Improved method of vibration exciting metal liquid shape crystal nucleus and its device

A liquid metal and metal technology, applied in the field of metal casting, can solve the problems of inability to act on unsolidified metal liquid, short ultrasonic action distance, complex equipment structure, etc. The effect of internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

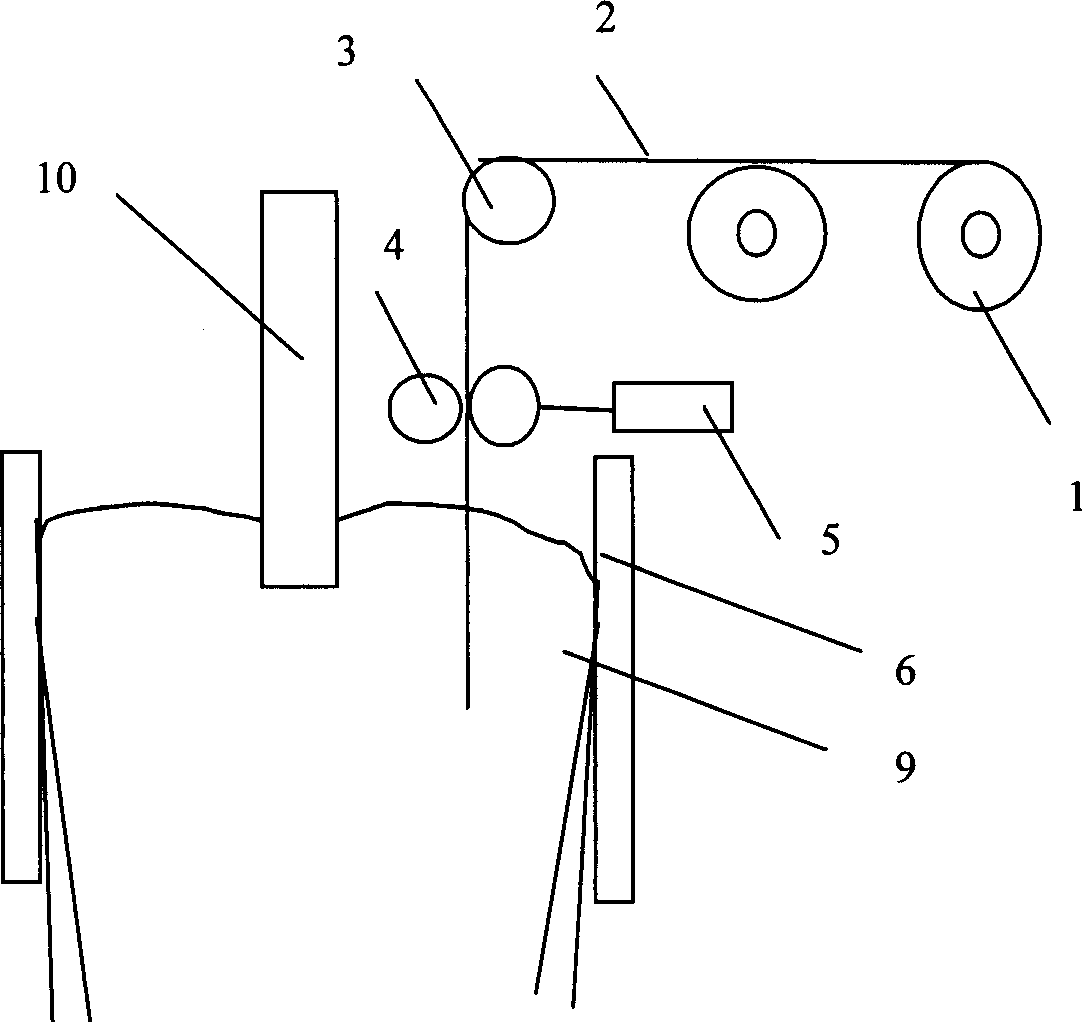

[0030] The specific implementation manner of the invention will be further introduced in detail below in conjunction with the accompanying drawings.

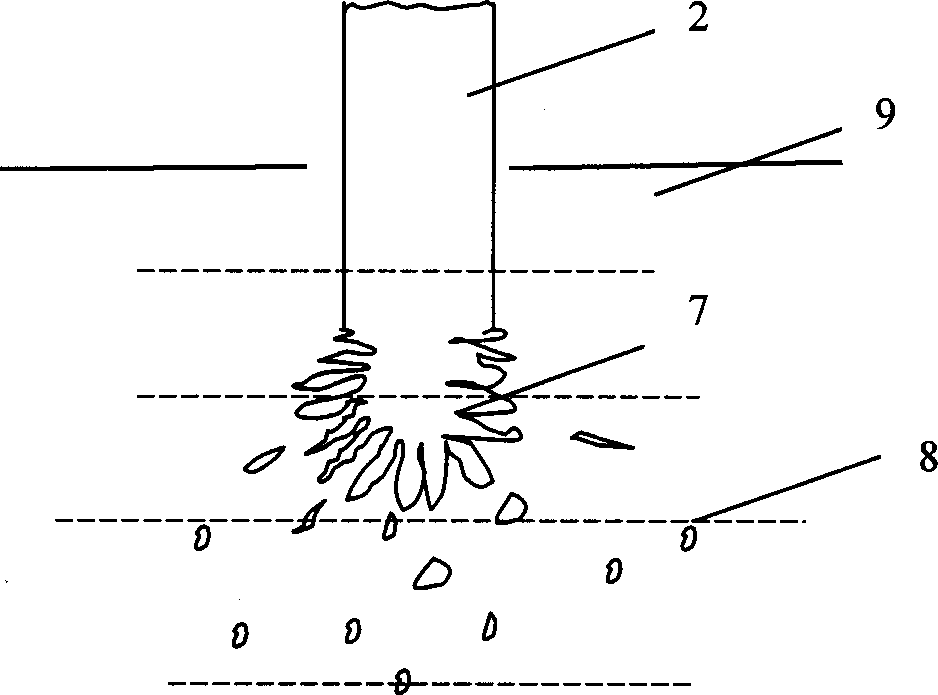

[0031] The device of this invention is made up of four parts (see figure 1 ): cold material uncoiling device, cold material straightening device, high-frequency small-amplitude vibration generating device, and vibration transmission and action device. Among them: through the action of the uncoiling device 1, the cold material 2 whose composition is within the required range is uncoiled and straightened in the straightening device 3, and the vibration source 5 and the vibration device 4 are used for high-frequency and small-amplitude vibration, and then continuously fed into the crystallizer 6. When the cold material is fed into the crystallizer 6 in the form of vibration (see figure 2 ), the front end of the cold material is in contact with the molten metal 9 in the crystallizer. While the cold material itself is continuously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com