Patents

Literature

62results about How to "High expansion factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterborne ultra-thin steel structure fire retardant coating and preparation method thereof

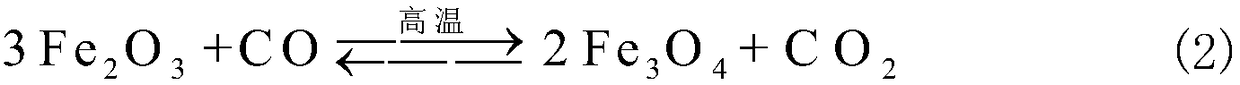

ActiveCN102838907AGood foaming effectThe pores are small and uniformFireproof paintsCarbonizationMaterials science

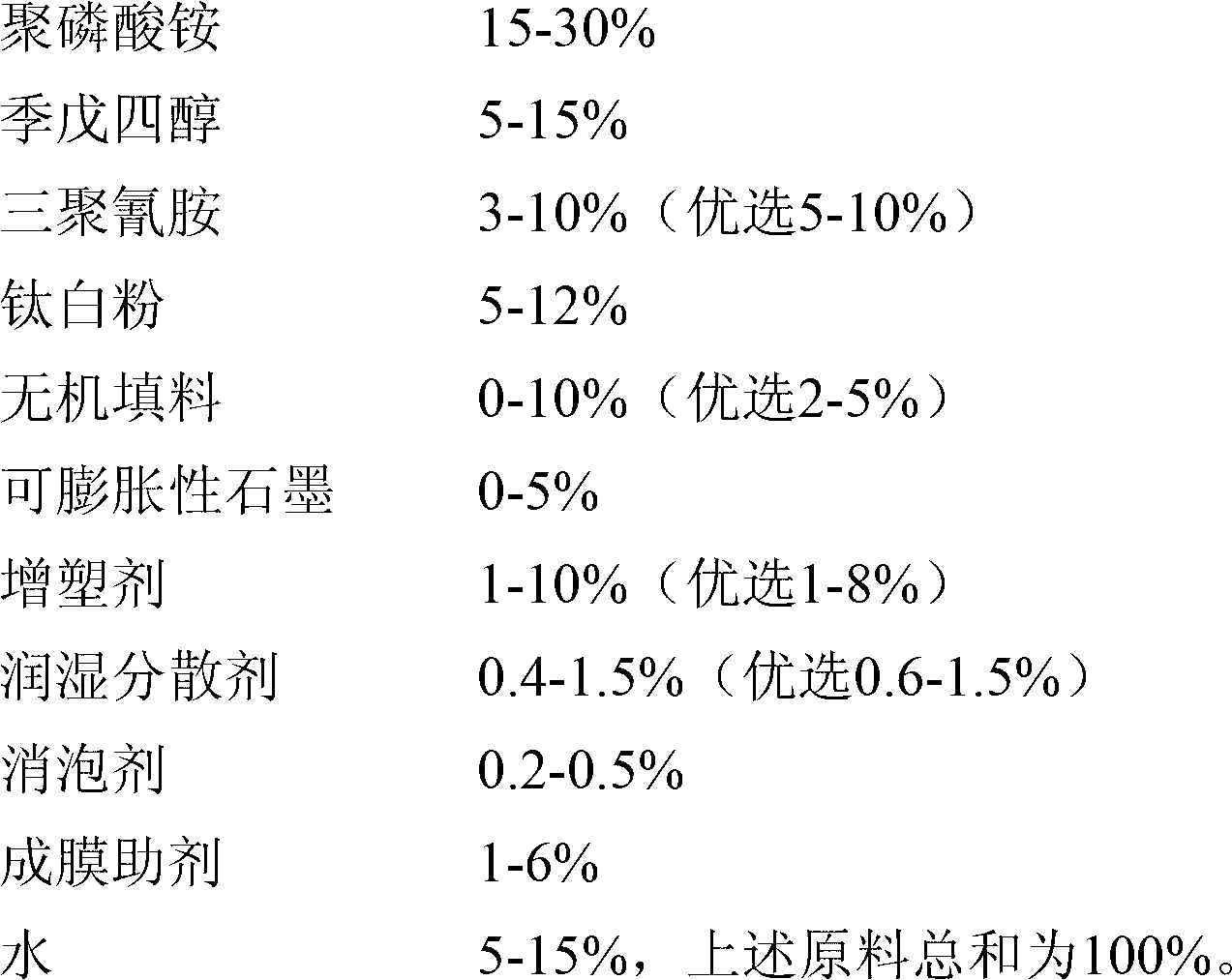

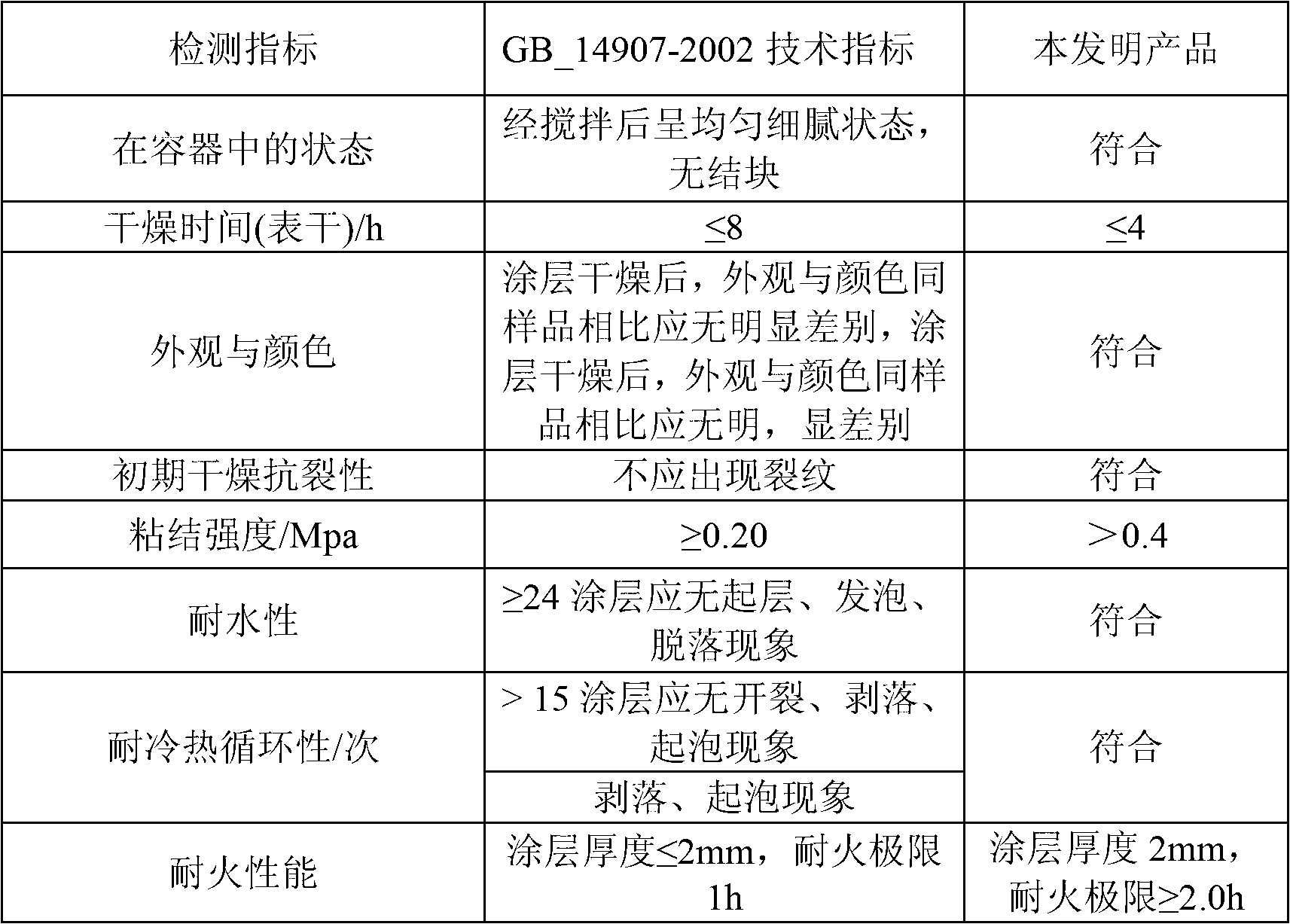

Provided is a waterborne ultra-thin steel structure fire retardant coating and a preparation method thereof. The raw material ratio of the coating includes 15-50% by weight of polymer latex, 15-30% by weight of ammonium polyphosphate, 5-15% by weight of pentaerythritol, 3-10% by weight of cyanurtriamide, 5-12% by weight of titanium dioxide, 2-13% inorganic filler, 0-5% by weight of expansiveness graphite, 1-10% by weight of plasticizer, 0.4-1.5% by weight of wetting dispersant, 0.2-0.5% by weight of defoamer, 1-6% by weight of coalescing agents and 5-15% by weight of water, and total raw material ratio is 100%. A high-speed dispersion method or a grinding dispersion method is adopted in preparation of the coating. A coating layer of the fire retardant coating can form a carbonization layer which is good in foaming effect, small and uniform in air holes and high in expansion times when in heating. The final fire retardant performance of the coating is far higher than technical requirements of a national standard. The waterborne ultra-thin steel structure fire retardant coating is a waterborne coating product, is non-poisonous and odorless and environment-friendly, and can be coated in a mode of brushing or spraying or roller coating.

Owner:SOUTH CHINA UNIV OF TECH +1

High-performance water swellable rubber and preparation method thereof

ActiveCN103087367AImprove the problem of difficult dispersion and uniformityImprove mechanical propertiesPolymer scienceHigh pressure

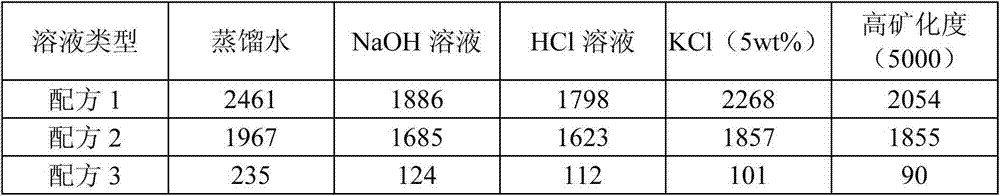

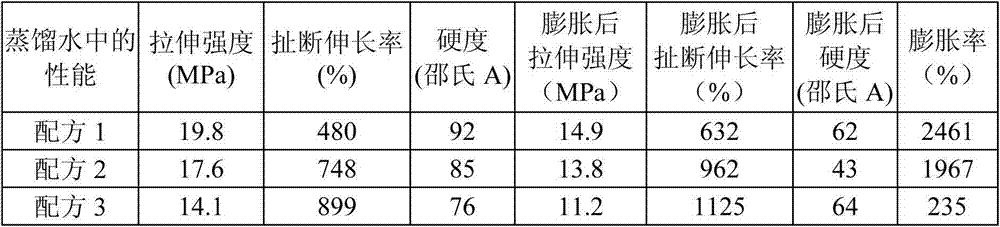

The invention relates to a high-performance water swellable rubber and a preparation method of the water swellable rubber. The water swellable rubber comprises the following raw materials in parts by weight: 100 parts of a rubber matrix, 1-5 parts of a nitrine coupling agent, 20-60 parts of a water absorbing material and 10-80 parts of a filling agent. The preparation method of the water swellable rubber comprises the following steps of: plasticating the rubber matrix so as to obtain plasticated rubber; subsequently adding the rest materials except for the rubber matrix into the plasticated rubber according to the sequence that small materials are added firstly, large materials are added secondly, and liquid, a vulcanizing agent and an accelerant are added at last, so as to obtain a rubber compound; vulcanizing the rubber compound and preparing so as to obtain the high-performance water swellable rubber. The high-performance water swellable rubber has excellent mechanical properties and high swelling performance, is simple in process of the preparation method, lower in production cost and wide in application range, and is particularly suitable for being used as a sealing material in a working environment of an oil field under high-temperature and high-pressure condition.

