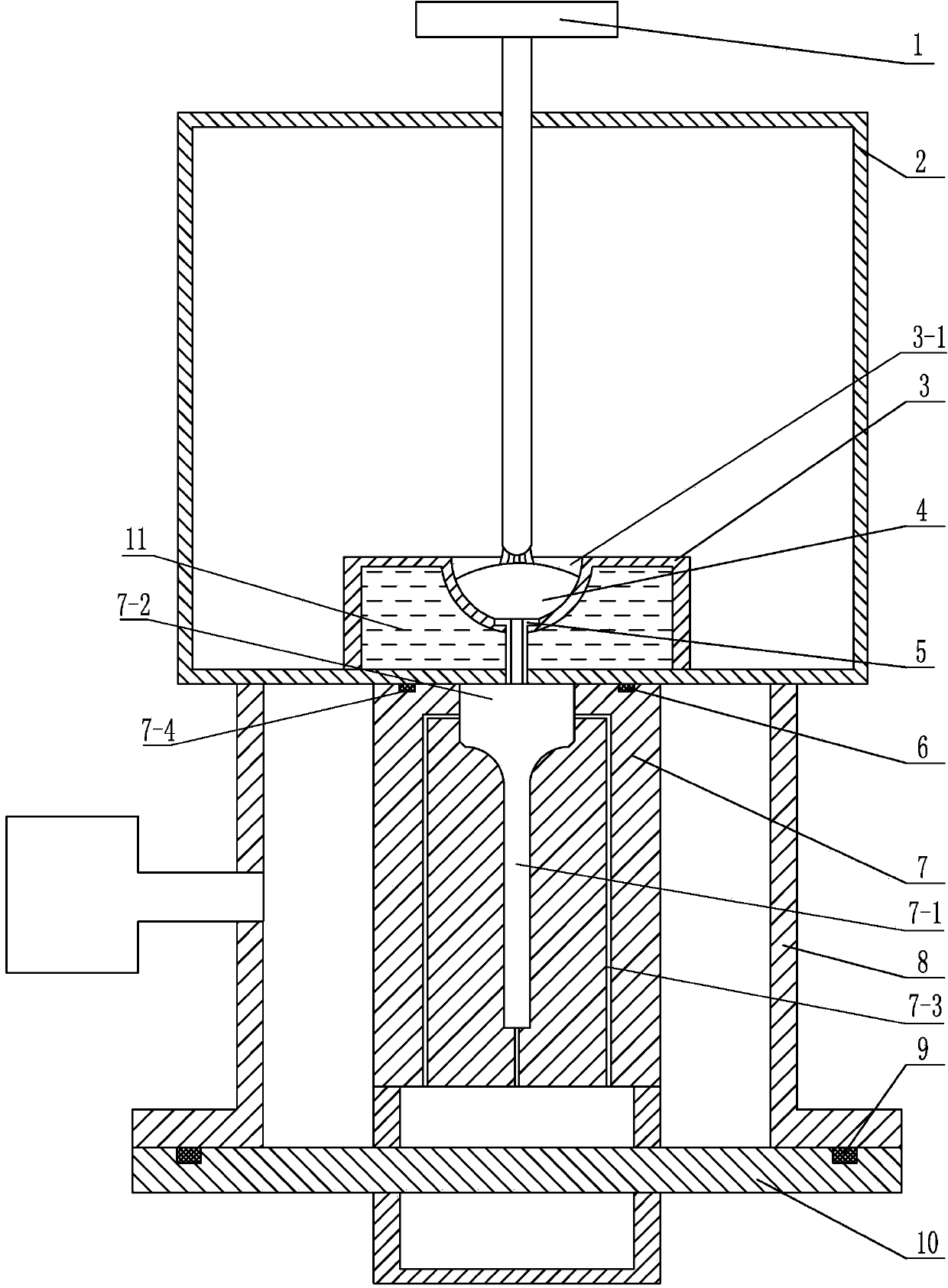

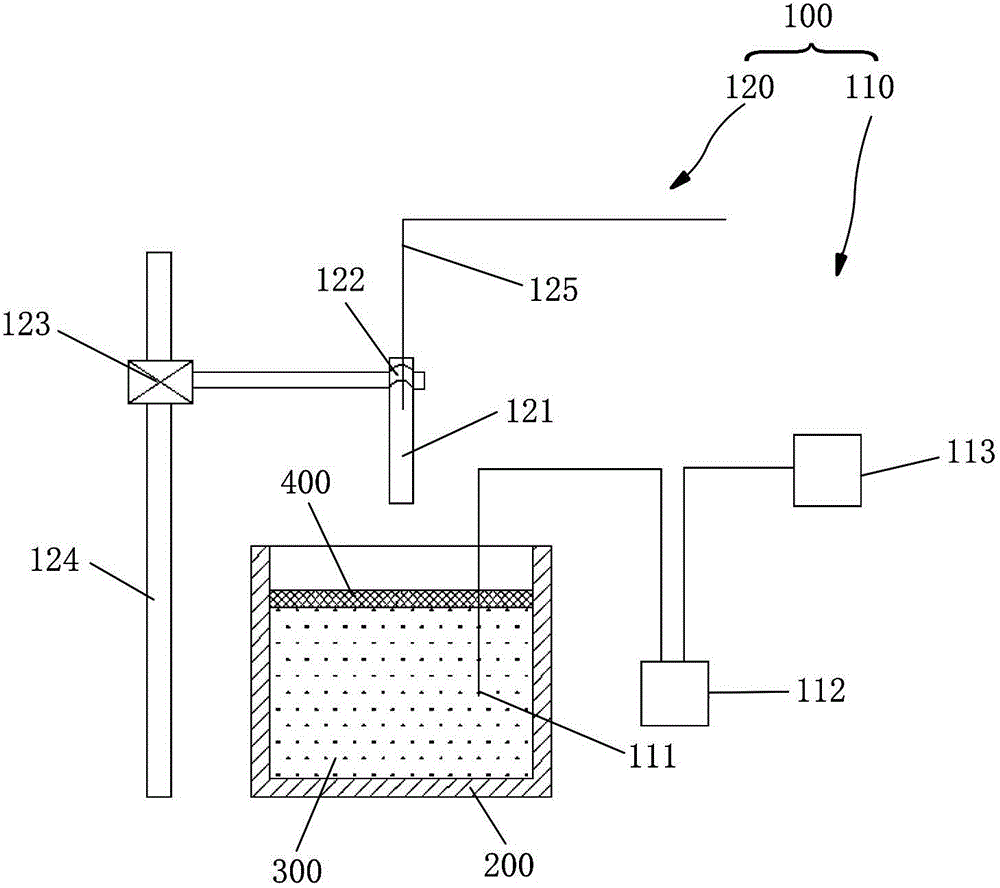

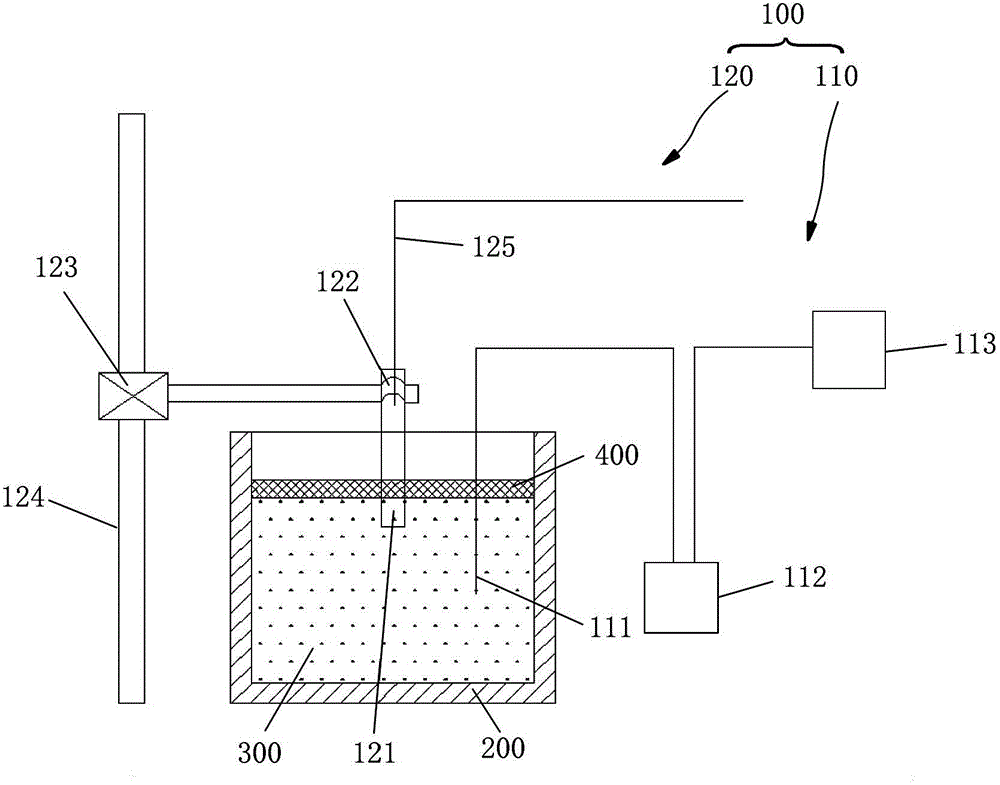

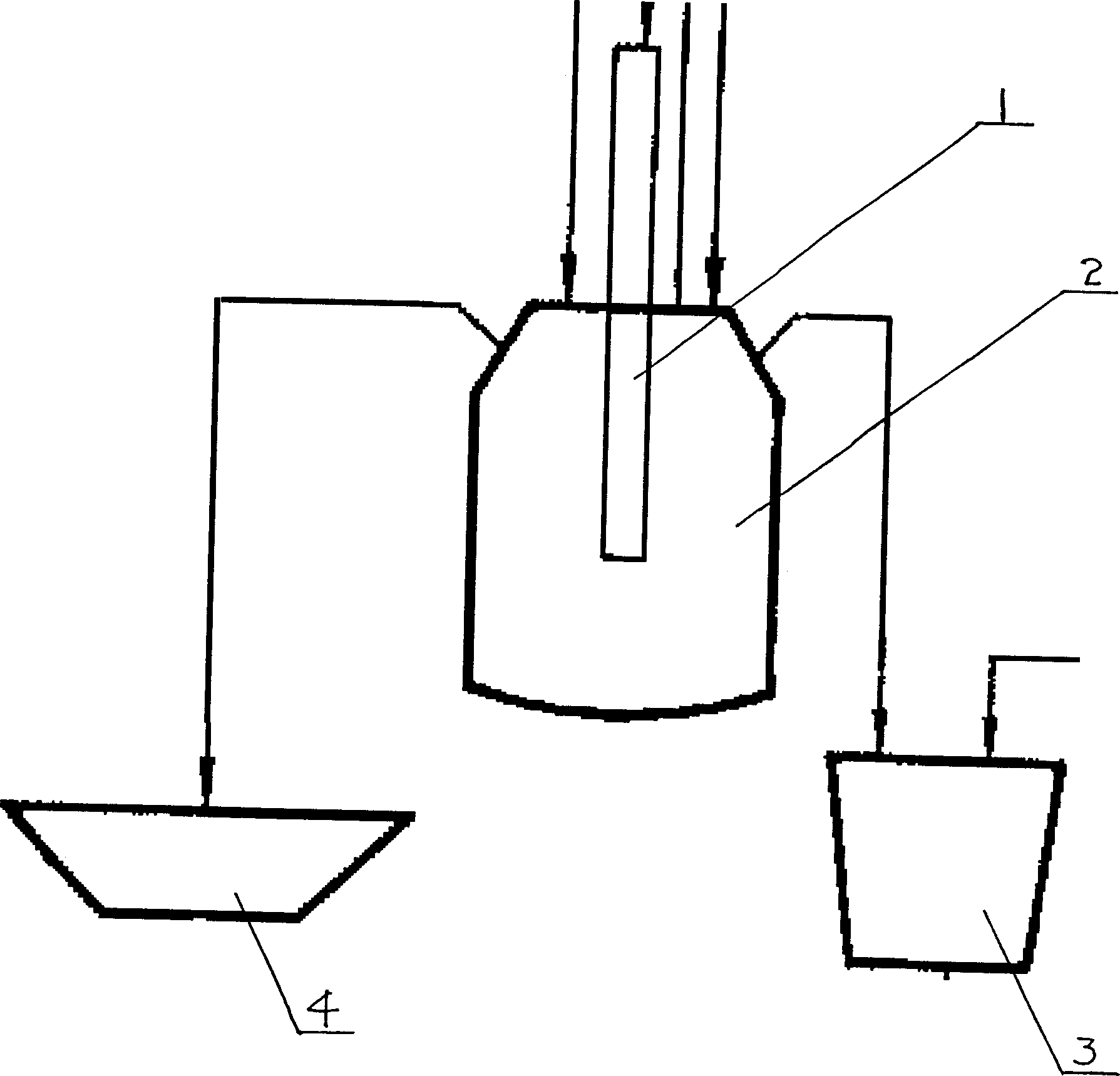

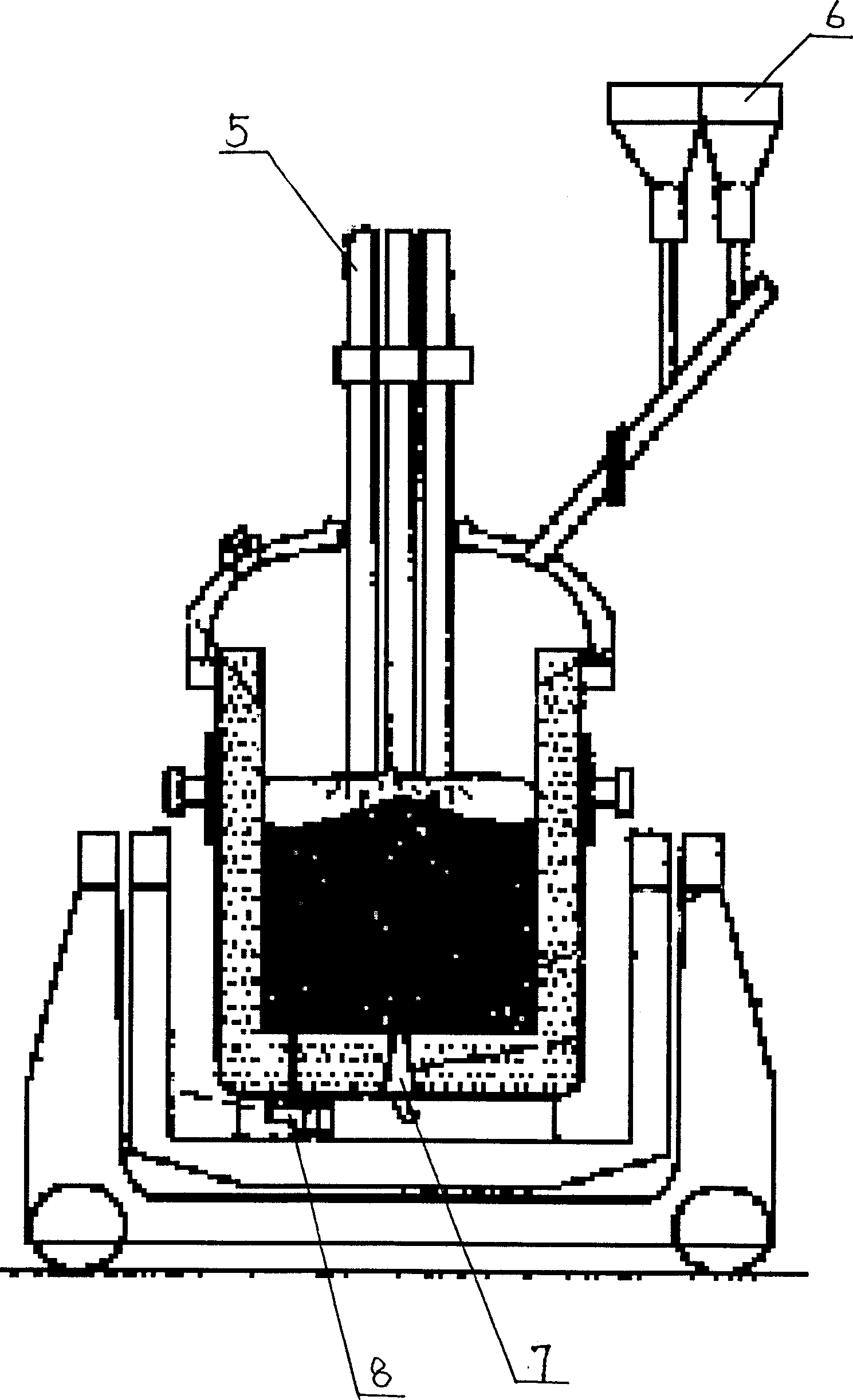

Device and method for controlling superheat degree of molten steel in continuous casting ladle or tundish

ActiveCN102909332AReduce superheatIncrease superheatCasting parameters measurement/indication devicesTemperature controlPower flow

The invention discloses a device and a method for controlling superheat degree of molten steel in a continuous casting ladle or a tundish. The device comprises a temperature measuring device for measuring the temperature of the molten steel in the continuous casting ladle or the tundish, and a temperature control device for controlling the temperature of the molten steel in the continuous casting ladle or the tundish; the temperature control device comprises a scrap body material or a steel bar, a device for moving the scrap body material or the steel bar, and an electroslag heating device; the device for moving the scrap body material or the steel bar can insert the scrap body material or the first end of the steel bar into the internal part of a slag in the continuous casting ladle or the tundish, and can insert the scrap body material or the first end of the steel bar into the internal part of the molten steel; the slag is arranged above the molten steel and contacts the molten steel, and the electroslag heating device is electrically connected to the scrap body material or the steel bar, so that the current flows through the slag to heat the slag when the scrap body material or the first end of the steel bar is inserted into the internal part of the slag.

