Optimum scheme of ultra-supercritical secondary reheating unit

A secondary reheating, ultra-supercritical technology, applied in mechanical equipment, steam engine installations, machines/engines, etc., can solve problems such as limiting the heat absorption of the secondary reheating system and compressing the effective enthalpy drop of high-pressure cylinders. Conducive to stability, improved regenerative power ratio, and reduced number of cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

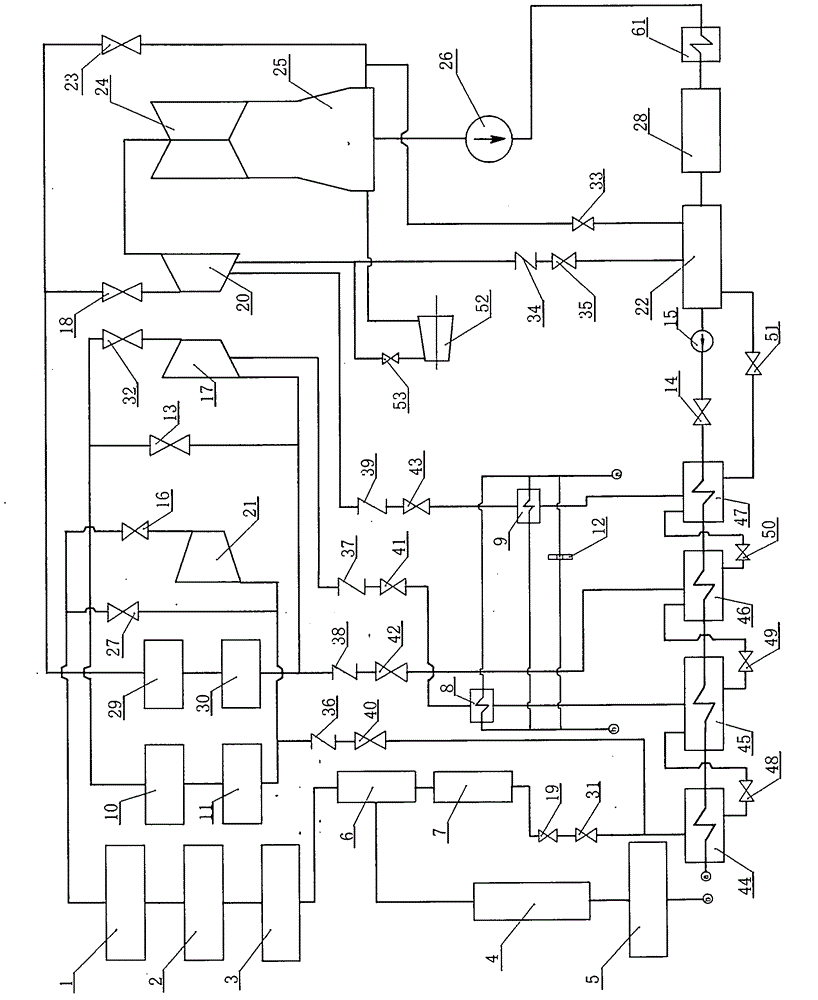

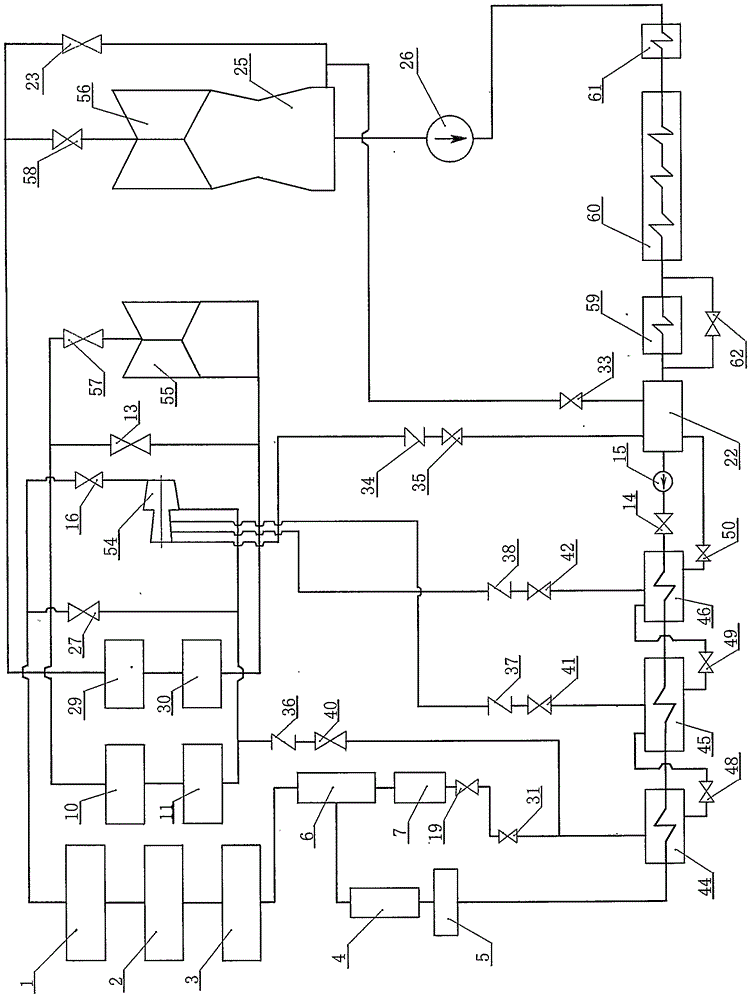

[0096] Combine now figure 2 , taking a 1200MW class, the design value of the main steam temperature / primary reheat steam temperature / secondary reheat steam temperature of the turbine side is 585°C / 620°C / 535°C as an example to illustrate the realization of the present invention preferred method.

[0097] The optimization scheme of an ultra-supercritical secondary reheating unit of the present invention includes: No. 1 high-intake steam inlet check valve (36), No. 1 high-intake steam inlet stop valve (40), and No. 2 high-intake steam inlet check valve Valve (37), No. 2 high-pressure inlet steam cut-off valve (41), No. 3 high-pressure gas inlet check valve (38), No. 3 high-pressure gas inlet cut-off regulating valve (42), deaerator decompression and exhaust steam Valve (33), deaerator inlet steam check valve (34), deaerator inlet steam stop valve (35), No. 1 high pressure heater (44), No. 2 high pressure heater (45), No. 3 high pressure heater Device (46), No. 1 high pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com