Owner:PETROCHINA CO LTD

Expandable graphite plugging agent system for deep channel blocking of heavy oil reservoir steam flooding and injection method

ActiveCN106640000AImprove mining efficiencyReduce economic costsFluid removalDrilling compositionAqueous solutionGraphite particle

The invention relates to an expandable graphite plugging agent system for deep channel blocking of heavy oil reservoir steam flooding. The system comprises, by mass fraction of the total mass of the plugging agent system, 0.5%-1.0% of low-temperature expandable graphite particles, 0.4%-0.8% of medium-temperature expandable graphite particles, 0.3%-0.6% of high-temperature expandable graphite particles, 0.1%-0.2% of carrying fluid, and the balance fluid preparation water; and the carrying fluid is a non-ion polymer water solution, and the mass fraction sum of all the components is 100%. According to the expandable graphite plugging agent system for deep channel blocking of the heavy oil reservoir steam flooding, the temperature-resisting non-ion polymer water solution serves as the carrying fluid, the graphite particles with different initial expansion temperatures are carried into a deep stratum, and according to the distributing characteristics of the temperature gradient field of a steam flooding steam channel, the graphite particles with the different initial expansion temperatures slowly expand, so that deep channel blocking for the steam flooding steam channel is achieved, and further the swept volume of the steam flooding is enlarged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +3

Method of using microcrystalline graphite to prepare expanded microcrystalline graphite

InactiveCN107285306AHigh expansion factorImprove corrosion resistanceCarbon compoundsGraphiteMaterials preparation

The invention belongs to the technical field of material preparation, and particularly relates to a method of using the microcrystalline graphite to prepare expanded microcrystalline graphite. The method includes: using microcrystalline graphite as a raw material, and performing chemical intercalation treatment for the first time to obtain primary expandable microcrystalline graphite; performing chemical intercalation treatment on the primary expandable microcrystalline graphite for the second time to obtain secondary expandable microcrystalline graphite; adopting a high-temperature expanding method to expand the secondary expandable microcrystalline graphite in a graphite expanding furnace at 900 DEG C to obtain the expanded microcrystalline graphite. By the method, 200-260-multiple secondary expanded microcrystalline graphite materials which are high in multiple, sulfur-free and short in production period can be prepared on a large scale.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

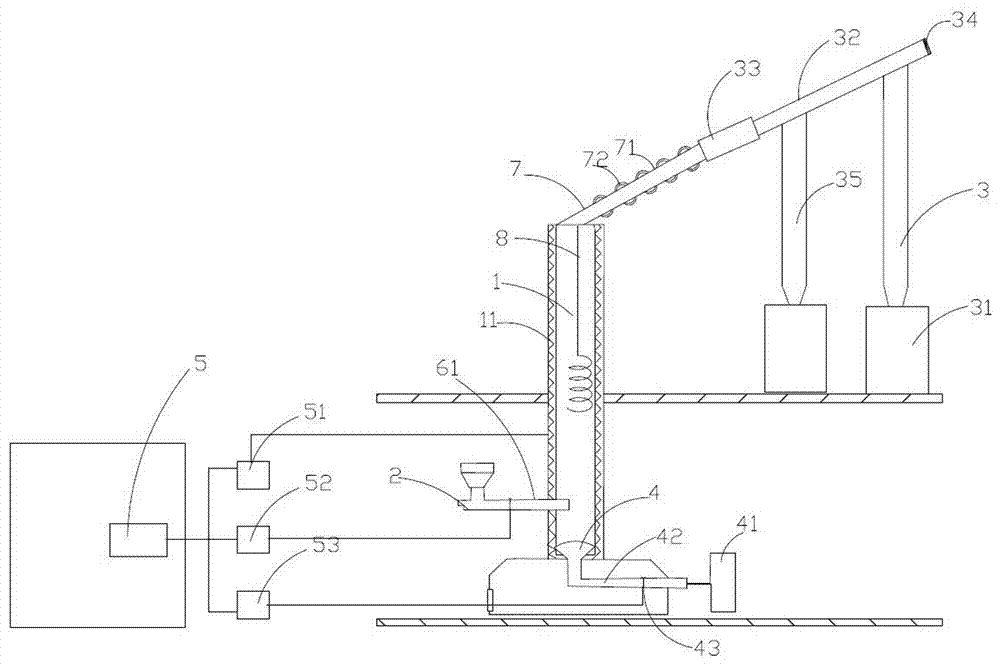

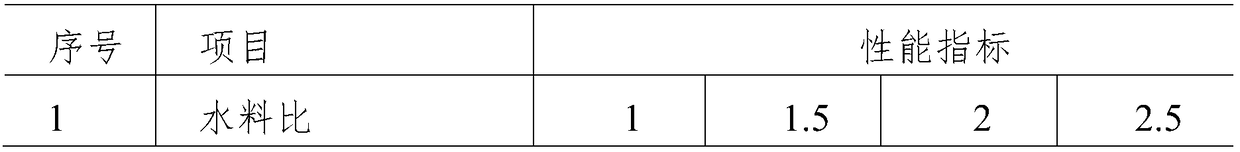

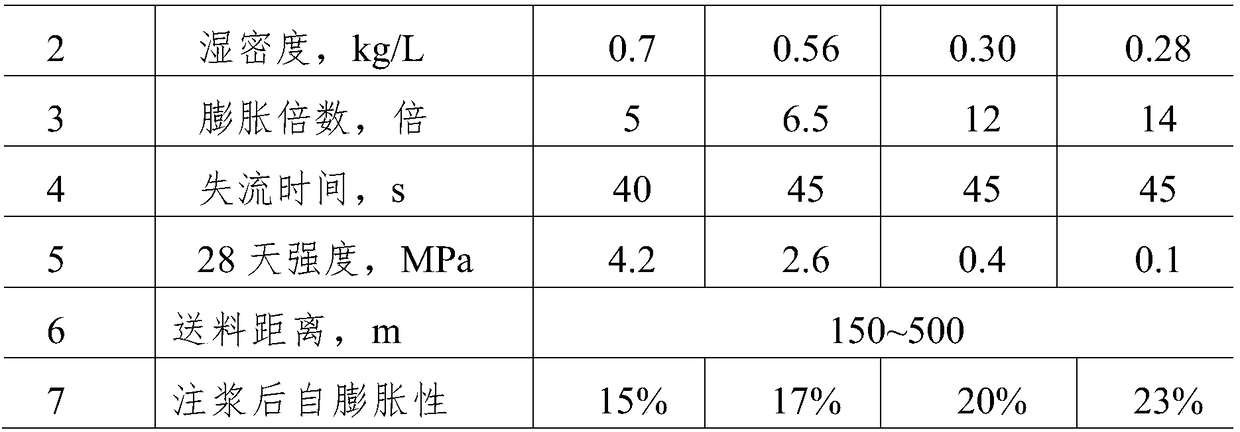

Self-expanding inorganic foam foaming filling material for mines

ActiveCN109020371ASelf-expandingPrevent leakage/accumulationDust removalFire preventionFoaming agentSlurry

The invention relates to a self-expanding inorganic foam foaming filling material for mines. The foaming filling material comprises, by weight, 82-96 parts of a hydraulic cementing material, 1-5 partsof an air entraining agent, 1-5 parts of a reactive chemical foaming agent, 0.5-2 parts of an early strengthening agent, 1-5 parts of a thickener, 0.5-1 part of a foam stabilizer and 1-5 parts of a coagulation accelerator. The foaming filling material can be conveyed for a long distance by screw grouting after being mixed with water having an amount 2-3 times the amount of the foaming filling material, so large-water-material ratio and long-distance conveying is achieved; and the above obtained slurry is continuously foamed and expanded in the conveying process, has a large expansion ratio after being discharged from a tube orifice, and also has the characteristics of certain self-expansion, permanent consolidation, and realization of no shrinkage or collapse and stable volume of a foamedbody before being completely solidified. The product has excellent construction performance, has a good fluidity in a conveying pipeline, makes the foamed body have a small specific gravity and a high strength, is suitable for filling and sealing treatment of the top-coal caving region and corners over and below of underground coal mines, is especially suitable for filling of irregular caving spaces, and realizes the dense topping effect by means of the self-expansion of the material.

Owner:BEIJING RUINUOANKE NEW ENERGY TECH

Preparation method of nanoscale organobentonite

ActiveCN104760968AGuarantee product qualityShorten the production cycleMaterial nanotechnologySilicon compoundsSodium BentoniteMass ratio

The invention discloses a preparation method of nanoscale organobentonite, which comprises the following six steps: (1) bentonite raw ore processing, (2) sodium modification, (3) centrifugation purification, (4) inorganic acid modification, (5) organic coating reaction, and (6) a post treatment stage. The preparation method has the characteristics that through substep purification, a mass ratio of a sodium agent to suspending liquid is kept at 0.3%; in an inorganic acid modification process, improvements are performed by adjustment of a PH value to subacid and a charging mode in the organic coating reaction stage; the bentonite is subjected to delaminating dispersion, centrifugation purification and superfine grading to prepare pure montmorillonite with the content greater than 95%; then, double octadecyl dimethyl ammonium chloride is used for performing the organic coating reaction; finally crushing to a nanoscale particle size is performed, that is, the average lamellar thickness is less than 25 nanometers; and the preparation method ensures the product quality, shortens the production cycle greatly, lowers the production cost, and is suitable for large-scale popularization and application.

