Mine ventilation mash gas burning and heat energy using device

A mine ventilation and combustion device technology, which is applied in the direction of using various fuel combustion, combustion methods, combustion types, etc., can solve the problems of unstable combustion inside porous media, complex equipment structure and operation, and difficult positioning of porous media, etc., to achieve improvement Effects of combustion stability and completeness, simplification of equipment and operation, and reduction of concentration limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

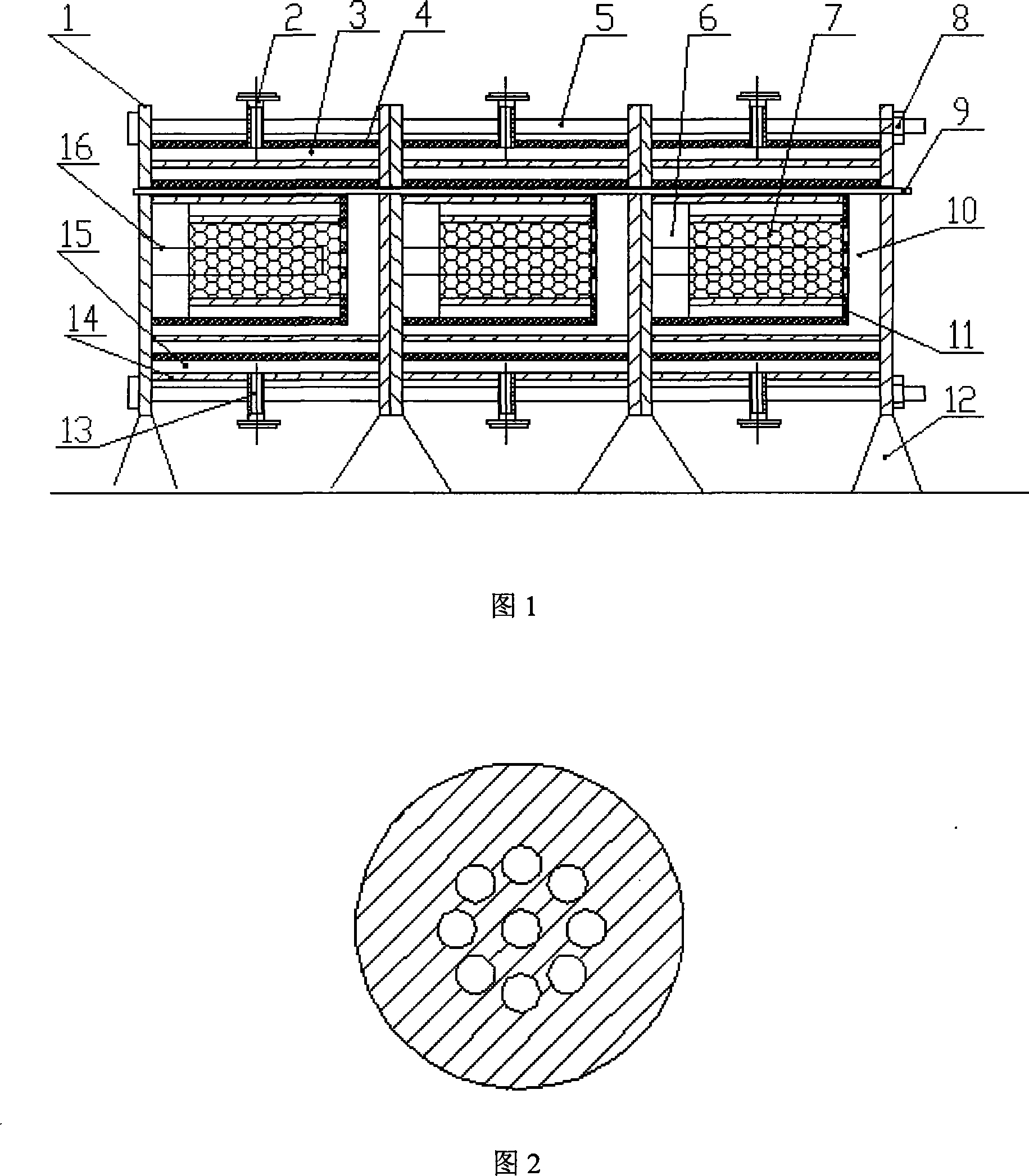

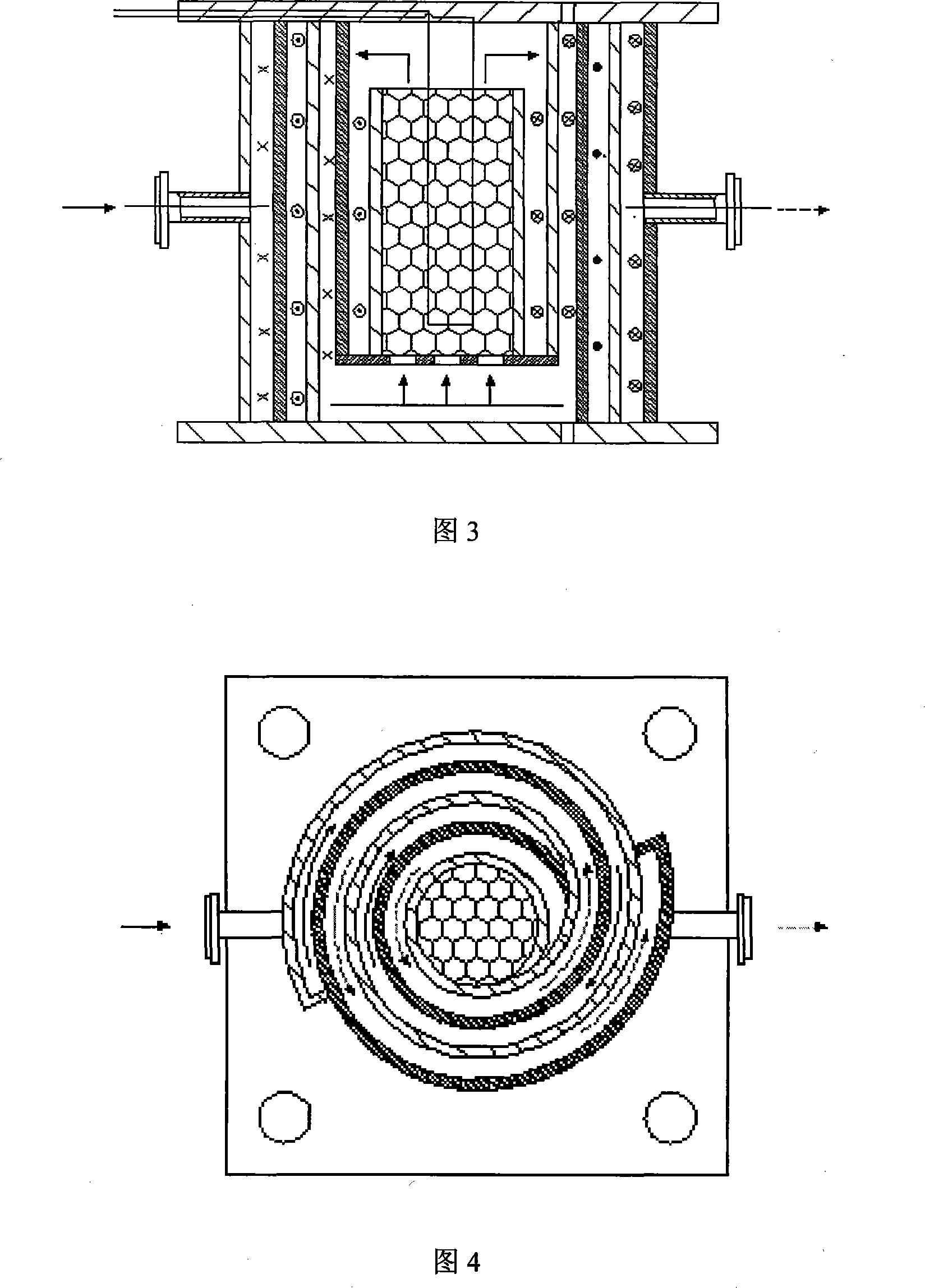

[0012] The specific implementation of a mine ventilation gas combustion and heat energy utilization device of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Fig. 1 shows a schematic structural diagram of an example of a mine ventilation gas combustion and heat energy utilization device of the present invention. A single burner has four holes on the plate 1, through which a rod 5 penetrates through the hole, and the end is fixed with a bolt 8, and a plurality of annular burners are assembled in parallel to form the device. The number of annular burners connected in parallel is determined by the maximum flow rate of mine ventilation gas in specific use. The gas inlet 13 and gas outlet 2 of the burner are respectively connected in parallel to the mine ventilation gas main pipeline and the flue gas discharge pipeline, and a solenoid valve is installed to control the number of burners used according to the real-time flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com