Electroslag smelting casting device with additional electromagnetic stirring and method

A technology of electroslag casting and electromagnetic stirring, which is applied in the field of electroslag metallurgy of special steel, can solve the problems of reducing the penetration ability of magnetic field and affecting the function of electromagnet, so as to improve the surface and subcutaneous quality, improve the solidification structure, and optimize the operating parameters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

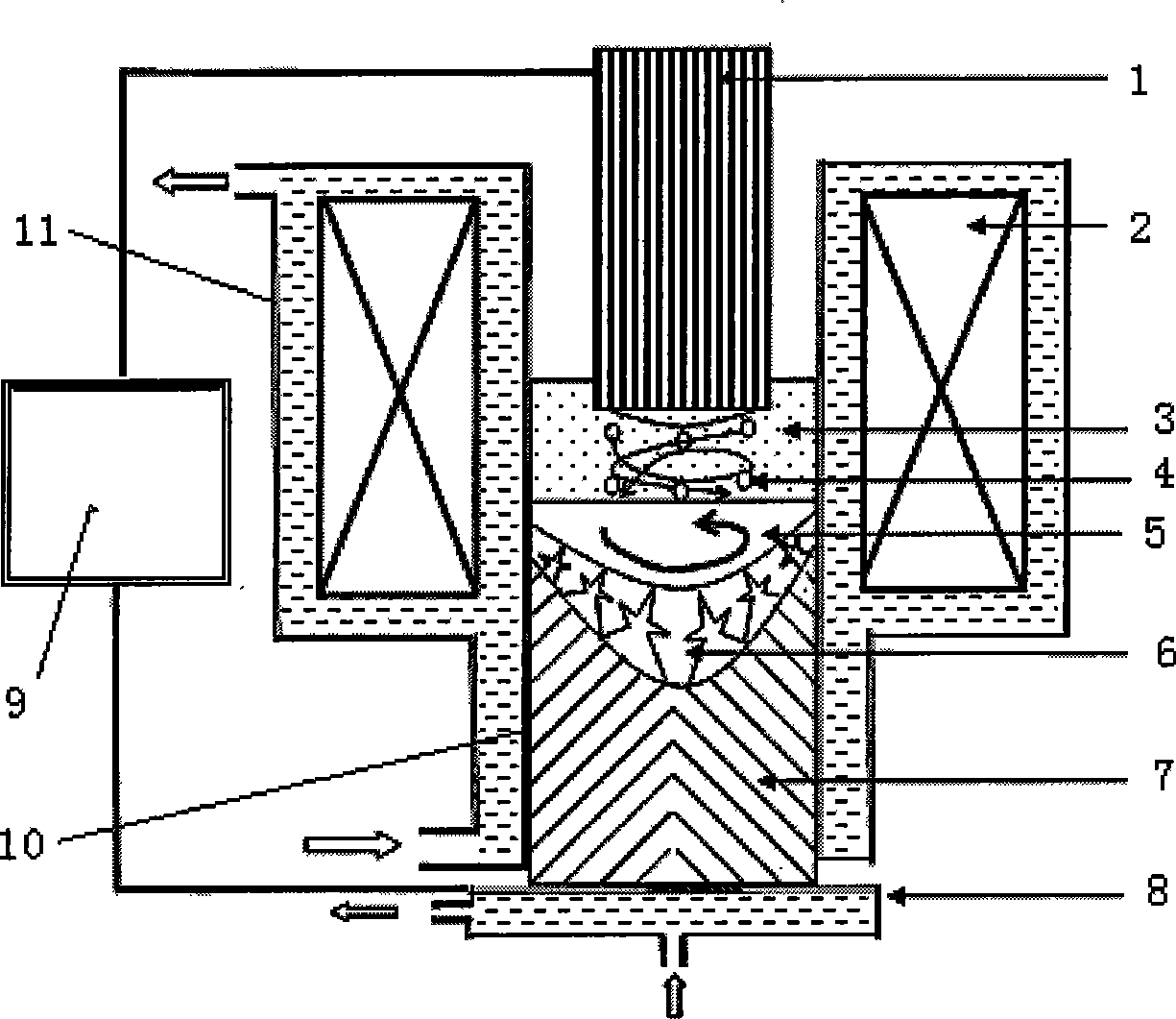

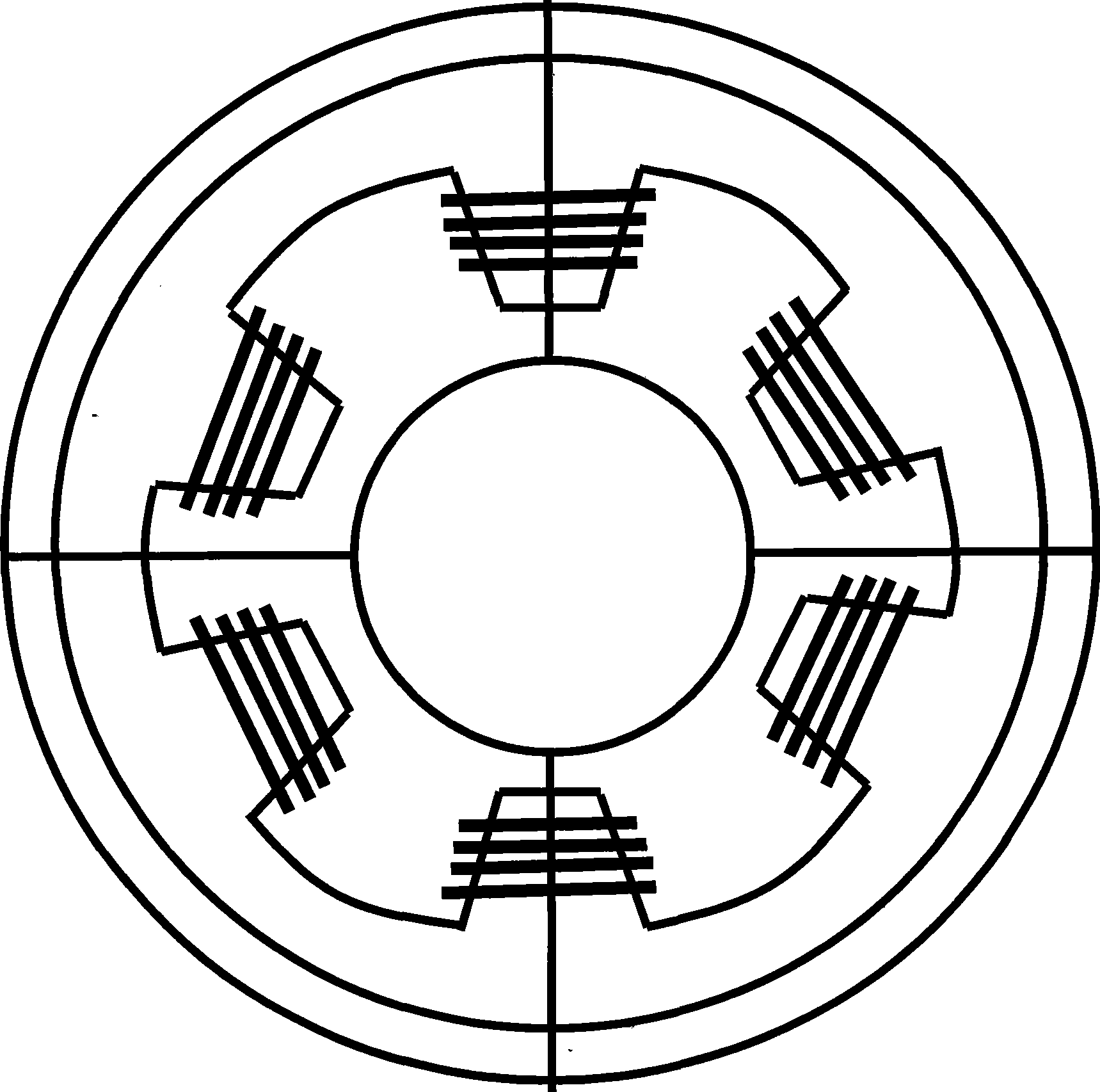

[0016] Such as figure 1 As shown, an electroslag casting device with external electromagnetic stirring includes a power supply 9, a consumable electrode 1, a crystallizer and a stirrer, and the crystallizer includes a slag pool 3 and a molten metal pool 5, a crystallizer and an electromagnetic stirrer Combined into one, the cooling water fed into the crystallizer is used not only for the solidification of the steel ingot, but also for the cooling of the coil that generates the magnetic field. The reduction of three layers to one layer can greatly reduce the loss of magnetic energy due to the skin effect of the magnetic field. There is a ring magnet on the outer wall of the crystallizer. The ring magnet is located above 1 / 2 of the mold, and a coil is wound on the iron core of the ring magnet. .

[0017] The cooling water is passed into the crystallizer from the cooling water inlet, the electromagnet and the coil 2 without power are also immersed in the cooling water at the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com