Owner:LAIWU IRON & STEEL GRP

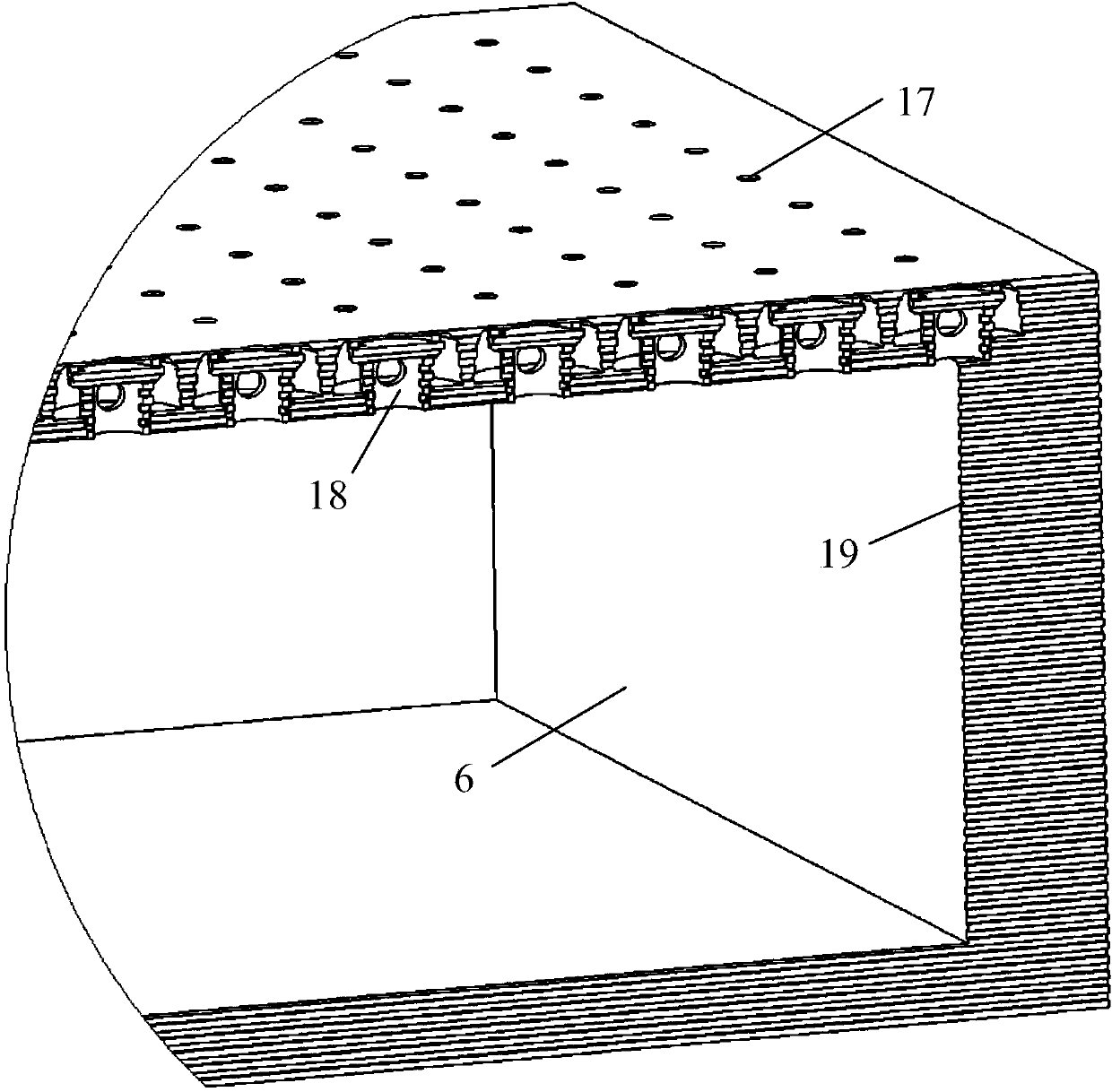

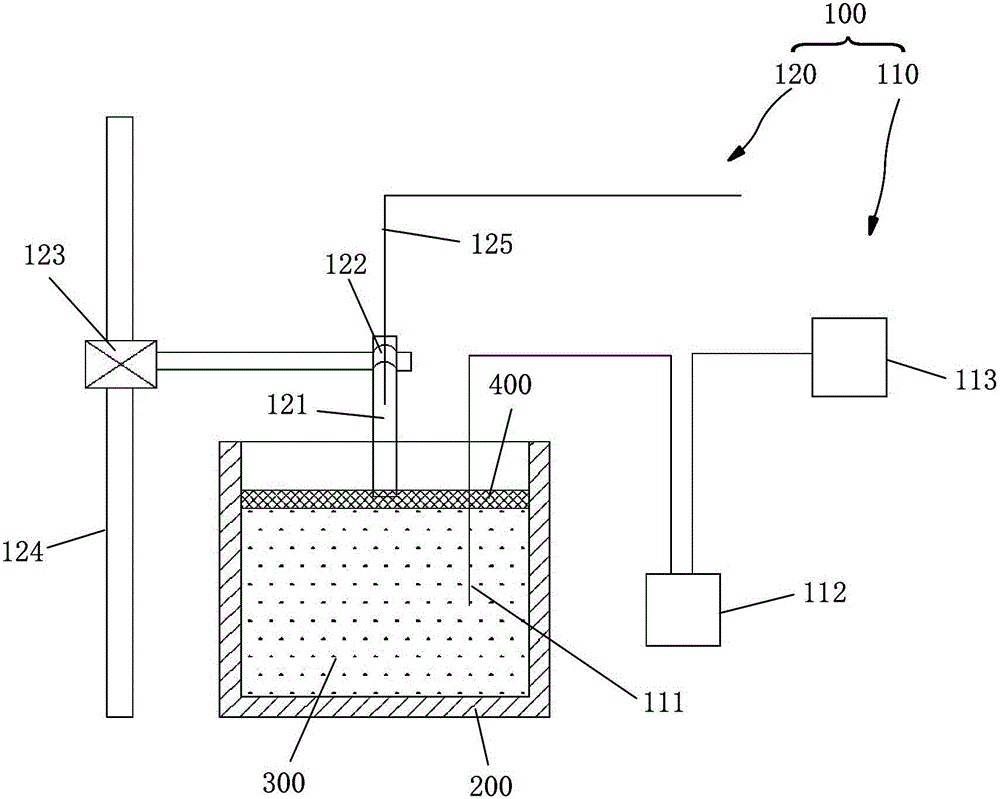

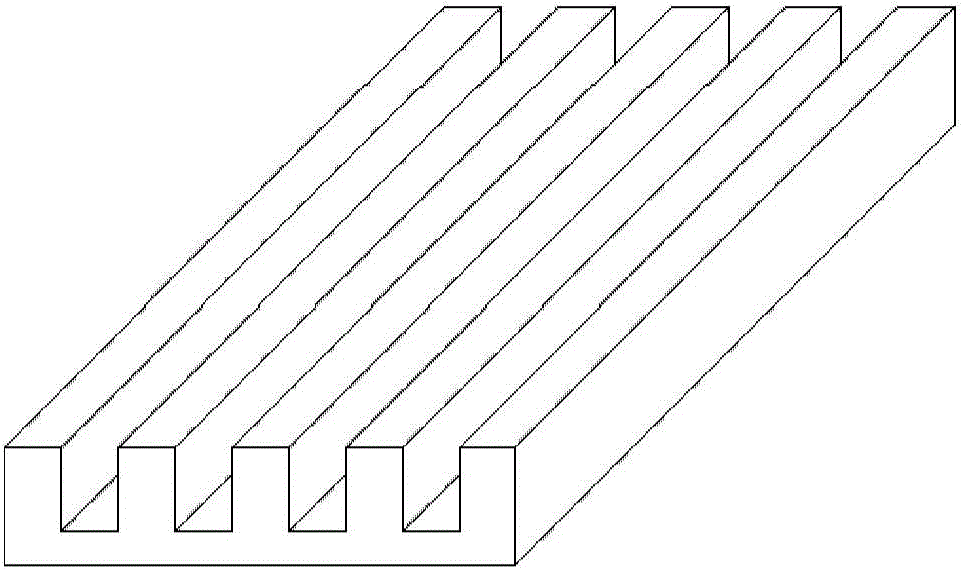

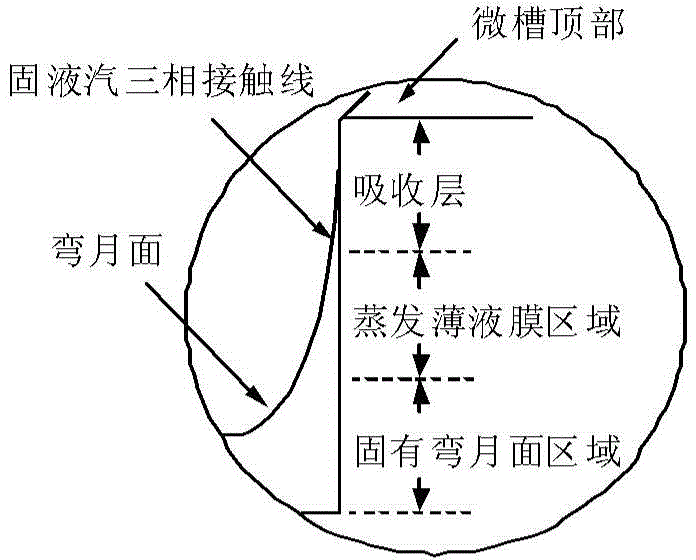

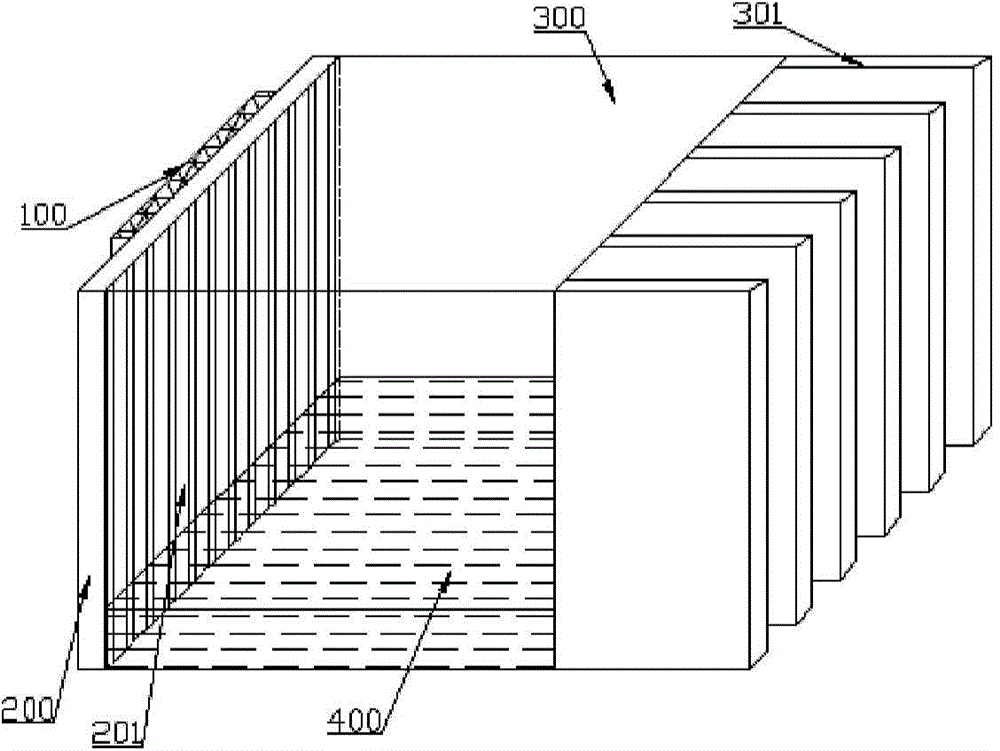

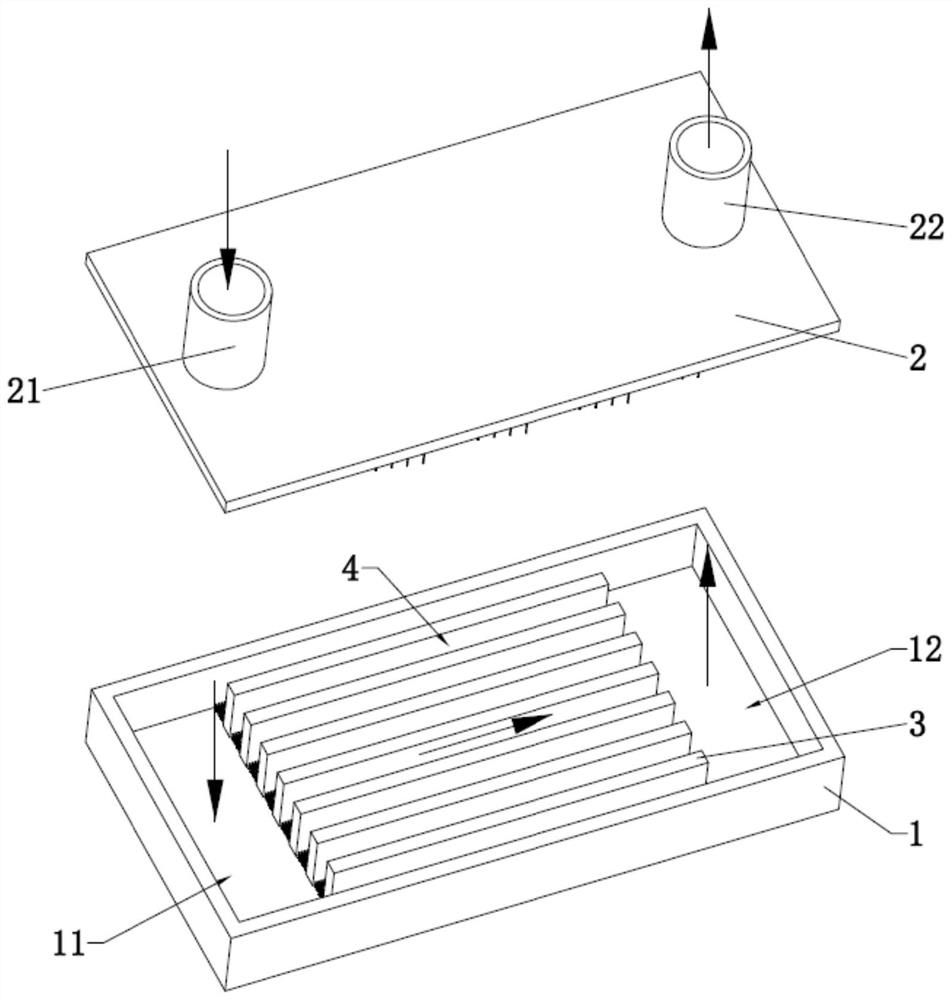

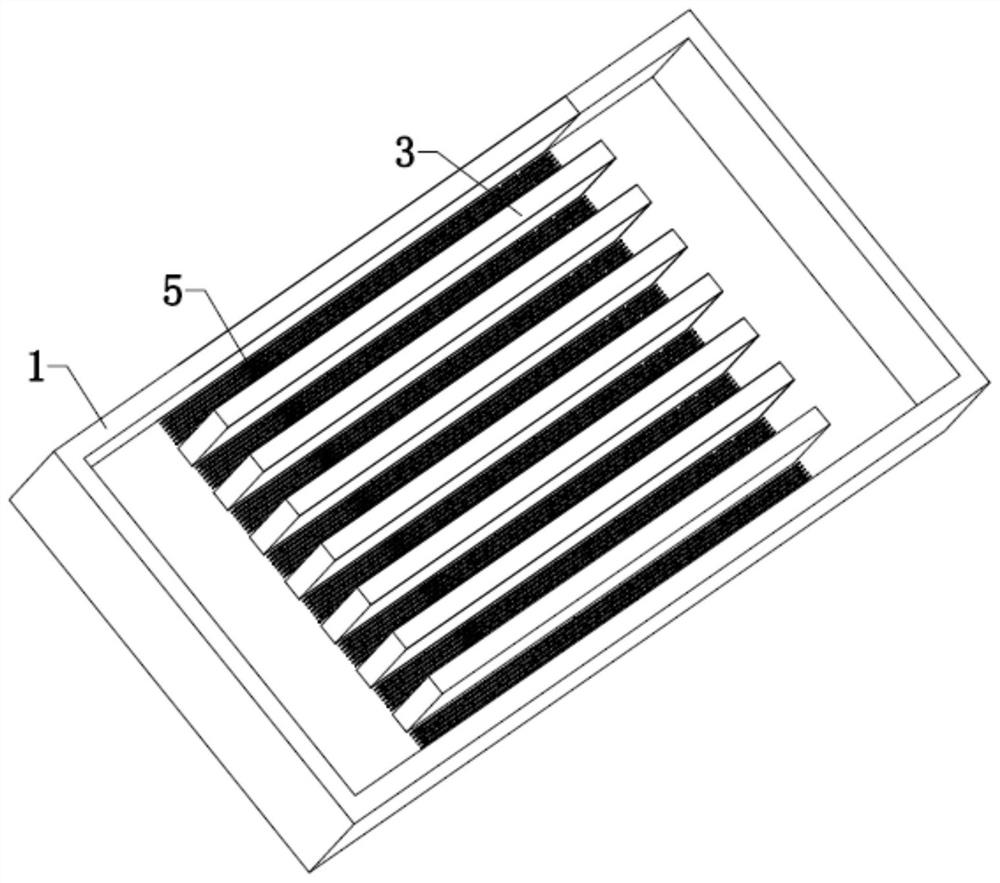

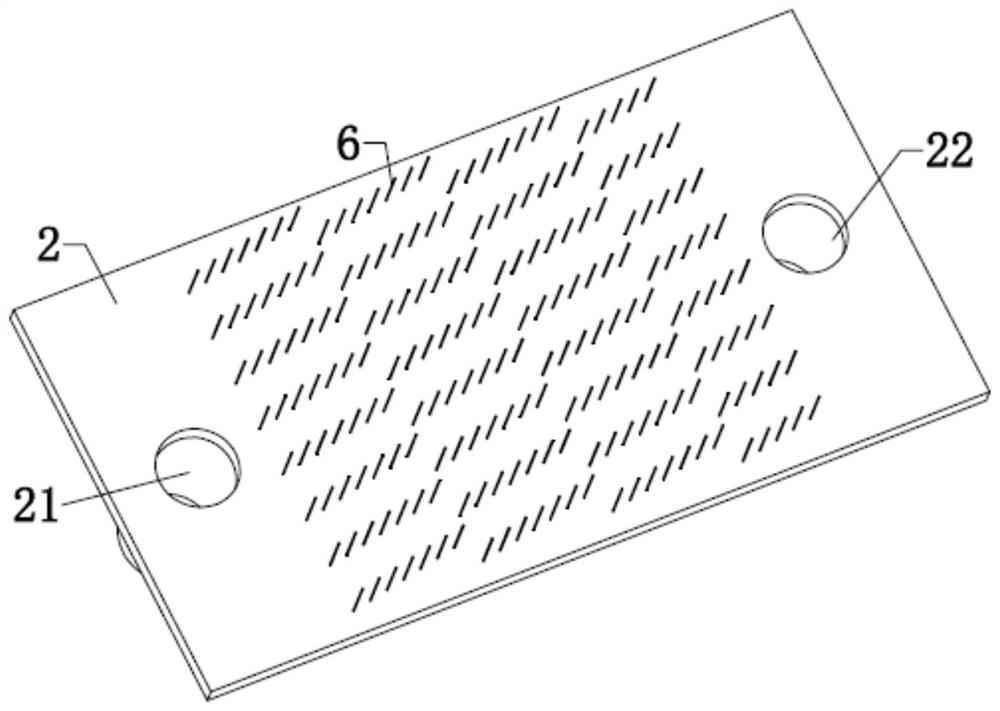

Microchannel phase-change heat transfer device

ActiveCN103824825AGood for heatImprove heat extraction capacitySemiconductor/solid-state device detailsSolid-state devicesTemperature controlShape-memory alloy

The invention provides a microchannel phase-change heat transfer device. The microchannel phase-change heat transfer device includes an outer heat dissipation body and a microchannel heat sink; the outer heat dissipation body is of a cylindrical structure of which one side is closed; the microchannel heat sink is made of a shape memory alloy material and is of a platy structure; the microchannel heat sink is embedded at one un-closed end of the cylindrical structure of the outer heat dissipation device, such that a closed cavity can be formed; and the closed cavity is filled with a liquid working medium; a surface of the microchannel heat sink, which faces the inner side of the closed cavity, is provided with a plurality of hundred-micron-level microchannels; trained micro ribs are located between every two adjacent microchannels; and the depth of the microchannels above a preset temperature is greater than the depth of the microchannels below the preset temperature. With the microchannel phase-change heat transfer device of the invention adopted, the heat removal ability of a microchannel structured surface can be improved, and the overheating degree of the microchannel structured surface can be reduced, and therefore, the temperature of a heat-emitting device can be controlled to be lower.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Technological process of making flat spring steel for automobile

