High-concentration beer fermentation type wort and preparation method and application thereof

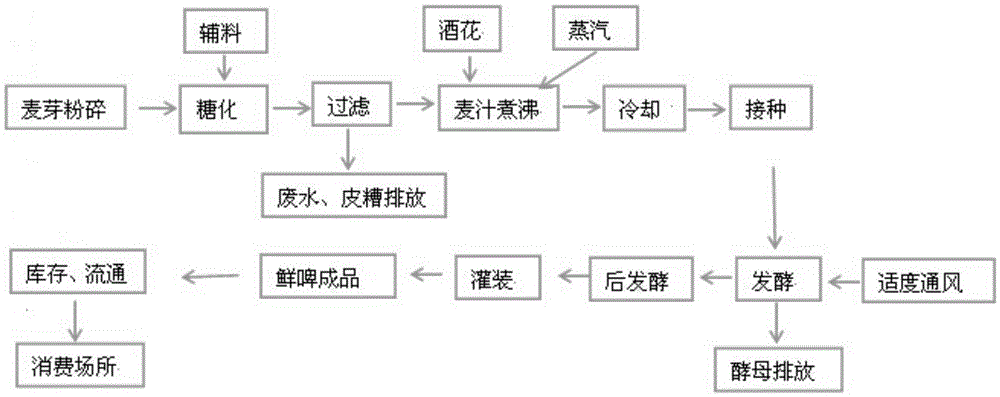

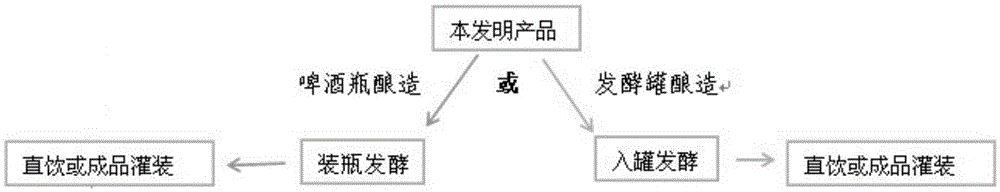

A beer fermentation and wort technology, which is applied in beer fermentation methods, biochemical equipment and methods, beer brewing, etc., can solve the problems of complex land occupation of equipment and facilities, environmental pollution, and difficulty in controlling procedures for non-professionals. Achieve the effects of small footprint, simplified process and equipment, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A high-concentration beer fermented wort, the components of which include: 160 parts of concentrated wort, 0.7 parts of hops and 0.2 parts of brewer's yeast.

[0030] The preparation method of above-mentioned high concentration beer fermented wort, the steps are as follows:

[0031] (1) Preparation of beer wort

[0032] The malt is crushed to a particle size of 400-500 μm, kept at 50°C for 20 minutes, saccharified at 65°C for 120 minutes, and filtered to obtain beer wort with a dry matter of more than 20wt%;

[0033] (2) Preparation of concentrated wort

[0034] Concentrating the beer wort prepared in the step (1) in a vacuum at 70° C. to a dry matter of more than 75 wt % to obtain concentrated wort;

[0035] (3) Basic beer fermentation

[0036] Dilute the concentrated wort obtained in step (2) with water until the sugar content is 12°P, add 0.3% hops by weight of concentrated wort slurry, boil and cool down to 12°C, inoculate brewer’s yeast with 0.1‰ concentrated wo...

Embodiment 2

[0043] A high-concentration beer fermented wort, its components include: 112 parts of concentrated wort, 0.52 parts of hops and 0.1 part of brewer's yeast.

[0044] The preparation method of above-mentioned high concentration beer fermented wort, the steps are as follows:

[0045] (1) Preparation of beer wort

[0046] The malt is crushed to a particle size of 500-800 μm, kept at 45°C for 20 minutes, saccharified at 65°C for 100 minutes, and filtered to obtain beer wort with a dry matter of more than 20wt%;

[0047] (2) Preparation of concentrated wort slurry

[0048] Concentrating the beer wort prepared in the step (1) in a vacuum at 80° C. to a dry matter of more than 75 wt % to obtain a concentrated wort slurry;

[0049] (3) Basic beer fermentation

[0050] Dilute the concentrated wort slurry prepared in step (2) with water until the sugar content is 12°P, add 2% hops of the concentrated wort slurry weight, boil and cool down to 12°C, inoculate the concentrated wort slurr...

Embodiment 3

[0057] A high-strength beer fermented wort, its components include: 225 parts of concentrated wort, 1.1 parts of hops and 0.15 parts of brewer's yeast.

[0058] The preparation method of above-mentioned high concentration beer fermented wort, the steps are as follows:

[0059] (1) Preparation of beer wort

[0060]The malt is crushed to a particle size of 700-800 μm, kept at 45°C for 20 minutes, saccharified at 63°C for 80 minutes, and filtered to obtain beer wort with a dry matter of more than 20wt%;

[0061] (2) Preparation of concentrated wort slurry

[0062] Concentrating the beer wort prepared in step (1) in vacuum at 60° C. to a dry matter of more than 75 wt % to obtain concentrated wort slurry;

[0063] (3) Basic beer fermentation

[0064] Dilute the concentrated wort slurry prepared in step (2) with water until the sugar content is 12°P, add hops with 1% of the concentrated wort slurry weight, boil and cool down to 12°C, inoculate the concentrated wort slurry with 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com