Display panel, manufacturing method thereof and display device

A display panel and substrate technology, applied in the field of display devices and display panels, can solve the problems of water molecules escaping, shortening the life of display products, and eroding the luminescent functional layer, so as to slow down the erosion, increase the lifespan, and slow down the release speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In order to further illustrate the display panel, the manufacturing method thereof, and the display device provided by the embodiments of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

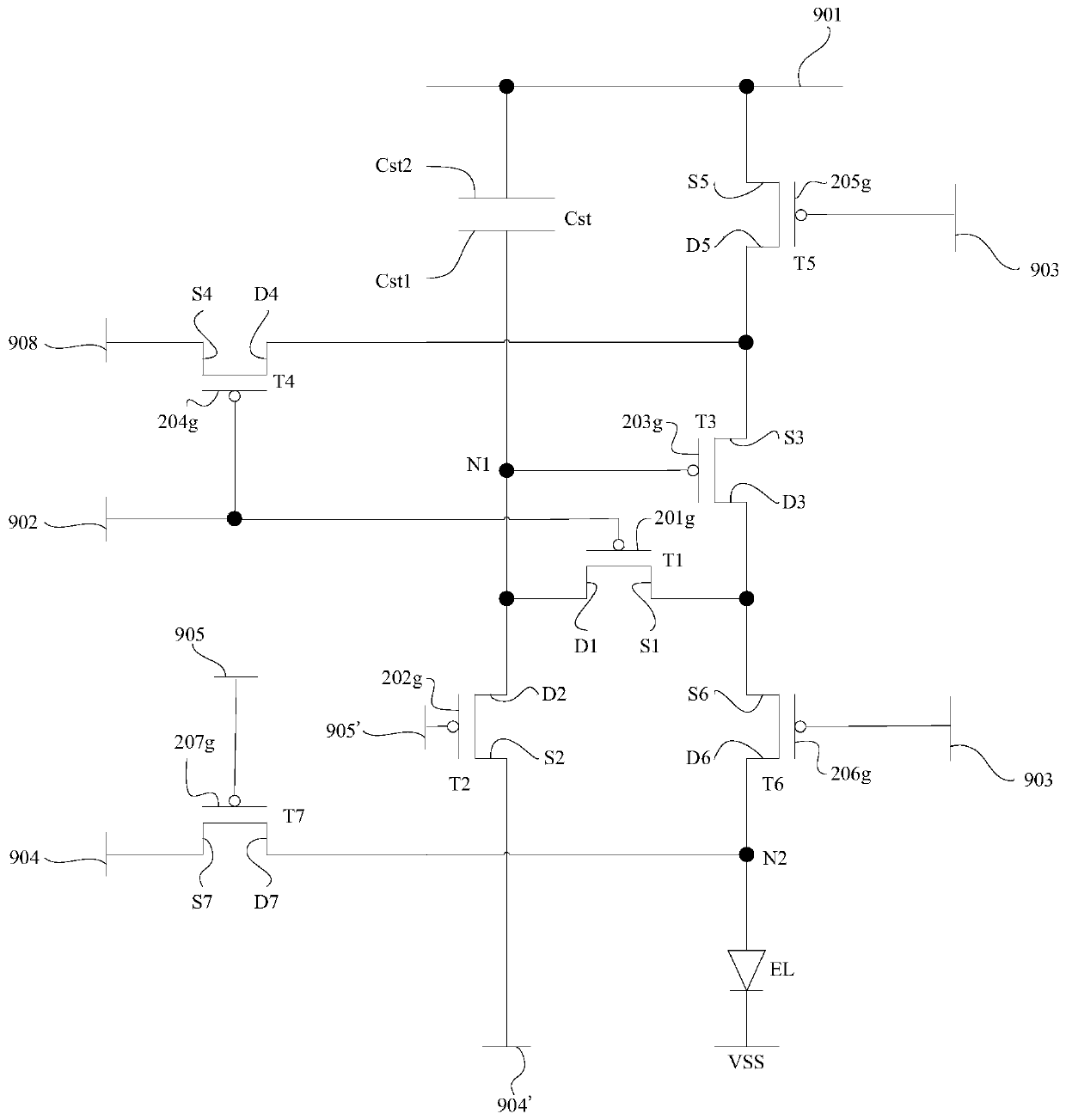

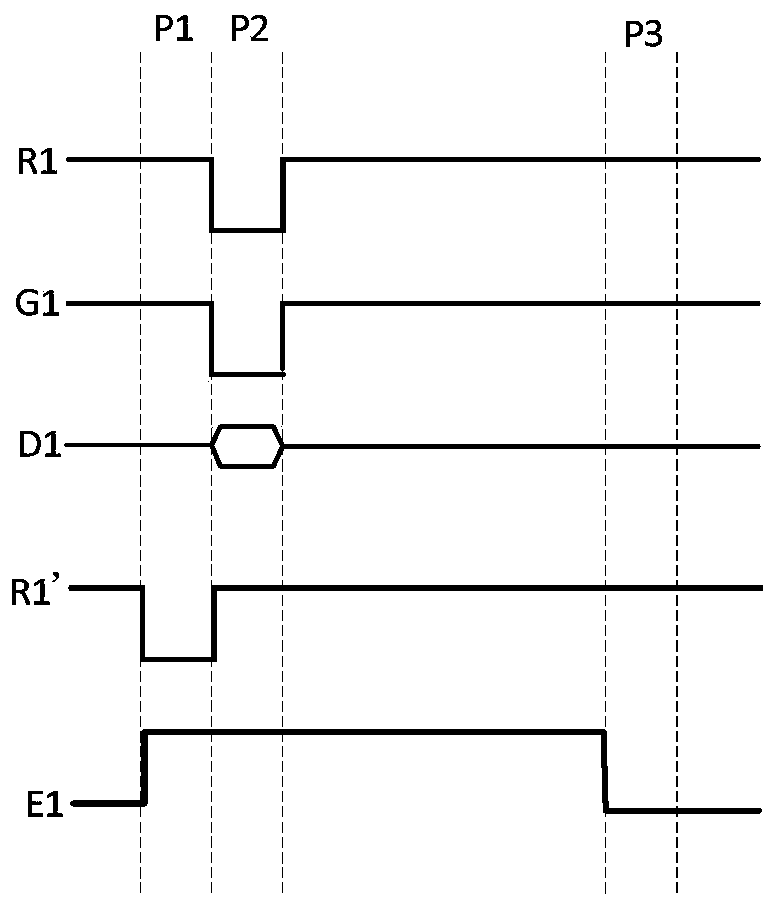

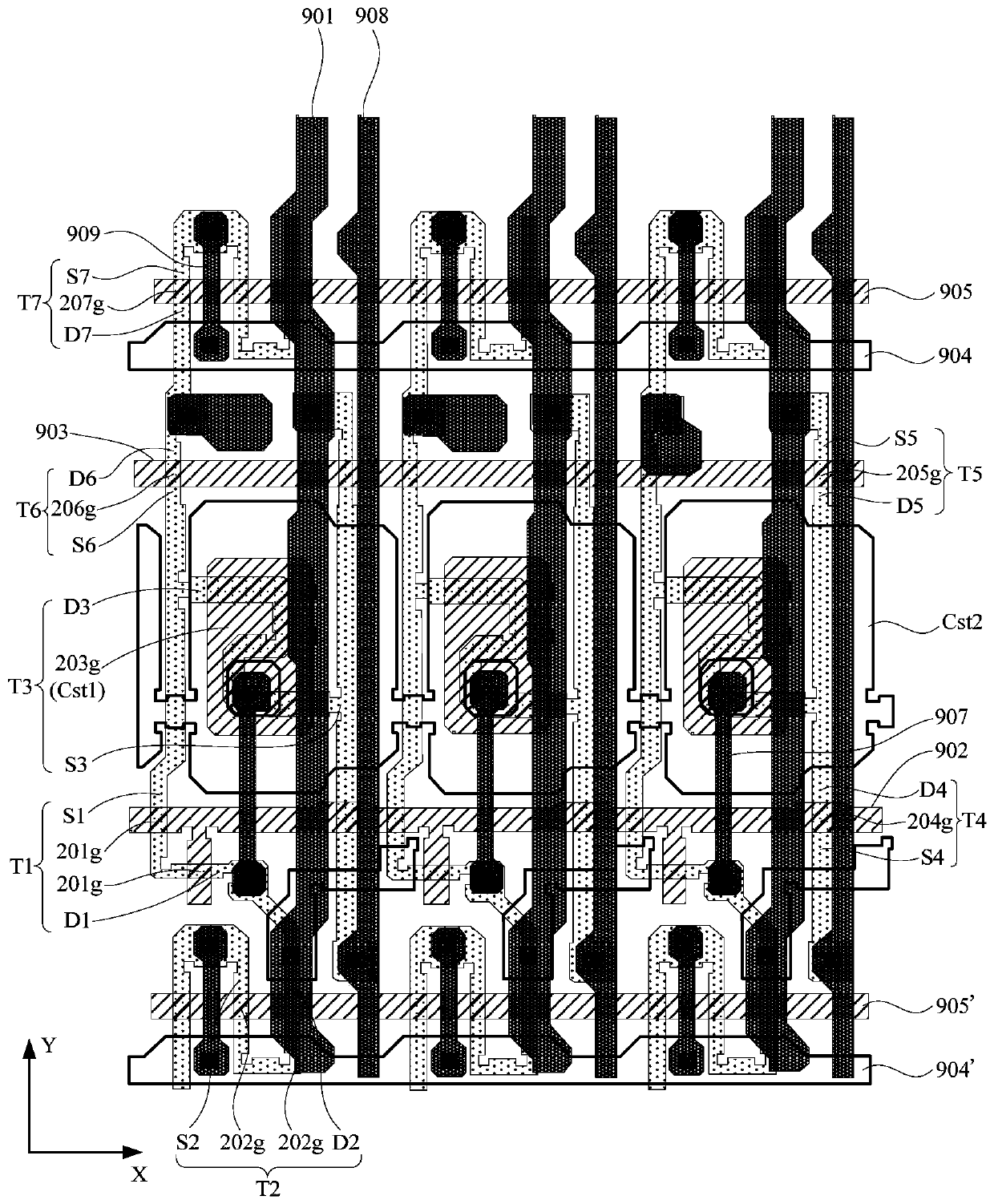

[0075] Such as image 3 and Figure 8 As shown, the present invention provides a display panel, which includes a plurality of pixel units distributed in an array, and each pixel unit includes a plurality of sub-pixels. Each sub-pixel includes a sub-pixel driving circuit, a power signal line pattern 901, a data line pattern 908, a gate line pattern 902, a light emission control signal line pattern 903, a reset signal line pattern 905, an initialization signal line pattern 904 and an anode pattern 320; At least part of the power signal line pattern 901 and the data line pattern 908 extend along the second direction; the gate line pattern 902, the light emission control signal line pattern 903, the reset signal line pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com