The flat spring steel for automobile is produced via converter smelting process. Compared with available technology, the present invention has the following advantages and positive effects: utilizing molten iron with less harmful elements as material to result in high flat spring steel quality; higher finished product rate and lower power consumption to result in lower cost than production in electric furnace; casting molten steel into small square billet to omit the billet cutting step and lower cost; and high size precision of the continuously cast small square billet to ensure high size precision of flat spring steel.

Owner:青岛钢铁控股集团有限责任公司

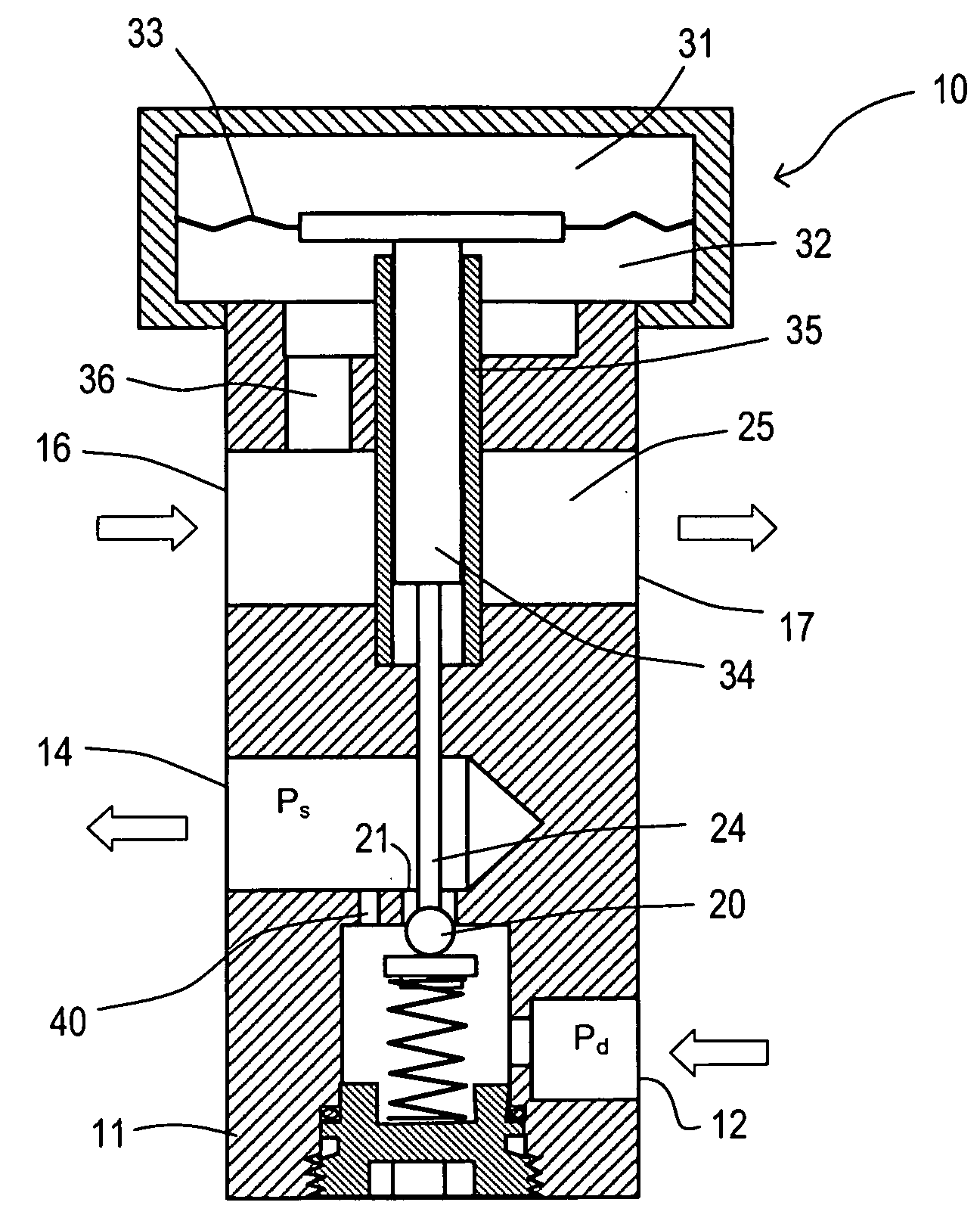

Automotive Thermostatic Expansion Valve With Reduced Hiss

ActiveUS20100186434A1Reduce superheatTemperature control without auxillary powerMechanical apparatusRefrigerantEvaporator

An expansion valve for an air conditioning system circulates refrigerant through a fixed-displacement compressor, a condenser, and an evaporator. An inlet is provided for receiving refrigerant liquefied in the condenser. An outlet of the expansion valve supplies refrigerant to the evaporator. A valve element controls flow of refrigerant between the inlet and the outlet, wherein the valve element is normally closed. A control assembly is coupled to the valve element and is responsive to at least one temperature or pressure in the air conditioning system to open the valve element to variably meter the refrigerant to the evaporator. A bleed passage bypasses the valve element to conduct refrigerant between the inlet and the outlet. The bleed passage is adapted to bleed refrigerant to the evaporator immediately after the compressor shuts off to prime the air conditioning system for a lower superheat when the compressor turns on, and the bleed path has a flow capacity substantially smaller than the flow capacity of the main valve aperture.

