Patents

Literature

73results about How to "Simplify equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

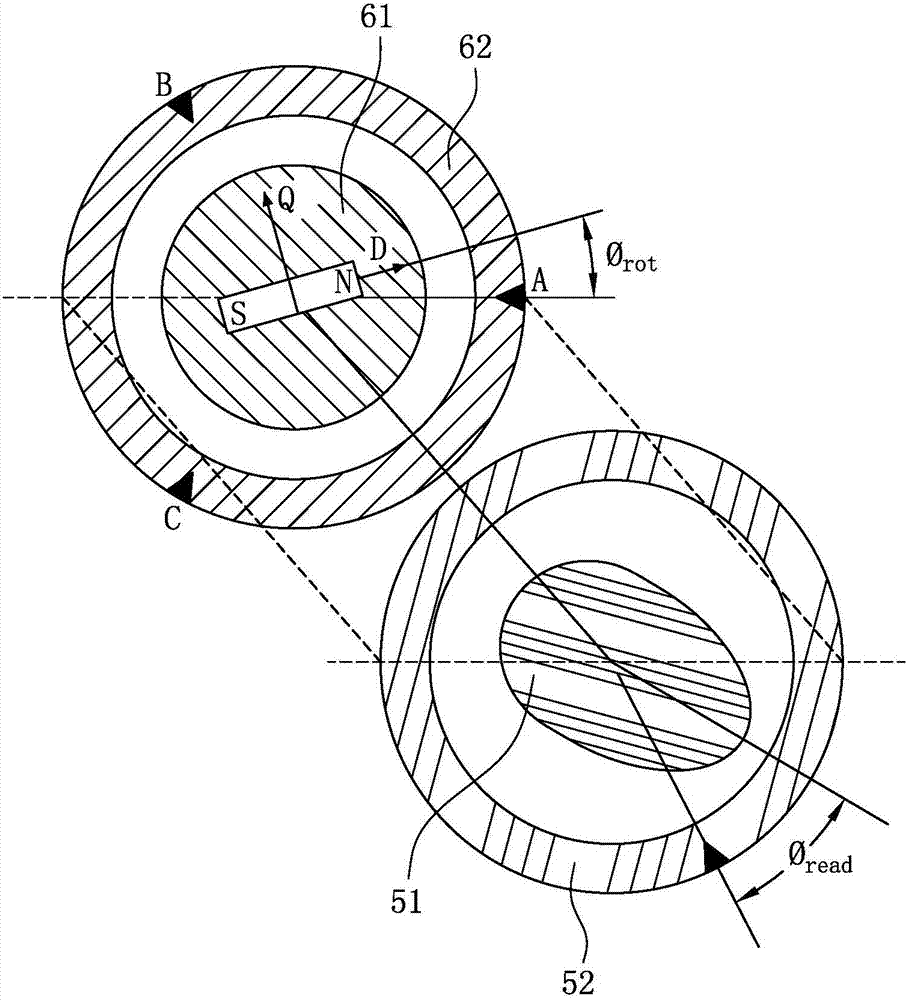

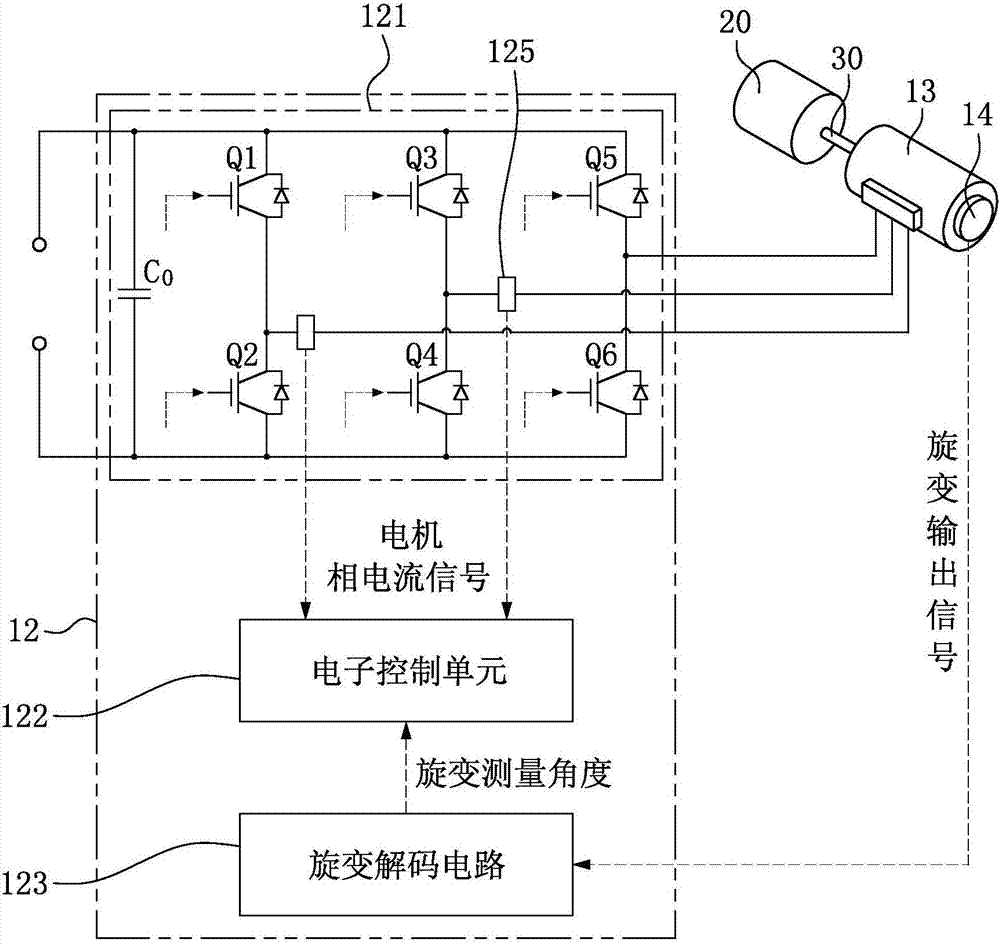

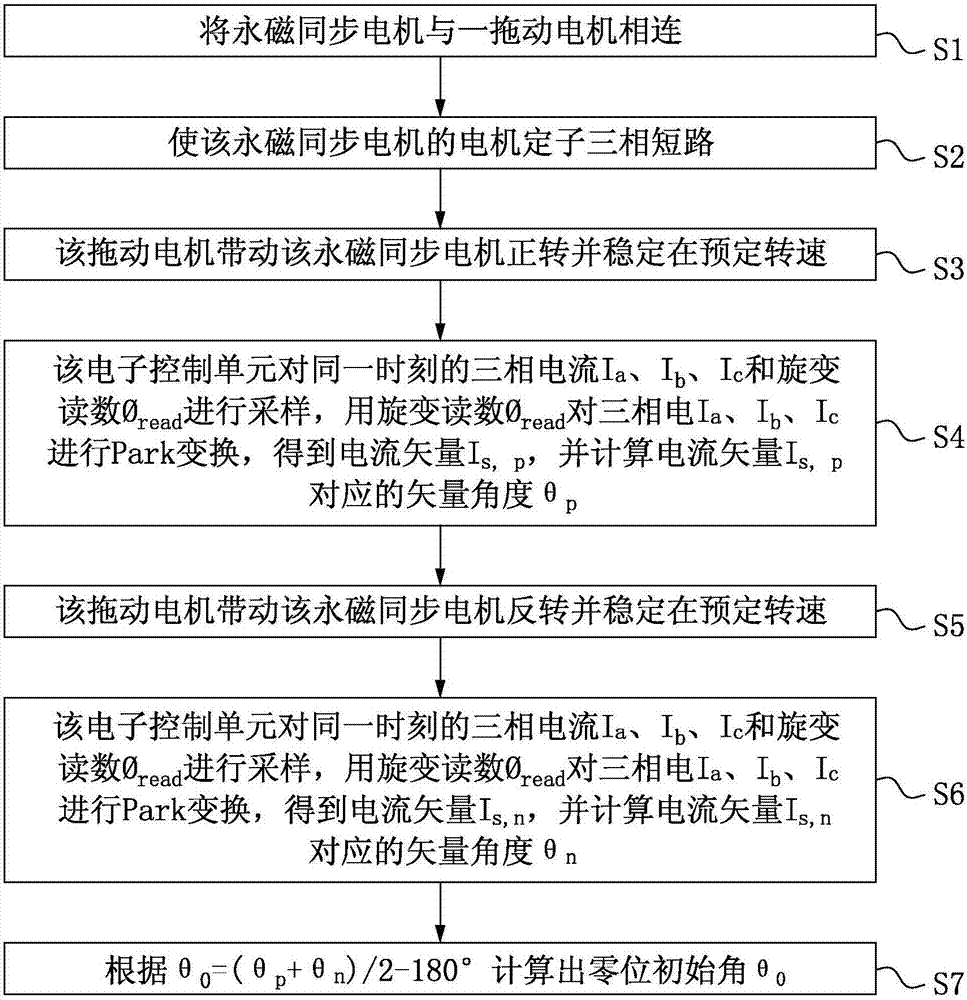

PMSM rotary transformer zero position initial angle calibration method and calibration system

ActiveCN107404272ACalibration is easy to operateCalculation method is simpleAC motor controlVector control systemsThree-phaseDrive motor

The invention discloses a PMSM rotary transformer zero position initial angle calibration method and calibration system. The PMSM rotary transformer zero position initial angle calibration method comprises steps of connecting an PMSM, on which a rotary transformer is installed, to a driving motor, enabling a motor stator of the PMSM to perform three-phase short circuit, using the driving motor to drive the PMSM to rotate forward and maintain at a preset rotation speed, using an electronic control unit to perform sampling on three phase current Ia, Ib and I c and a rotary transformer reading phi read at a same moment, using the rotary transformer reading phi read to perform Park conversion on three phase current Ia, Ib and Ic to obtain current vectors Is,p, calculating a vector angle theta p corresponding the current vector Is,p, using the driving motor to drive the PMSM to rotate backwards and maintaining the rotation at a preset rotation speed, using the electronic control unit to record a vector angle theta n corresponding to a current vector Is,n when the motor is rotated backwards, and calculating that a practical electric rotation angle theta 0 corresponding to the rotary transformer reading zero point angle is a zero position initial angle according to a formula theta 0=(thetap+thetan) / 2-180 degree.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Foam compound oil displacement agent and preparation method thereof

ActiveCN101735789AEvenly distributedSimplify the construction processDrilling compositionChemical reactionNitrite

The invention provides a foam compound oil displacement agent, comprising the following components by weight percent: agent A containing 50-70% of urea, 10-30% of ammonium chloride and 8-25% of acid producing substance, agent B containing 30-60% of nitrite, 8-35% of sodium dichloroisocyanurate, 10-20% of surfactant and 10-20% of polymer. The foam compound oil displacement agent provided by the invention enters into stratum or rock shaft, gas is produced by chemical reaction under stratum condition, surfactant and polymer in oil displacement agent are coordinated, and massive foam is formed onthe stratum, the generated foam is stable and evenly distributed, the gas produced by self reaction of solution instead of external gas is utilized to form foam, thus simplifying construction processand device.

Owner:华鼎鸿基采油技术服务(北京)有限公司

In situ modified waste rubber powder composite material and preparing method thereof

The invention refers to a kind of in situ modified waste rubber powder compound material and the manufacturing method. The method puts the waste rubber powder pulverized by normal machine without surface preprocessing into each kind of rubber or thermal plasticity plastics by normal rubber plastic process and device, through specific conjugate ternary interpenetration polymer network and the interface conjugate interpenetration technique, the rubber powder and the rubber or the plastic are modified in situ and combined tightly, thus forms the sulfide rubber or thermal plasticity elastic material. The process is simple, the cost is low, and the product has a good performance, it can be applied to produce each kind of sulfide product or thermal plasticity elastic product.

Owner:SOUTH CHINA UNIV OF TECH

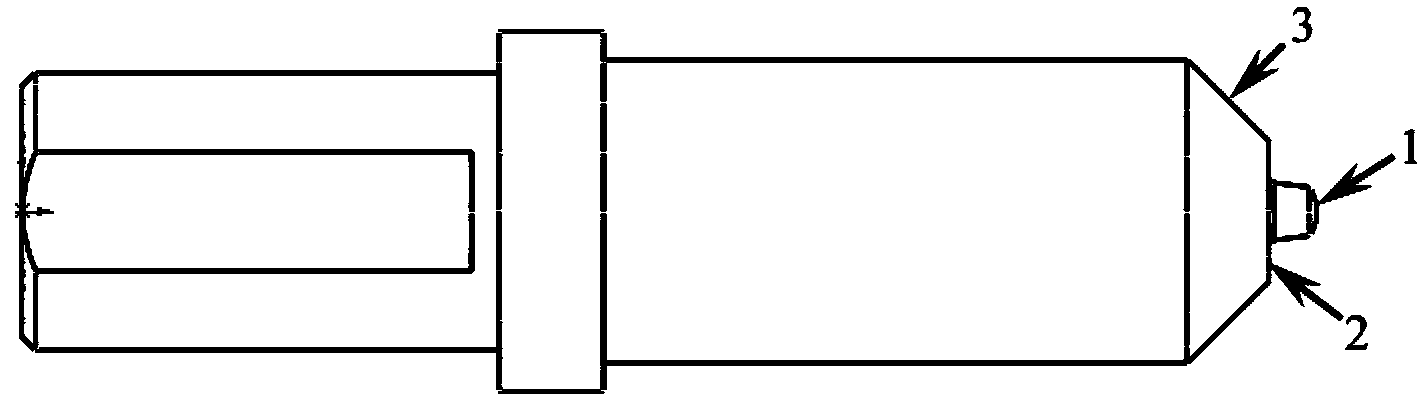

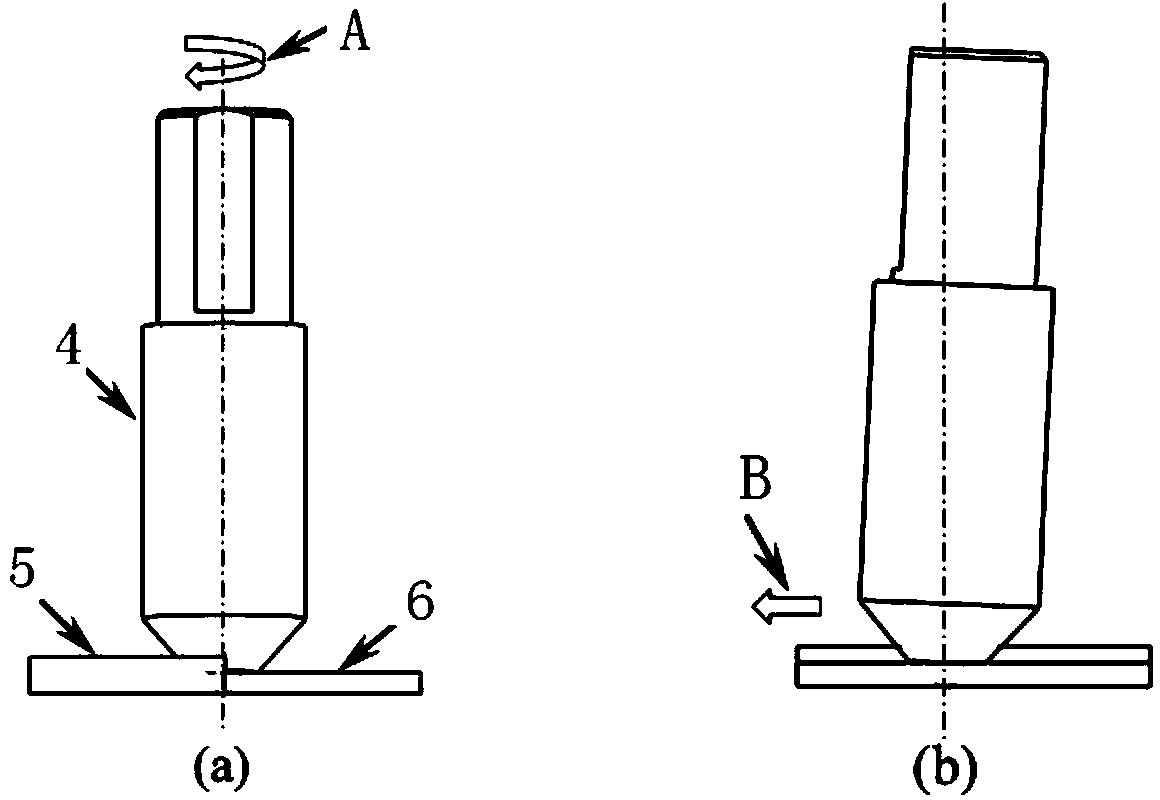

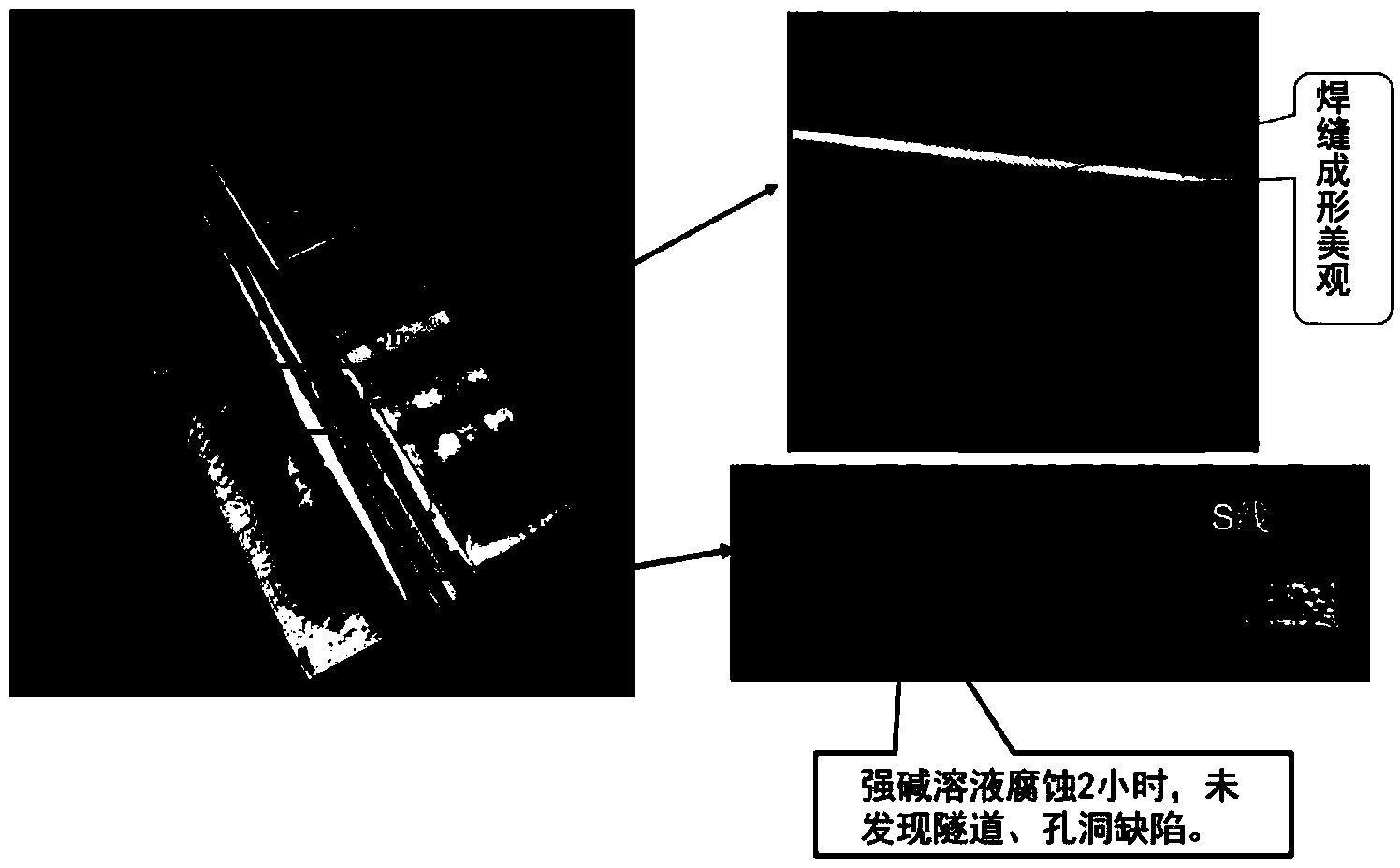

Stirring head for friction stir welding used for welding parts with different thicknesses and welding method

InactiveCN103949769AIntegrity guaranteedGuaranteed reliabilityWelding/soldering/cutting articlesMetal working apparatusEngineeringFriction stud welding

The invention relates to a stirring head for friction stir welding used for welding parts with different thicknesses and a welding method. A cutting accessory shaft shoulder is added on the basis of the existing stirring head, and the accessory shaft shoulder plays a role in cutting and removing the redundant material on the thicker side of connectors having different thicknesses to acquire a flat friction stir welding joint. The method is carried out on common friction stir welding equipment, a nose or tool of the equipment is not transformed at all, then the requirements on the equipment and the welding method are greatly simplified; in addition, in the welding process, a shaft shoulder of the stirring head and the two side surfaces of the part are parallel, so that the phenomena that metal of the connector is insufficiently extruded or damaged by shearing are not caused, the integrity and the reliability of the part are guaranteed; moreover, the accessory cutting shaft shoulder of the stirring head also plays an important role as for the part whose thickness suddenly changes, and the smooth welding process of the part is guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