Owner:HUANGSHAN BAIYUE ACTIVATED CLAY

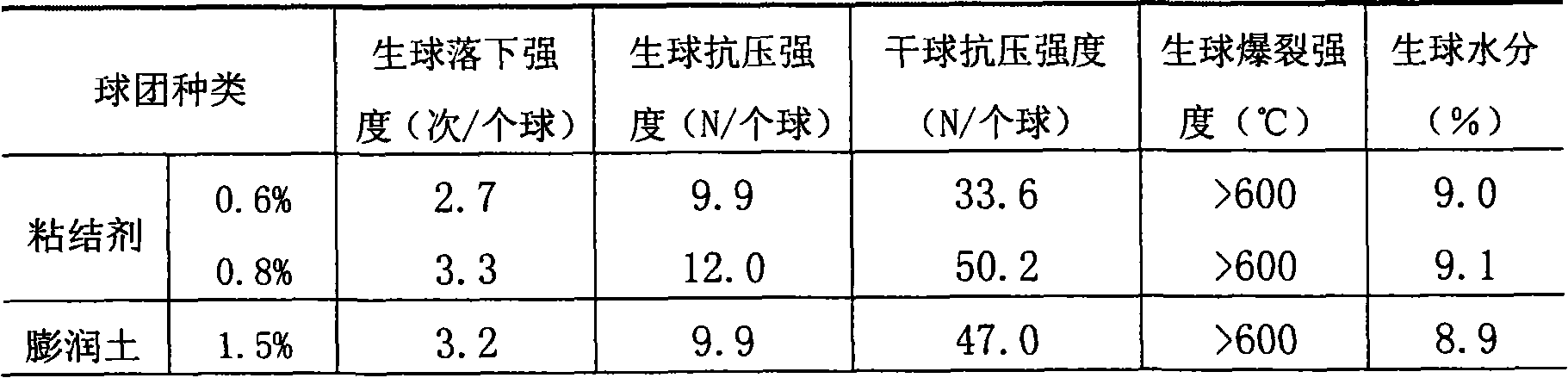

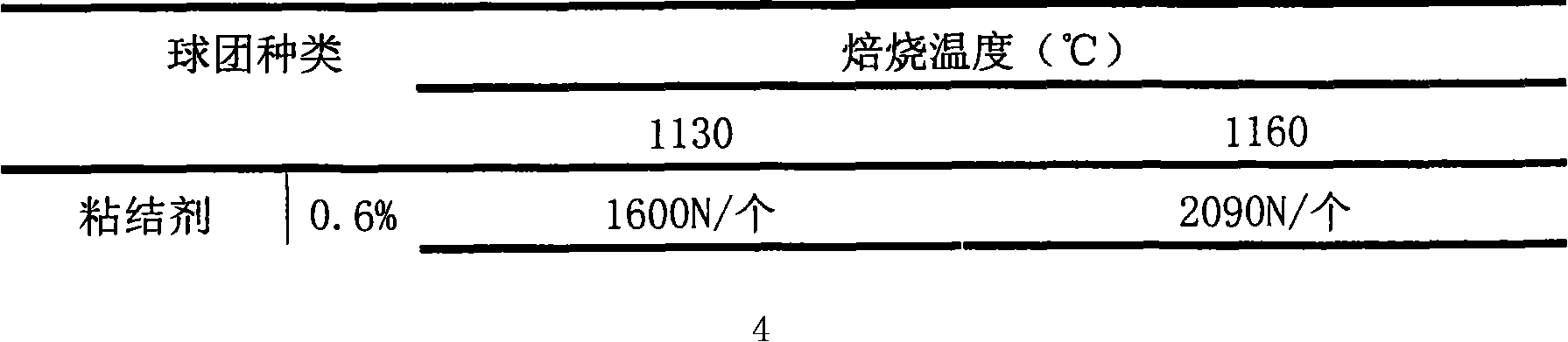

Pellet ore binder

InactiveCN101525688AWarranty requirementsGuaranteed all requirements for smeltingCarboxymethyl celluloseCarboxymethylcellulose Sodium

The present invention relates to a pellet ore binder which belongs to the technical field of pellet ore production of the iron and steel metallurgy industry. The binder is the mixture of organic matter and inorganic matter, wherein the ratio satisfies the following relationship: organic matter: inorganic matter=10%-50%:50%-90%. The organic matter is one compound or a plurality of compounds selected from Carboxymethyl cellulose, carboxymethyl cellulose, hydroxypropylmethylcellulose or carboxymethylcellulose sodium and sodium carboxymethyl cellulose. The inorganic matter is one compound or a plurality of compounds selected from silicates. The pellet ore binder of the invention has the characteristics of simple preparing, low cost, convenient application, etc. The matching of fusing agent of pellet ore binder can be greatly reduced thereby increasing the grade of pellet ore.

Owner:廊坊江宇化工建材有限公司

Polyurethane gas hole sealing material for underground coal mine and preparation method thereof

The invention belongs to the technical field of materials, and particularly relates to a polyurethane gas hole sealing material for an underground coal mine and a preparation method thereof. The hole sealing material disclosed by the invention comprises three components A, B and C, wherein the component A is isocyanate and accounts for 35-55% of total mass of the materials; the component B is polyether polyol and auxiliary materials, and accounts for 5-55% of total mass of the materials, wherein the polyether polyol accounts for 60-84.9% of the mass of the component B, a catalyst accounts for 0.1-5% of the mass of the component B, a fire retardant accounts for 10-30% of the mass of the component B, a foam stabilizer accounts for 0-15% of the mass of the component B, a foaming agent accounts for 5-20% of the mass of the component B and a chain extender accounts for 0-10% of the mass of the component B; the component C is sodium silicate, and accounts for 10-50% of total mass of the materials. The preparation method comprises the following steps: burdening according to the ratio of the components A, B and C, and fully mixing to obtain the hole sealing material. The hole sealing material disclosed by the invention is the gas hole sealing material which is low in price, low in viscosity, large in expansion times, good in air-tightness, strong in binding power and good in flame retardant property, and the safety and the economical efficiency of gas hole sealing for the underground coal mine can be greatly improved.

Owner:LIAONING TECHNICAL UNIVERSITY

Method used for preparing lightweight ceramsite from sludge and copper slag

InactiveCN109251012AAchieving and Controlling BloatAchieve and control product propertiesCeramic materials productionCeramicwareSludgeThermal insulation

The invention discloses a method used for preparing lightweight ceramsite from sludge and copper slag. The method comprises following steps: 1, sludge and copper slag micropowder are mixed and stirring at a mass ratio of 65-90:10-35, and are subjected to milling and granulation so as to obtain raw material balls of a certain size, and the raw material balls are dried; 2, the dried raw material balls are introduced into a high temperature furnace, pre-heating to 350 to 550 DEG C is carried out at a preheating speed of 5 to 15 DEG C / min, thermal insulation is carried out for 2 to 8min; 3, sintering is carried out at a sintering speed of 5 to 15 DEG C / min until the sintering temperature reaches 1050 to 1150 DEG C, and thermal insulation is carried out for 3 to 30min; and 4, after thermal insulation sintering, the obtained sintered balls are taken out from the high temperature furnace, and are cooled to room temperature under natural conditions, or are cooled to room temperature at power off conditions so as to obtain sludge ceramsite. The method is capable of increasing copper slag solid waste utilization rate, and is high in economical value. The ceramsite prepared using the method possesses thermal insulation, sound insulation, and sound absorbing performance, and is high in quality; and the efficiency is high.

Owner:HUBEI DABEIJIANG ENVIRONMENTAL TECH CO LTD +1

Method of using microcrystalline graphite to prepare secondary expanded microcrystalline graphite

InactiveCN107285307AHigh expansion factorImprove corrosion resistanceMaterial nanotechnologyCarbon compoundsMaterials preparationSulfur

The invention belongs to the technical field of material preparation, and particularly relates to a method of using microcrystalline graphite to prepare secondary expanded microcrystalline graphite. The method includes: using the microcrystalline graphite as a raw material, performing chemical intercalation treatment for the first time, filtering, washing and drying a product obtained after intercalation treatment to obtain primary expandable microcrystalline graphite, and adopting a high-temperature expanding method to expand the expandable microcrystalline graphite in a graphite expanding furnace at 800 DEG C to obtain primary expanded microcrystalline graphite; using the primary expanded microcrystalline graphite as a raw material, performing chemical intercalation treatment for the second time, filtering, washing and drying a product obtained after intercalation treatment to obtain secondary expandable microcrystalline graphite, and adopting a high-temperature expanding method to perform high-temperature expanding on the secondary expandable microcrystalline graphite for the second time in the graphite expanding furnace at 900 DEG C to obtain secondary expanded microcrystalline graphite. By the method, 200-287-multiple secondary expanded microcrystalline graphite materials which are high in multiple, sulfur-free and short in production period can be prepared on a large scale.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

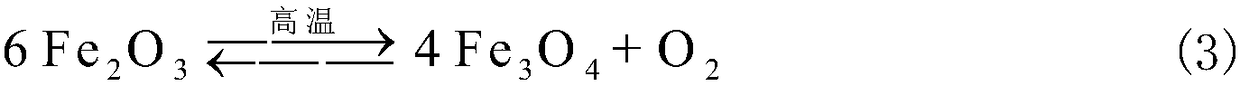

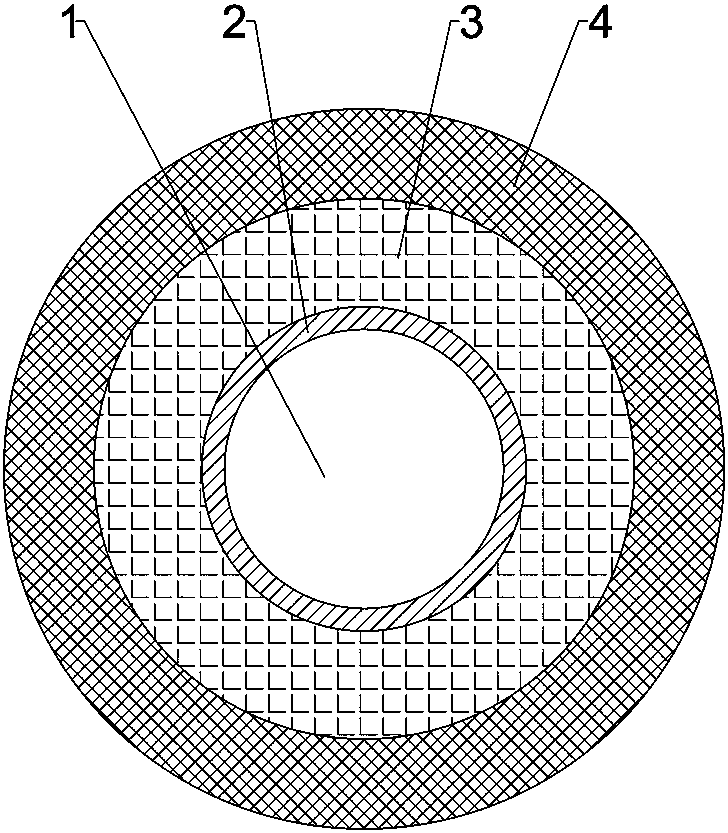

Anti-flaming inhaul cable

PendingCN109457612ALow costImprove heat resistanceBridge structural detailsWater basedThermal insulation

The invention relates to the technical field of bridge inhaul cables, in particular to an anti-flaming inhaul cable. The inhaul cable comprises a cable body, a polyurethane packaging belt, a thermal insulation layer and a fireproof rubber layer. The polyurethane packaging belt wraps the outer surface of the cable body, the thermal insulation layer wraps the outer surface of the polyurethane packaging belt, the fireproof rubber layer wraps the outer surface of the thermal insulation layer, and the fireproof rubber layer is formed by raw material compositions including water-based resin, ammonium polyphosphate, vermiculite, expanded graphite, perlite and water through a polymerization reaction. The fireproof rubber layer has the good heat resistance, cold resistance, anti-corrosion propertyand small environment factor influences, the full-fireproof cable body can be manufactured in a factory easily, the installing difficulty is lowered, the fireproof function of the inhaul cable is added, and the problem of traditional inhaul cable outer layer high-density polyethylene stress cracking is solved.

Owner:LIUZHOU OVM MASCH CO LTD

acidified bentonite

ActiveCN103979559BPromotes natural weatheringImprove the disintegration effectAluminium silicatesFiberSodium Bentonite

The invention discloses an acidified bentonite. The technical scheme is as follows: the acidified bentonite is composed of bentonite, sulfuric acid, instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium carbonate. The production method of the acidified bentonite comprises the following steps: inputting acidified bentonite materials into a mill, and milling into powder, thereby obtaining the acidified bentonite. The composite proportioning is performed after acidification, thereby avoiding the chemical reaction between the sulfuric acid and the instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium carbonate, fully displaying the respective characteristics of the raw materials in the formula, and ensuring the inherent quality of the acidified bentonite. The acidified bentonite has favorable adsorbability, high-temperature stability and lubricating property, and the water absorptivity, colloid index, plasticity, expansion coefficient, colloid viscosity and thixotropy are greatly enhanced. The acidified bentonite is suitable for producing products in the fields of paints, aviation, metallurgy, chemical fibers, petroleum, firefighting and the like.