Owner:FORD GLOBAL TECH LLC

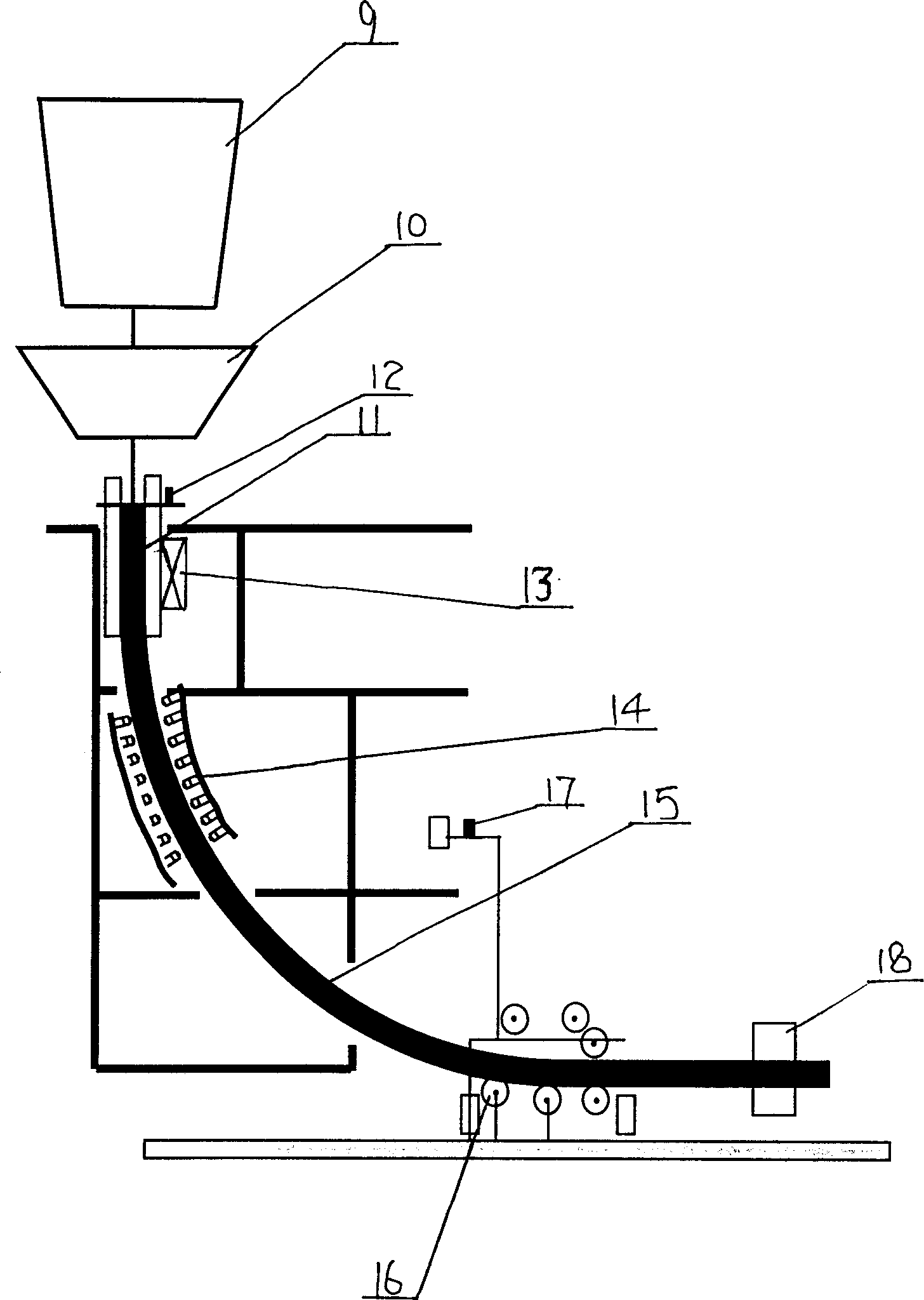

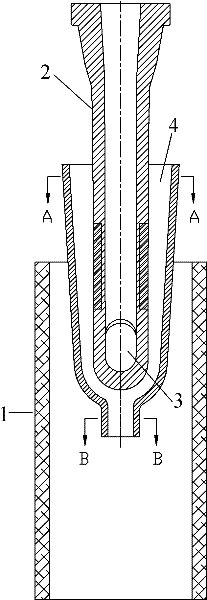

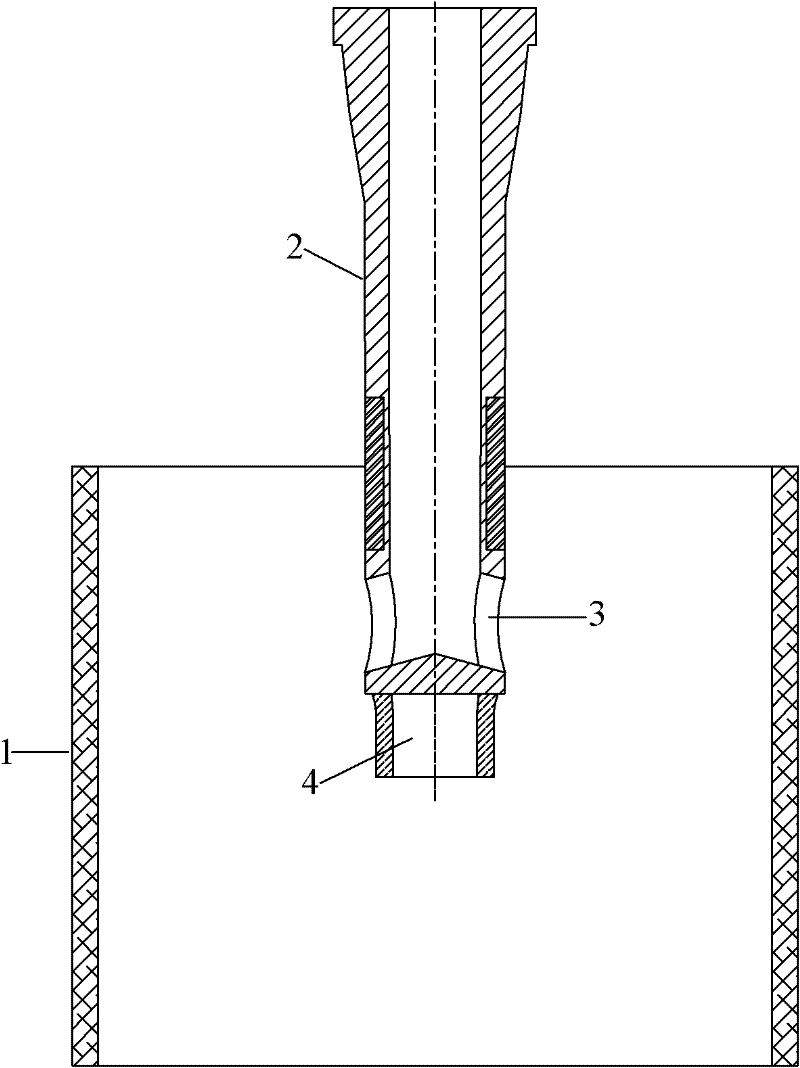

Method for improving internal quality of continuous casting and submerged nozzle for implementing method

The invention relates to a method for improving the internal quality of a continuous casting and a submerged nozzle for implementing the method. The submerged nozzle mainly comprises a long-barrel flat annular body submerged nozzle body with the bottom sealed, two arc surfaces at the upper end of the bottom of the nozzle are provided with symmetrical side holes; the two opposite side surfaces and hollow surfaces respectively arranged at the periphery are connected in a closing way to form an integrated feeding guide pipe; each hollow surface is inclined downward and extends while a certain distance is kept with each side surface of the nozzle body, thus all the feeding guide pipe are communicated at the bottom and form an exit section at the bottom of the nozzle body. In a continuous casting process, granular or bead-like, piece-like and strap-like part steel or iron product is continuously fed from the feeding guide pipes of the submerged nozzle and creeps down to the center of a molten pool of a crystallizer, degree of superheat of molten steel can be reduced, the cooling speed at the center is increased, formation of a central isometric crystal is promoted, enrichment and segregation of solute element at the center of a cast blank are prevented, solidification structure at the center of the cast blank is effectively optimized, and the density at the center of the cast blank is strengthened.