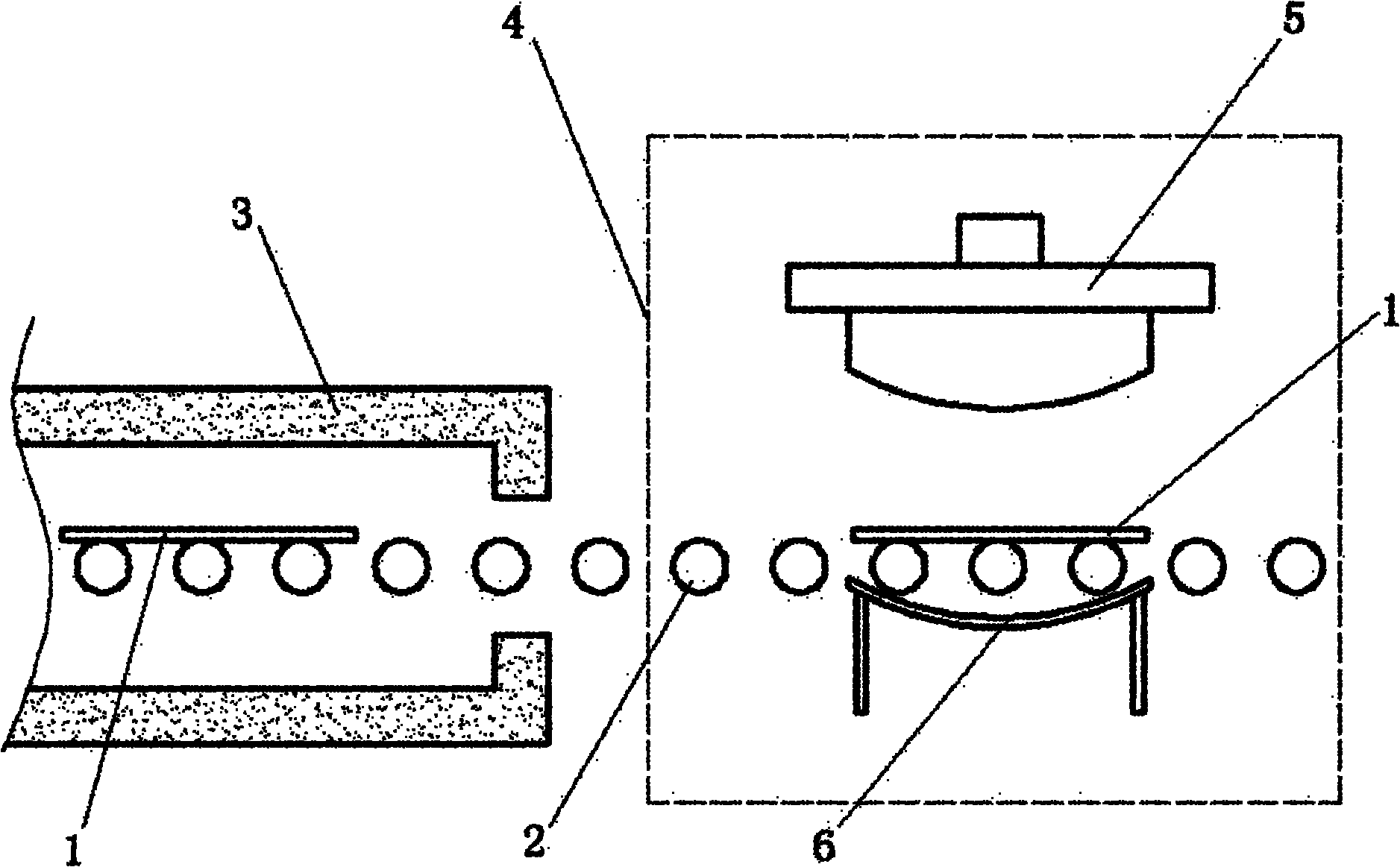

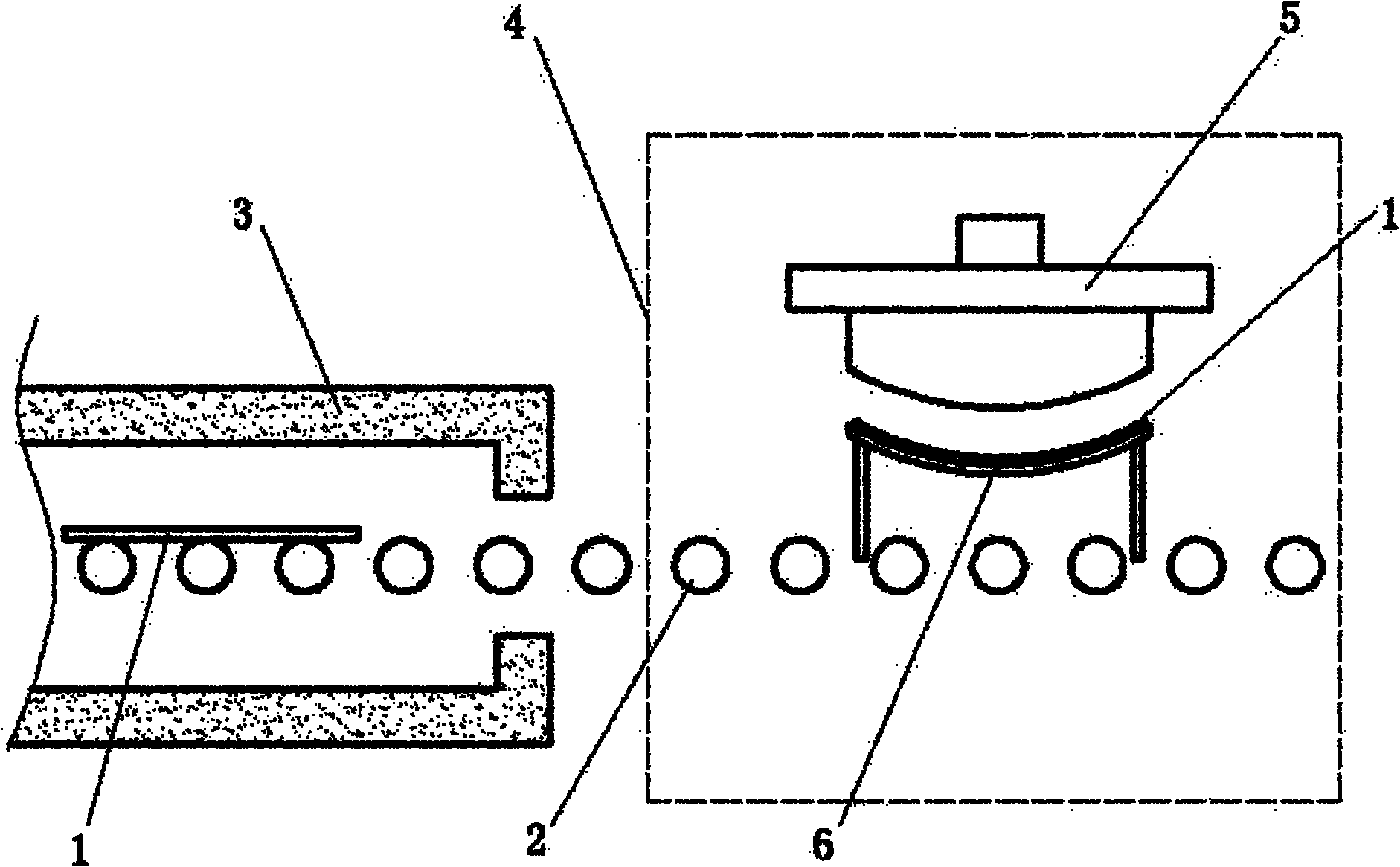

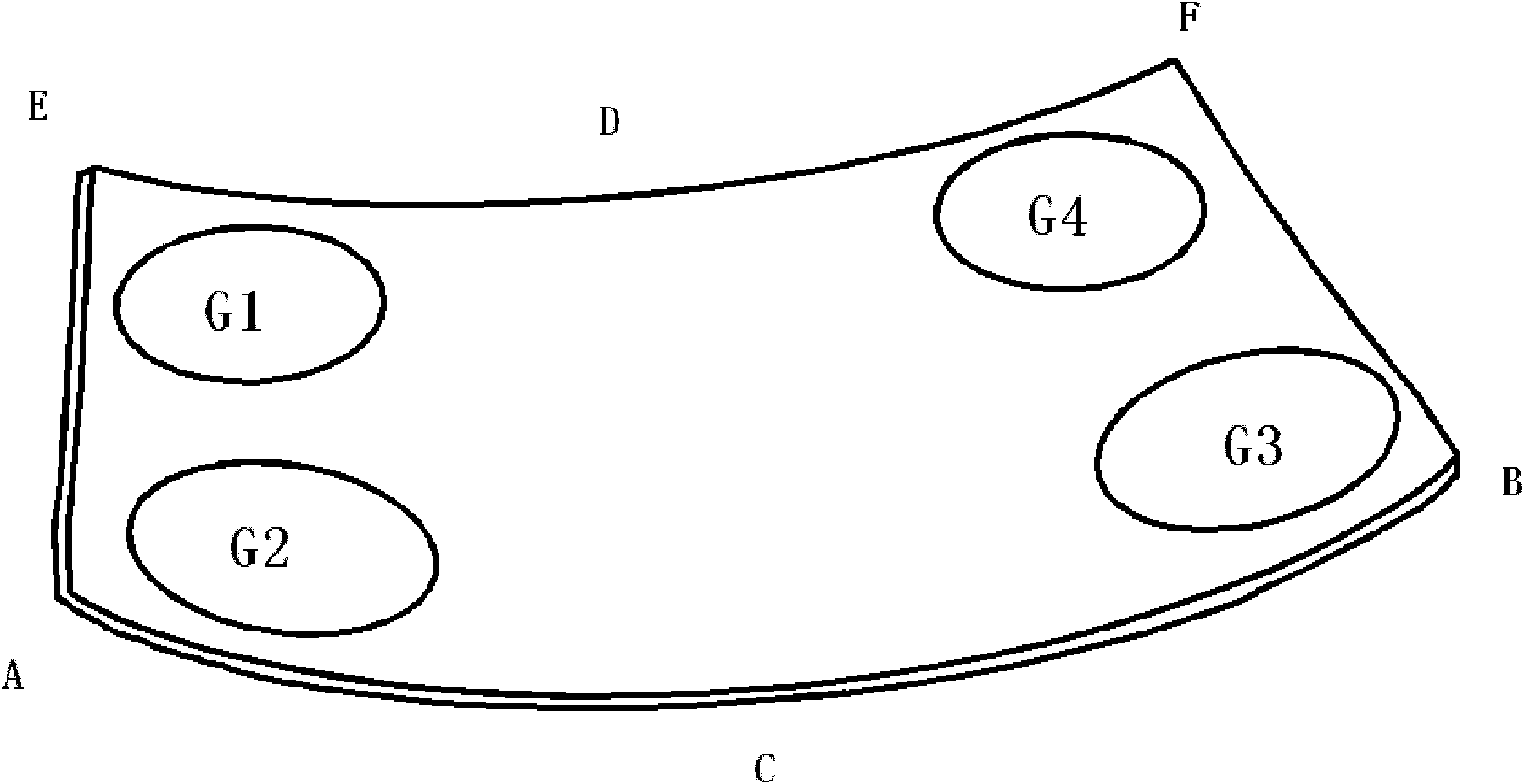

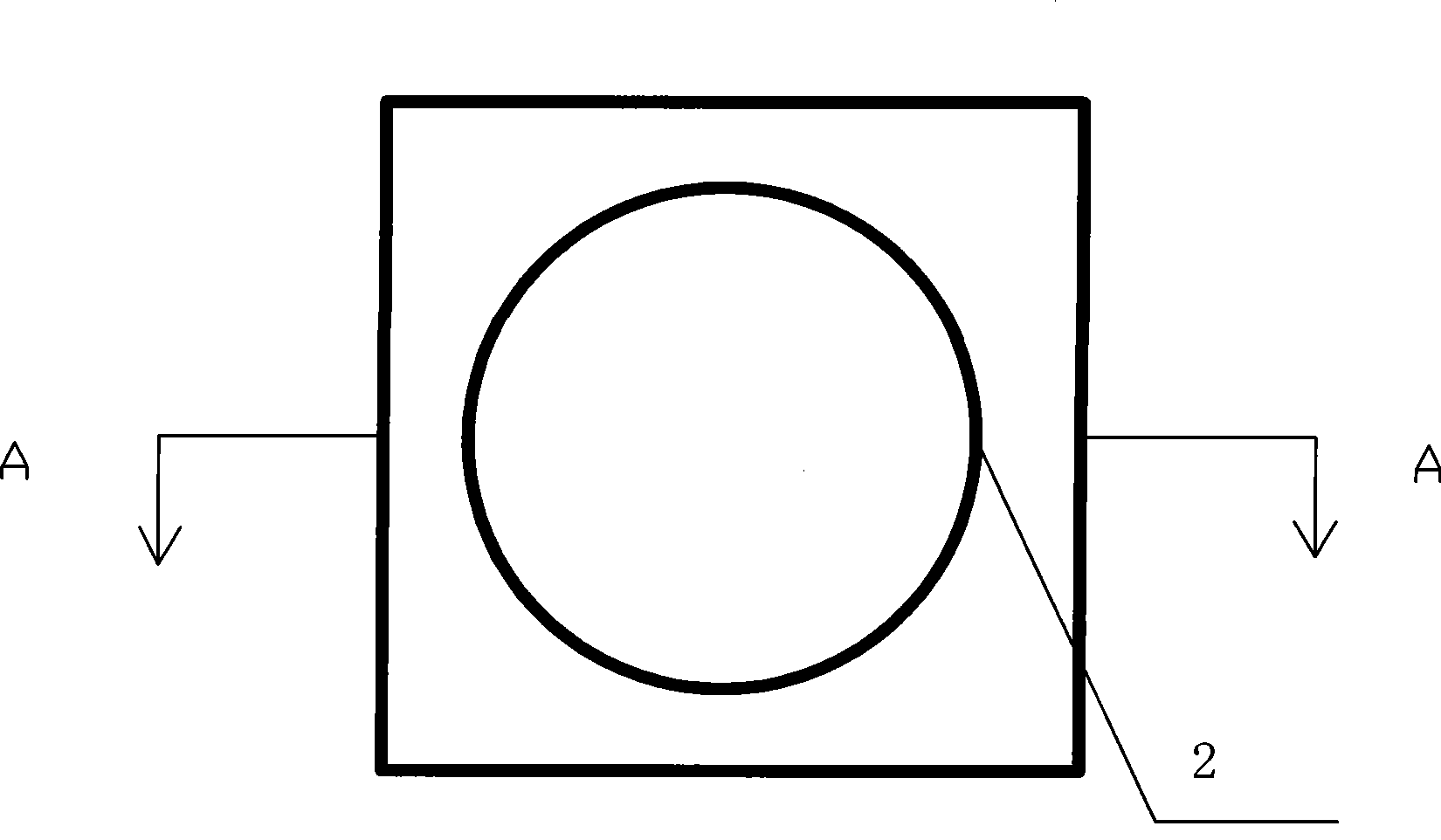

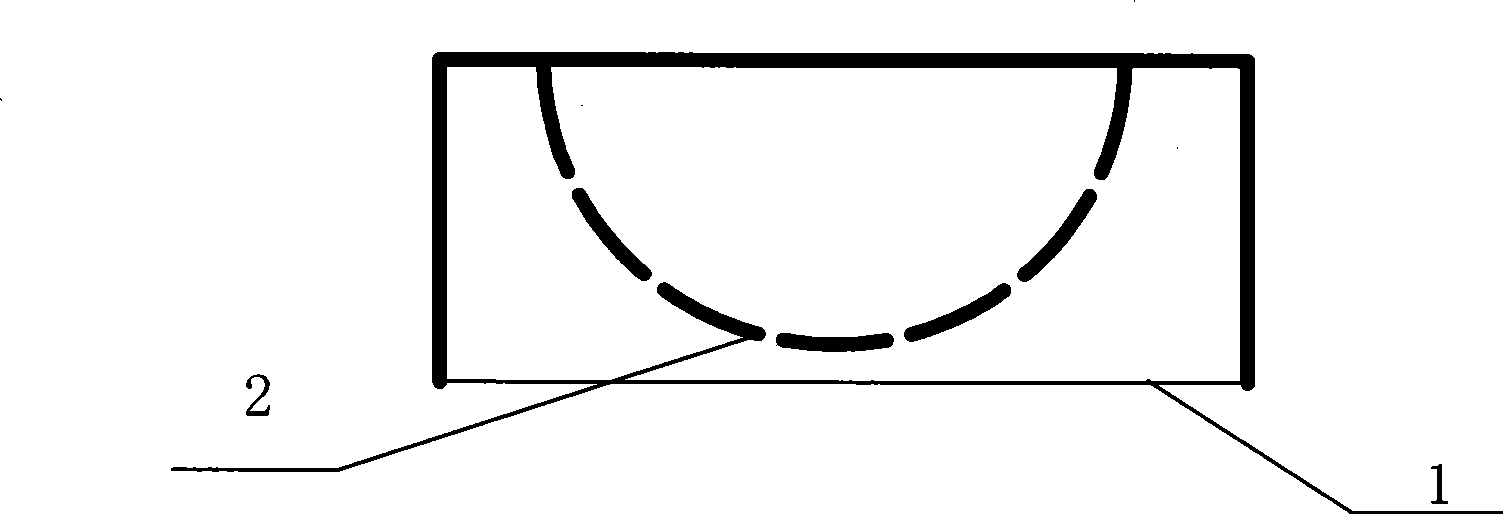

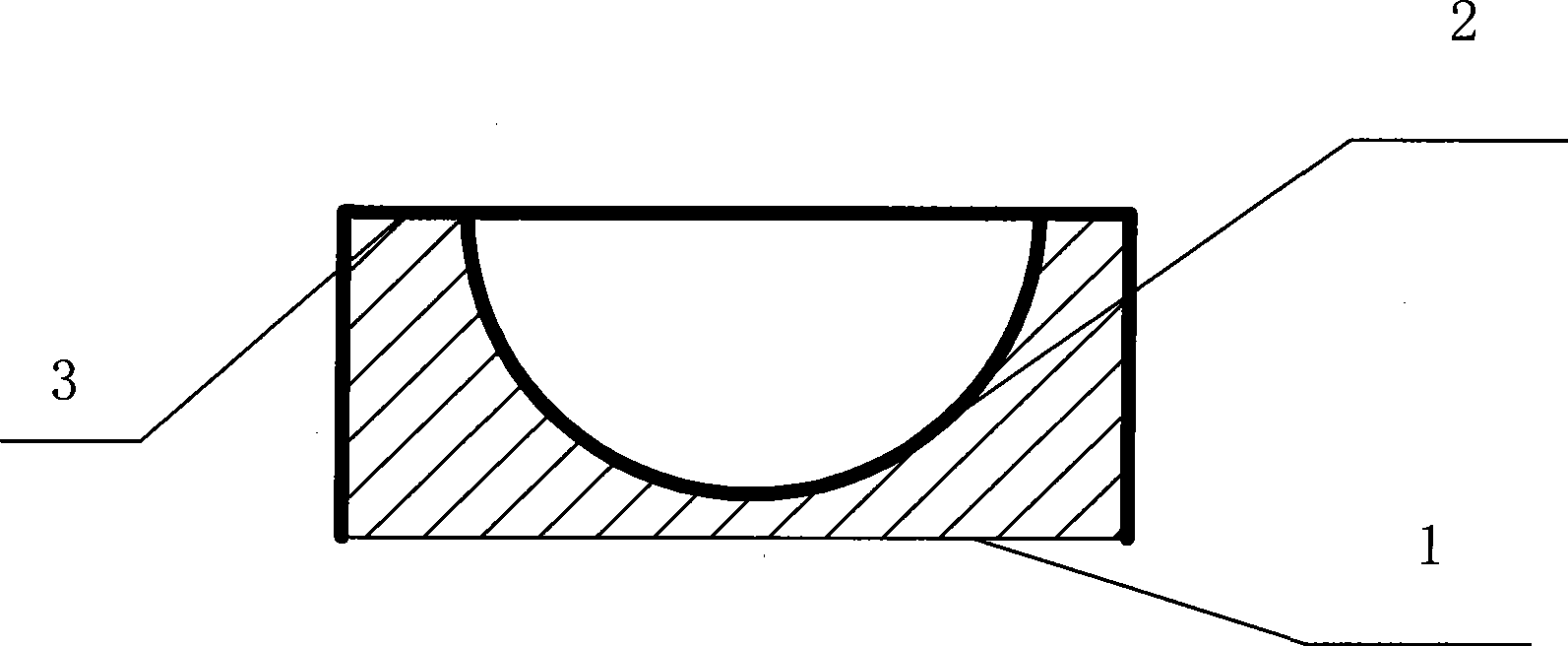

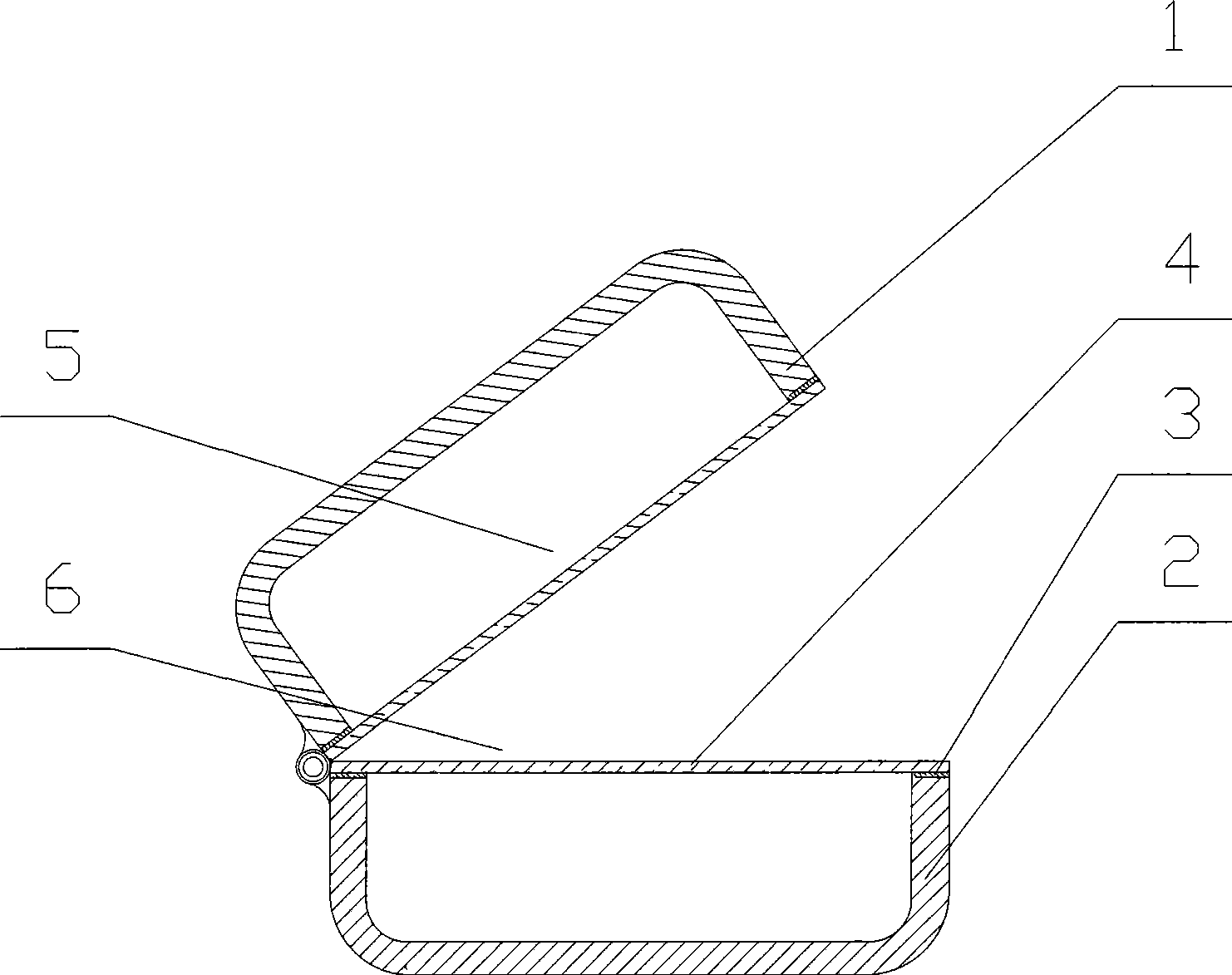

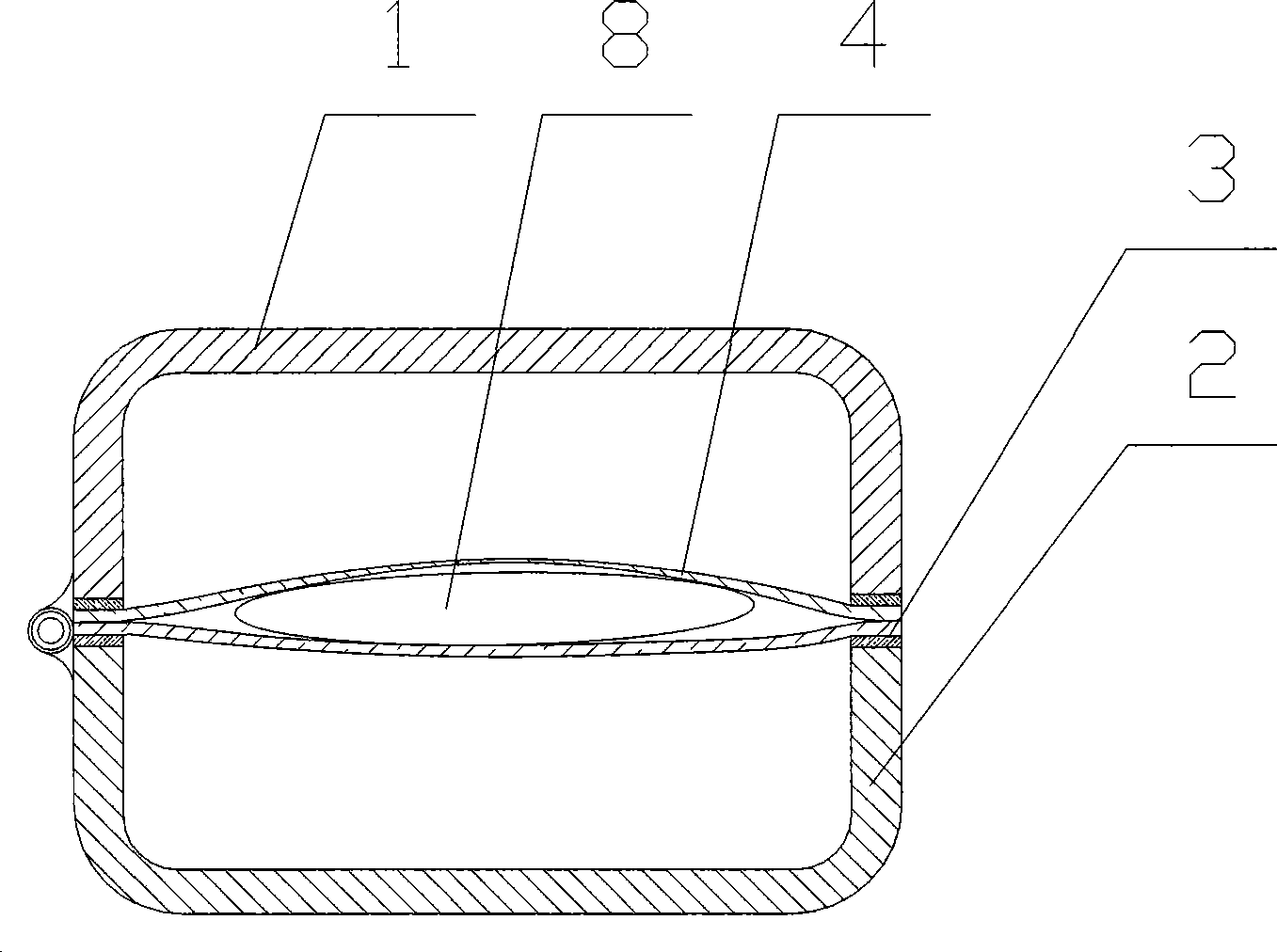

Method and device for bending glass plate

ActiveCN102173568AGood transition profileReduce contact timeGlass reforming apparatusGlass productionContact timeEngineering

The invention relates to a method for bending a glass plate and a device for bending a glass plate by using the method. The method comprises the following steps of: heating and softening the glass plate, transporting the glass plate into a forming region, lifting a supporting die, pre-bending the glass plate, lifting the glass plate by an upper pressing concave die, finally bending the glass plate, and transporting the glass plate into a cooling region or a tempering region for treatment. The device comprises a heating furnace, a transverse transportation roller bed, an upper pressing convex die, a lower pressing concave die and the supporting die. By using the method and the device provided by the invention, the heated and softened glass plate is quickly disengaged from the transverse transportation roller bed through the supporting die, the contact time between the glass plate and the transverse transportation roller bed is reduced, and the possibility of producing a roller trace on the glass plate is eliminated. Through the method and the device, the machining process and equipment are simplified, the production cost is saved, and the production efficiency of the product is also improved.

Owner:FUYAO GLASS IND GROUP CO LTD

Method for non-destroyed real time continuously testing concrete carbonization depth

InactiveCN101377464AEnsure smooth continuityImplement non-destructive testingMaterial analysis by observing effect on chemical indicatorMechanical depth measurementsChordal distanceNon destructive

A non-destructive real-time continuous concrete carbonation depth testing method comprises the following steps: firstly making concrete test block with spherical concave, having drying process after test block curing, sealing all surfaces with the heated paraffin except a bottom surface, placing the test block in a carbonization box, taking the test block out at different days to test the carbonation depth thereof, having groove-catching process upon the segmental paraffin-sealed surface of the test blcok, injecting R alizarin yellow reagent, draining the reagent, after confirming the discolouring interface, selecting the testing points, measuring the chordal distance of each point of the four laterals, calculating the carbonation depth value for each point, taking the mean value as the testing value and drawing the relation curve between the carbonation time and the carbonation depth with the carbonation depths tested at different days to express the development rule of the concrete under the condition. The invention can test the carbonation depth continuously in real time with high precision, which is beneficial for the study of concrete durability.

Owner:孙炳全

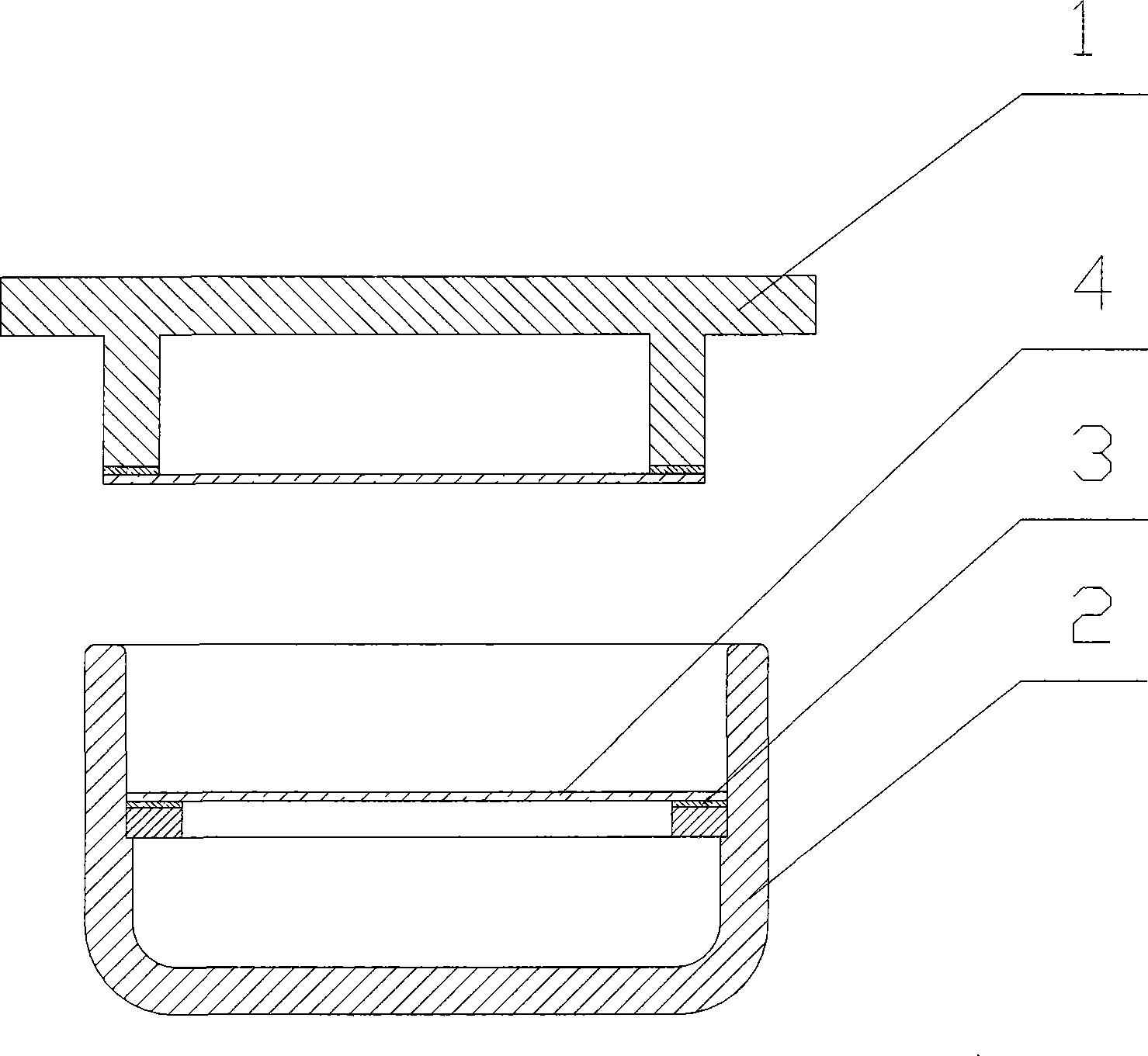

Novel packaging box and manufacturing technology thereof

ActiveCN101362529AFast curingReaction is easy to controlClosure with auxillary devicesBoxesManufacturing technologyAdhesive

The invention relates to a novel packing case and the manufacturing process thereof, which is characterized in that the novel packing case comprises an upper casing body and a lower casing body which are oppositely covered, and an elastic tensioning diaphragm which can elastically clip objects when the casing bodies are oppositely covered is respectively adhered to the upper casing body and the lower casing body by adopting UV adhesive. The novel packing case has the advantages that the structure is simple, the design is reasonable, is in favor of simplifying the production processes, reducing the production cost and re-utilization. Due to the advantages of the UV adhesive, the elastic tensioning diaphragm which is adhered by adopting the adhesive has the significant advantages of high bonding strength, high speed and high degree of automation, etc.

