Novel composite tritium resisting coating and preparation method thereof

A technology for blocking tritium and coating, applied in the field of novel composite tritium blocking coating and its preparation, can solve the problems of difficult sintering and densification of ceramic coating, and achieve the effects of high production efficiency, good bonding force, simple and mature process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

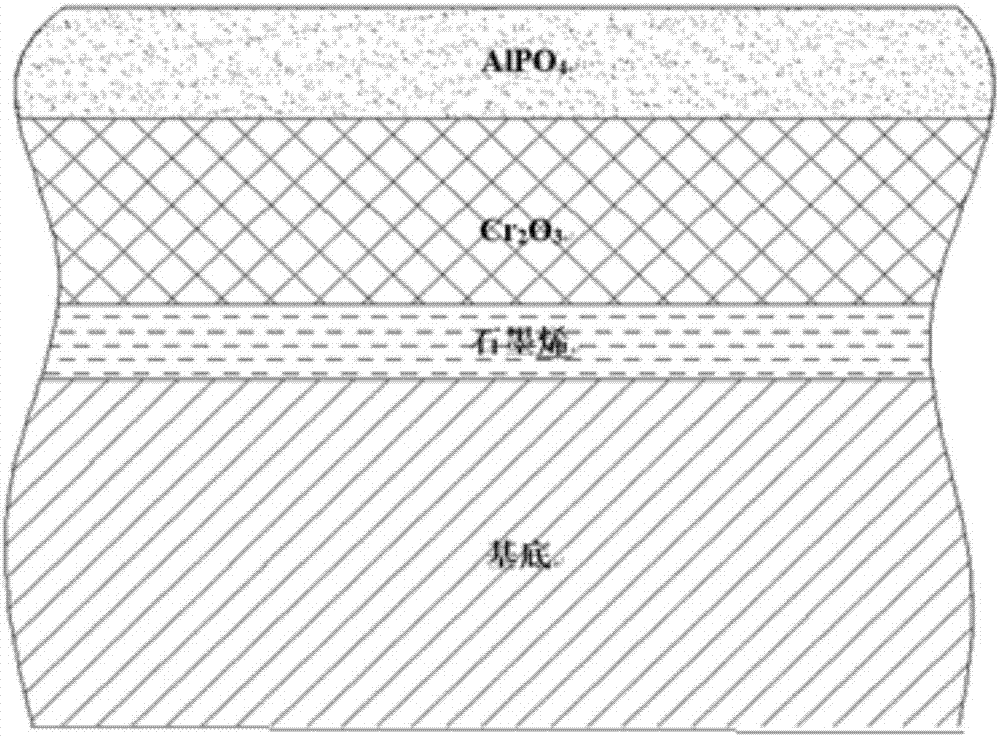

[0037] The preferred embodiment of the present invention also provides a preparation method of the novel composite tritium-blocking coating as described above, the preparation method comprising the following steps:

[0038] Step 1, forming a layer of graphene film on the base layer, specifically includes the following sub-steps:

[0039] (11) The graphene solution is evenly coated on the surface of the base layer by dipping and pulling method. Specifically, after immersing the base layer in a graphene solution with a concentration of 0.01-1.0 wt % and standing for 2-10 minutes, the base layer is pulled out at a speed of 0.1-1 mm / s, and the base layer is Dry at a temperature of 50-60°C for 5-10 minutes.

[0040] (12) Repeat step (11) 5 to 50 times, then heat-treat the product of step (11) in an argon or nitrogen atmosphere for 20 to 300 minutes, and then naturally cool to room temperature to obtain a graphene film. In this embodiment, the heat treatment temperature is 500-800...