Owner:WISDRI ENG & RES INC LTD

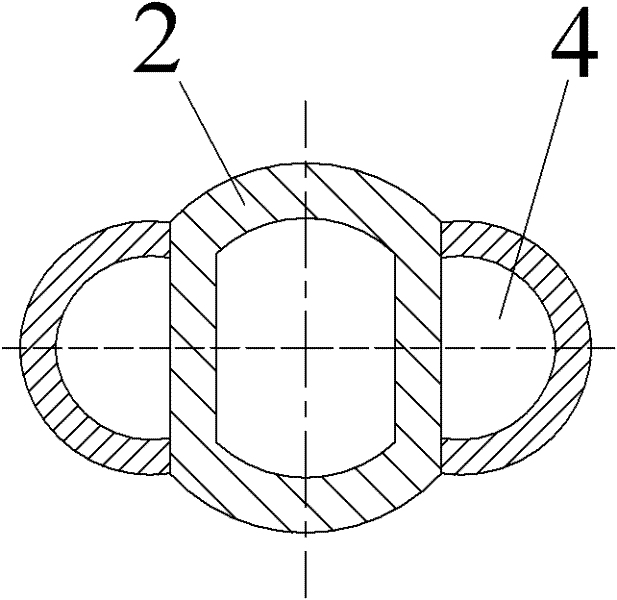

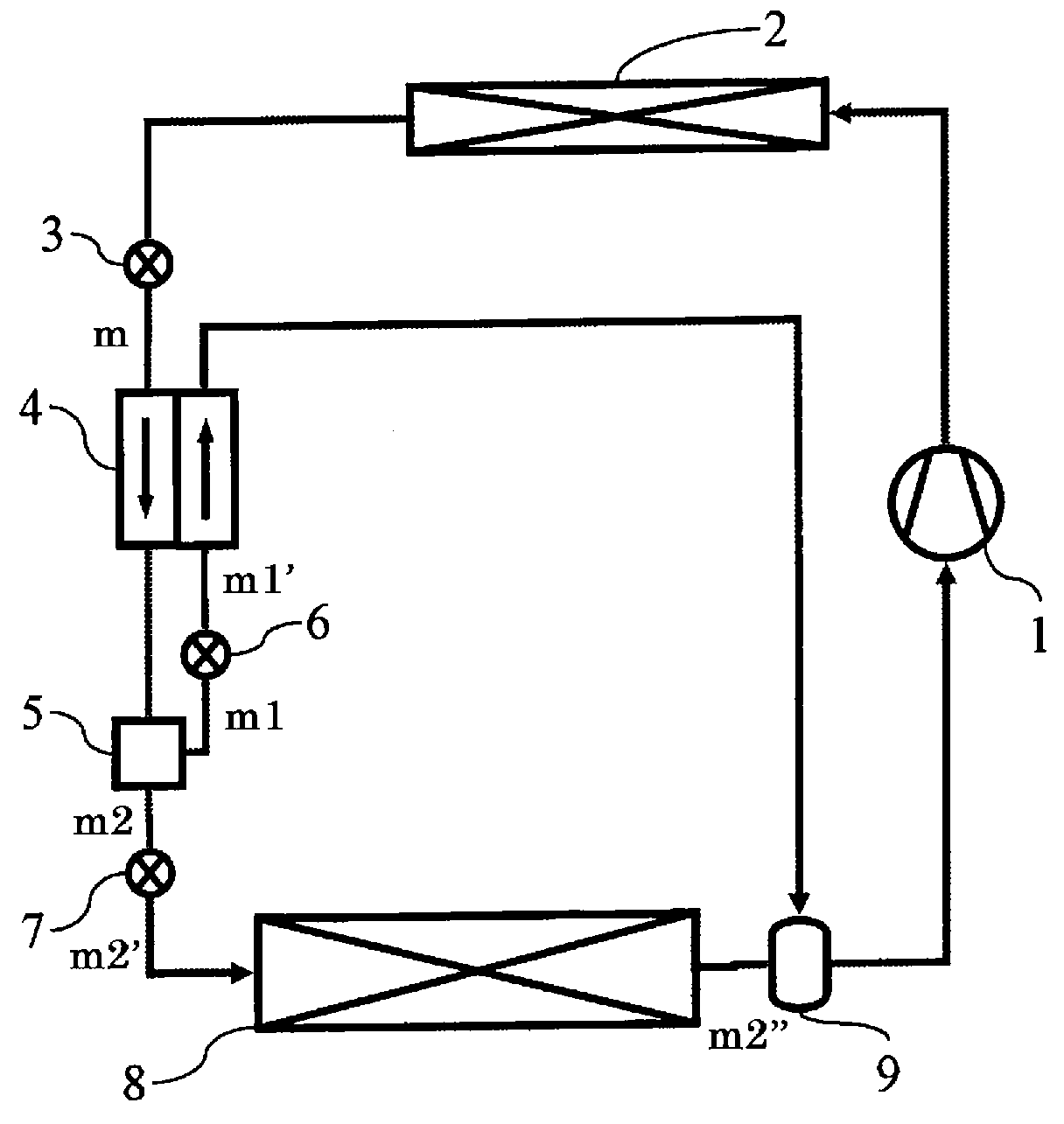

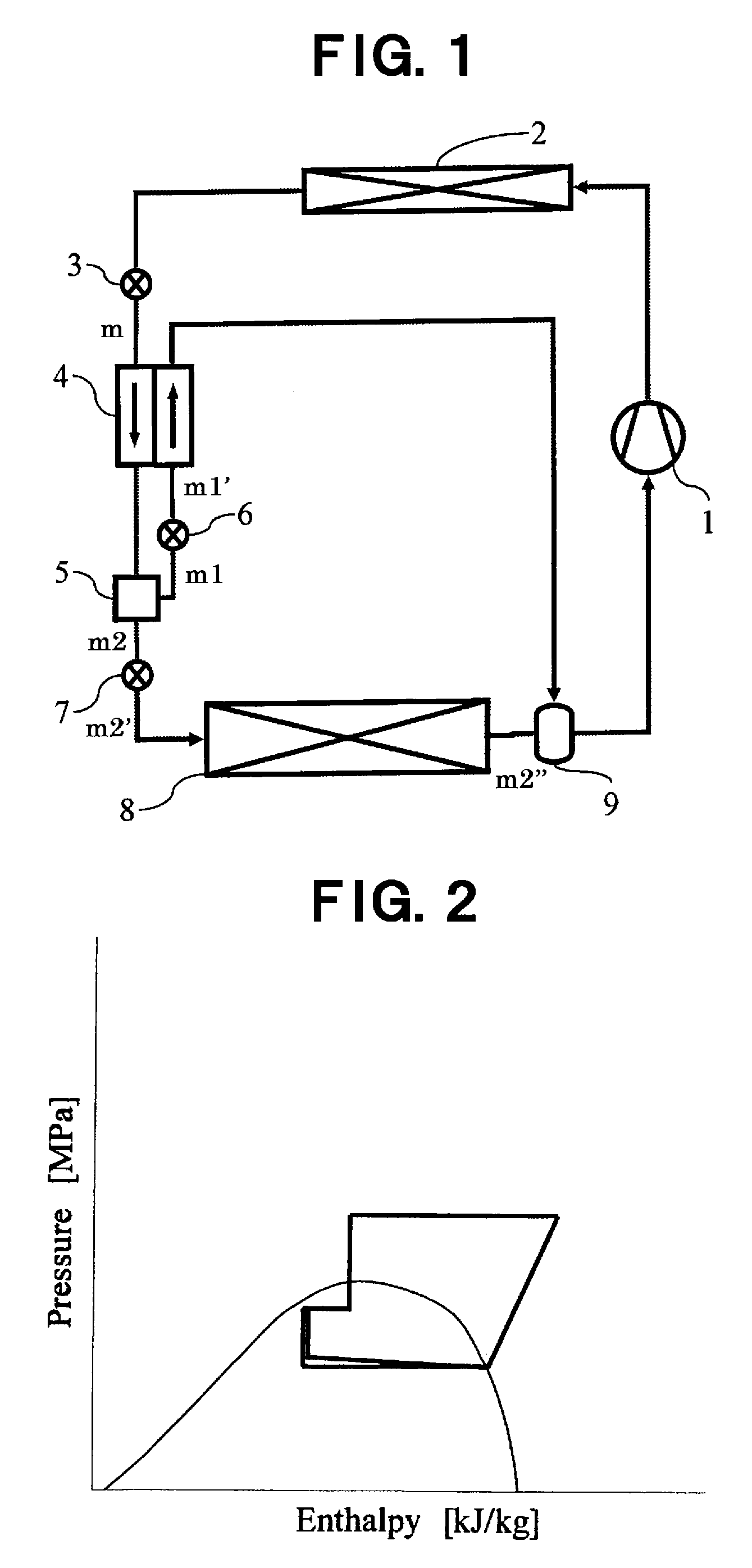

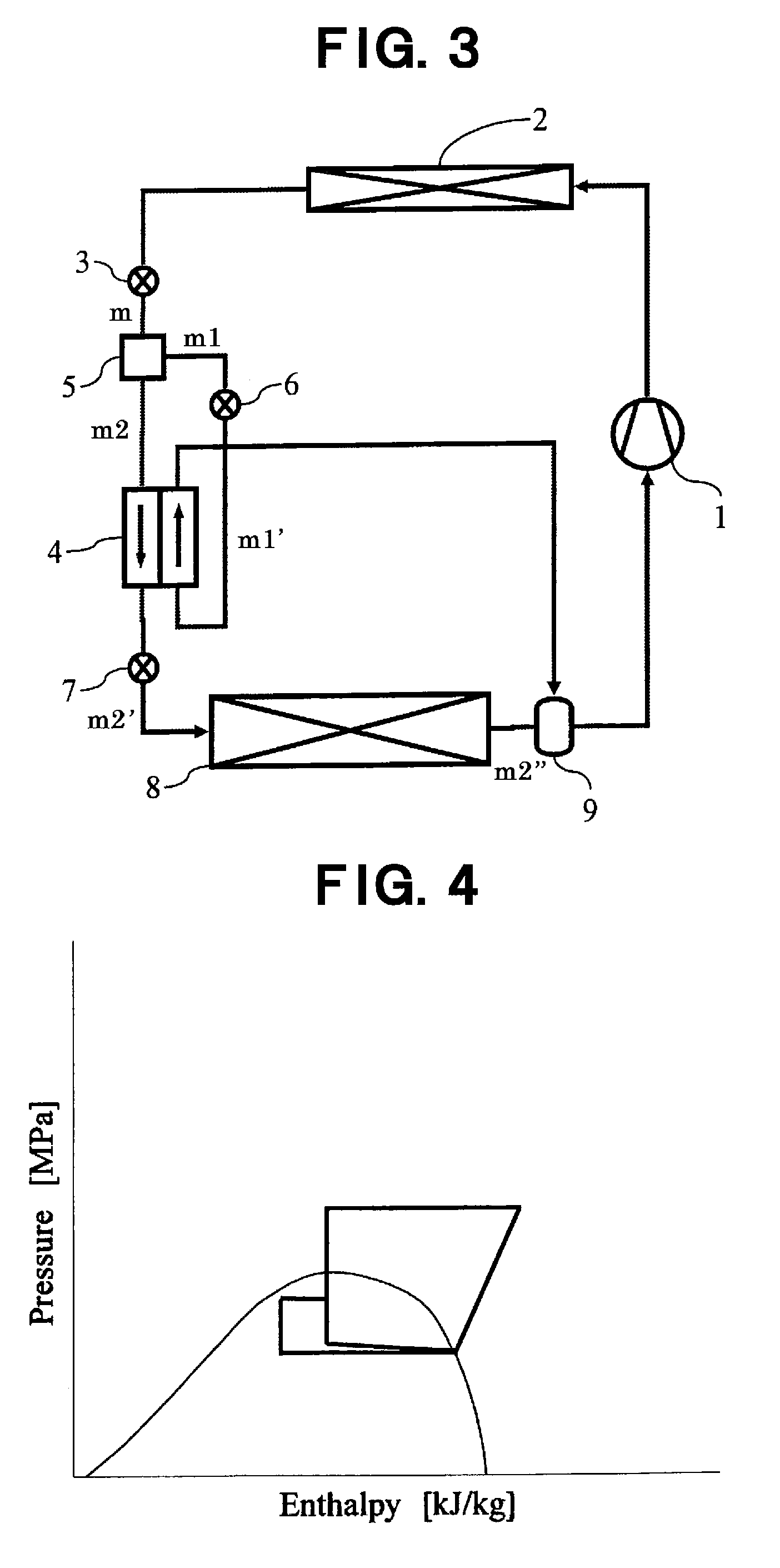

Vapor compression refrigerating systems

InactiveUS7370493B2Reduce superheatImprove the coefficient of performanceMechanical apparatusCompression machines with non-reversible cycleEngineeringRefrigerant

Owner:SANDEN CORP

Container refrigeration apparatus

ActiveCN102725597AAdjust heating capacityIncrease temperatureMechanical apparatusCompression machines with non-reversible cycleRefrigerantRefrigeration

Disclosed is a container refrigeration apparatus including a refrigerant circuit (20) which performs a refrigeration cycle and includes a main circuit (21) sequentially connecting a compressor (30), a condenser (31), a main expansion valve (32) and an evaporator (33), and a hot gas bypass circuit (22) through which a refrigerant compressed in the compressor (30) bypasses the condenser (31) and the main expansion valve (32) to flow into the evaporator (33); and a compressor control section (81) which controls operating speed of rotation of the compressor (30) during heating operation for heating inside of a container by the evaporator (33) while returning the compressed refrigerant from the compressor (30) to the compressor (30) through the hot gas bypass circuit (22) and the evaporator (33) so that a temperature inside the container reaches a target temperature.

