System and method for comprehensive treatment of salt-containing wastewater

A technology for comprehensive treatment of salt-containing wastewater, applied in the field of MVR evaporation and crystallization system, can solve the problems of high economical moisture content, high recycling cost and low evaporation temperature of recovered crystalline salt, and achieves enhanced phase transformation heat effect, recovery The effect of fast efficiency and high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

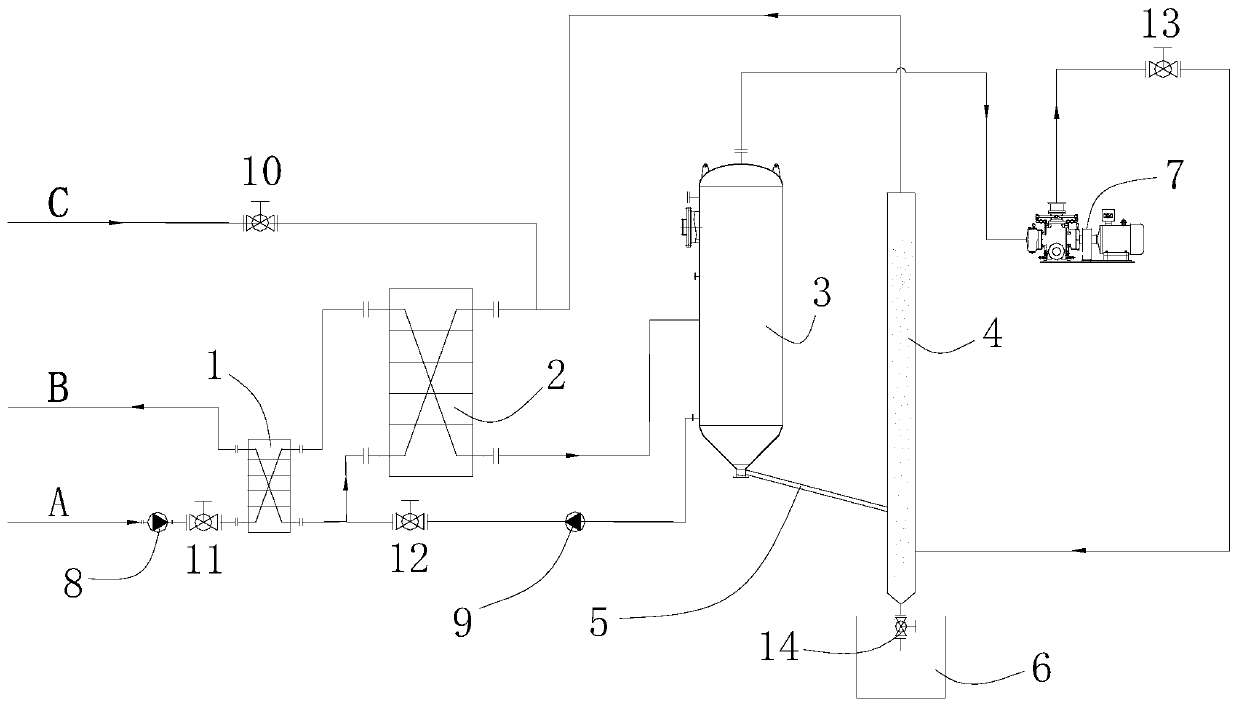

[0020] The experimental equipment and reagents in the present invention are conventional products in this technical field, figure 1 The arrows in indicate the flow direction of materials, condensed water or steam; A represents the normal temperature feed, B represents the condensed water outlet, and C represents the tap water inflow direction.

[0021] see figure 1 , which is a comprehensive treatment system for salty wastewater, including a preheater 1, an evaporator 2, a flash tank 3, a dryer 4, a descending pipe 5, a crystalline salt collection tank 6, a steam compressor 7, a feed pump 8, Circulating pump 9 and related connecting pipes; the inlet pipe of the cold side of the preheater 1 is communicated with the normal temperature raw material liquid through the connected feed pump 8, the inlet of the hot side of the preheater 1 is communicated with the outlet of the hot side of the evaporator 2; the cold side of the evaporator 2 is communicated The inlet pipes are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com