Owner:福州康派克光电科技有限公司

Preparation method of trimethylaluminium

InactiveCN105175440AHigh yieldHigh purityGroup 3/13 element organic compoundsEvaporationMethyl group

The invention relates to a preparation method of trimethylaluminium. The method comprises steps as follows: (1) magnalium and haloalkane have a contact reaction in the presence of an ether solvent and in the inert atmosphere to produce a trimethylaluminium ether complex; (2) the trimethylaluminium ether complex and an amine and / or phosphine compound with the high boiling point have a contact reaction to produce a trimethylaluminium amine complex and / or a trimethylaluminium phosphine complex; (3) the complexes obtained in Step (2) are decomposed. With the adoption of the preparation method, the yield and the purity of the trimethylaluminium can be significantly increased, the yield of the trimethylaluminium can be higher than 80%, the purity can be 99.9999%, besides, a reaction kettle used in the method can be used as an evaporation kettle, the technology and equipment are simplified, the reaction process is easy to control, the prepared product can be separated from raw materials and byproducts more easily, the method is very applicable to industrial production, in addition, the byproducts can be used for synthesizing aluminum sulfate, and almost no waste is produced.

Owner:JIANGXI JIAYIN PHOTOELECTRIC MATERIAL

Production process for lignin alcohol fuel

InactiveCN1566289ARealize comprehensive utilizationAlleviate the situation of increasing energy shortageLiquid carbonaceous fuelsAlcohol fuelEthanol

Owner:SHAANXI UNIV OF SCI & TECH

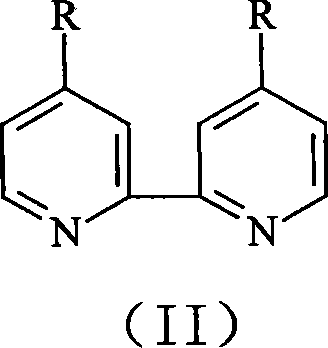

Synthesis of 4,4í»disubstituted-2,2í»-dipyridine

The invention discloses a method for synthesizing 4, 4'-disubstituted-2, 2'-bipyridine, which mainly mixes a 4-substituent pyridine and a metal catalyst according to a weight ratio of 100: 0.2 to 40. The mixture is put in a closable reactor which can be heated and pressurized, which is bubbled for 5 to 30 minutes with inert gases; then the reactor is closed to be heated to a temperature of 140 to 300 DEG C, reacted for 2 to 350 hours under a condition of stirring; after cooling, filtering, rotating steaming and re-crystallization, a target product 4, 4'-disubstituted-2, 2'-bipyridine can be obtained. The method of the invention is simple with the advantages of high efficiency and low cost, thus being suitable for large-scale industrial production.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

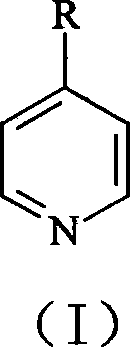

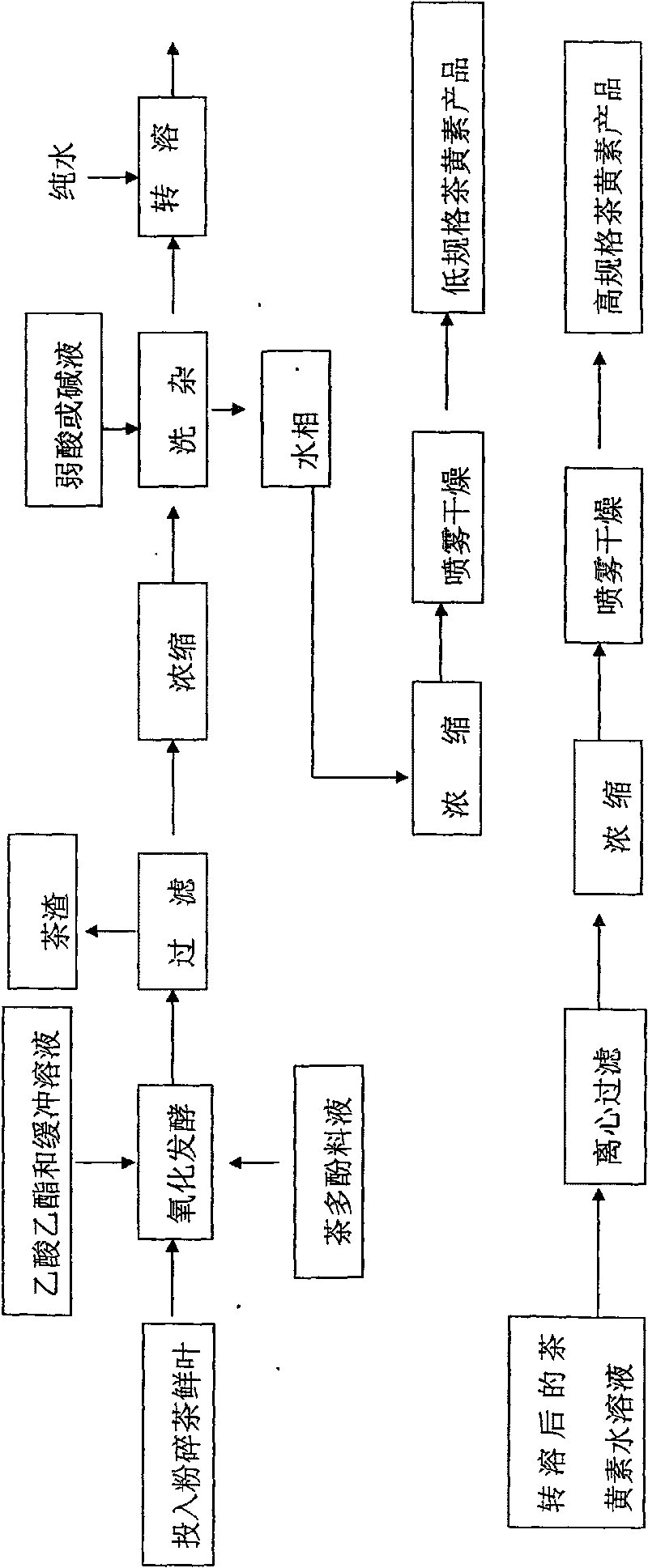

Industrial preparation method of theaflavin

InactiveCN101691591AReduce generationEnsure gentlenessOrganic chemistryFermentationAcetic acidTheaflavin

The invention relates to an industrial preparation method of theaflavin, which comprises the following steps: (1) preparing an ethyl acetate solution containing rich tea polyphenol; (2) respectively adding pulverized fresh tea leaves and the ethyl acetate solution into a oxidation-fermentation tank, orderly adding ethyl acetate and a buffering solution, introducing air at normal temperature, and stirring, oxidizing and fermenting to obtain the theaflavin ester-phase solution; (3) filtering the theaflavin ester-phase solution, concentrating and washing to remove impurities; (4) concentrating the water-phase solution, and spray-drying to obtain low-specification dry theaflavin powder; (5) concentrating the ester-phase solution to recycle ethyl acetate, and adding water so that the theaflavin is dissolved in the water; (6) centrifugally filtering the theaflavin water solution to obtain a pure theaflavin solution; (7) and concentrating the theaflavin solution, and spray-drying to obtain the dry theaflavin powder. The method of the invention simultaneously enhances the yield and the quality of the theaflavin, saves the energy and the man hours and reduces the emission of waste water.