Owner:DAIKIN INDUSTRIES LTD

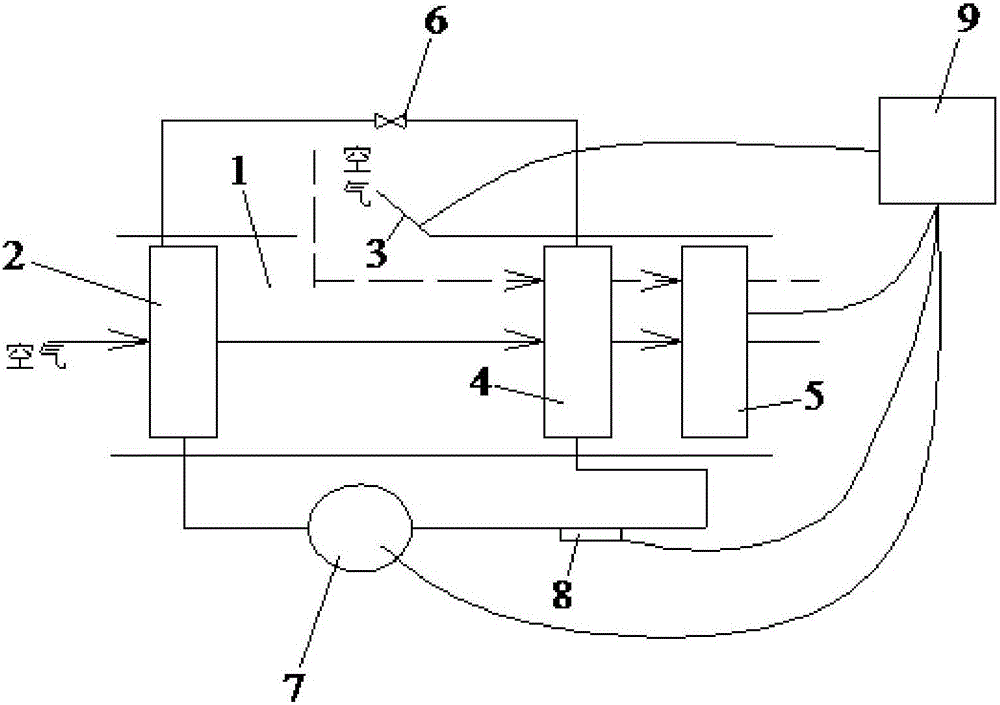

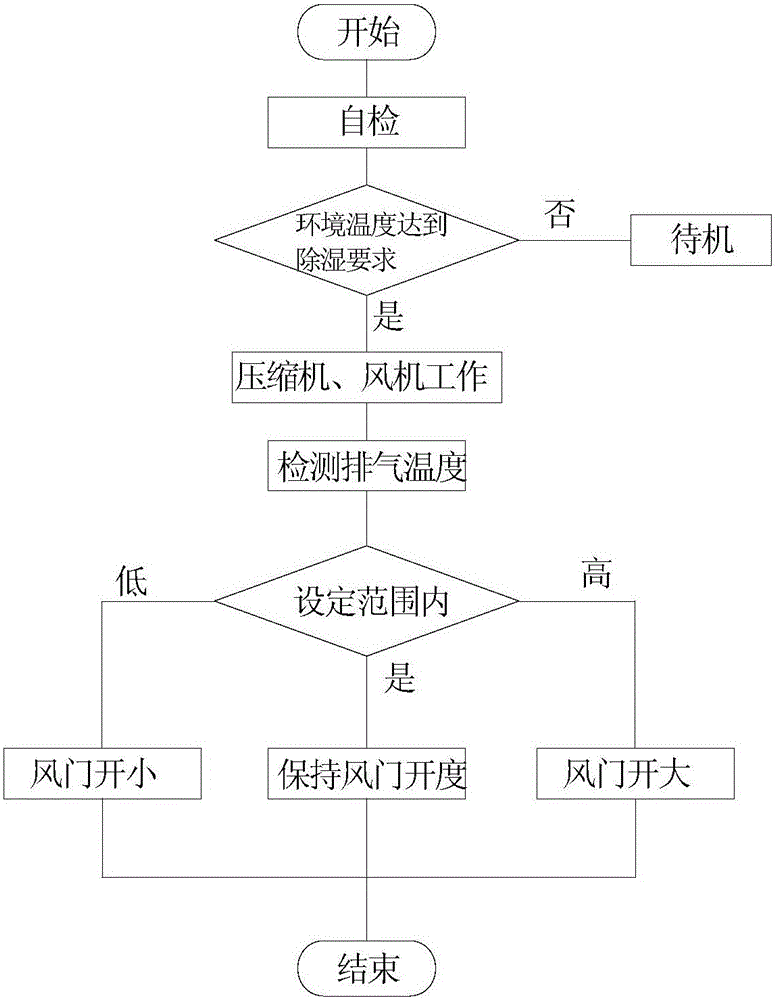

Dehumidifier with air volume regulation function

InactiveCN105757807AReduce air volumeIncrease air volumeMechanical apparatusSpace heating and ventilation safety systemsAir volumeEngineering

The invention discloses a dehumidifier with an air volume regulation function. The dehumidifier comprises a compression vapor refrigeration cycle part, an air volume regulation part and a control part, wherein the compression vapor refrigeration cycle part is composed of a compressor, a condenser, an expansion valve and an evaporator circularly connected by a pipeline in sequence; the compression vapor refrigeration cycle part is filled with a refrigerant; the air volume regulation part comprises an air duct, an air door, an execution device for opening and closing the air door, and a fan; the control part comprises a temperature sensor and an integrated circuit board. The dehumidifier provided by the invention adopts an air volume regulation method to reduce the air volume flowing through the evaporator and increase the air volume flowing the condenser at high temperatures, so that an effect of reducing the degree of superheat and reducing the high pressure of a system is achieved, the reliability of the dehumidifier working in high temperature conditions is improved effectively, and the dehumidifier can dehumidify a dehumidifying space within a wider range of ambient temperatures.

Owner:合肥天鹅制冷科技有限公司

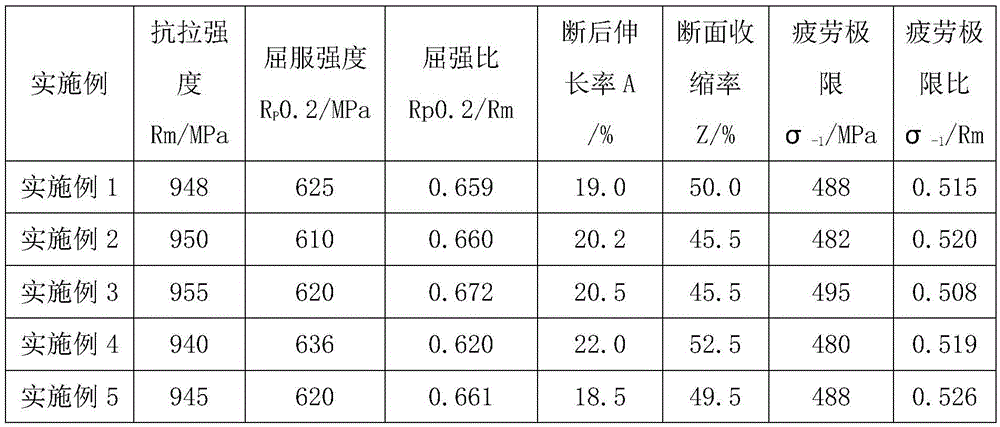

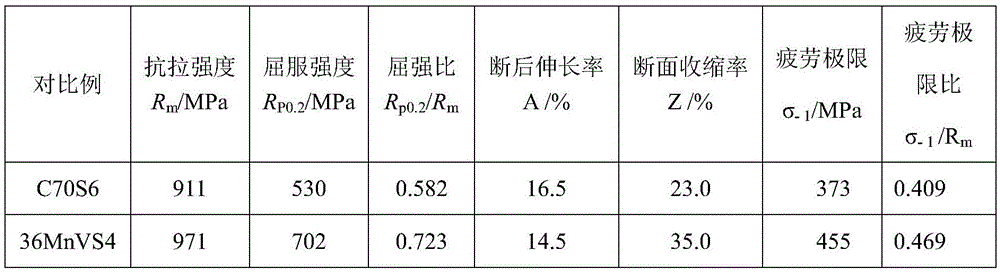

Non-quenched and non-tempered steel, production method of non-quenched and non-tempered steel and cracking connecting rod manufactured through non-quenched and non-tempered steel

ActiveCN105463318AImprove fatigue toughnessHigh fatigue toughnessConnecting rodsProcess efficiency improvementChemical compositionToughness

The invention provides non-quenched and non-tempered steel, a production method of the non-quenched and non-tempered steel and a cracking connecting rod manufactured through the non-quenched and non-tempered steel. The non-quenched and non-tempered steel is prepared from, by mass percent, 0.46%-0.52% of C, 0.70%-0.80% of Si, 1.53%-1.60% of Mn, 0.008%-0.015% of P, 0.02%-0.035% of S, 0.15%-0.25% of Cr, 0.20%-0.25% of Ni, 0.04%-0.07% of Mo, 0.02%-0.04% of Al, 0.14%-0.16% of V, 0.025%-0.035% of Nb, 0.001%-0.002% of B, 0.14%-0.25% of N and the balance Fe and inevitable impurity elements. The fatigue toughness of the steel can be improved through the element Nb. The element B can be segregated in a grain boundary and fused in ferrite separated out of the grain boundary, the separated-out ferrite is strengthened, and the cracking performance is improved.

