A multifunctional electronic chip cooling and boiling enhanced heat transfer experimental device

An electronic chip, heat-enhancing technology, applied in the direction of measuring device, measuring electricity, material thermal development, etc., can solve the problems of power supply and control operation equipment and repeated operation process, inability to achieve single chip cooling, small jet impact cooling range, etc. , to achieve the effect of small footprint, guaranteed contact and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

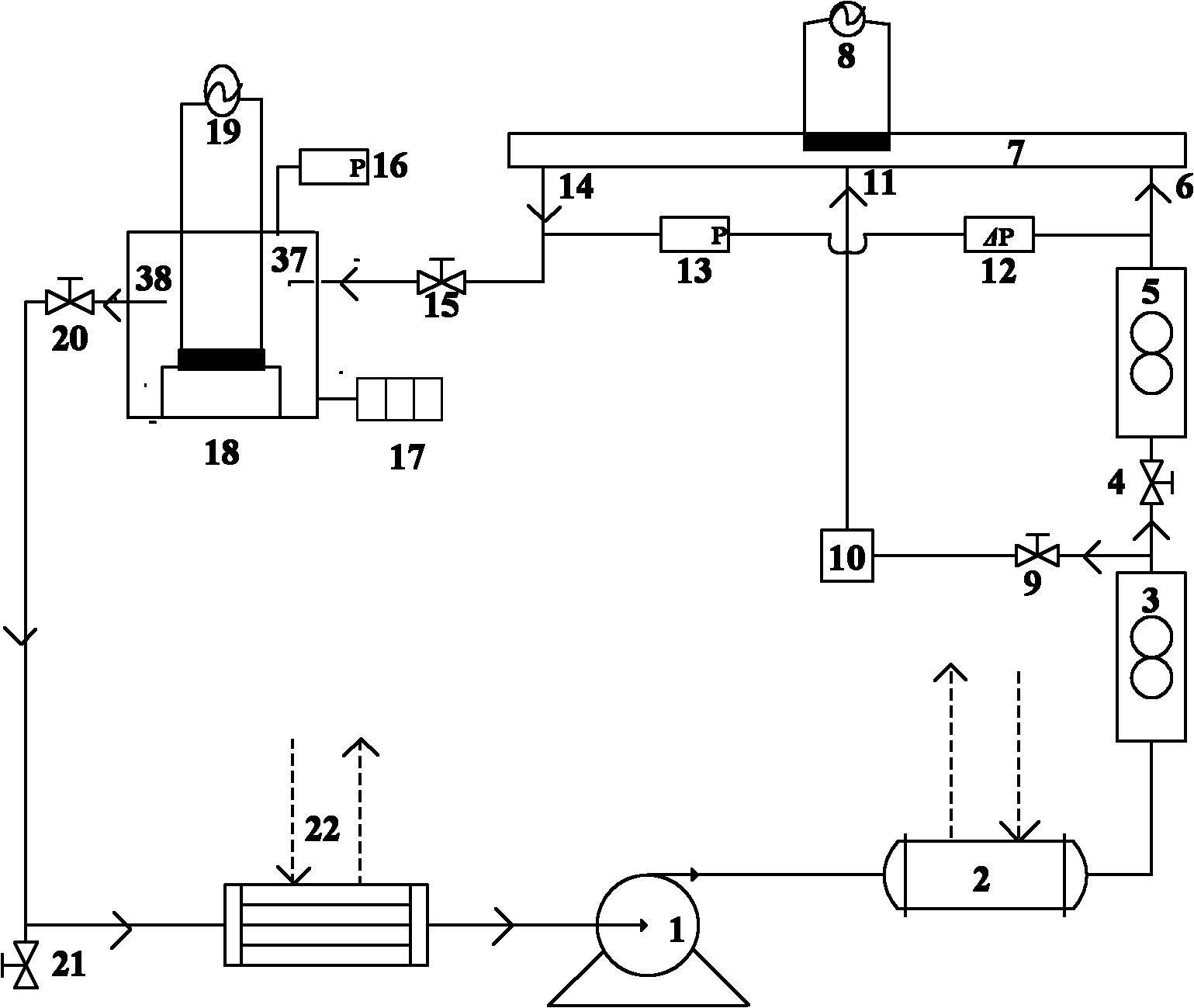

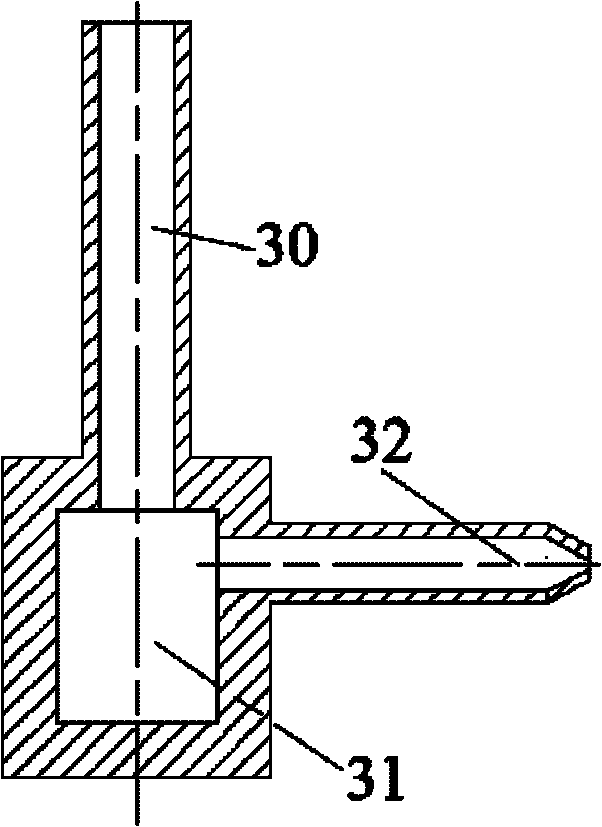

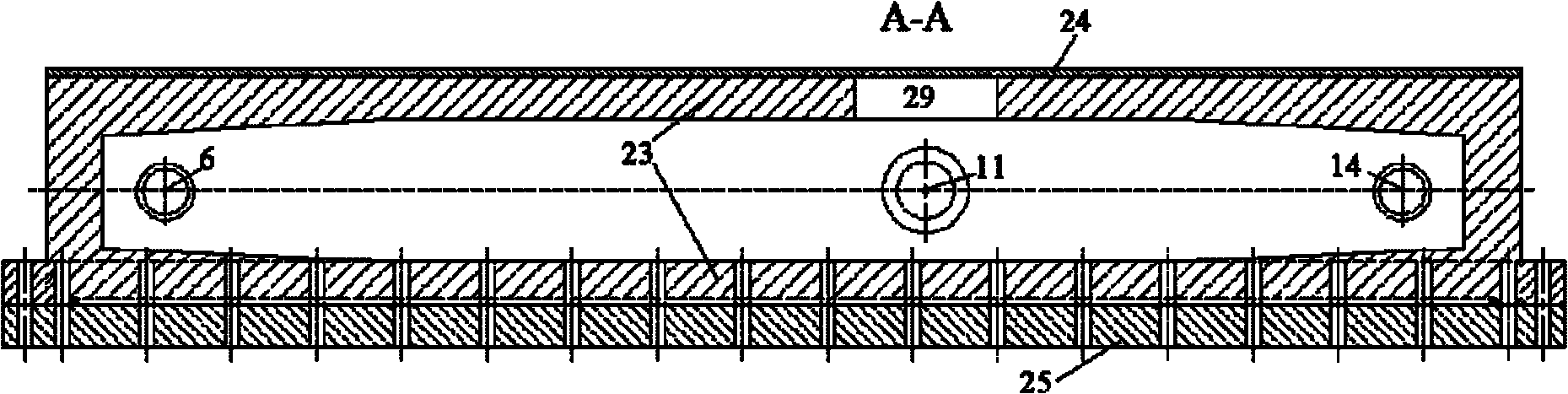

[0027] refer to figure 1 , Pic 4-1 with Figure 4-2 , a multifunctional electronic chip cooling and boiling enhanced heat transfer experimental device, including a vortex pump 1, the outlet of the vortex pump 1 is connected to the inlet of the heater 2, the outlet of the heater 2 is connected to the inlet of the total flow meter 3, and the outlet of the total flow meter 3 is divided into Two roads, one road enters the pure flow section 7 after passing through the cross-flow branch, and the other enters the pure flow section 7 after passing through the injection branch. The outlet 14 of the pure flow section is connected to the inlet 37 of the pool boiling section through the third control valve 15, and the pool boiling section The outlet 38 is divided into two paths after passing through the fourth control valve 20, one path is connected with the fifth control valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com