Owner:江苏世澳非金属应用科技有限公司

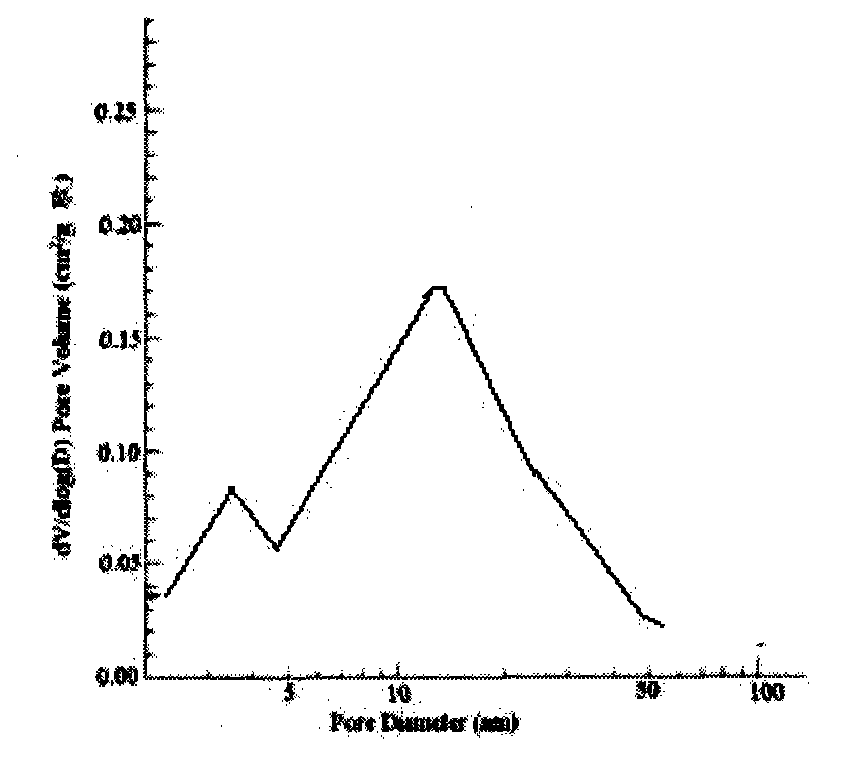

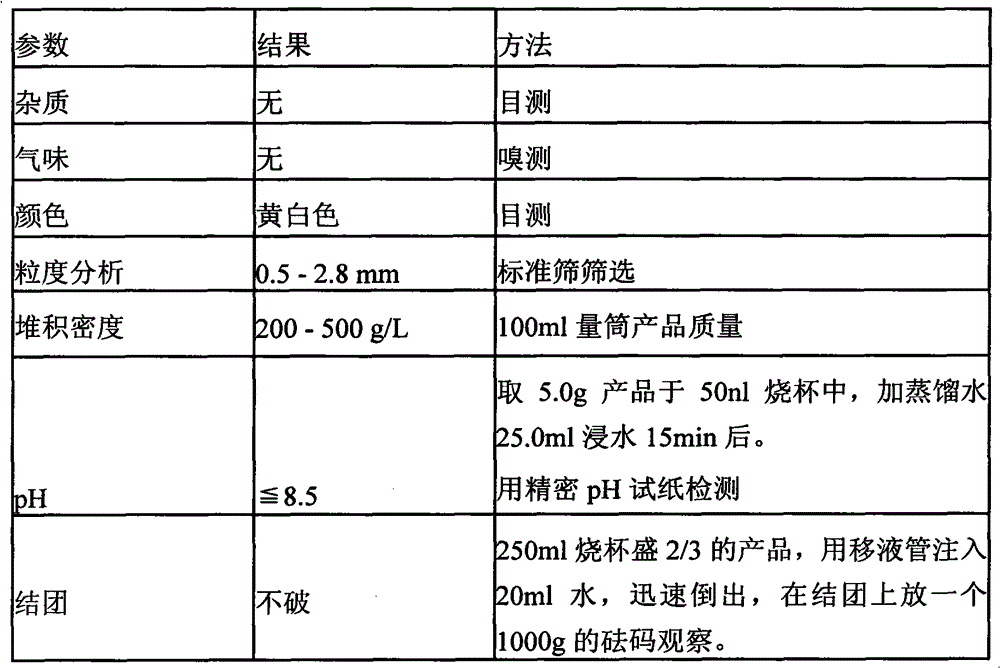

Ultralow-density natural compound clumping cat litter and production process thereof

The invention discloses ultralow-density natural compound clumping cat litter which comprises, by weight percent, 20%-70% of natural sodium bentonite, 1%-10% of column chromatography silica gel, and 20%-50% of pearlite. The invention further discloses a production process of the ultralow-density natural compound clumping cat litter. The production process is characterized by including the steps of firstly, by total weight of combination, adding 25%-65% of the natural sodium bentonite, 3%-8% of the column chromatography silica gel and 25%-35% of the pearlite into a mixer, mixing for 3-8 minutes by the mixer, and using a screw conveyor to feed the mixture into a U-shaped spiral chute for preparing discharging and pelletizing; secondly, placing the materials mixed in the first step on a disk or other proper rotary machines, adding a certain amount of water, and pelletizing under process conditions; and thirdly, drying pellets by multiple drying ways such as reverse drying to enable water content to reach 8-10%. The ultralow-density natural compound clumping cat litter has the advantages of light weight 60-70% less than that of tarditioanl bentonite cat litter, convenience to carry, high clumping capacity, and easiness to treat.

Owner:QINGDAO FRANK FINE CHEM

Casting powder for casting round ingots and manufacture method of casting powder

InactiveCN102814472AImprove surface qualityImproved packing qualityProcess efficiency improvementThermal insulationSlag

The invention discloses a casting powder for casting round ingots and a manufacture method of the casting powder. The casting powder comprises the following raw materials: 36% of power-plant flue dust, 20% of granulated blast-furnace slag, 16% of expanded perlite powders, 9% of fluorite powders, 6% of soda ashes, 10% of expanded graphite powder, and 3% of crystalline graphite powders; and the manufacture method of the mould powder comprises the following steps: weighing all raw materials according to the weight ratio of the raw materials, stirring and mixing the raw materials, controlling the dosing error to be less than 0.1%, controlling the material temperature at 105-110 DEG C, controlling the moisture to be less than 0.7%, grinding the raw materials until the particle size is less than and equal to 0.106mm, and packaging the obtained materials after passing the inspection. A thermal insulation material with low carbon content, high expansion times, and ultralow carbon content of the expansion product, is added to the mould powder disclosed by the invention, so that both the surface quality of ingots and the feeding quality of ingot heads are improved without adding a heating agent and a thermal insulating agent.

Owner:马鞍山科润冶金材料有限公司

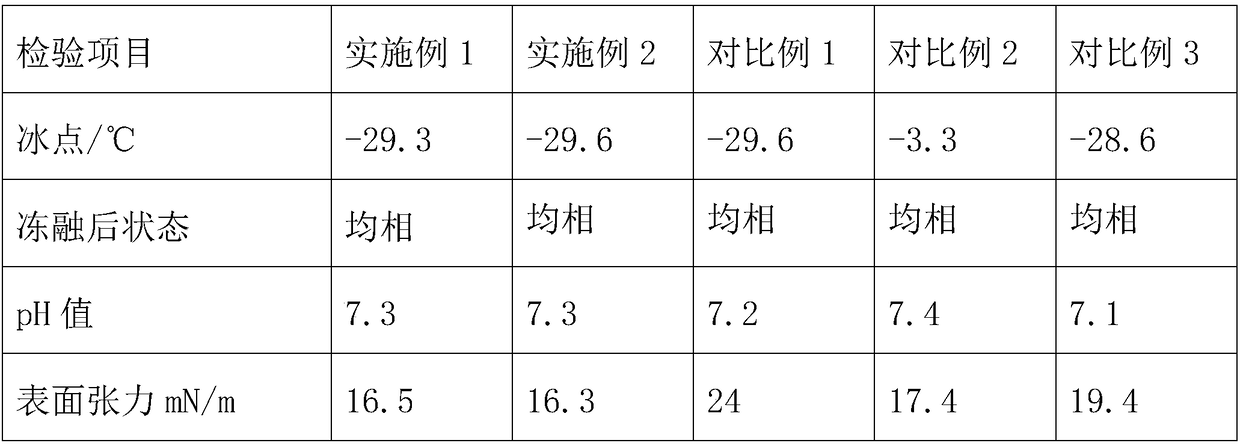

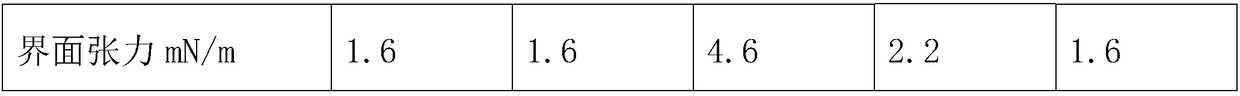

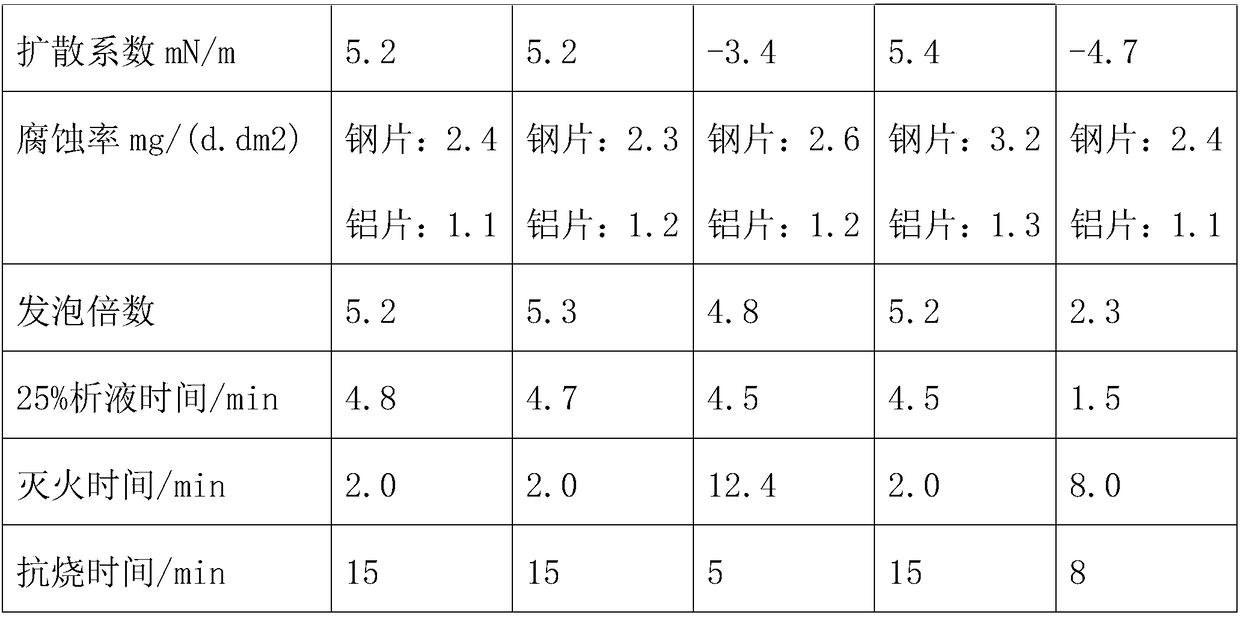

Environment-friendly aqueous film forming foam fire extinguishing agent and preparation method thereof

InactiveCN108853862ALower freezing temperatureHigh expansion factorFire extinguisherBetaineSurface-active agents

The invention discloses an environment-friendly aqueous film forming foam fire extinguishing agent and a preparation method thereof. The fire extinguishing agent comprises, by weight part, 5-10 partsof water-soluble ammonium polyphosphate, 5-10 parts of urea, 0.5-1 part of xanthan gum, 2-10 parts of cocoalkanoylamido propyl betaine, 2-10 parts of APG, 10-15 parts of modified nano-crystalline cellulose, 0.25-1.5 parts of perfluorohexyl sulfonyl betaine, 2-6 parts of amphiprotic fluorinated acrylate emulsion, 2-5 parts of a buffering agent and 35-75 parts of deionized water. The product manufactured through the method includes no high-melting-point organic solvent or non-ionic surface active agent hard to degrade, the use level of an alkyl fluoride betaine surface active agent is greatly reduced, the pollution damage to the environment is relieved, the foam expansion is high, the fire extinguishing time is short, the anti-burning time is long, and foam is stable.