Owner:SUZHOU SUXIN SPECIAL STEEL +2

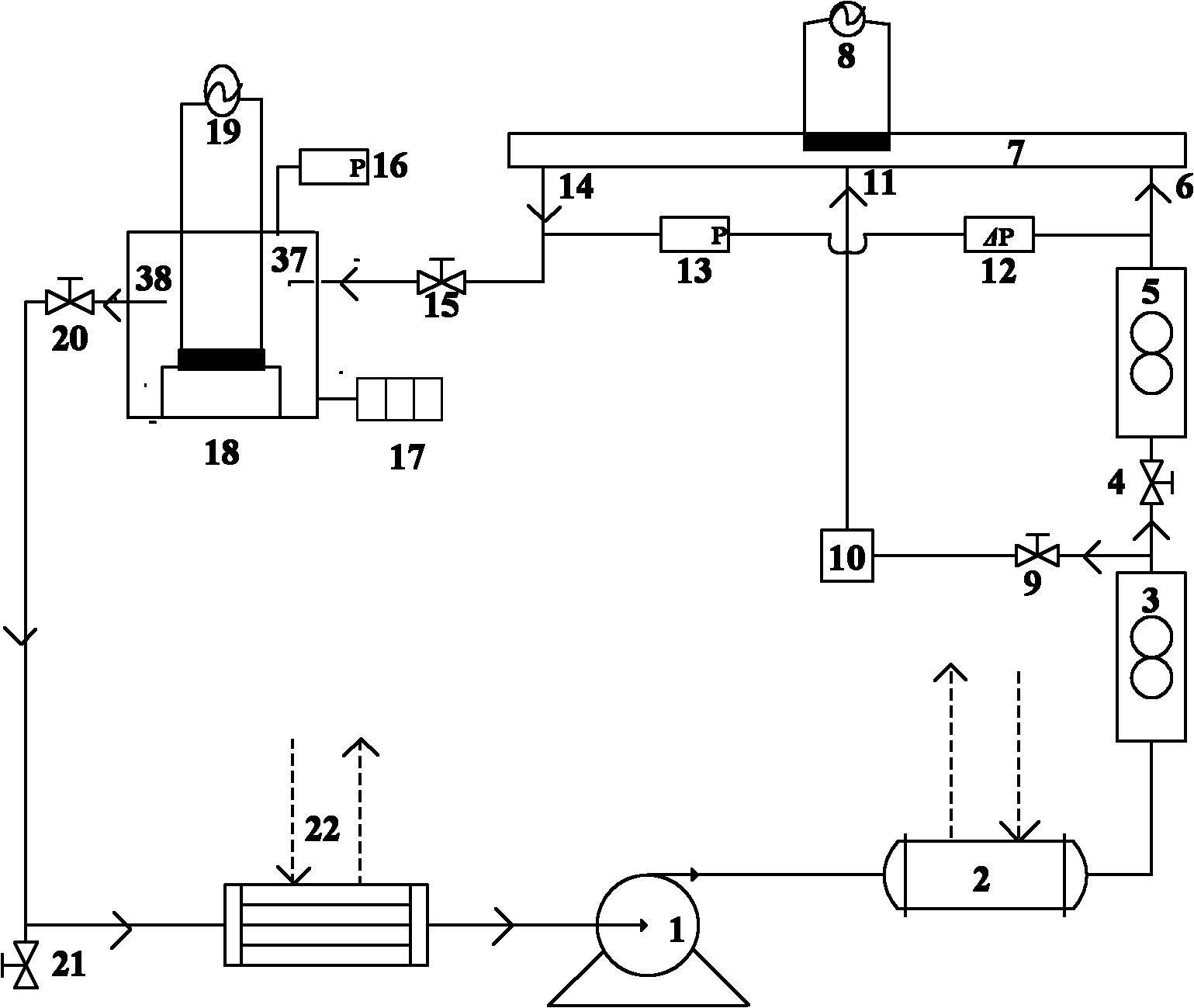

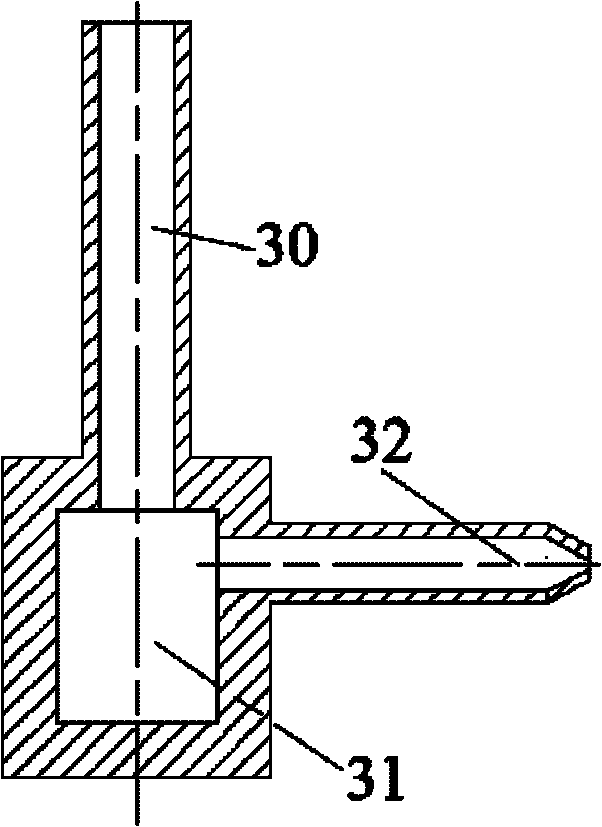

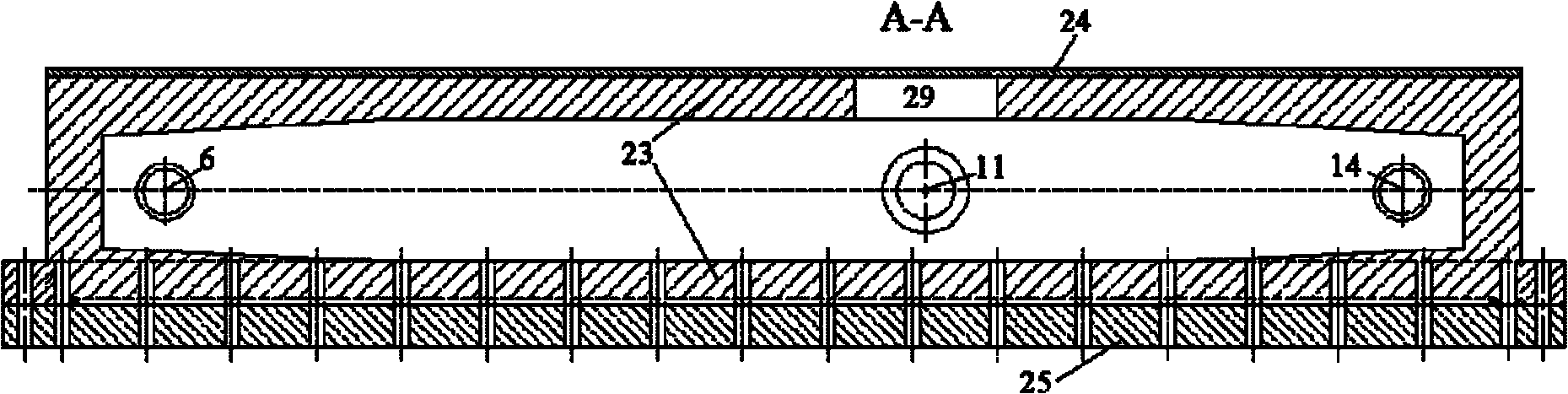

A multifunctional electronic chip cooling and boiling enhanced heat transfer experimental device

InactiveCN102279205AFlexible operationEasy to controlMaterial heat developmentElectrical testingEngineeringSmall footprint

A multifunctional electronic chip cooling and boiling enhanced heat exchange experimental device, comprising a vortex pump, the outlet of the vortex pump is connected to the inlet of a heater, the outlet of the heater is connected to the inlet of a total flowmeter, and the outlet of the total flowmeter is divided into two paths, one of which passes through a cross-flow branch. The back of the road enters the pure flow section, and the other road enters the pure flow section after passing through the injection branch. The outlet of the pure flow section is connected to the inlet of the boiling section of the pool. The outlet of the boiling section of the pool is divided into two paths. The inlet of the condenser is connected to the inlet of the vortex pump, and the outlet of the condenser is connected to the inlet of the vortex pump to complete a cycle, which combines the advantages of pool boiling, pure flow boiling and jet impingement boiling heat transfer, and removes some repetitive equipment and operation processes. Advantages of small land area.

Owner:XI AN JIAOTONG UNIV

Phase change heat exchanger

InactiveCN112797827AAvoid instability or even blockageReduce superheatIndirect heat exchangersHeat exchanger casingsEngineeringHeat sink

The invention relates to the technical field of heat dissipation and heat exchangers, and discloses a phase change heat exchanger. The phase change heat exchanger comprises a body, a cover plate and a heat dissipation assembly. The heat dissipation assembly comprises a plurality of heat dissipation parts, the adjacent heat dissipation parts are arranged at intervals to form micro-channels, a plurality of first pin fins are arranged in each micro-channel, and the micro-channels are combined to form a micro-channel area. The body comprises an inlet cavity and an outlet cavity, and the inlet cavity communicates with the outlet cavity through the micro-channel area. The cover plate is provided with an inlet pipe and an outlet pipe, the inlet pipe communicates with the inlet cavity, and the outlet pipe communicates with the outlet cavity. A brand-new micro-channel heat sink is provided mainly from the angles of increasing vaporization cores and enhancing the turbulence degree of fluid in the micro-channels, that is, pin fin structures are arranged on the upper bottom surfaces and the lower bottom surfaces of the micro-channels, so that the flowing boiling stability in the heat exchanger is enhanced, and the cooling and temperature equalizing effects of the heat sink are greatly improved.

Owner:GUANGDONG INST OF SEMICON IND TECH

Refrigerating system

InactiveCN1590931AReduce superheatLower evaporation temperatureDomestic cooling apparatusRefrigeration safety arrangementPressure riseLower limit

To provide a refrigeration system that can effectively solve an efficiency reduction due to a reduced low pressure side pressure of a refrigerant circuit. The refrigeration system 1, in which the refrigerant circuit comprises a controllable displacement compressor 37, a condenser 38, an expansion valve 44 and an evaporator 43, according to a low pressure side pressure of the refrigerant circuit, reduces the displacement of the compressor if the low pressure side pressure lowers to a lower limit value, which is set along with an upper limit value as limits of a given set value, or increases the displacement of the compressor if the upper limit value is reached, and also changes the set value according to the deviation of an actual temperature in a chamber cooled by the evaporator 43 from a set temperature of the chamber.

Owner:SANYO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com