Owner:ZHEJIANG PAINUO BIO TECH

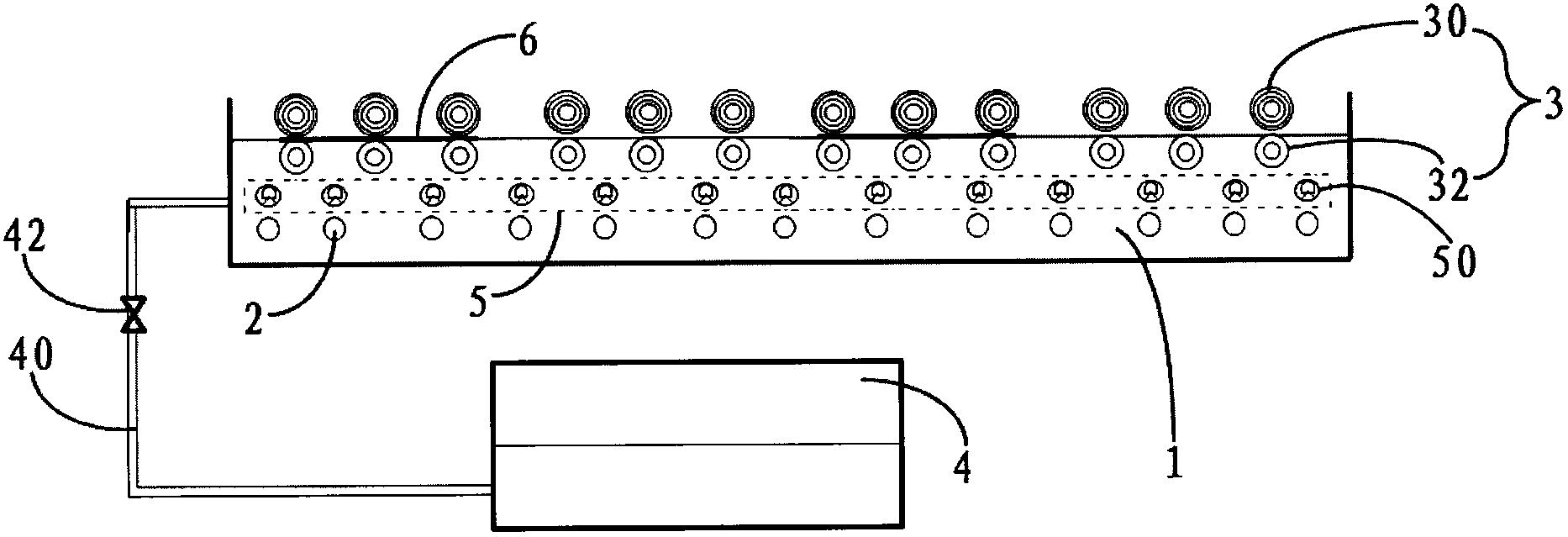

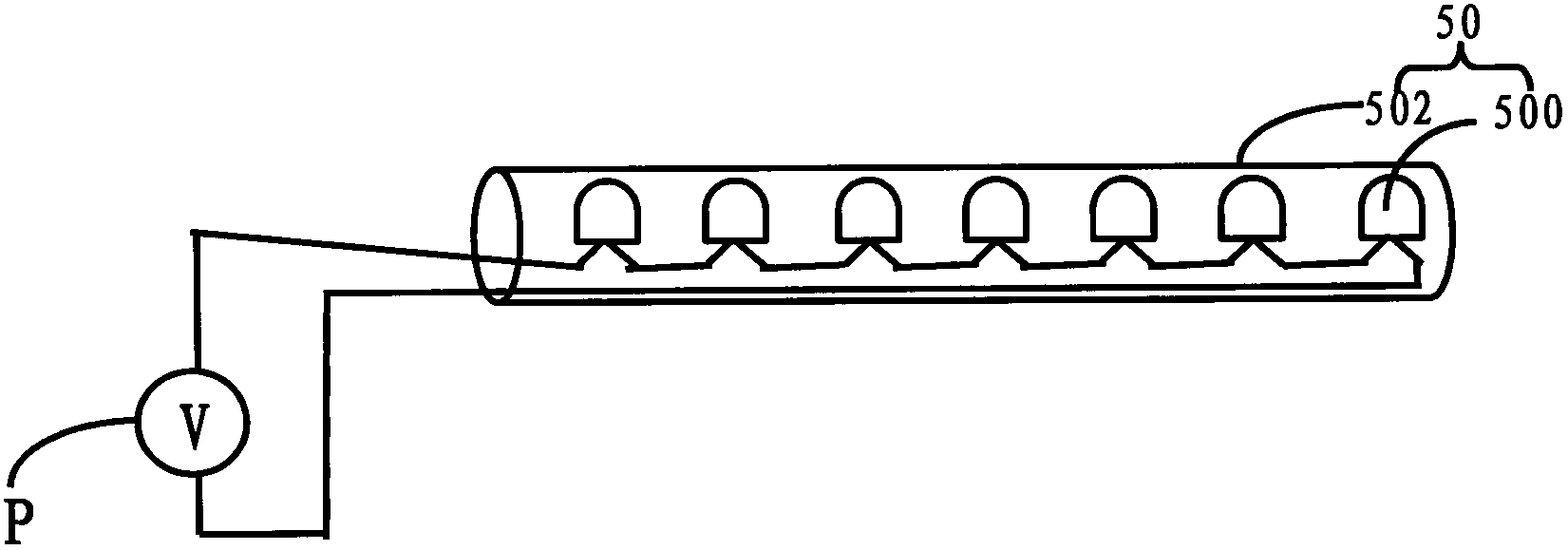

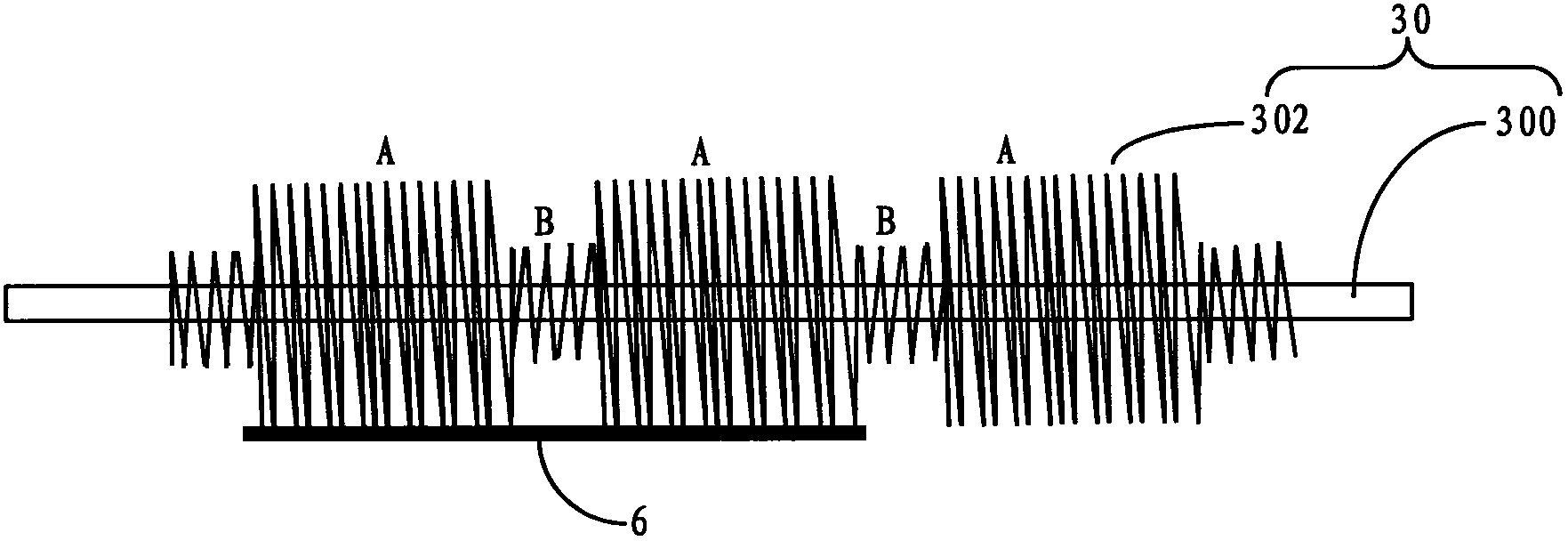

Solar cell film plating equipment and film plating method

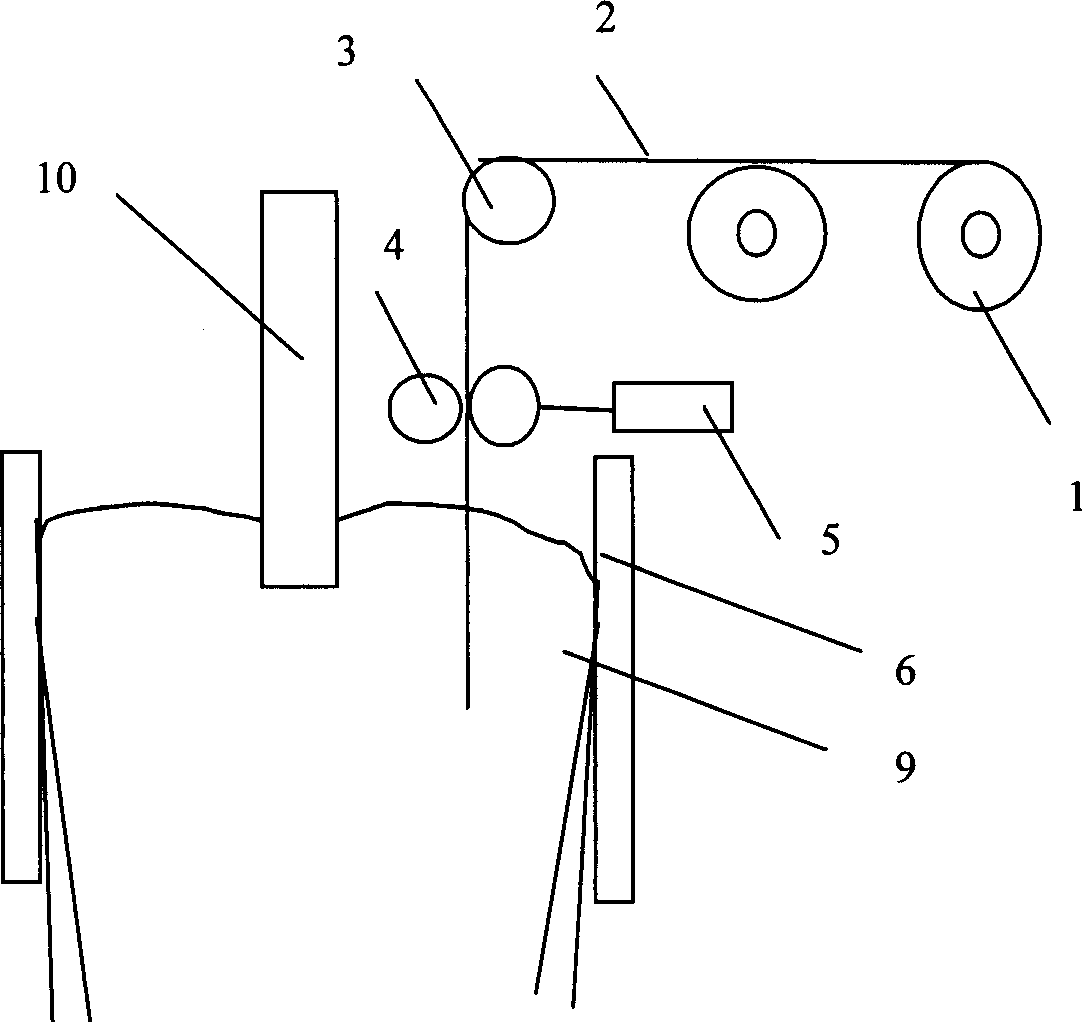

InactiveCN102660761AImprove production efficiencyImprove reliabilitySemiconductor devicesEngineeringSolar cell

The invention provides solar cell film plating equipment and a film plating method thereof. In the prior art, a solar cell can be transferred to electroplate liquid for electroplating by using an externally connected electroplating power supply or through a simple rolling wheel, so that the problems of high probability of damage to the solar cell and poor film plating quality exist. The solar cell film plating equipment provided by the invention comprises a film plating slot, a to-be-plated solar cell transmission module, and a film plating light source, wherein the transmission module is provided with a plurality of upper rolling wheel and a lower rolling wheel which are arranged in a matched manner and transfer the solar cell to be plated in an identical linear velocity, the solar cell to be plated forms an electroplating loop with electroplating liquid through an upper rolling wheel, the solar cell to be plated is transferred into the film plating slot horizontally through the to-be-plated solar cell transmission module and is partly submerged into the electroplating liquid, the film plating light source irradiates the light receiving surface of the to-be-plated solar cell and generate photoproduction electrical energy thereon, and the to-be-plated area of the to-be-plated solar cell is plated through the photoproduction electrical energy. In the invention, the reliability and the efficiency of the film plating are improved, the scrap rate in solar cell film plating is lowered, and that the externally connected electroplating power supply is required can be avoided.

Owner:WUXI SUNTECH POWER CO LTD

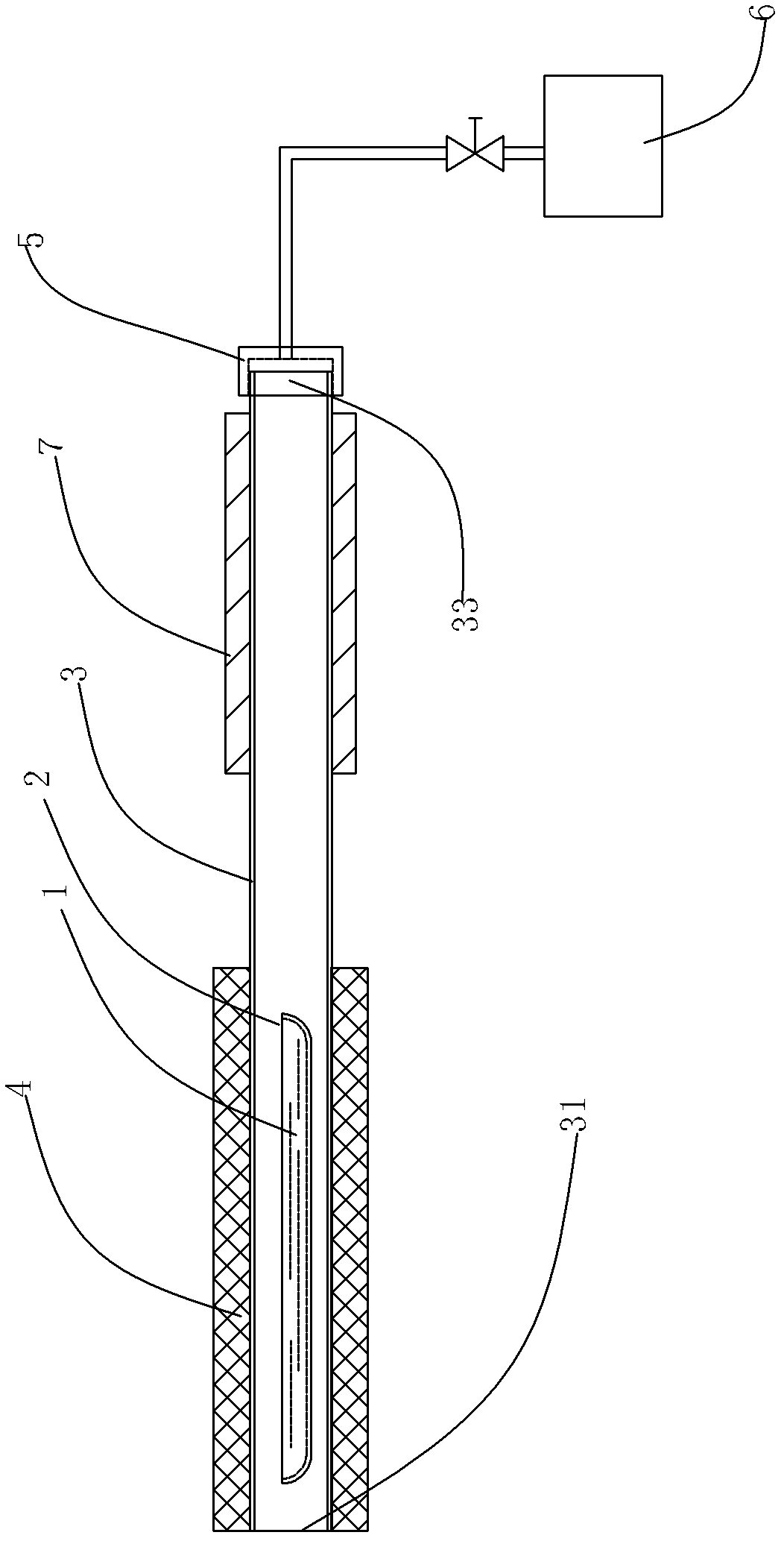

Gallium arsenide processing device and processing method

InactiveCN103184339AHigh recovery rateLow costProcess efficiency improvementGallium arsenideCrystal growth

The invention provides a gallium arsenide processing device and a processing method, the processing device comprises a quartz boat used for placing a waste gallium arsenide material; a quartz tube with an closed end and an opened end, wherein the quartz boat used for placing a waste gallium arsenide material is placed at the closed end; a horizontal crystal growth furnace which comprises a horizontal crystal growth furnace heating zone, wherein the horizontal crystal growth furnace heating zone encircles the closed end of the quartz tube and the quartz boat in the quartz tube; a sealing member used for enclosing the opened end of the quartz tube; and a vacuum set communicated to the quartz tube through the sealing member. According to the invention, metal gallium and simple substance arsenic can be directly separated, the gallium recovery rate is high, and the cost is low, the technology and device can be simplified, the processing device and the processing method have no pollution on environment, no noxious material is generated, and the processing device and the processing method are in favor of operation and staff safety.

Owner:FIRST SEMICON MATERIALS

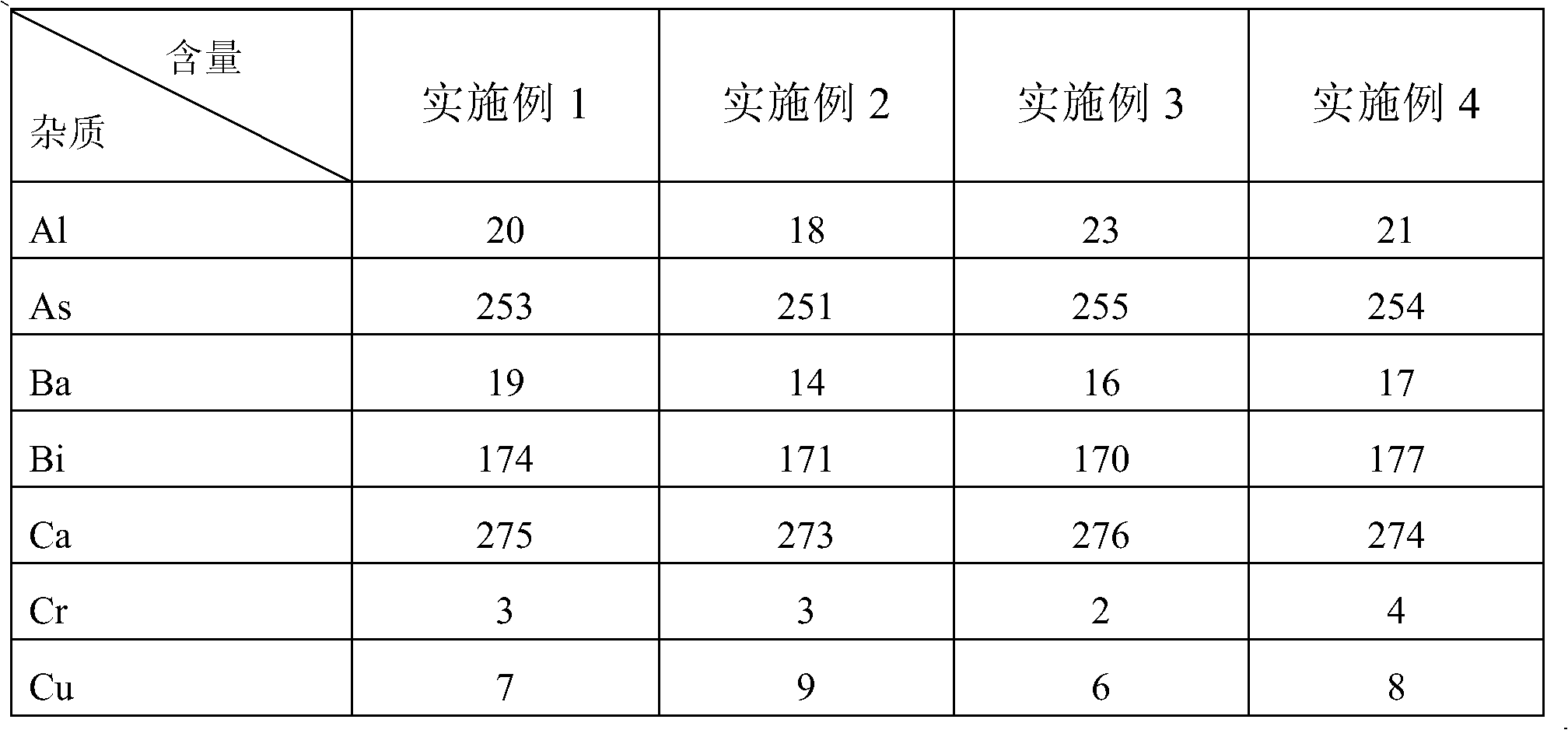

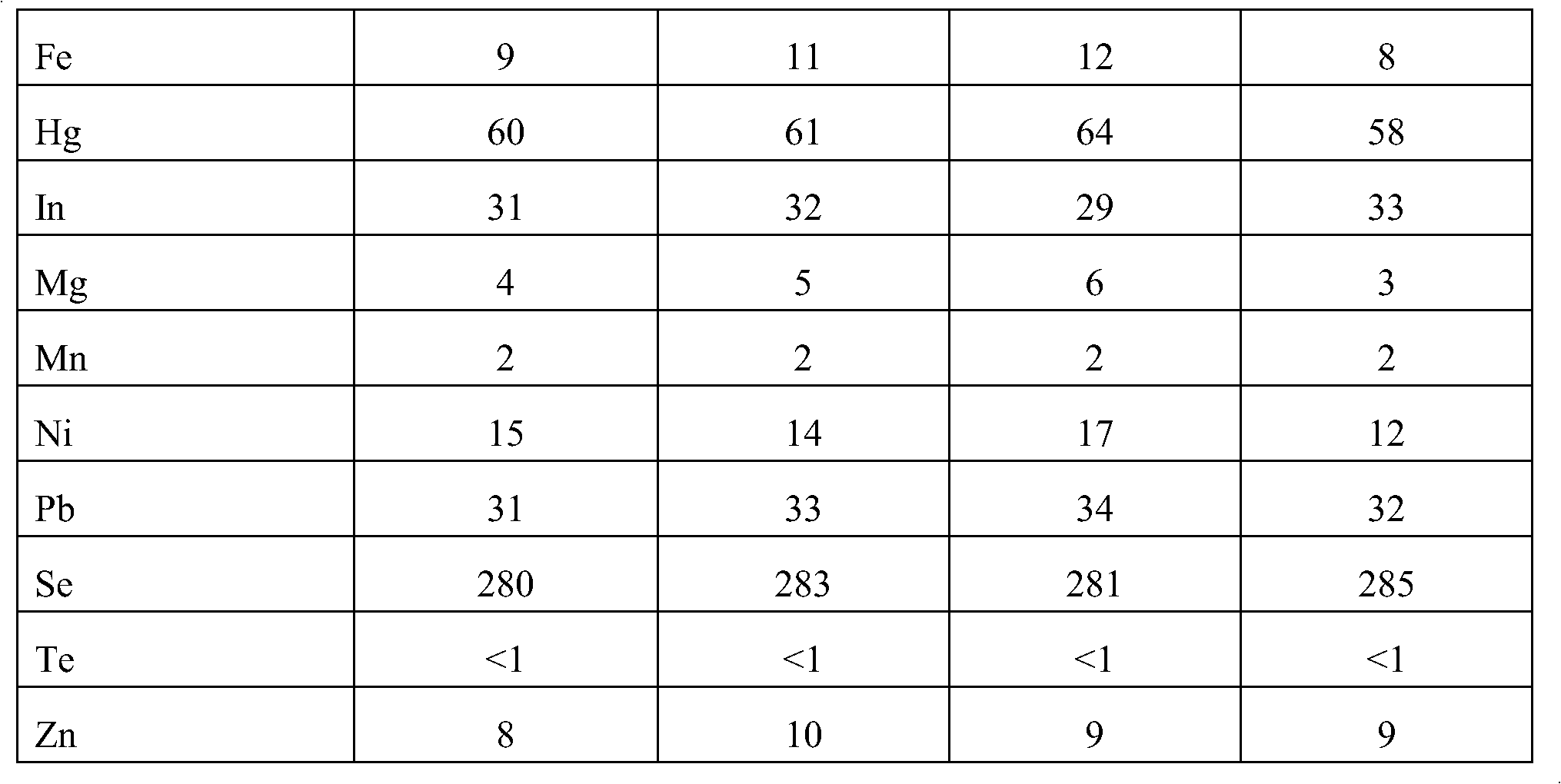

Preparation method of hemp husk fibers

InactiveCN103757964ALow lignin contentLow ash contentCellulosic pulp after-treatmentSpinningPulp and paper industry