Owner:JUHUA GROUP TECH CENT

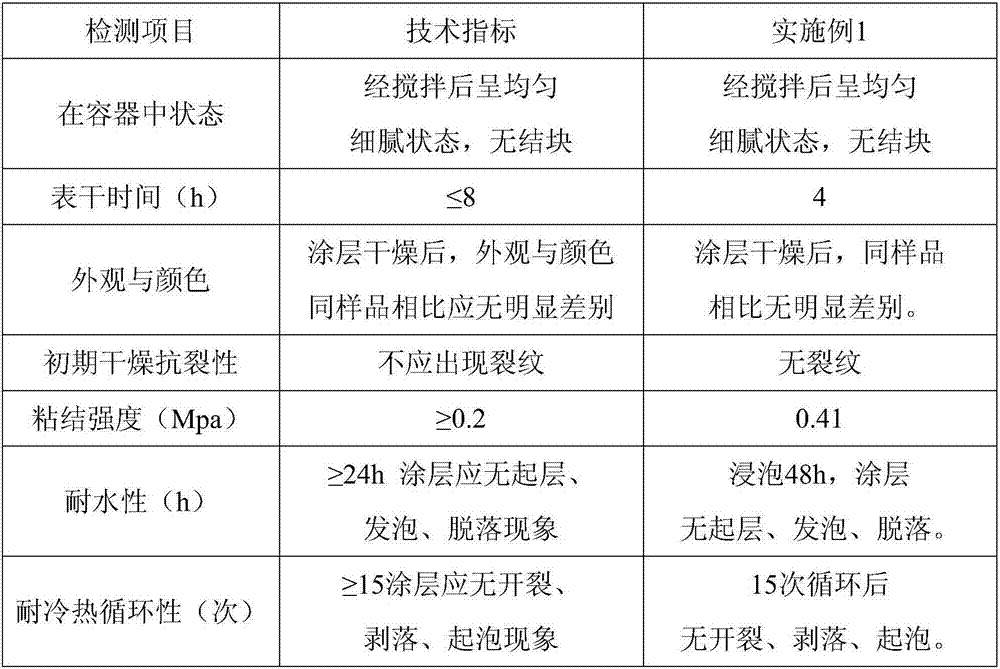

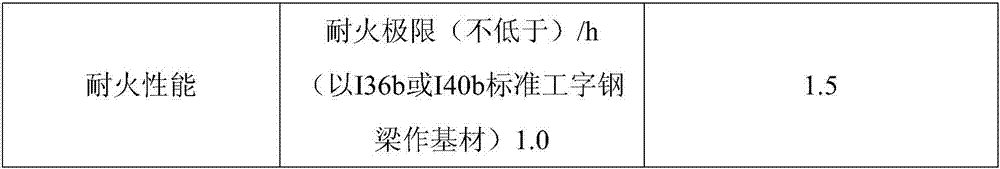

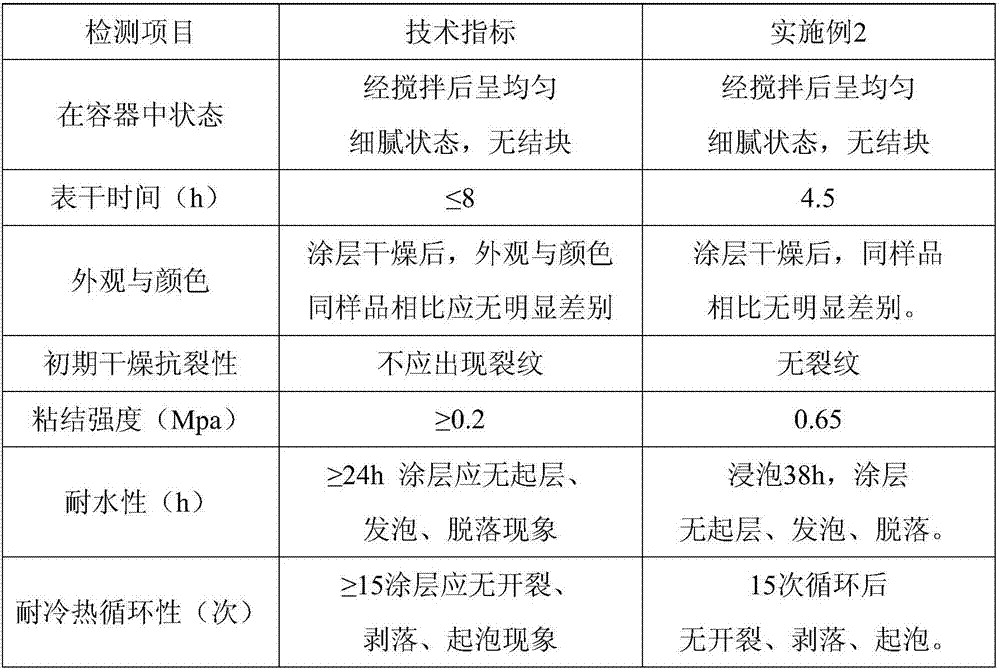

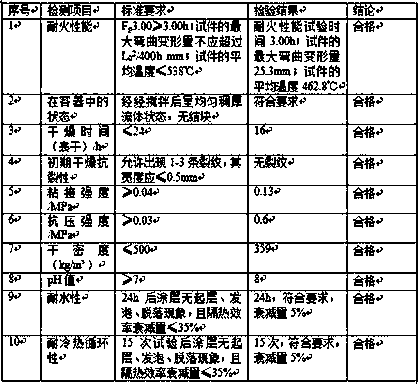

Waterborne ultrathin steel structure fireproof coating material and preparation method thereof

ActiveCN107083129AImprove water resistanceHigh expansion factorFireproof paintsCrack resistanceLayer thickness

The invention discloses a waterborne ultrathin steel structure fireproof coating material, prepared from the following components in percentage by weight: 17 to 23.5 percent of vac-veova emulsion, 18 to 25 percent of MF resin modified ammonium polyphosphate, 7 to 12 percent of tripolycyanamide, 7.5 to 12.5 percent of pentaerythritol, 0.8 to 1.5 percent of coalescing agent, 0.20 to 0.50 percent of defoamer, 0.30 to 0.60 percent of dispersant, 0.10 to 0.30 percent of preservative, 0.2 to 0.8 percent of thickener, 4 to 8 percent of titanium dioxide, 2 to 6 percent of inorganic filler, 0.15 to 0.30 percent of pH regulator and the balance of water. The coating material is proper in fire resistance, and has outstanding water resistance and good cracking resistance; a prepared coating layer is stable in physical and mechanical properties, outstanding in cracking resistance and water resistance and excellent in fire resistance, and when the coating layer thickness is 1.8mm, the fire-resistant time is 90min or longer.

Owner:NANJING CHANGJIANG PAINT

Method for improving expansion performance of vermiculite

ActiveCN108793178ASimple control methodHigh expansion factorSilicon compoundsPollutantExpansion ratio

The invention discloses a method for improving expansion performance of vermiculite. The method comprises the following steps: hydrothermally modifying raw ore vermiculite and water or a salt solutionwhile heating and magnetically stirring at high temperature and high pressure, and then expanding a hydrothermally modified material to obtain expanded vermiculite. By the method, through the high temperature and the high pressure, water molecules and ions between vermiculite layers are regulated and controlled so as to achieve the purpose of regulating and controlling the expansion rate or the peeling degree of the vermiculite; the method has the advantages of a simple and effective regulating and controlling method, a high expansion ratio, easiness in separation, simple equipment, improvedproduction efficiency, less pollutants, an obvious economic value and the like.

Owner:TARIM UNIV

Chitosan tetramethylene phosphonium sulphate flame retardant, and preparation method and application thereof

The invention provides a preparation method for a chitosan tetramethylene phosphonium sulphate flame retardant. The preparation method comprises the following steps: performing electrostatic adsorption on tetrakis hydroxymethyl phosphonium sulphate and chitosan in water to obtain a tetrakis hydroxymethyl phosphonium sulphate / chitosan compound; performing dehydration covalent graft reaction on thetetrakis hydroxymethyl phosphonium sulphate / chitosan compound to obtain the chitosan tetramethylene phosphonium sulphate flame retardant. The chitosan tetramethylene phosphonium sulphate flame retardant prepared by the method provided by the invention does not contain halogen, has an antibacterial effect, and is non-toxic, degradable, green and environmentally friendly; the flame retardant is highin molecular weight, keeps linearity, does not have volatility, and has water washing resistance, migration resistance, good compatibility, high stability and good flame retarding effect.

Owner:JILIN INST OF CHEM TECH

Waterborne expansion fire-proof coating with weather resistance and fire resistance and preparing method

InactiveCN106752477AImprove fire resistanceEasy constructionFireproof paintsUltraviolet lightsChlorinated paraffins

The invention discloses a waterborne expansion fire-proof coating with the weather resistance and the fire resistance and a preparing method. The waterborne expansion fire-proof coating is mixed by A components and B components; the A components are prepared from a thickening agent, a dispersing agent, an antifoaming agent, a sterilizing agent, titanium dioxide and water; the B components are prepared from modified acrylic emulsion, pentaerythritol, tripolycyanamide, ammonium polyphosphate, chlorinated paraffin, a coalescing agent and water. The waterborne expansion fire-proof coating is an environment-friendly waterborne expansion fire-proof coating, and has the advantages of being good in ultraviolet light resistance, low in water absorption rate, high in fire resistance and the like, and the defects that the physical and chemical performance, the fire resistance and the like of domestic similar products are poor are overcome. Compared with foreign similar products, the physical and chemical performance and the stability of the fire resistance of a product are improved; meanwhile, the coating has the good construction performance, the decorative performance is high, the product storage stability is good, the raw materials are easy to obtain, and the cost is moderate; the weather resistance of the product meets the requirements of the standard technology.