example 1

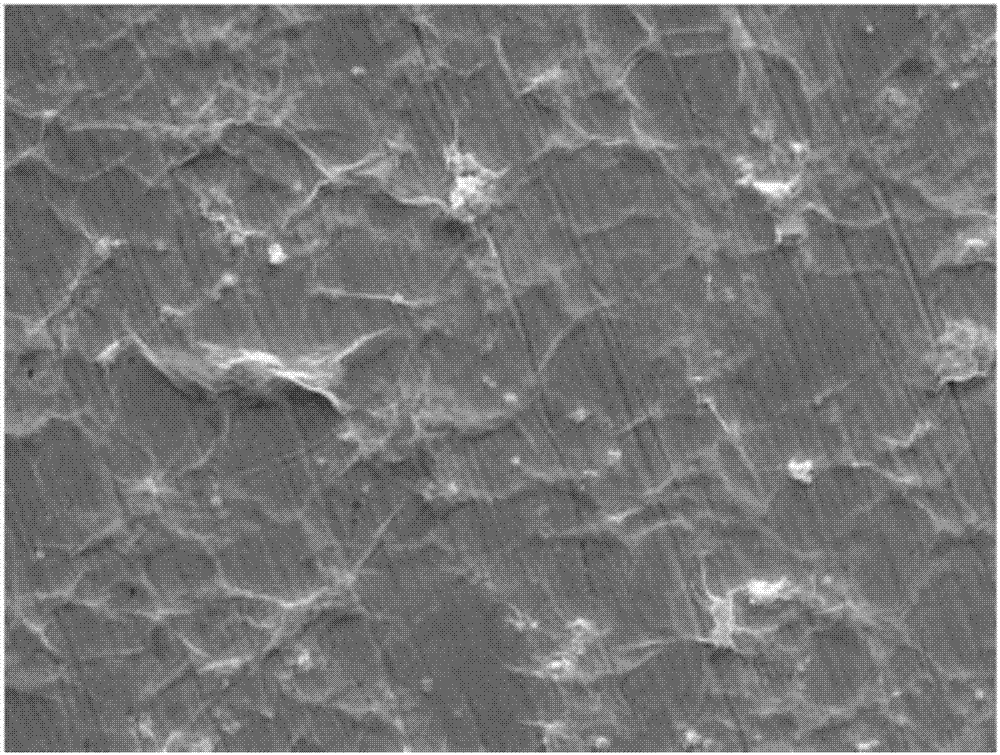

[0049] At room temperature, after immersing the polished and cleaned stainless steel substrate in a graphene solution with a concentration of 0.01 wt% and standing for 10 minutes, the stainless steel substrate was pulled out at a speed of 0.1 mm / s, and then After the stainless steel substrate was dried at a temperature of 60° C. for 10 min, the above-mentioned dipping and pulling-drying step was repeated 50 times to form a layer of graphene film on the stainless steel substrate; after that, the graphene film coated with After the stainless steel substrate was heat-treated for 20min in Ar atmosphere, it was naturally cooled to room temperature, and the heat treatment temperature was 500°C; then, the stainless steel substrate and Pt electrode coated with graphene film were immersed in CrO 3 The concentration is 100g / L, the concentration of concentrated sulfuric acid is 1.0g / L CrO 3 - Start electroplating after the sulfuric acid solution stands for 2 minutes, the distance between...

example 2

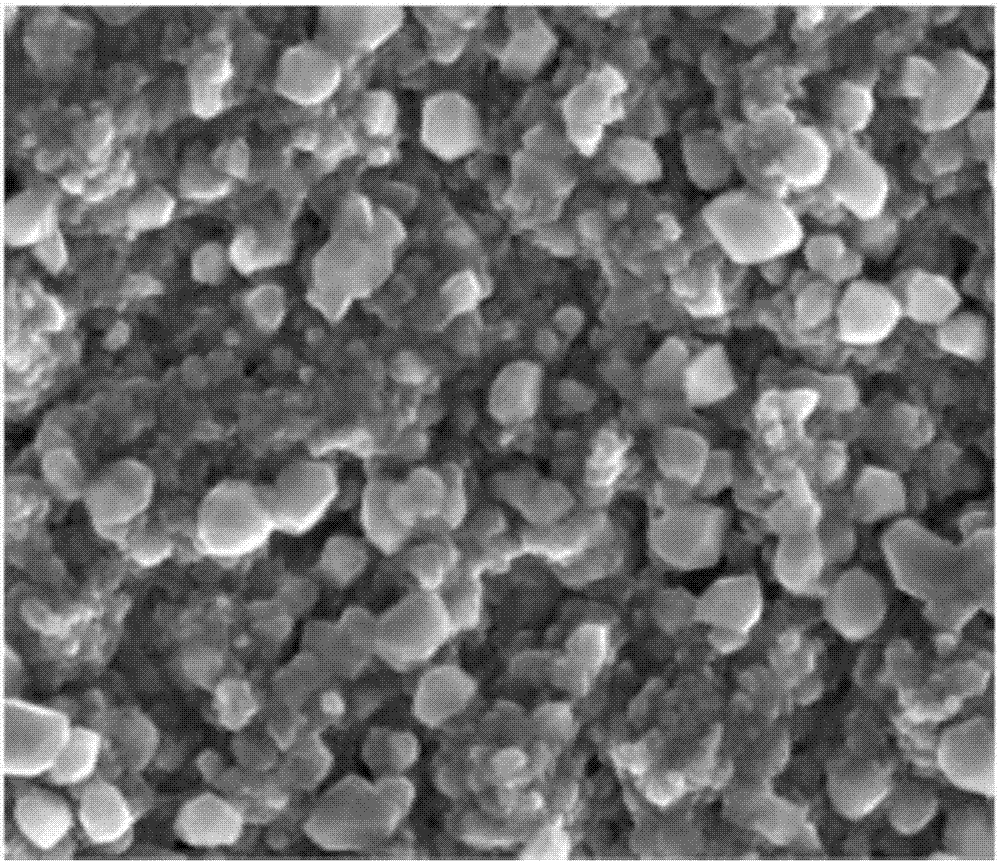

[0053] At room temperature, immerse the polished and cleaned stainless steel substrate in a graphene solution with a concentration of 0.1 wt% and let it stand for 2 minutes, then pull out the stainless steel substrate at a speed of 1.0mm / s and dry it at 60°C After 5 minutes, repeat the above-mentioned dipping and pulling-drying steps 5 times; after that, heat-treat the stainless steel substrate coated with graphene film under Ar atmosphere for 5 hours, then cool to room temperature naturally, and the heat-treatment temperature is 800°C; Graphene-coated stainless steel substrate and Pt electrode immersed in CrO 3 CrO with a concentration of 300g / L and a concentrated sulfuric acid concentration of 3.0g / L 3 - Start electroplating after standing in the sulfuric acid solution for 10 minutes, the distance between the two electrodes is 50mm, the electroplating temperature is 50°C, and the electroplating current is 0.8A / cm 2 , the electroplating time was 4h; the sample after electrop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com