The invention discloses a preparation method of hemp husk fibers. Bleached hemp husk fibers which have whiteness exceeding 78% and complete degumming, degreasing, delignification and decoloring are obtained by directly digesting the whole hemp husks or the whole hemp stalks chemically, extruding and washing the whole hemp stalks and directly gas-bleaching the washed strip-shaped hemp husk fibers with ozone. The hemp husk fibers can serve as hemp husk pulp for papermaking after being pulped and cut off, and can serve as hemp husk fibers for spinning after being air-dried. By adopting the preparation method, the hemp stalks and the hemp husks are unnecessary to be sliced, so that the forms of the hemp husk long fibers can be furthest maintained; the aim of bleaching can be achieved by carrying out one-stage bleaching on the hemp husk fibers obtained after digesting with zone; high-concentration shoving and powerful dispersion equipment before conventional ozone bleaching of pulp is not needed; for either the hemp husk pulp for papermaking or the hemp husk fibers for spinning, the preparation method with the characteristics of efficiency, cleanliness, economy, simplicity and directness has important values for processing and utilization of hemp fibers.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

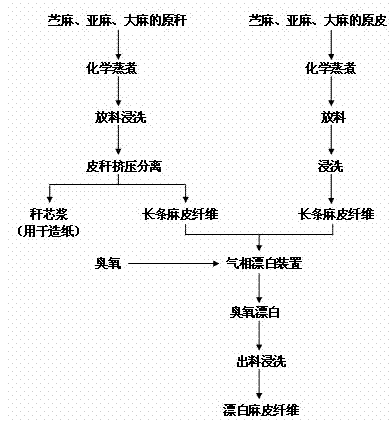

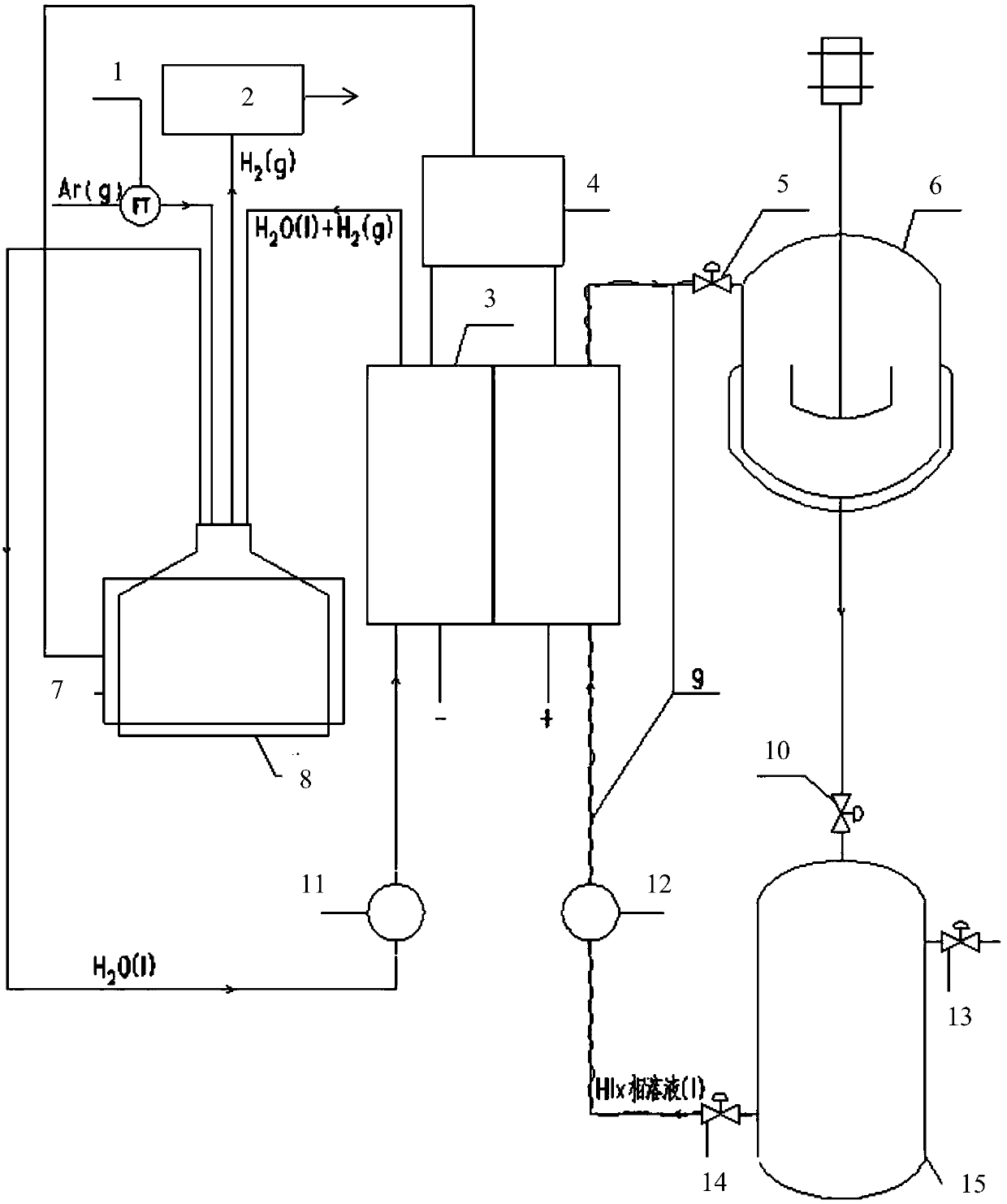

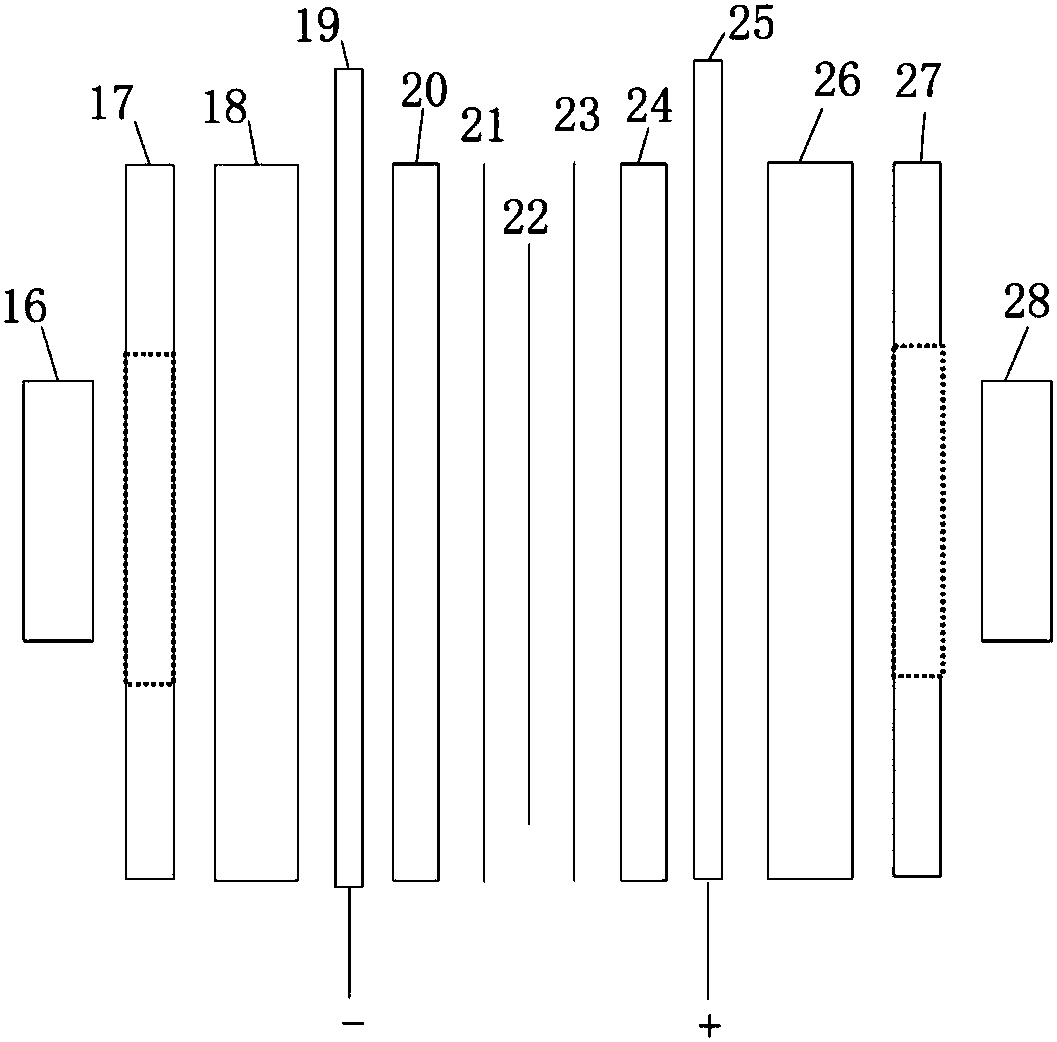

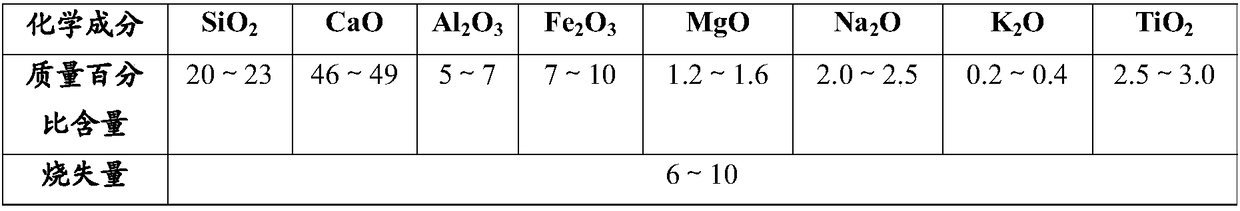

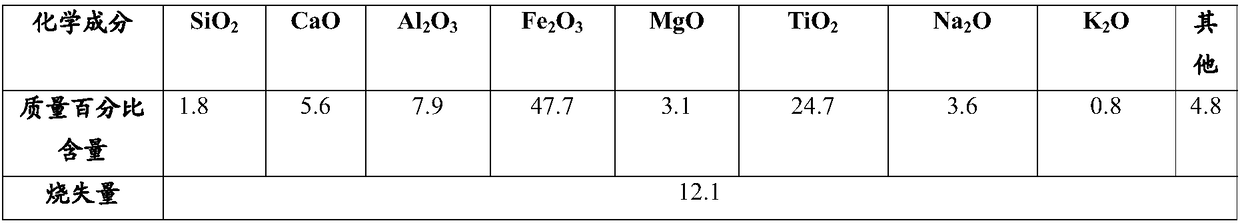

Hydrogen production method adopting electrochemistry to disintegrate HI in sulphur and iodine circulation hydrogen production and device

ActiveCN107904617AOmit enrichmentEliminate the distillation processCellsDiaphragmsElectrolysisDistillation

The invention relates to the technology of sulphur and iodine circulation hydrogen production, and particularly provides a hydrogen production method adopting electrochemistry to disintegrate HI in sulphur and iodine circulation hydrogen production and a device. The method includes the steps that a monocell is used as a reactor, the monocell has anode graphite electrode and cathode graphite electrode, and a proton exchange membrane is used as a diaphragm; HIx homogeneous solution in the sulphur and iodine circulation hydrogen production system is injected into the anode side, and deionized water is injected into the cathode side; power supply is turned on to carry out decomposition reaction, I- of the anode side HIx homogeneous solution is oxidized to I2, and generated H+ passes through proton exchange membrane to reach the cathode side and is reduced to hydrogen; HIx homogeneous solution of the anode side enters a Bunsen reactor to be Bunsen reaction raw material in a circulating modeafter electrolytic reaction, and hydrogen generated from cathode side is sent out. According to the hydrogen production method adopting electrochemistry to disintegrate HI in sulphur and iodine circulation hydrogen production, an HIx solution is directly decomposed adopting electrochemistry method, the original process of concentration and distillation is omitted, and the process and the device are greatly simplified. Hydrogen is generated from cathode, and the separation problem with HI gas does not need to be considered.

Owner:ZHEJIANG UNIV

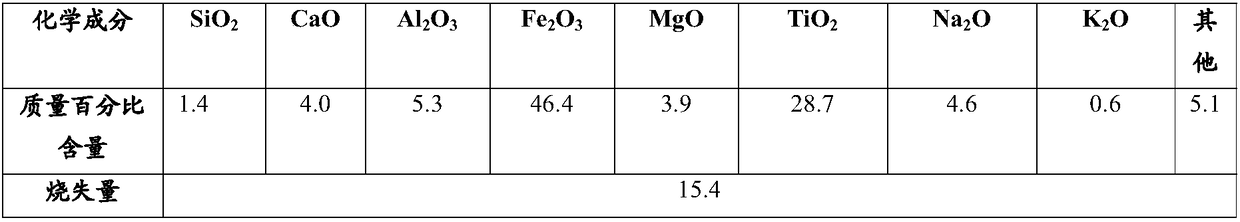

Method for producing aluminum hydroxide by roasting bauxite at low temperature

InactiveCN109279633AReduce trafficReduce sintering energy consumptionAluminium silicatesProcess efficiency improvementAluminium hydroxideRed mud

The invention belongs to the technical field of aluminum industries, and specifically discloses a method for producing aluminum hydroxide by roasting bauxite at a low temperature. The method includesmixing crushed bauxite with a caustic solution to obtain raw slurry; roasting the raw slurry with 160-890 DEG C to obtain clinkers; performing dissolution reaction on the clinkers to obtain digestionliquor, and performing solid-liquid separating on the digestion liquor, wherein a solid phase is a pug whose iron content is larger than or equal to 40%, the pug can be sold as an iron concentrate rawmaterial after washing, a liquid phase is crude liquid, and a desilication solid phase is a sodium aluminosilicate product after the desiliconization of the crude liquid; and adding aluminum hydroxide seeds into the liquid phase to perform decomposition reaction, and performing solid-liquid separating on decomposition liquid, wherein the obtain liquid phase is seeded precipitation spent liquor, and the solid phase is an aluminum hydroxide product. The method enhances decomposition rate and cyclic efficiency, and reduces energy consumption; and compared with traditional sintering methods, theroasting temperature can be obviously reduced, the method does not generate red mud, more than 70% of silicon dioxide in the bauxite is made into the sodium aluminosilicate products, and the standardof the quality of the prepared aluminum hydroxide is better than that of the aluminum hydroxide produced by the traditional sintering methods and Bayer process.

Owner:陈湘清

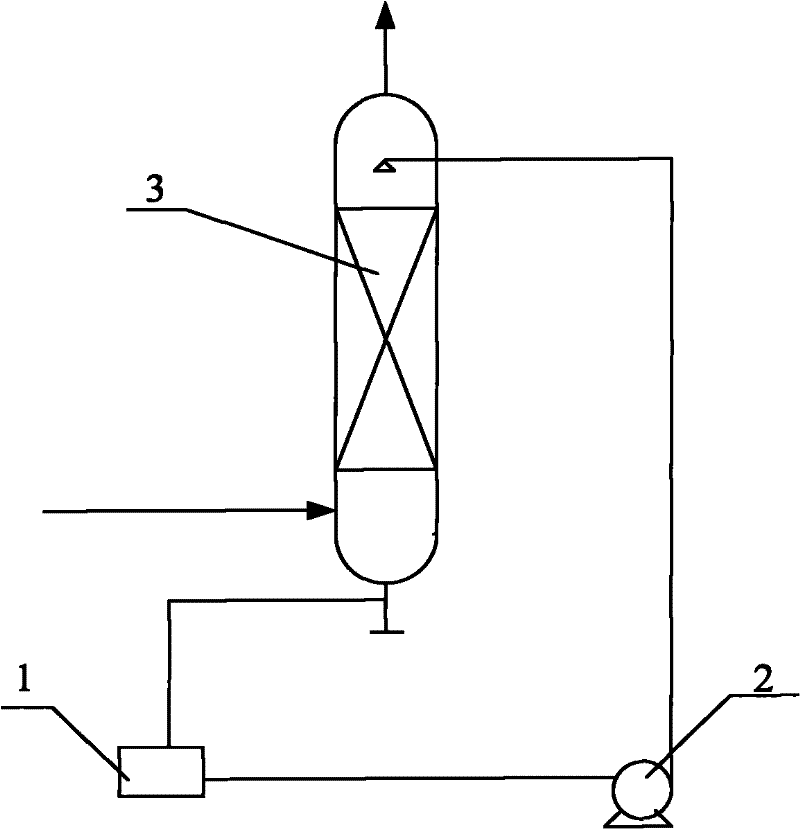

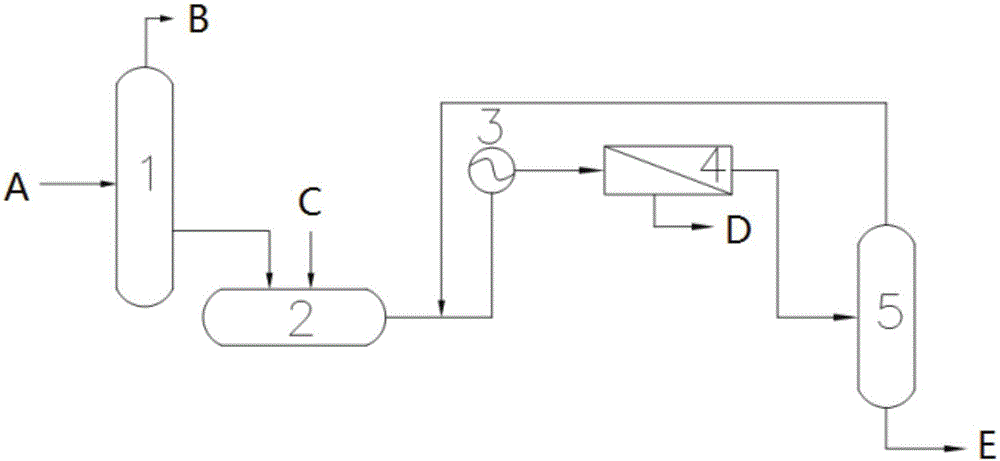

Byproduct hydrogen purification recovery system and method in chlorine industry

ActiveCN102173382ASimplify equipmentSimplify industrial processesHydrogen separationDeoxidizationWater tanks

The invention provides a byproduct hydrogen purification recovery system and method in the chlorine industry. The byproduct hydrogen in the chlorine industry enters a washing tower, the solution in a water tank enters the spraying tube in the washing tower through a water pump at the same time, the hydrogen dechlorinated by the washing tower is discharged from the top of the washing tower and then enters a buffer tank, then the hydrogen buffered by the buffer tank enters a hydrogen compressor for pressurization and then enters a gas-liquid separator, after gas-liquid separation, the hydrogen enters a deaerator for removing the oxygen in the hydrogen, after deoxidization, the hydrogen enters a first adsorber for dehydration and impurity removal and then enters a gas filter, and finally after filtration, the hydrogen enters a hydrogen recovery device. The system provided by the invention simplifies the instrument and equipment and industrial processes, and saves industrial costs.