Owner:TIANJIN FIRE RES INST

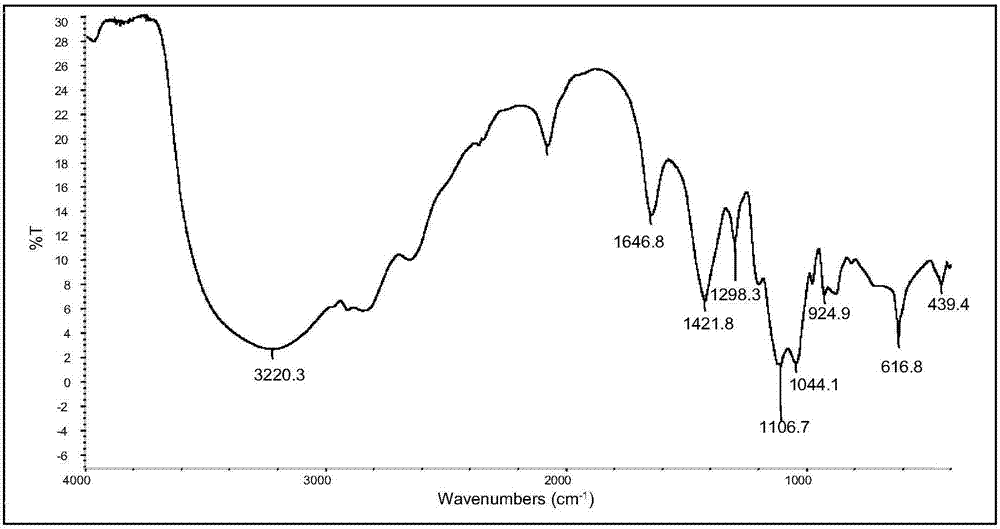

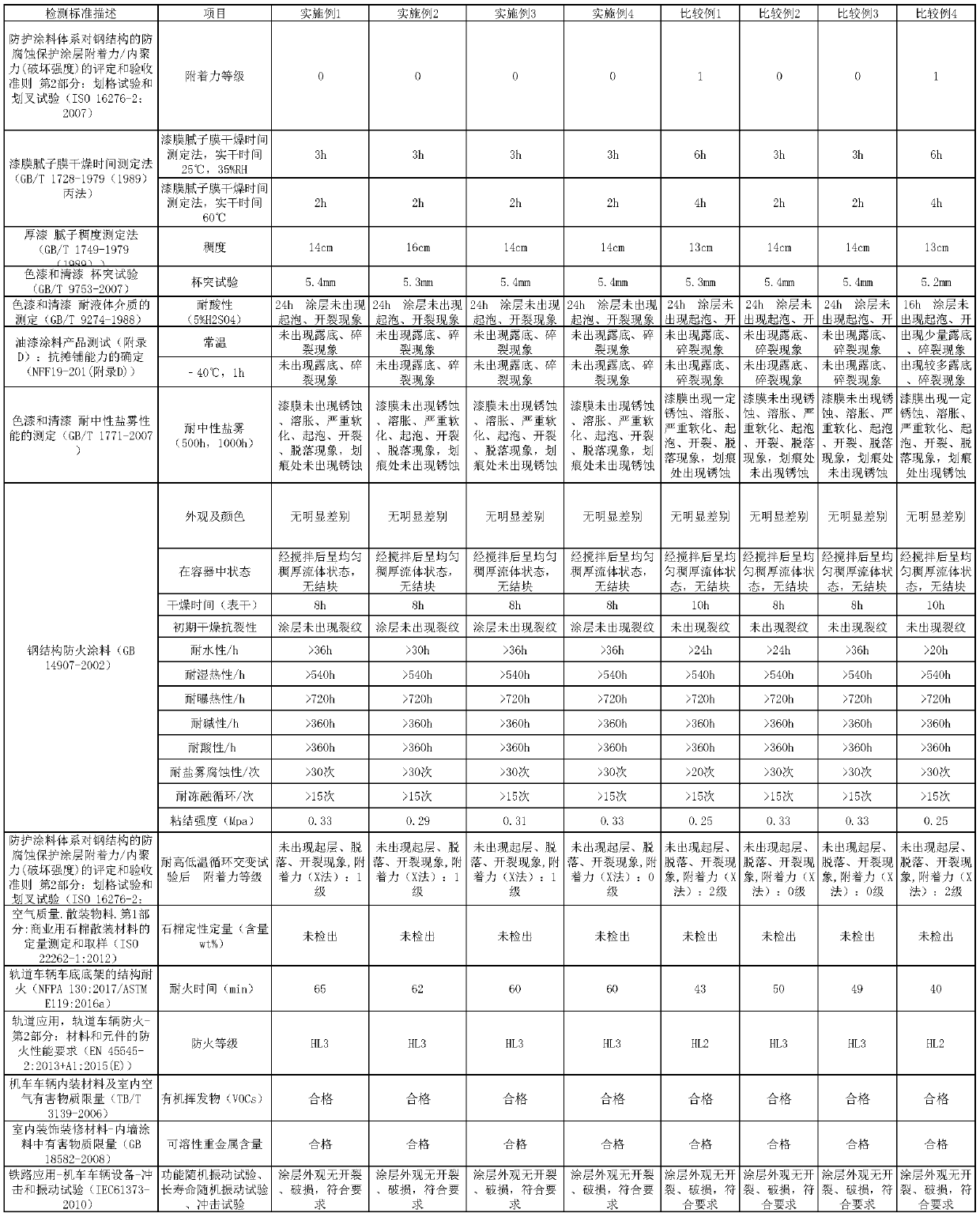

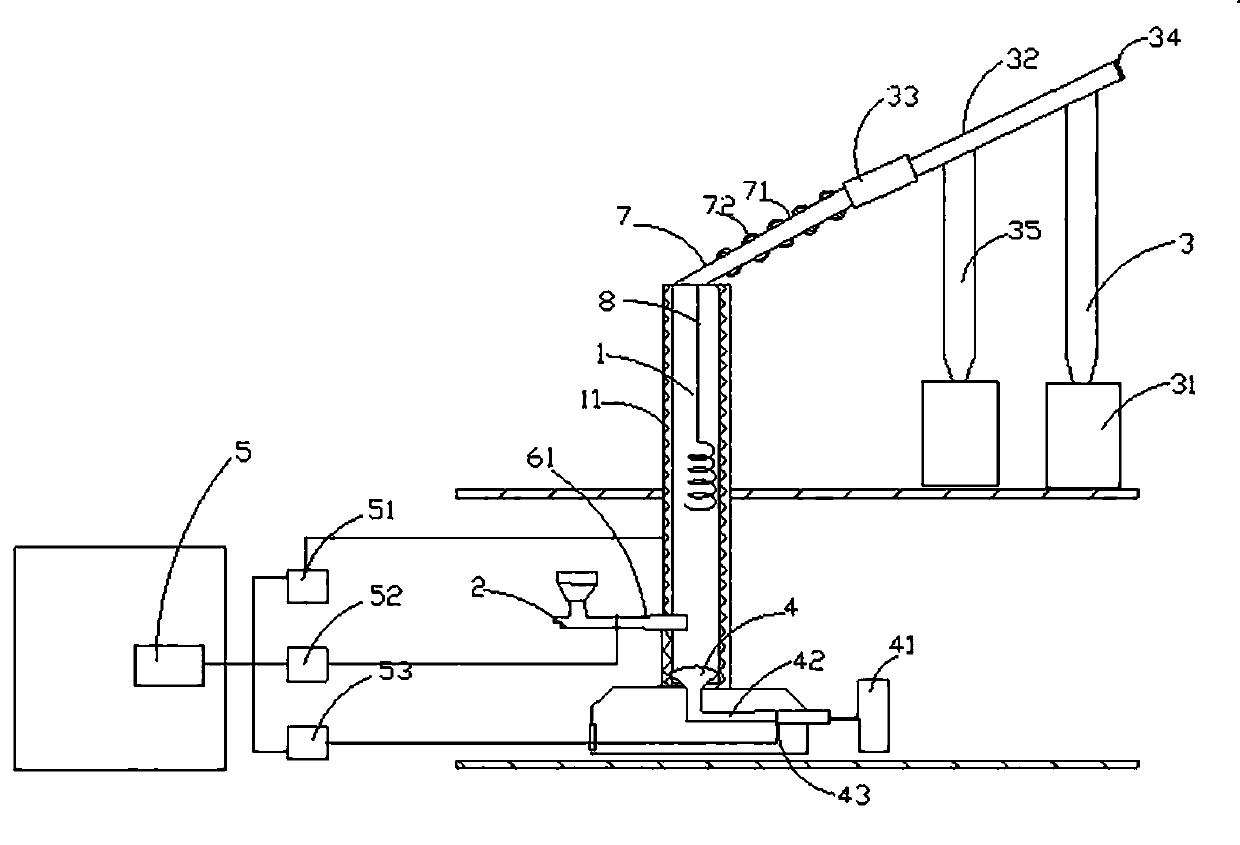

Water-based fireproof coating suitable for railway vehicle chassis and preparation method thereof

InactiveCN110591509AHigh expansion factorStable structureFireproof paintsEpoxy resin coatingsWater basedMelamine phosphate

The invention relates to a water-based fireproof coating suitable for railway vehicle chassis and a preparation method thereof, and belongs to the field of water-based fireproof coating. The water-based fireproof coating disclosed by the invention is prepared from the following substances in parts by mass: 20-30 parts of a film-forming substance, 40-60 parts of an intumescent flame-retardant system, 5-8 parts of titanium dioxide, 2-4 parts of nano magnesium aluminum hydroxide, 1-2 parts of organic bentonite, 1-3 parts of expandable graphite, 9-17 parts of deionized water, 0.8-1.3 parts of a film-forming aid, 0.2-0.5 part of a dispersing agent and 0.2-0.5 part of a defoaming agent; the intumescent flame-retardant system is prepared from melamine phosphate, dipentaerythritol and melamine, and the mass part ratio of the melamine phosphate to the dipentaerythritol to the melamine is 1.8-2.3: 0.8-1.2: 0.8-1.2. The water-based fireproof coating can met structure fire-resistant requirement of the chassis of the railway vehicles; no volatilization of harmful substances such as organic solvents is caused in the construction and drying processes; the occupational health and safety of constructors are guaranteed; equipment can be flexibly selected for use according to different scenes; investment of special equipment is reduced; and production cost is reduced.

Owner:河北萨迪科轨道交通科技有限公司

Improved coal mine polyurethane blocking material and preparation method thereof

The invention relates to an improved coal mine polyurethane blocking material and a preparation method thereof, and belongs to the technical field of underground-mine crack blocking reinforcement materials. The improved coal mine polyurethane blocking material comprises a component A and a component B, wherein the components A comprises a polyether polyol, a diluent, a cross-linking agent and a catalyst, and the component B is diphenyl methane diisocyanate. According to the present invention, under the premise of no influence on the consolidation strength required by the polymer pressing injection blocking material, the obtained polyurethane consolidation body has the significantly-improved expansion multiple, such that the higher tightness of the product during the crack filling process compared to other products is ensured; the material reaction curing is rapid, such that the rapid blocking filling under the complex underground mine condition is ensured; the related raw materials have characteristics of no pollution, no volatile toxicity and no harm to human body, such that the personal safety of the underground mine workers is ensured; and the preparation process is simple, and the curing foaming is performed at the normal temperature, and the original synthesis process cost of the polyurethane blocking material is reduced.

