Ceramic with light weight, high strength and high toughness and preparation method thereof

A high-toughness, ceramic technology, applied in the field of high-strength, light-weight, high-toughness ceramics, can solve the problems of difficult preparation of nanocrystalline ceramic products, difficulty in ensuring mixing uniformity, and insignificant toughening effect, etc., to achieve light weight, The effect of high toughness and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

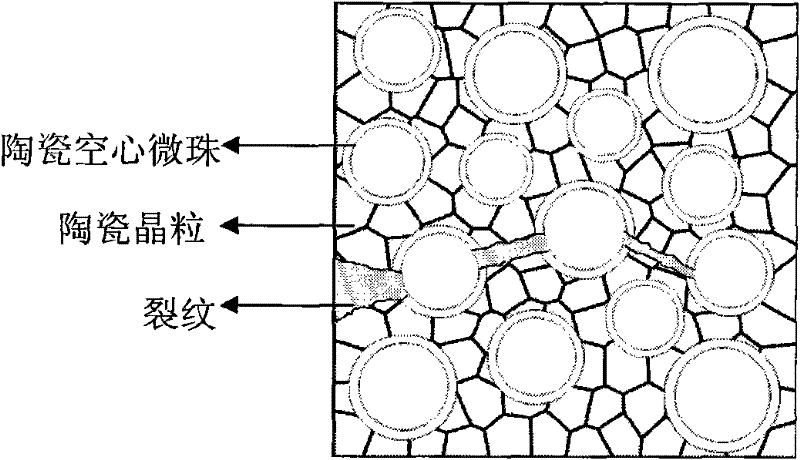

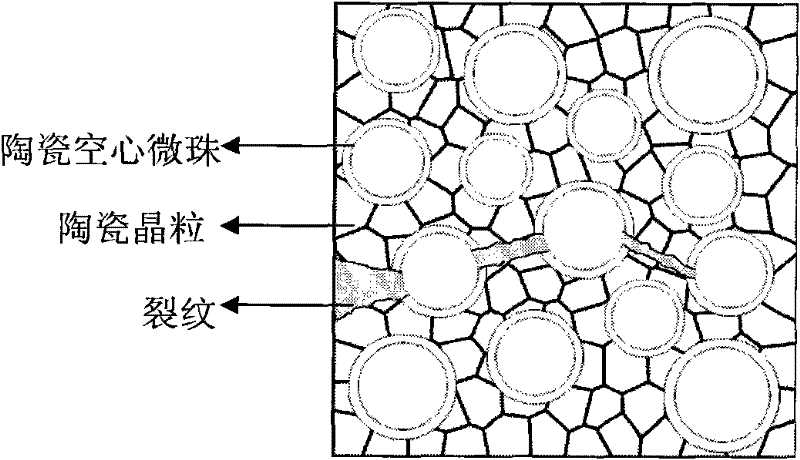

Image

Examples

preparation example Construction

[0025] A kind of preparation method of light weight, high strength, high toughness ceramics of the present invention comprises the following steps:

[0026] Step 1, pre-sintering the ceramic hollow microsphere powder to improve the strength of the ceramic hollow microsphere powder;

[0027] Step 2, adding the above-mentioned pre-fired ceramic hollow microsphere powder to the ceramic powder, and adding relevant additives;

[0028] Step 3, select a forming process to form ceramics;

[0029] Step 4, drying the green body;

[0030] Step five, sintering the dried green body.

[0031] The ceramic hollow microsphere powder is pre-sintered. The sintering atmosphere is air or nitrogen. Different powder systems choose different sintering atmospheres. For example, silicon nitride hollow microspheres are pre-sintered in a nitrogen atmosphere, and alumina, zirconia, etc Other oxide ceramics can be pre-sintered in an air atmosphere.

[0032] Wherein, the ceramic hollow microsphere powde...

Embodiment 1

[0041] Example 1: Preparation of light, high-strength, high-toughness silicon nitride ceramic material

[0042] First, the silicon nitride hollow microsphere powder is pre-sintered. The sintering system is as follows: the temperature is raised at a rate of 10°C / min, the sintering temperature is 1600°C, and the sintering is carried out under a nitrogen atmosphere. The holding time at 1600°C is 0.5 hours. Dissolve monomer acrylamide and cross-linking agent N,N'-methylenebisacrylamide in water, the monomer concentration is 14.5%, the cross-linking agent concentration is 0.5%, to form a monomer premix, in the monomer premix Add 107.1g of silicon nitride powder to 80mL, add 2.99g of alumina powder as a sintering aid with a silicon nitride powder content of 2.5%, and 8.86g of yttrium oxide powder with a silicon nitride powder content of 7.5%, and a dispersant of alkaline water Agent 1.19g, silicon nitride hollow microsphere powder 11.9g, stir to obtain ceramic slurry, add the cataly...

Embodiment 2

[0043] Embodiment 2: Preparation of light weight, high strength, high toughness silicon nitride ceramic material

[0044] Add 11.9g of silicon nitride hollow microsphere powder, 2.99g of sintering aid alumina powder and 8.86g of yttrium oxide powder to 107.1g of silicon nitride powder, add alcohol and balls to wet mill for 24 hours, dry and sieve , adding 5% paraffin as a molding agent, pressing the elongated sample in a steel mold with a pressure of 120Mpa, and sintering after dewaxing. The bulk density, strength, fracture toughness and other properties of the sintered body are tested. The results show that the prepared silicon nitride ceramics have a bulk density of 3.2, a flexural strength of 550MPa, and a fracture toughness of 9MPa·m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com