Owner:考克利尔竞立(苏州)氢能科技有限公司

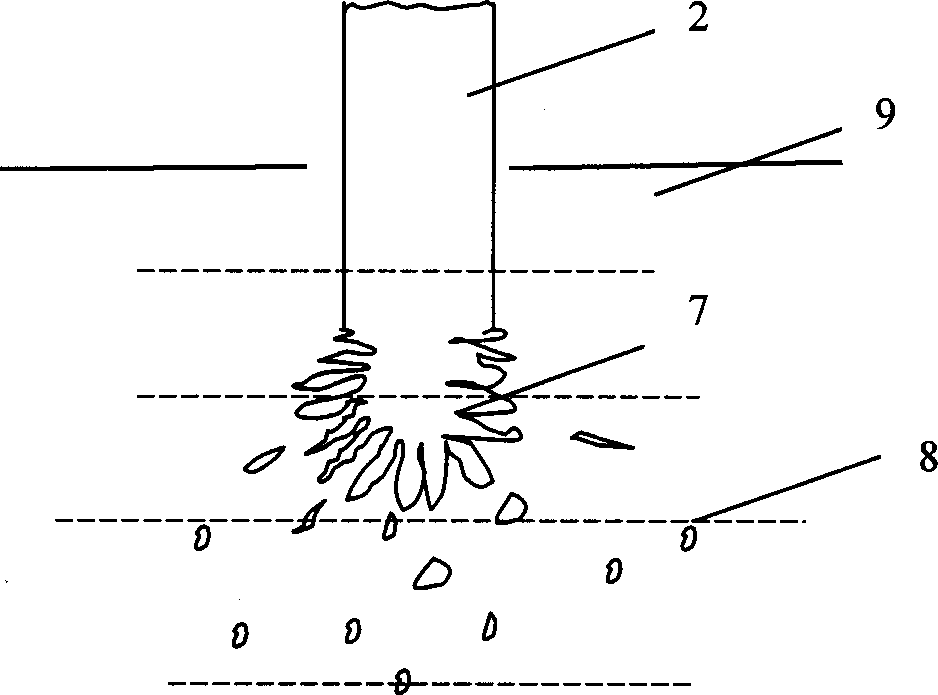

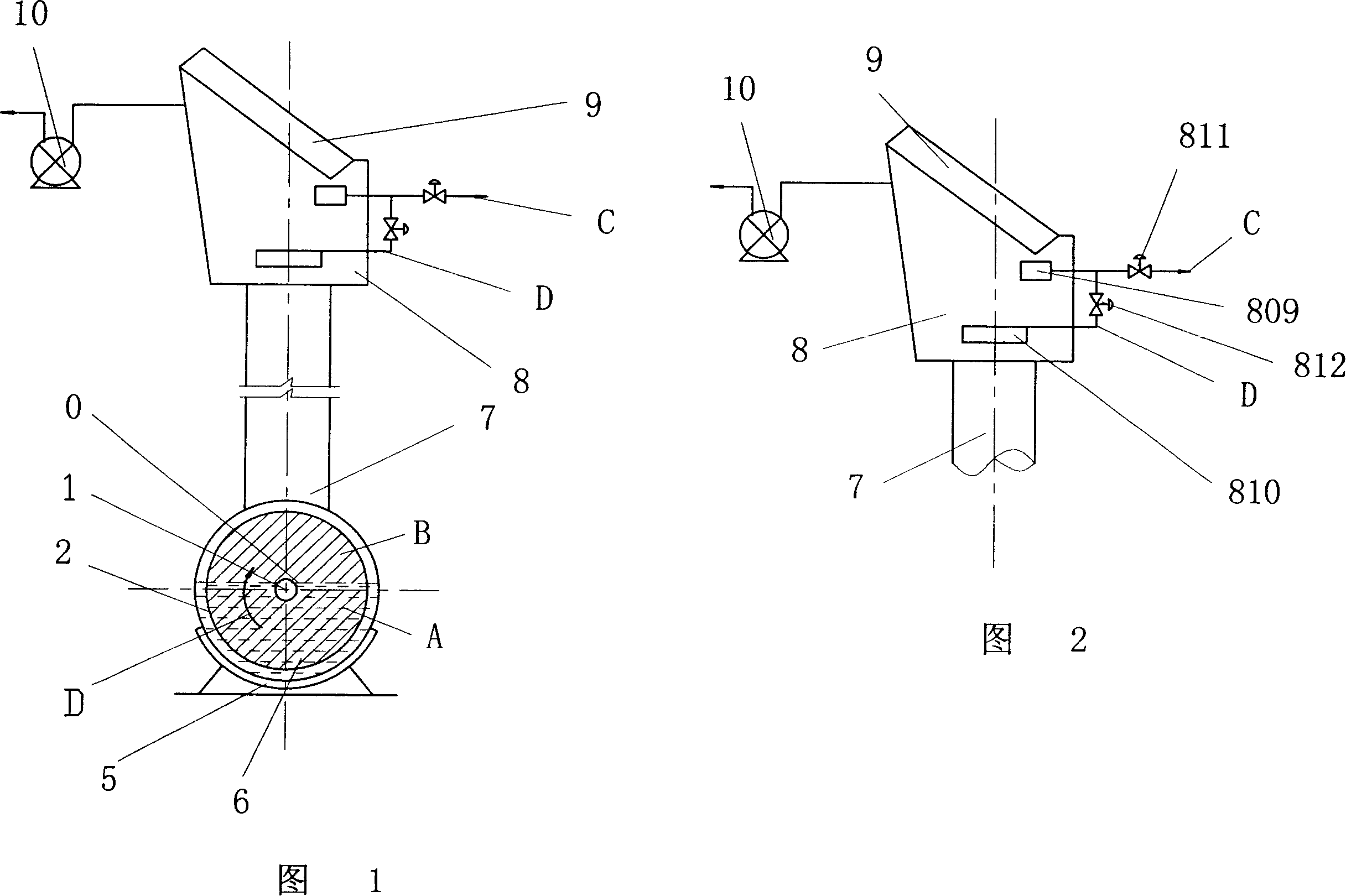

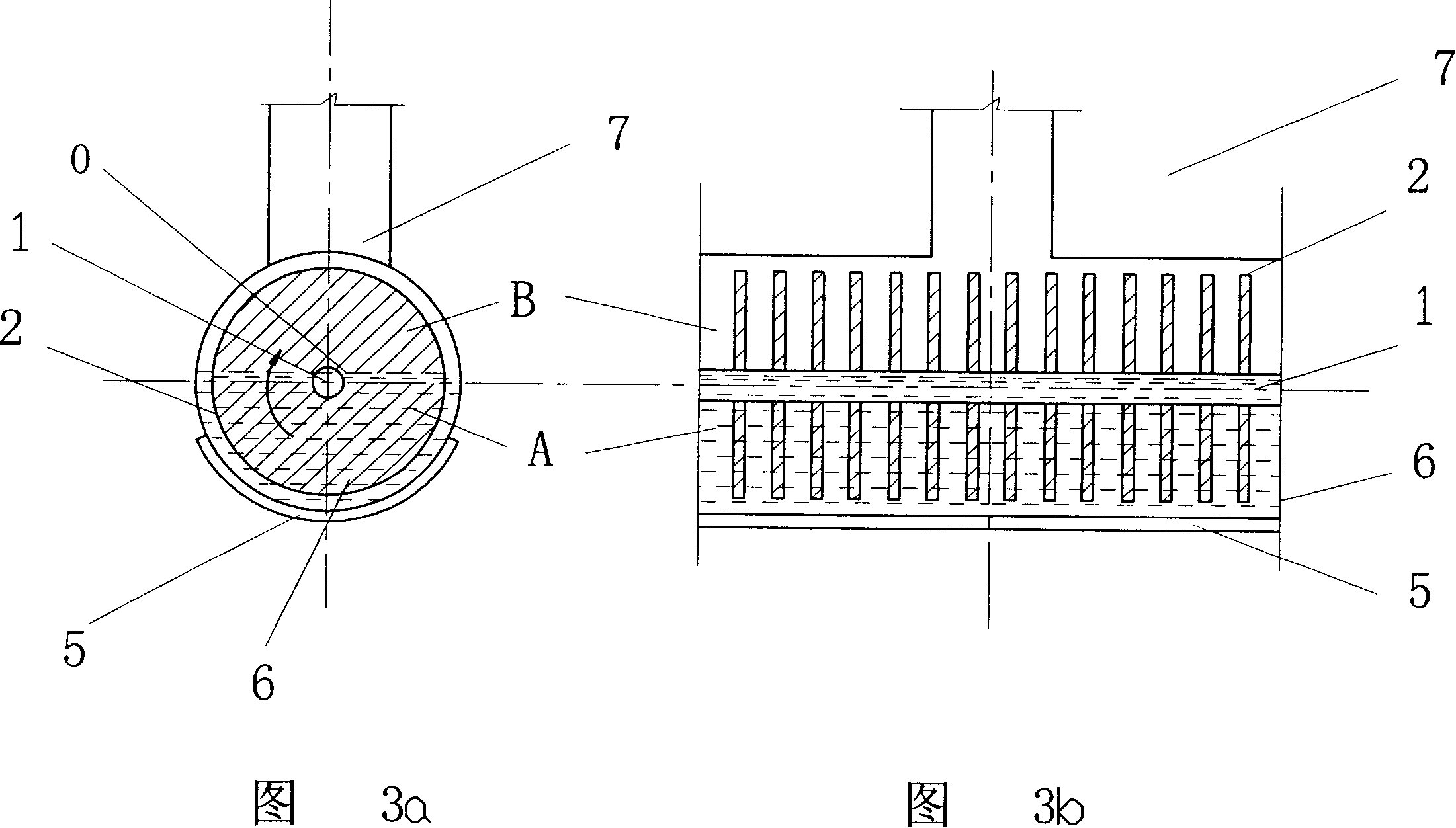

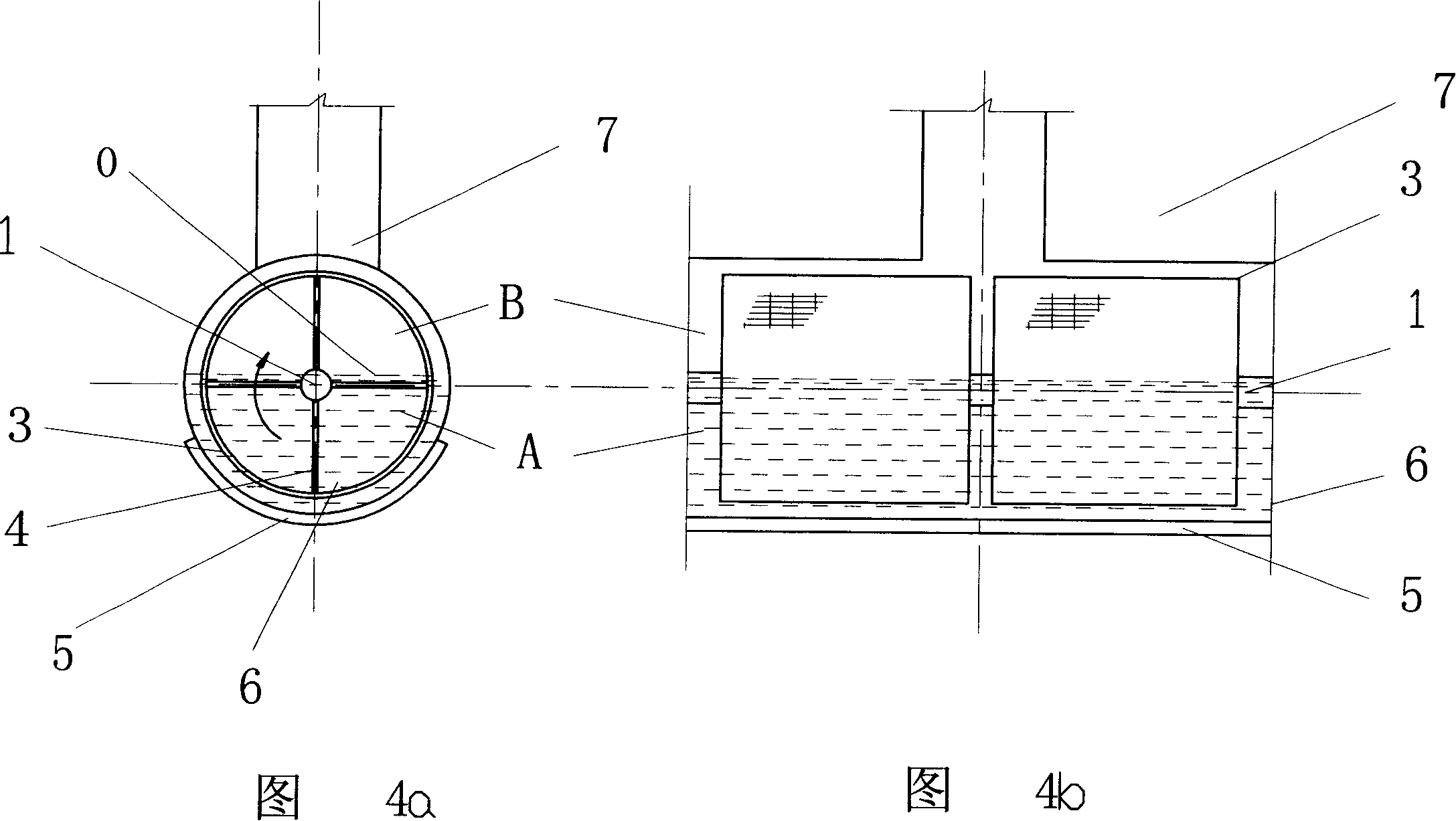

Improved method of vibration exciting metal liquid shape crystal nucleus and its device

An improved method for vibration excitation of the nucleuses in molten metal includes such steps as immersing at least one crystal nucleus ejector with high-frequency low-amplitude in molten metal, quickly generating a lot of crystal nucleuses in the front of said ejector, and ejecting them in the molten metal to form a lot of crystal nucleuses of equiaxed crystals. It features that said crystal nucleus ejector is a consumable cold metal material.

Owner:CENT IRON & STEEL RES INST

Laser cutting method for hard brittle non-metallic material

ActiveCN101077551ARealize three-dimensional damage-free cuttingShort processing timeWelding/cutting media/materialsSoldering mediaNon destructiveLaser processing

The present invention is non-destructive laser cutting process for hard brittle non-metal material, and belongs to the field of laser processing technology. The non-destructive laser cutting process includes focusing laser beam with peak power of 700-4000 W and duty ratio of 4-50 % onto the material to perforate one through hole under the cooperation of auxiliary gas in the pressure of (1-5)x10<5> Pa; and moving the laser beam or the workpiece in the speed of 100-500 mm / min to perforate serial through holes of 0.05-0.65 mm diameter in the interval of 0.05-0.2 mm along the machining path, with the adjacent through holes possessing edges connected mutually, so as to complete the cutting of the material. The non-destructive laser cutting process has less local heat effect.

Owner:BEIJING UNIV OF TECH

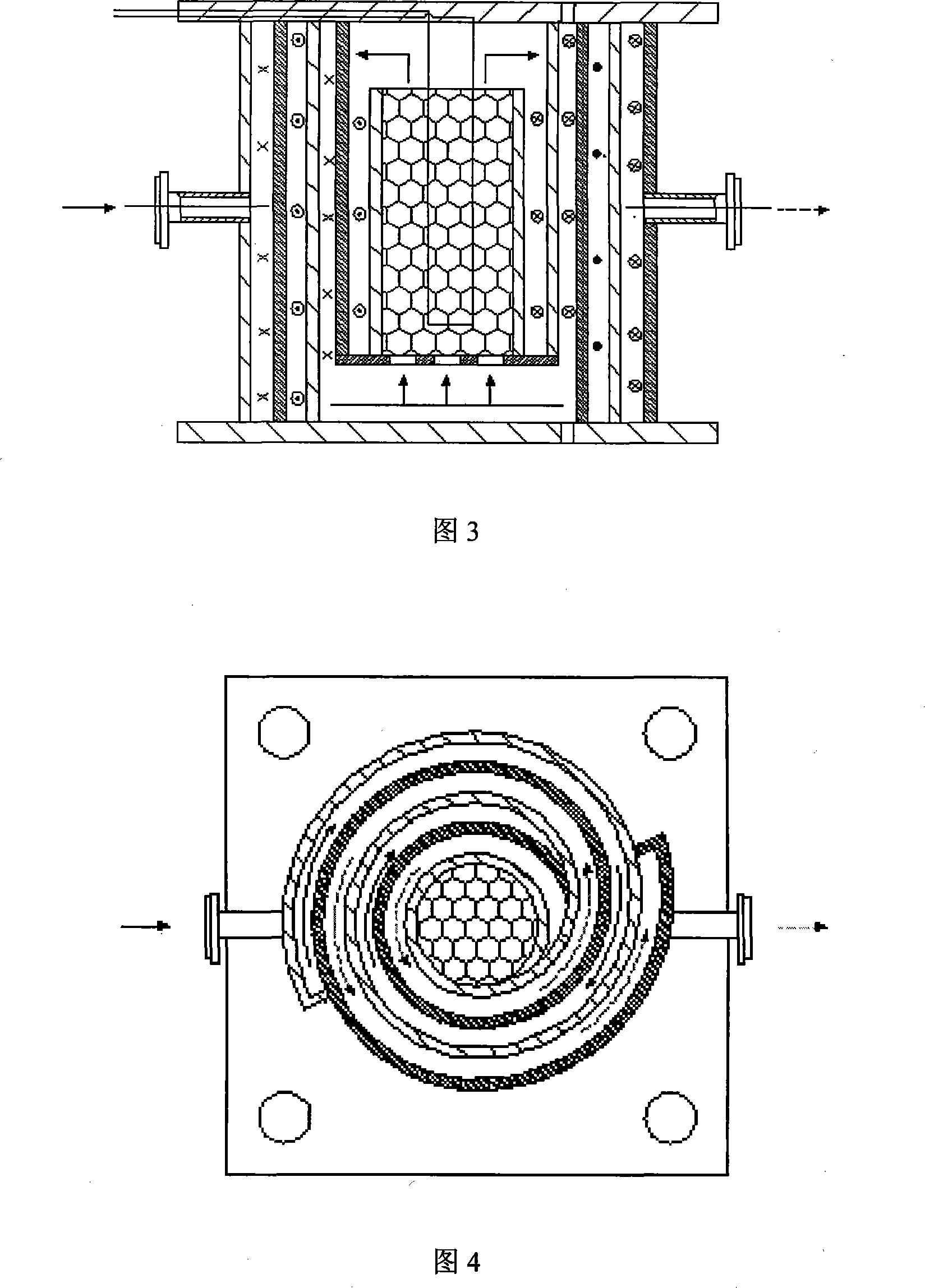

Mine ventilation mash gas burning and heat energy using device

InactiveCN101135441AExtended pathSimple structureCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermal energyCombustor

This invention belongs to the thermal energy utilization device of the mine ventilation gas and includes the counter current circular channel, the centrally positioned porous material and high temperature resistant heat pipe. The mine ventilation gas is conducted circlewise to the bottom of the combustion center, rectified by the gas distribution board, and combusted axially inside the porous medium. The flume is marshaled above and conducted to the circular channel for heat exchange with the mine ventilation gas. Through parallel installation of the combustion units, the real time control of the operational number of combustor based on the mine ventilation gas flux, the control of steam flux and electrical heating components in the high temperature heat pipe based on the temperature of the combusting area, this invention meets the requirement of mine ventilation gas processing on the flux and concentration, and ensures the stable operation of the devices.

Owner:UNIV OF SCI & TECH OF CHINA

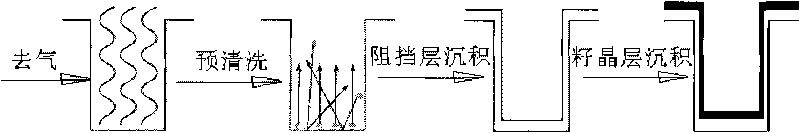

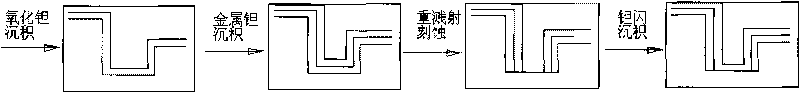

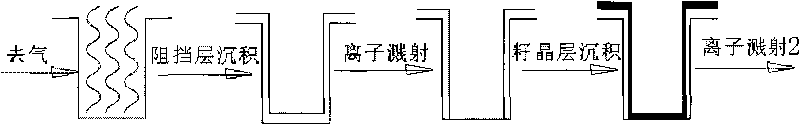

Method for preparing copper barrier layer-seed crystal layer film

ActiveCN101764084ANo pollution in the processSimple processVacuum evaporation coatingSputtering coatingTantalum nitrideInterconnection

The invention discloses a method for preparing a copper barrier layer-seed crystal layer film, which includes the steps of forming a through hole and a groove on a substrate at first, and performing deaeration treatment on the through hole and the groove; then depositing a tantalum nitride film and an antalum film; performing ion sputtering and finally depositing a seed crystal layer. The pre-cleaning step and re-sputtering step can be omitted through the ion sputtering step, which simplifies process and equipment and cannot generate pollution to the substrate. The method for preparing the copper barrier layer-seed crystal layer film can be applied to an interconnection process between copper and dual damascene with technical nodes below 45nm to expand the technical nodes below 32nm and avoid the expenses for updating ship manufacturing equipment when expanding to smaller technical nodes.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Plate glass on-line hot-state cutting and toughening technique

InactiveCN103159397AReduce the cost of temperingHigh strengthGlass tempering apparatusFlat glassProduction line

The invention relates to a plate glass on-line hot-state cutting and toughening technique which is characterized by comprising the following steps: arranging an on-line plate glass transverse cutting or\and longitudinal cutting apparatus in a certain section position at the hot end of a glass production line; carrying out on-line quenching and toughening on the cut hot-state glass plate with an on-line quenching apparatus, or carrying out on-line quenching and toughening with an on-line quenching apparatus after carrying out on-line hot bending with an on-line hot bending apparatus. The certain section position at the hot end of the glass production line refers to a certain section position of the glass plate after molding and before starting annealing. The on-line plate glass transverse cutting or\and longitudinal cutting apparatus is a laser glass cutting machine.