Owner:BEIJING UNIV OF TECH

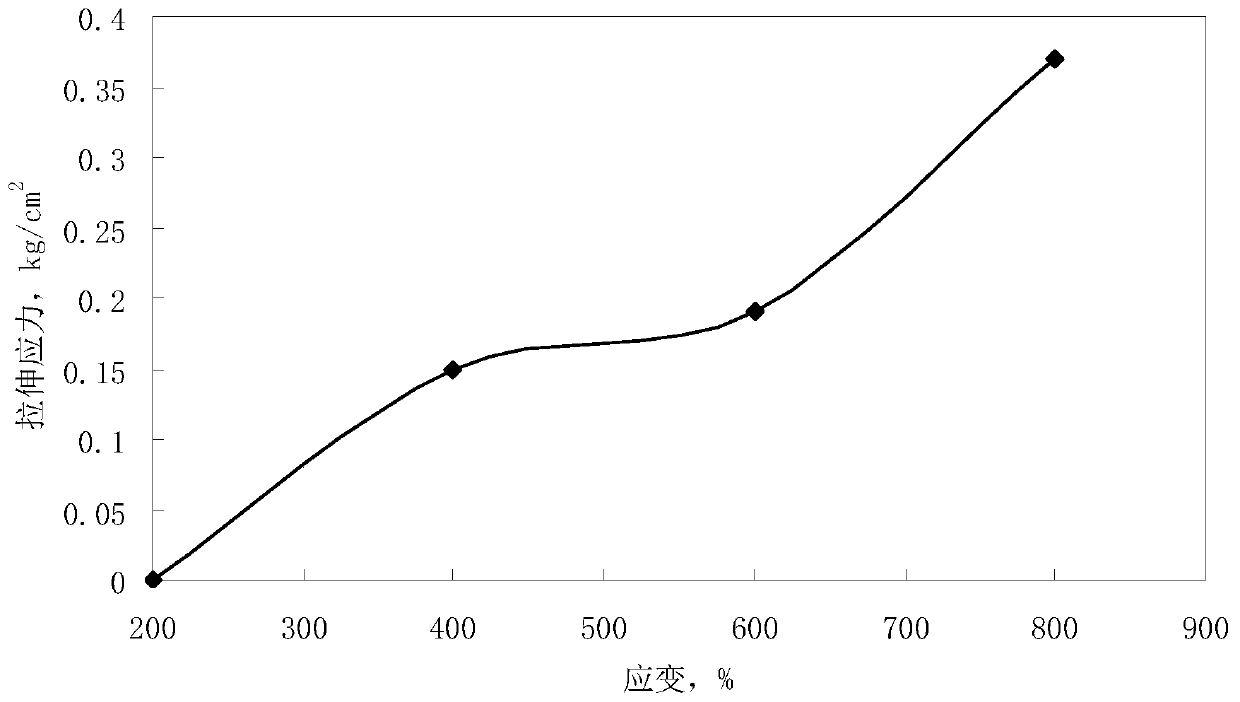

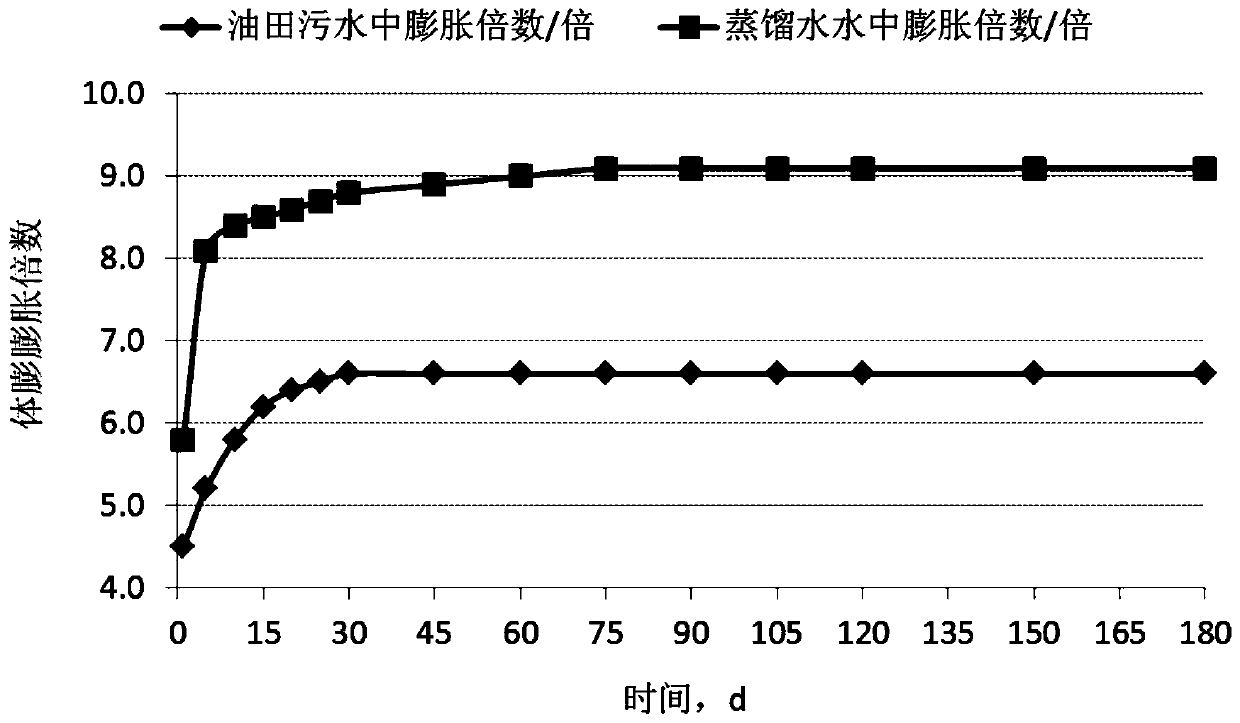

Flexible particles for profile control, and preparation method thereof

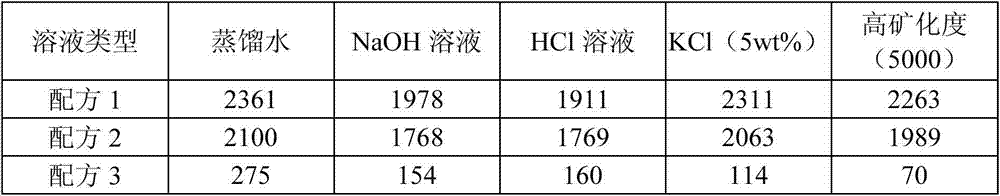

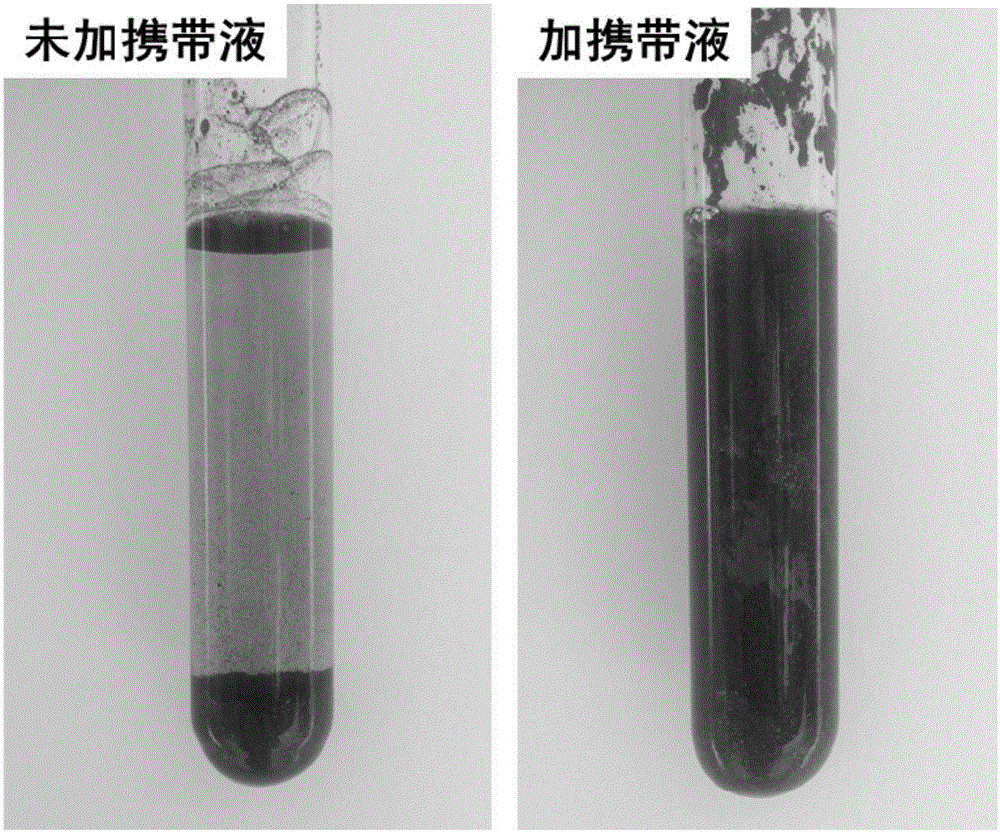

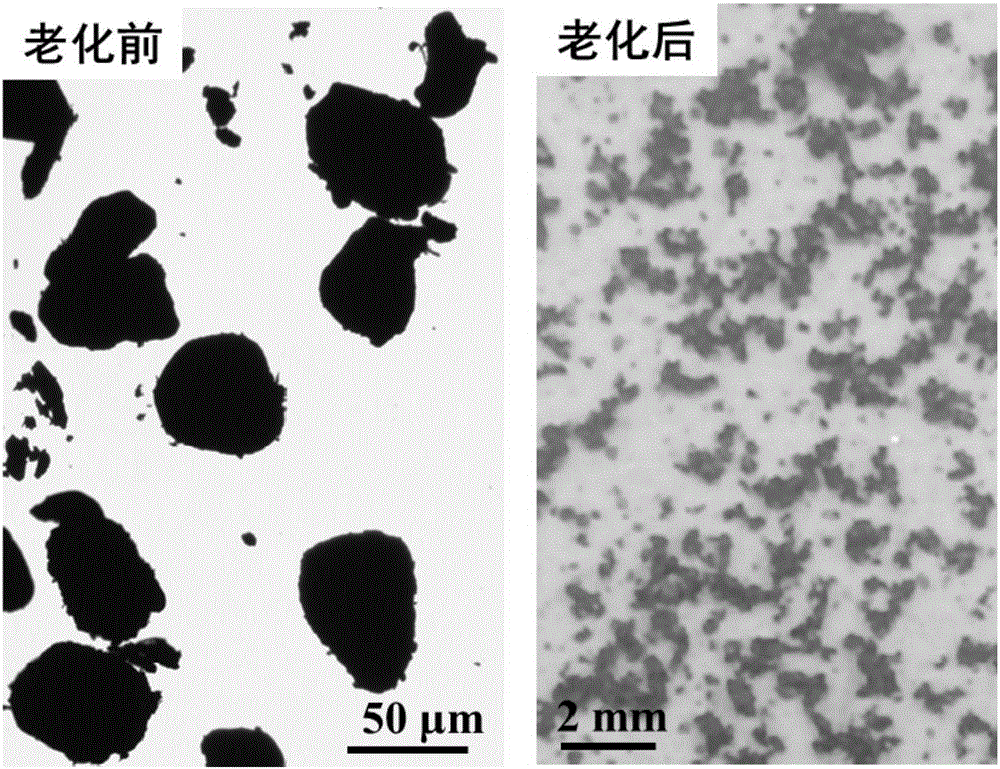

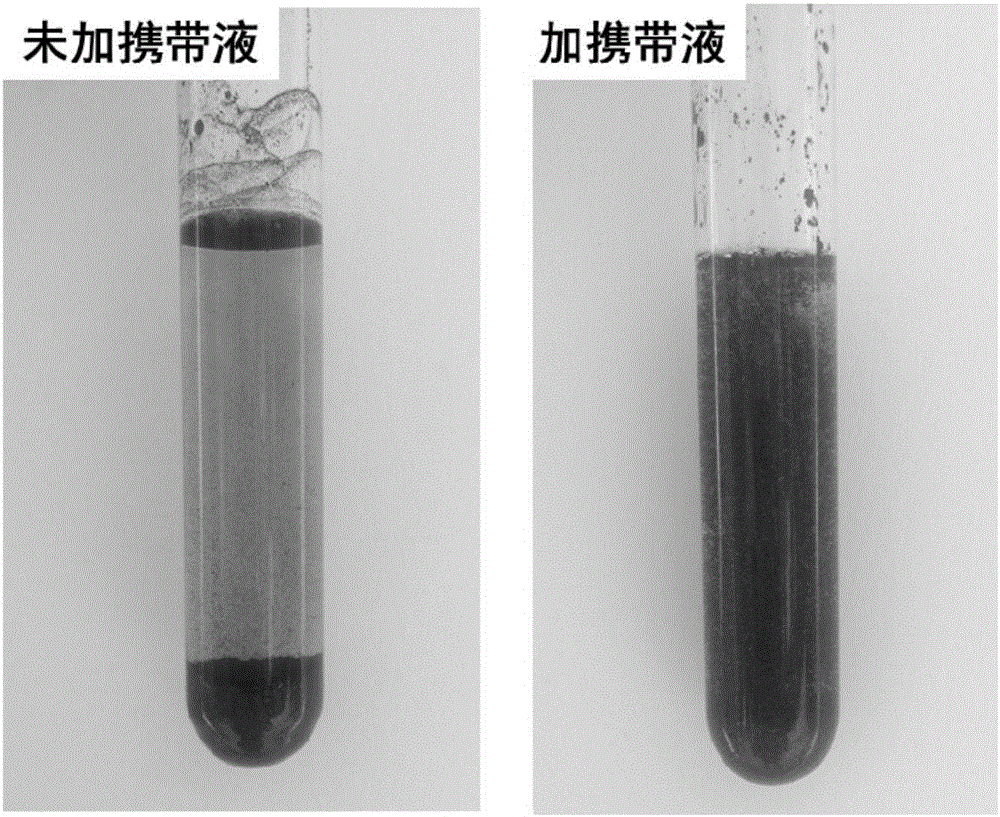

ActiveCN106632835AHigh expansion factorSmall particle sizeDrilling compositionChemistrySalt resistance