Owner:徐林波

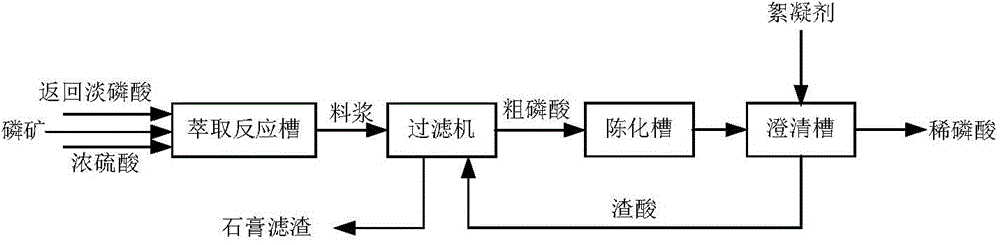

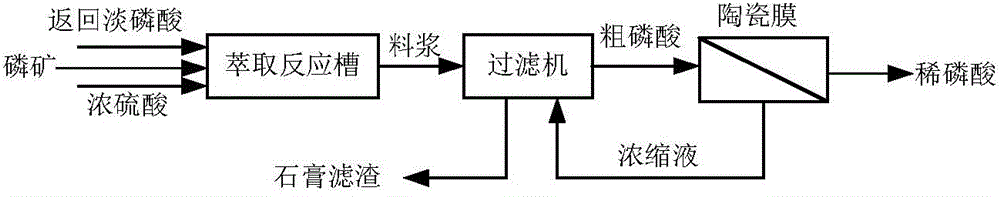

Wet phosphoric acid production process through ceramic membrane method

ActiveCN104828795AExcellent resistance to phosphoric acid corrosionLow resistance to phosphoric acid corrosionPhosphorus compoundsPhosphoric acidSmall footprint

The invention relates to a wet phosphoric acid production process through a ceramic membrane method. The wet phosphoric acid production process is characterized in that crude phosphoric acid filtered by a filter is pumped into a ceramic membrane separation system to be filtered, so that suspended matter in the crude phosphoric acid is removed, and clarified and transparent diluted phosphoric acid is obtained; and a ceramic membrane concentrated solution returns into the filter to circulate and is discharged along with gypsum filter residues. Compared with a conventional wet phosphoric acid production process, the wet phosphoric acid production process provided by the invention has the characteristics that the crude phosphoric acid filtered by the filter is not aged and clarified and directly enters the ceramic membrane separation system to be filtered, and therefore, the technological process and the crude phosphoric acid processing time are shortened; furthermore, a flocculating agent is not needed in the treating process; and, after the crude phosphoric acid is filtered, the solid content in the crude phosphoric acid is reduced to 0.01 wt% and below. The wet phosphoric acid production process disclosed by the invention can effectively solve the technical problems of long technological process and crude phosphoric acid processing time and low suspended matter removing efficiency in the traditional wet phosphoric acid production process; simultaneously, the ceramic membrane separation system in the invention is simple in equipment and small in occupation area; and continuous operation can be realized.

Owner:NANJING UNIV OF TECH

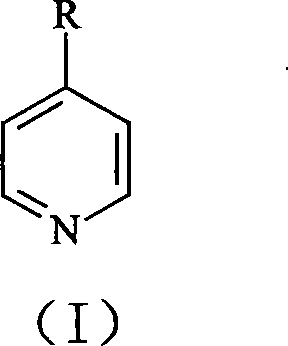

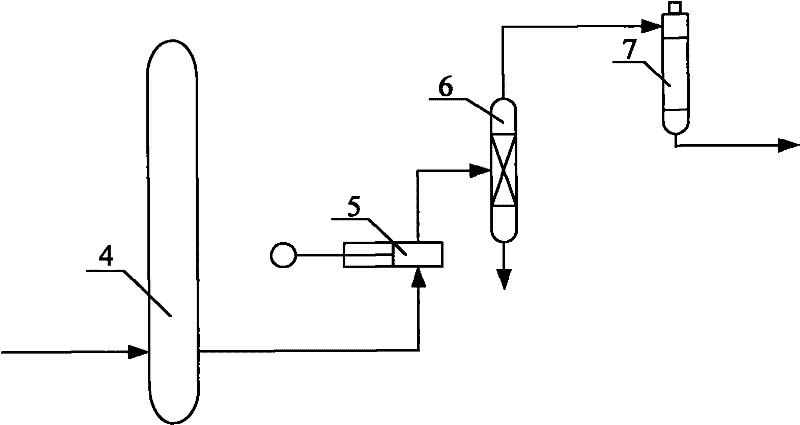

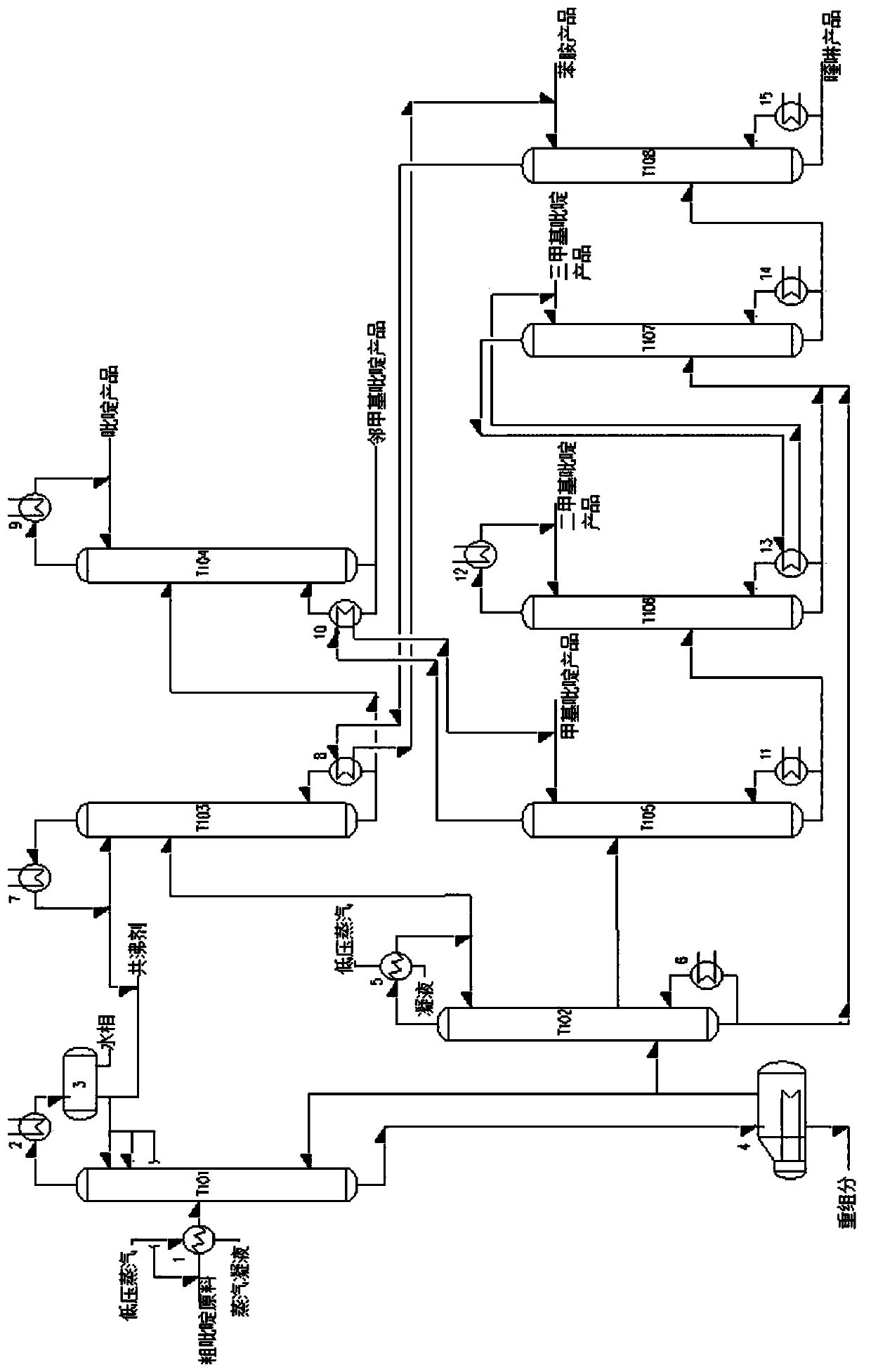

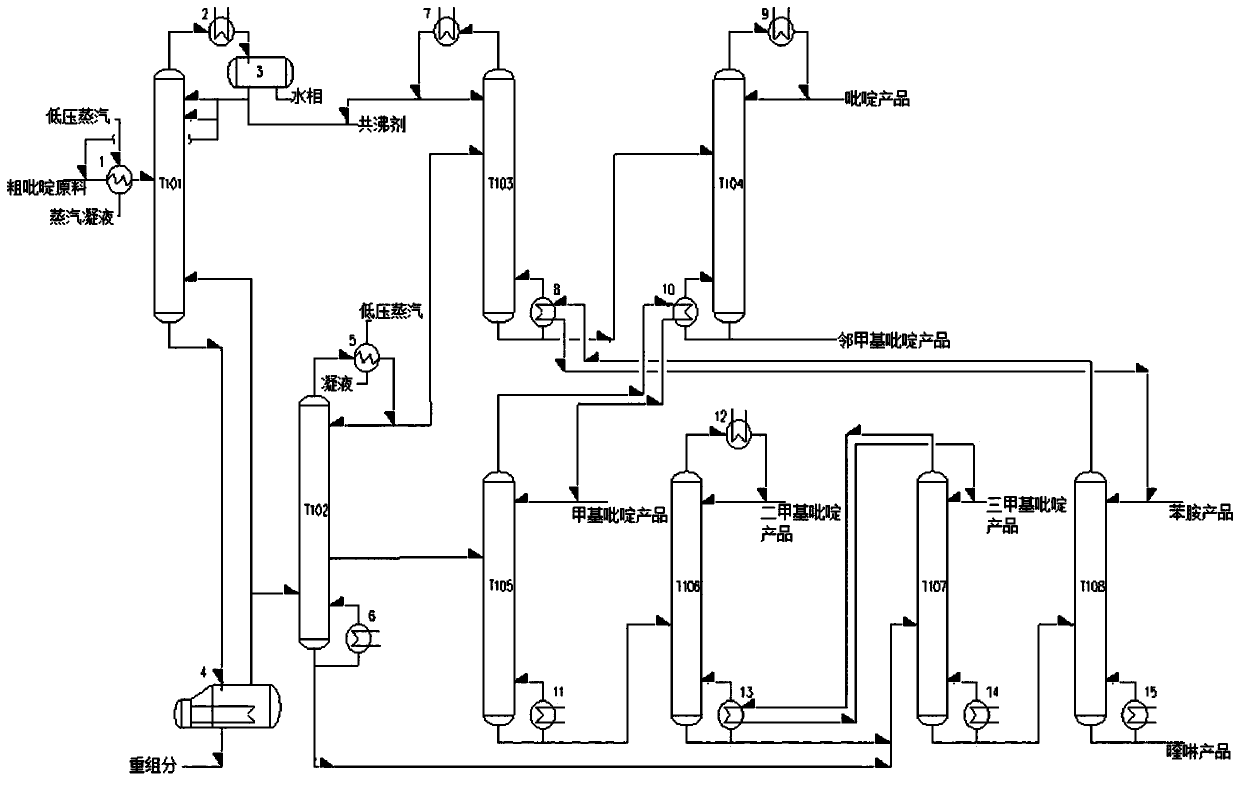

Method and device for preparing high-purity pyridine series products from crude pyridine by refining

ActiveCN109912500ASimple processSimplify equipmentOrganic chemistryChemical industryGas phaseEvaporation

The invention discloses a method for preparing high-purity pyridine series products from crude pyridine by refining. The method comprises following steps: (1), drying: a crude pyridine raw material and an entrainer are mixed and preheated to enter a drying tower for azeotropic distillation, water phase and the entrainer are obtained at the top of the drying tower, the entrainer is recycled or extracted for standby application, and a crude pyridine material is obtained at the bottom of the drying tower; (2), heavy component removal: the crude pyridine material obtained in step (1) enters an evaporation kettle and is subjected to the heavy component removal treatment, part of gas phase at the top of the evaporation kettle returns to the drying tower, and the other part enters a pre-fractionation tower and is subjected to light and heavy material fractionation; (3), distillation of the pyridine series products. The pyridine series products with high added value are separated out with adoption of azeotropic distillation, atmospheric and vacuum distillation and heat integration technologies, purity of pyridine, o-methylpyridine, methylpyridine, dimethyl pyridine and trimethyl pyridine reaches 96wt% or higher, and one energy-saving and high-efficiency technical method for preparing the high-purity pyridine series products from crude pyridine by refining is obtained.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

Method for refining waste lubricating oil and device thereof

ActiveCN101104832AAvoid crackingQuality improvementVacuum distillationLubricant compositionEvaporationImpurity effect

The invention discloses a method of refining disused lube. The method adopts low temperature adherent-film volatilizing rectification to regenerate disused lube into high quality lube. As the method adopted low temperature volatilizing.gasification to substitute boiling evaporation gasification in the general rectification, thereby the method can reduce energy consumption and pollution, and can prevent lube cracking and improve doffing impurity effect to ensure the regenerating effect. The invention also provides equipment used in the method which includes a rotating tablet adherent-film volatilization device without heat source provided in the vaporizing kettle. And the simple structure of the volatilization device makes the operation of refining high grade lube very easy.

Owner:北京百慧生化制药有限责任公司

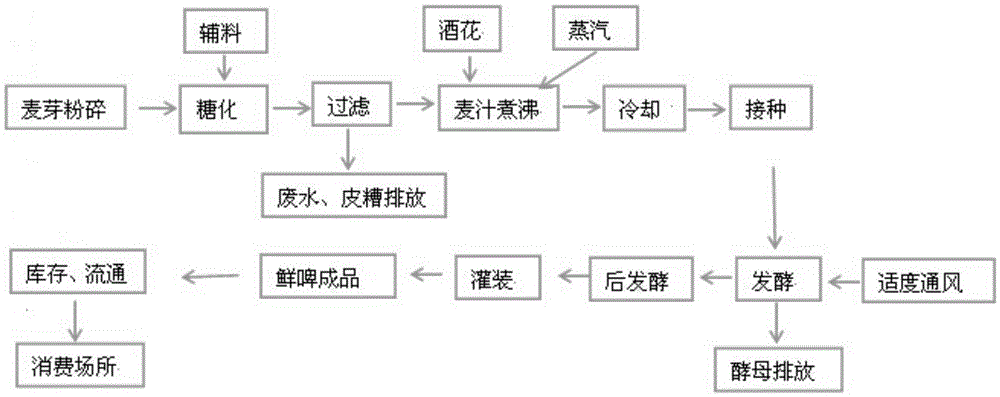

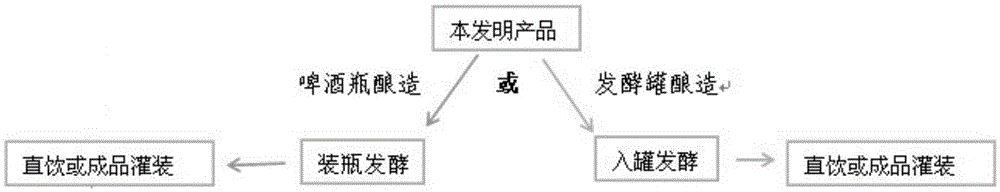

High-concentration beer fermentation type wort and preparation method and application thereof

ActiveCN105586193AEasy to storeEasy to transportBeer fermentationMicroorganism based processesHigh concentrationWastewater

The invention belongs to the technical field of preparation of alcoholic beverages, and particularly relates to high-concentration beer fermentation type wort and a preparation method and application thereof. The prepared high-concentration beer fermentation type wort serves as a semi-finished product, is convenient to store and transport, is directly supplied to a beer home-brewing site, and is fermented for 3-5 days by adding water with a certain proportion according to the taste, and beer with a fresh taste can be made. The needed process and equipment are greatly simplified, only a fermentation container and a fermentation process are needed, the fermentation period is shortened to 1 / 5 to 1 / 3 of that of the prior art, no waste water is drained in the fermentation process, steam heating is not needed, the occupied space is small, cleanliness and sanitation are achieved, and the procedure of producing fresh beer on special occasions (such as bars, hotels and other places with limited space and harsh environment requirements) is greatly simplified.

Owner:烟台麦特尔生物技术有限公司

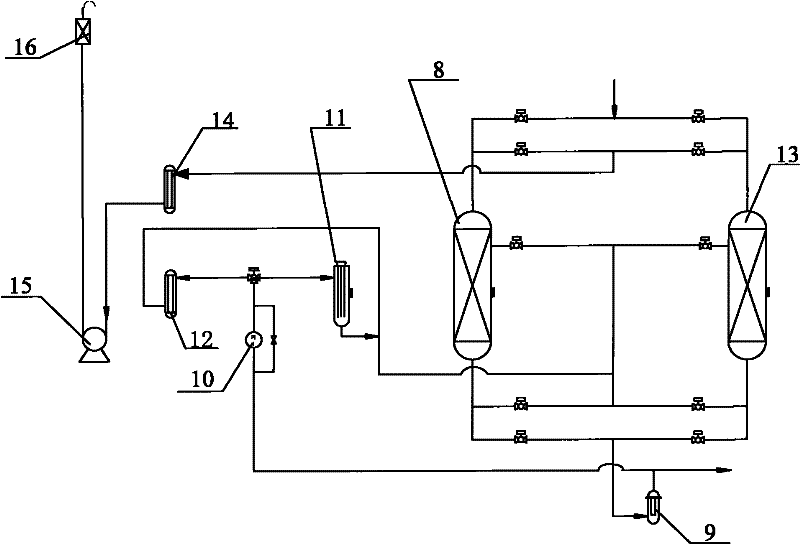

Acetonitrile refining technology and device

ActiveCN106631890ALow costReduce energy consumptionCarboxylic acid nitrile purification/separationChemical reactionBoiling point

The invention relates to an acetonitrile refining technology and a device. The technology comprises the following steps: feeding coarse acetonitrile into a flash evaporation tank for flash evaporation to obtain acetonitrile, water and a few tower bottoms with high boiling point; feeding the tower bottoms into a chemical reaction kettle, and adding a strong oxidizer and alkali to obtain a mixture mainly containing acetonitrile, water and heavy component; preheating the mixture and feeding into a permselective organic membrane separation device, wherein the acetonitrile penetrates the membrane to become permeating vapor through selective pervaporation; vacuumizing on the permeation side; condensing the permeating vapor and then feeding into a rectifying tower; and rectifying and separating to obtain high-purity acetonitrile in the tower kettle. According to the invention, the production technology and equipment are simplified; the adopted specific functional membrane for permselective organic acetonitrile is not limited by azeotropy, the energy consumption for pervaporation is low, the liquid mixture can directly enter the permselective organic membrane separation device, the equipment such as an evaporator is not needed, and the purity of the obtained acetonitrile can exceed 99.99%; and moreover, the technology has the characteristics of easiness in operation, low energy consumption, high yield and low production cost.

Owner:JIANGSU JIUMO HIGH TECH CO LTD

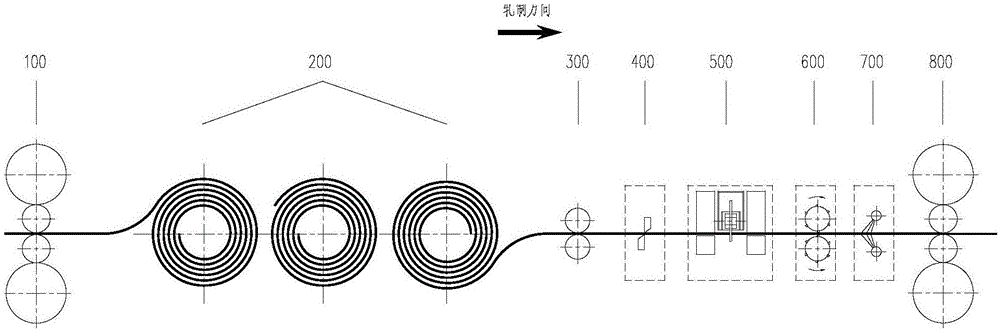

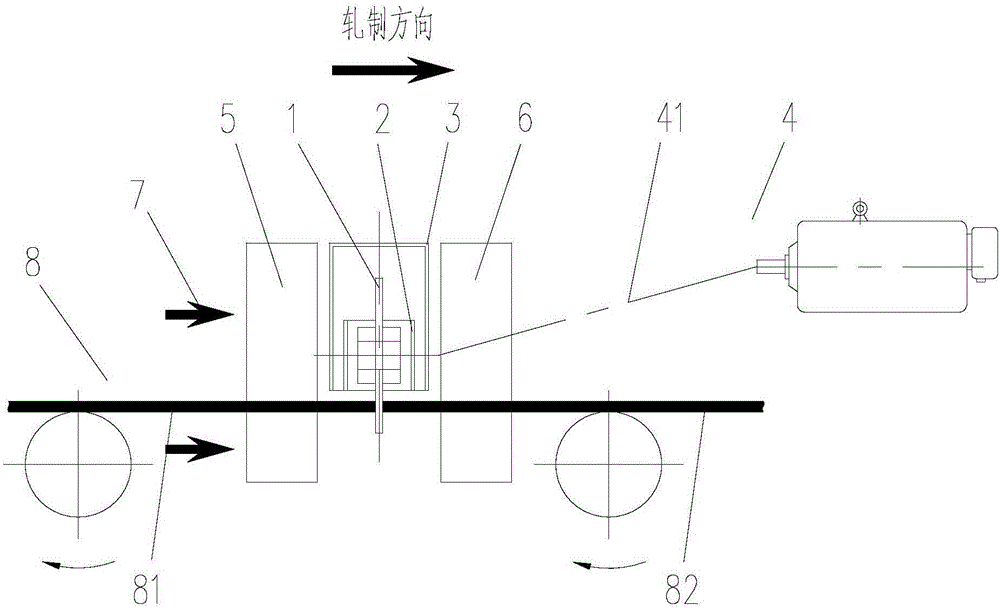

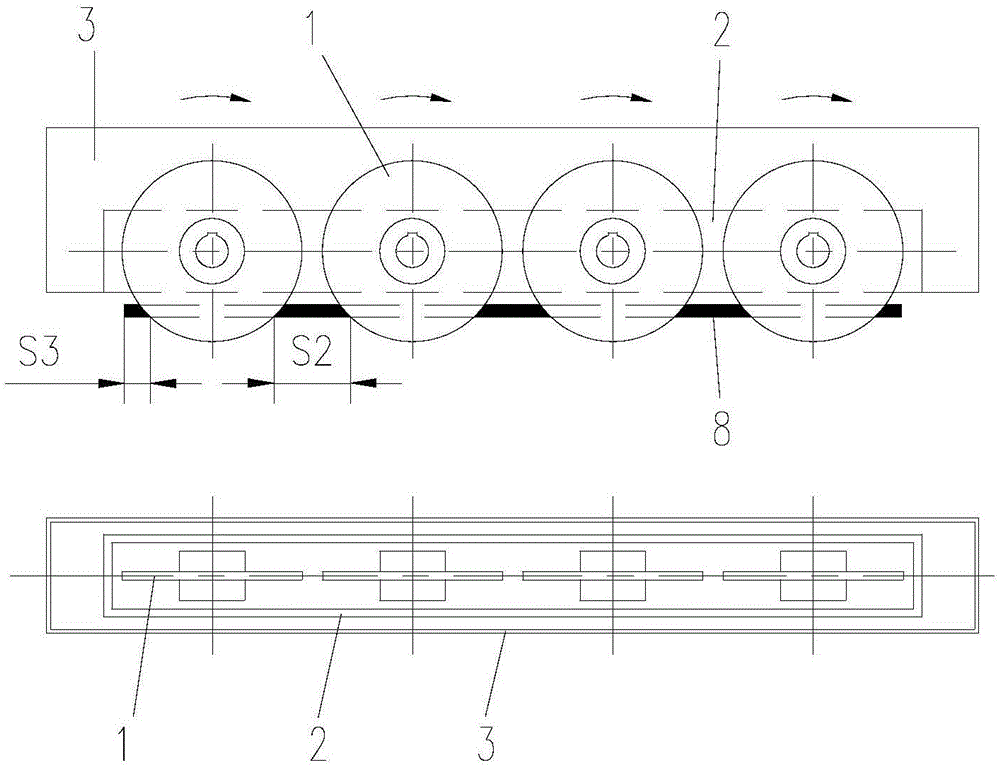

Connecting method and system for endless rolled intermediate slabs

ActiveCN106808082AFast connectionImprove connection strengthMetal rolling arrangementsNon-electric welding apparatusUltimate tensile strengthMechanical engineering

The invention provides a connecting method for endless rolled intermediate slabs. The method comprises the following steps: aligning the head and tail end portions of front and back intermediate slabs; rubbing the tail portion end surface of the front intermediate slab and the head portion end surface of the back intermediate slab; applying a forward force to the back intermediate slab in the rubbing period; and when the temperature of the connecting end surface of the front and back intermediate slabs is raised to a viscoplastic state, connecting the head of the back intermediate slab forward together with the tail portion of the front intermediate slab under the action of an upsetting force. The method provided by the invention is high in connecting strength, fast in connecting speed and low in energy consumption and is suitable for connecting slabs made from different materials.

Owner:CISDI ENG CO LTD

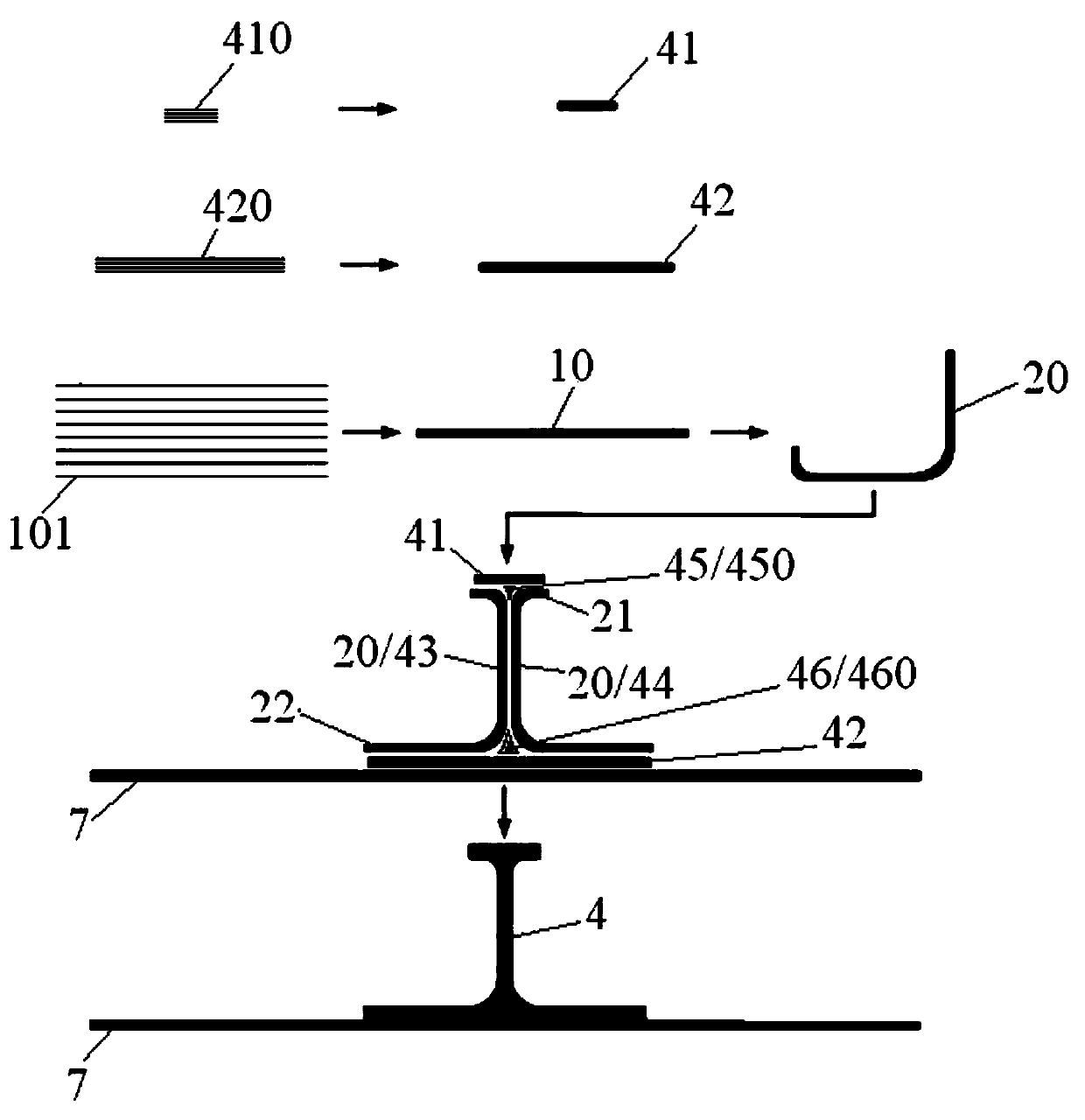

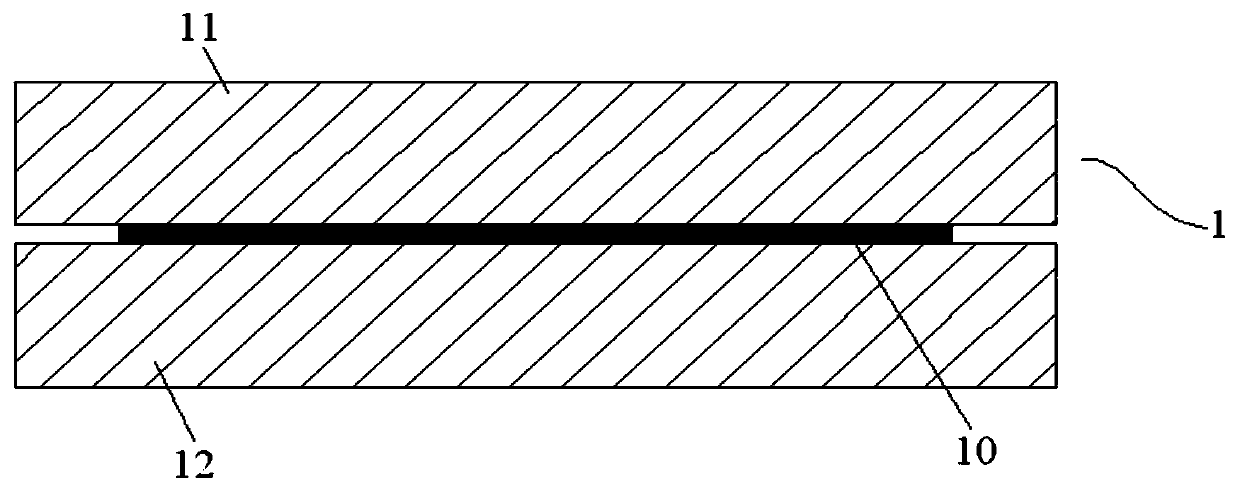

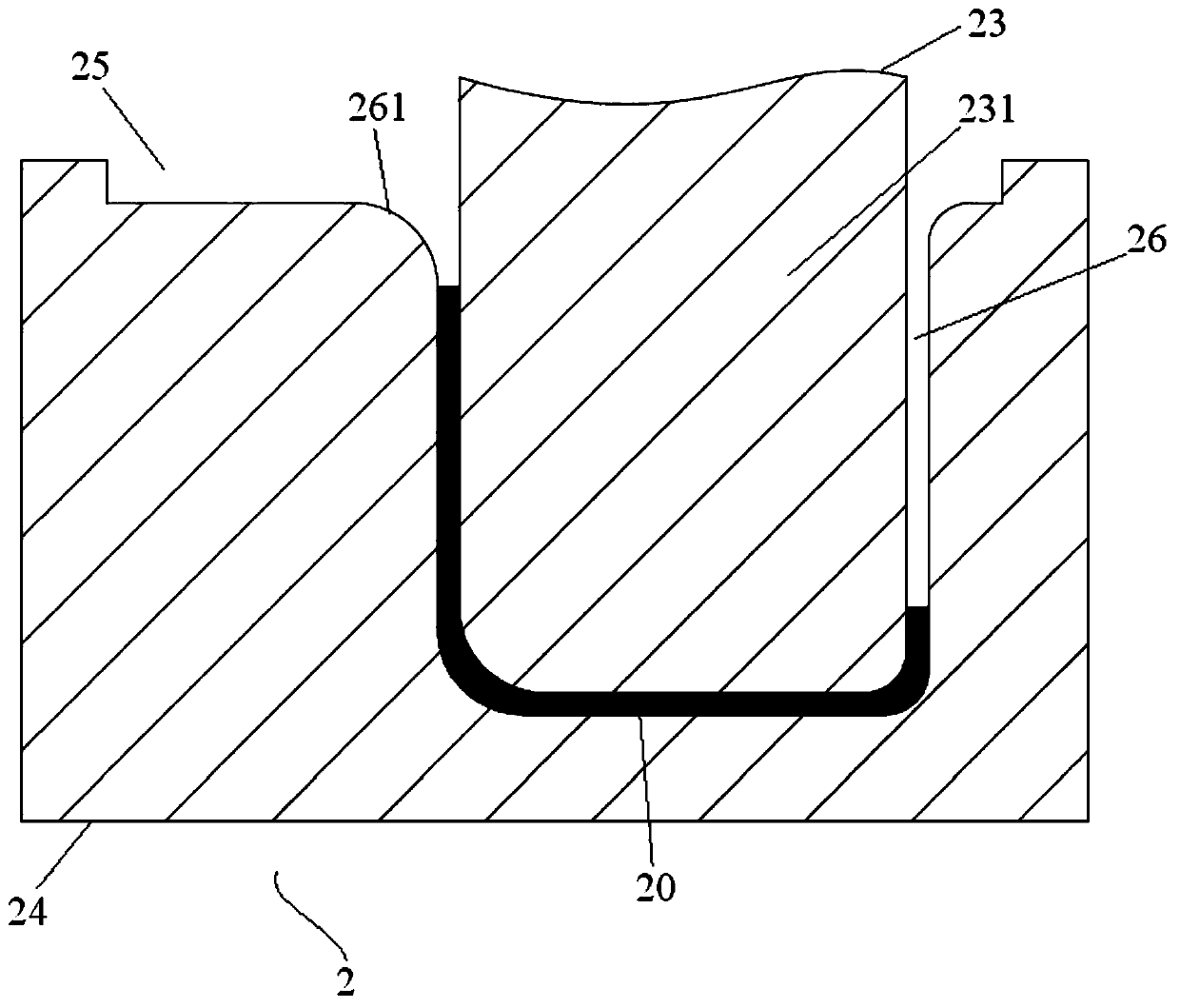

Compression molding method of thermoplastic composite component with I-shaped reinforcing ribs

ActiveCN110341210AOvercome uniformity issuesOvercoming problems such as high porosityCompression moldingAviation

The invention provides a compression molding method of a thermoplastic composite component with I-shaped reinforcing ribs. The compression molding method of the thermoplastic composite component withthe I-shaped reinforcing ribs includes: first prefabricating a flat plate prefabricated member and upper and lower edge block prefabricated members from thermoplastic composite prepreg sheets throughprimary mold pressing, then prefabricating two C-shaped prefabricated members by performing secondary mold pressing on the flat plate prefabricated member, then performing preassembly on the I-shapedreinforcing ribs by using the upper and lower edge block prefabricated members in combination, and finally preforming third mold pressing for shaping the component. Wide-end-up inclined planes are arranged on a left trapezoid strip and a right trapezoid strip of an I-shaped reinforcing rib component mold, and downward mold pressure of a pressing block is converted by the left trapezoid strip and the right trapezoid strip into horizontal direction pressure pointing at the I-shaped reinforcing ribs. The compression molding method of the thermoplastic composite component with the I-shaped reinforcing ribs overcomes the problems that multidirectional pressure transmission cannot be performed and a complex component is difficult in molding pressure transmission, and therefore the complex component is uneven in thickness, high in porosity rate and the like, thereby achieving low cost manufacture of the I-shaped reinforcing rib component, and laying a foundation for application of advanced thermoplastic resin matrix composites in the aviation field.

Owner:CENT SOUTH UNIV

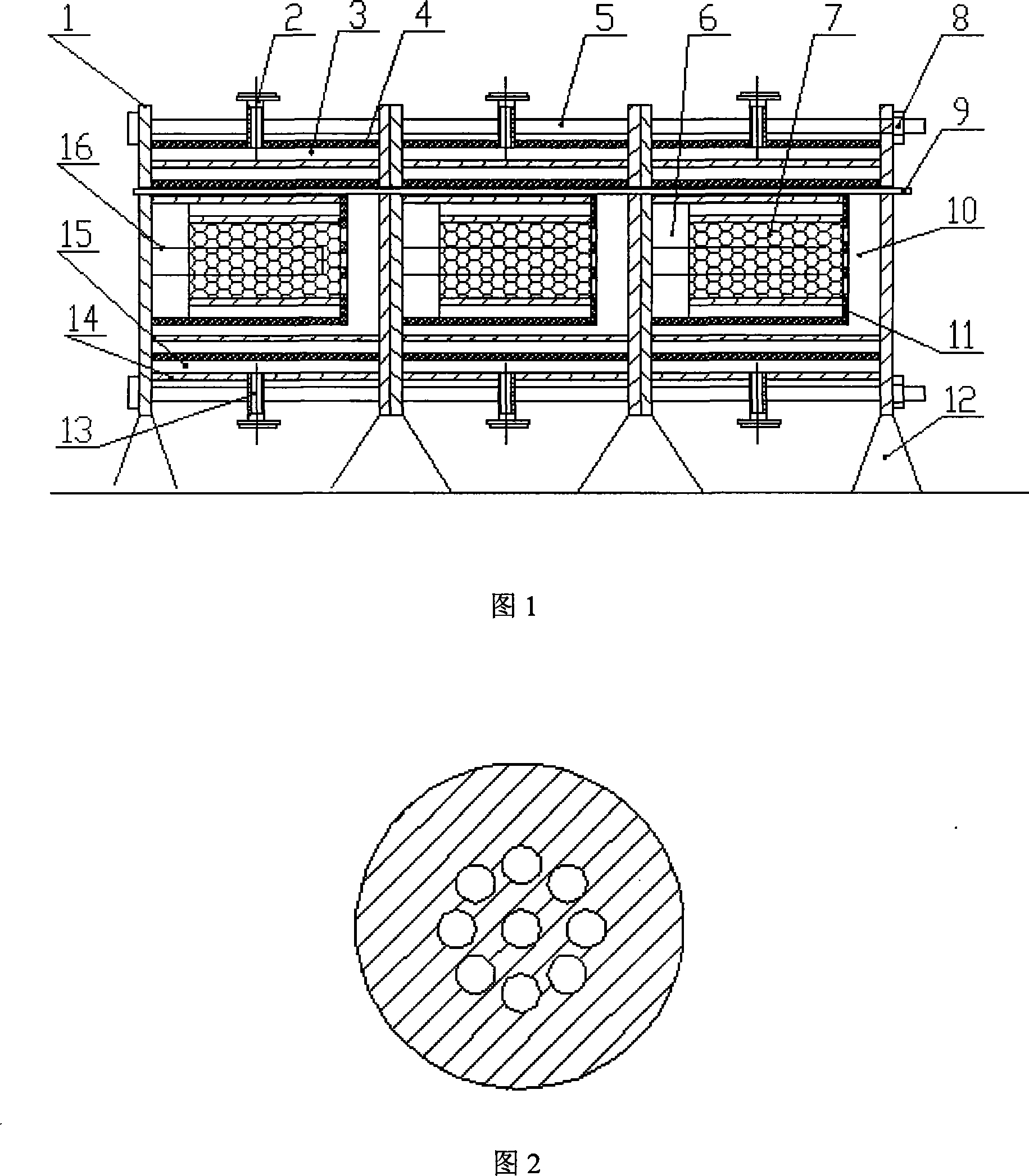

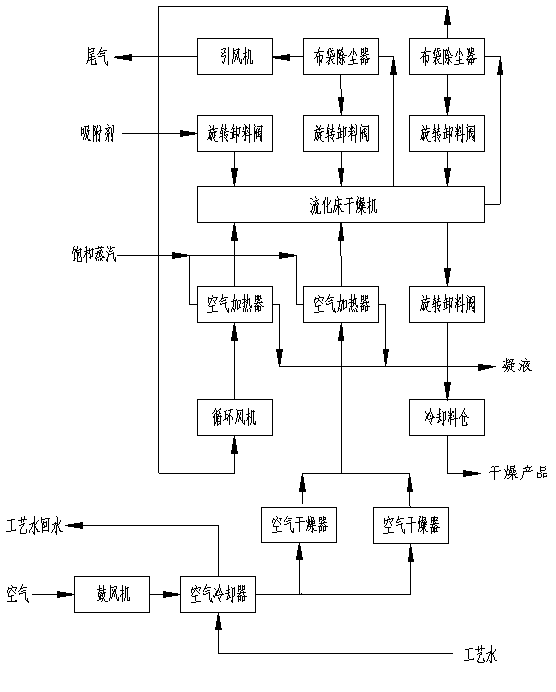

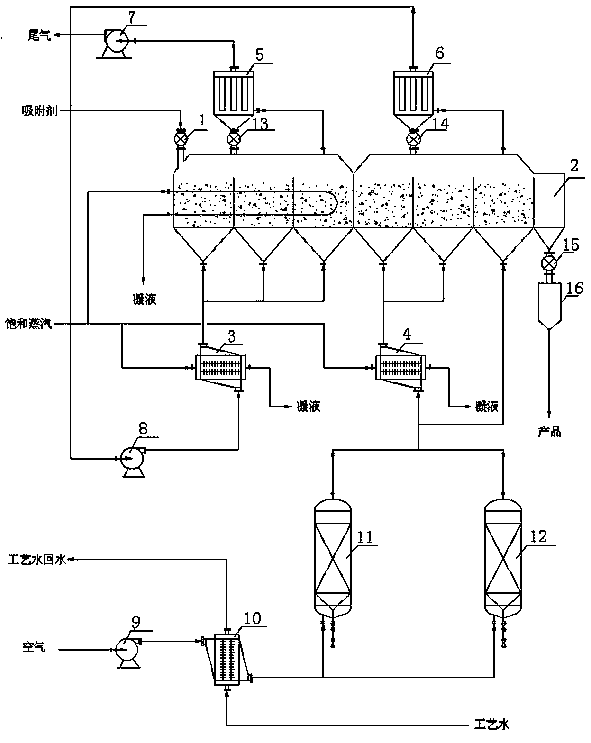

Drying and cooling integrated device for aromatic hydrocarbon adsorbent multi-chamber fluidized bed

InactiveCN103900347AImproved dwell time distributionImprove distributionDrying solid materials with heatHearth type furnacesFluidized bed dryingSorbent

The invention relates to a drying and cooling integrated device for an aromatic hydrocarbon adsorbent multi-chamber fluidized bed. The bottom of the fluidized bed is provided with a multi-hole sieve plate. Vertical baffles are arranged above the sieve plate and sequentially divide the fluidized bed into a dehydration chamber, a drying chamber, a cooling chamber and an unloading chamber in the automatic feeding opening direction. A saturated steam heating pipeline is arranged in the dehydration chamber, and tail gas, with low water content, exhausted from the drying chamber is used as carrier gas of the dehydration chamber so as to improve the system heat efficiency. According to the drying and cooling integrated device, dehydrating, drying, cooling and unloading of the aromatic hydrocarbon adsorbent are carried out in the same equipment, the process and the equipment are simplified to the maximum degree, the automation degree and the integration degree are high, and the functionality is high.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com