The present invention provides flexible particles for profile control, and a preparation method thereof. The flexible particles at least comprise a water phase substance and an oil phase substance according to a weight ratio of 35:65-25:75, wherein the water phase substance comprises, by weight, 70.77-82.70 parts of water, 15.0-25.0 parts of acrylamide, 1.0-2.0 parts of acrylic acid, 0.6-0.9 part of N,N-methylenebisacrylamide, 0.6-1.2 parts of sodium hydroxide, 0.02-0.03 part of potassium persulfate, and 0.08-0.10 part of 2,2'-azobis(2-methylpropionamidine) dihydrochloride, and the oil phase substance comprises, by weight, 97.71-98.83 parts of n-butane, 1.0-2.0 part of Span 80, 0.05-0.1 part of Tween 80, 0.01-0.02 part of hydrogenated polyisoprene, and 0.01-0.02 part of cetyl polyethylene glycol. The flexible particles of the present invention have characteristics of small particle size, good expansion salt resistance, high expansion multiple, high separable solid content, and rapid dispersion.

Owner:西安长庆化工集团有限公司

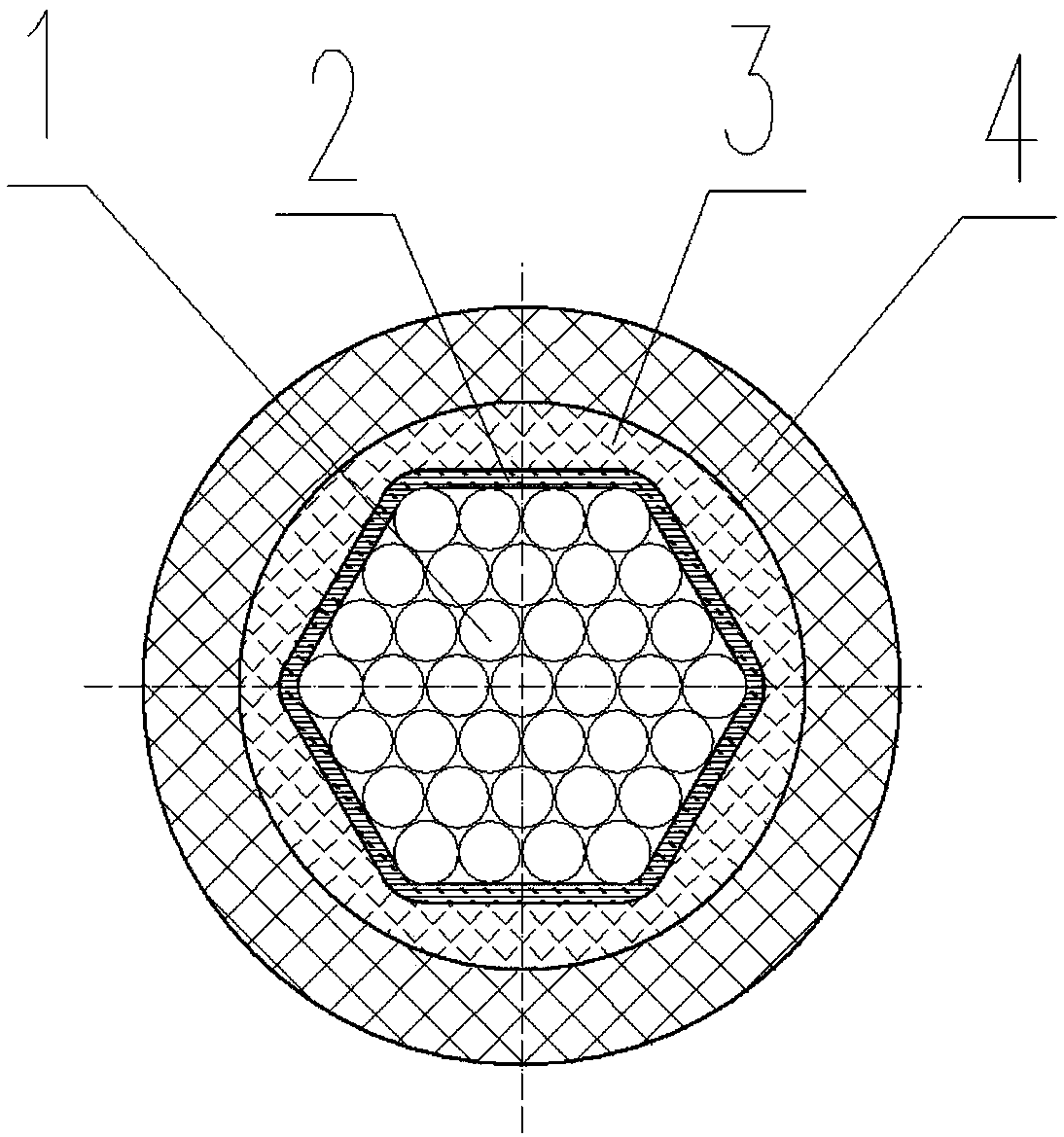

Preparation method of nanometer iron oxide particle/expanded microcrystalline graphite composite material used for lithium ion batteries

InactiveCN107799752AIncrease the gapHigh expansion factorMaterial nanotechnologyCell electrodesFerroceneLithium-ion battery

The invention discloses a preparation method of a nanometer iron oxide particle / expanded microcrystalline graphite composite material used for lithium ion batteries. The preparation method comprises the following steps: taking microcrystalline graphite as a raw material, and carrying out first chemical intercalation treatment and high temperature expansion to obtain primary expanded microcrystalline graphite; then taking the primary expanded microcrystalline graphite and ferrocene as raw materials, then carrying out mixing ball-milling by taking the primary expanded microcrystalline graphite and ferrocene as raw materials, and then carrying out second expansion to obtain the nanometer iron oxide particle / expanded microcrystalline graphite composite material. A twice high temperature expansion method is creatively combined, the prepared composite material is tightly combined, nanometer iron oxide particles are uniformly dispersed on the surface of expanded microcrystalline graphite, thelithium storage capacity is relatively high, and the circulation and rate capacity are excellent.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

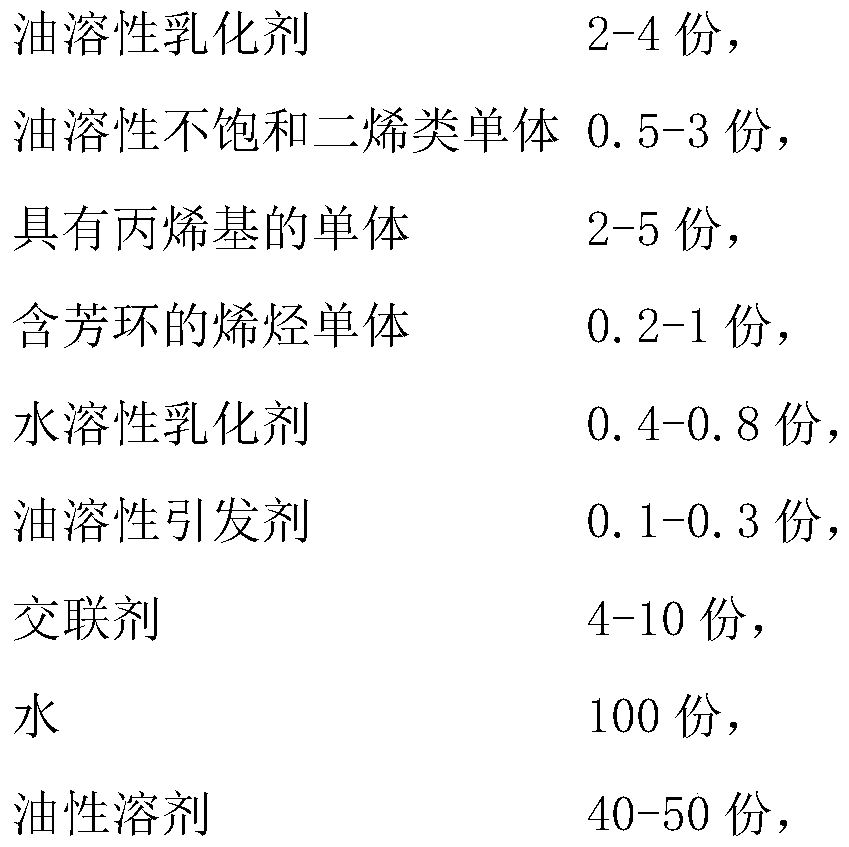

Polymer microsphere modifying and flooding agent for high-temperature and high-salinity oil reservoir as well as preparation method and application thereof

The invention discloses a polymer microsphere modifying and flooding agent for a high-temperature and high-salinity oil reservoir as well as a preparation method and application of the polymer microsphere modifying and flooding agent. The modifying and flooding agent is prepared from an oil-soluble emulsifier, an oil-soluble unsaturated diene monomer, an acrylamide monomer, an aromatic ring-containing olefin monomer, a water-soluble emulsifier, an oil-soluble initiator, a cross-linking agent, water and an oily solvent through water-in-oil-in-water double emulsion polymerization. The polymer microsphere profile modifying and flooding agent prepared by the invention is not easy to degrade in a medium with high mineralization degree, molecules of the modifying and flooding agent do not contain groups easy to hydrolyze, so that the rigidity of a polymer molecular chain is increased, the tackifying, salt resistance and temperature resistance of a polymer are improved, and meanwhile, the polymer microsphere modifying and flooding agent is relatively high in breakthrough pressure gradient, relatively strong in expansibility and relatively good in plugging performance; the preparation process is simple, and drying and granulation processes after the conventional polymer microsphere modifying and flooding agent is prepared are omitted.

Owner:成都新驱势石油技术开发有限公司

Method for preparing sulfur-free expansible graphite

The invention belongs to the field of preparation of functional materials and discloses a method for preparing sulfur-free expansible graphite. The method comprises the following steps: (1) subjecting graphite to a contact reaction with acid so as to obtain a mixture; (2) carrying out a first expansion reaction on the mixture obtained in the step (1) so as to obtain first expansible graphite; and (3) carrying out a second expansion reaction on the first expansible graphite obtained in the step (2). By adopting the method disclosed by the invention, the sulfur-free expansible graphite which is free of sulfur and high in expanded ratio can be prepared; and the reaction is simple, the yield is high, the cost is low, no pollution is caused, and the operation is easy, so that large-scale production can be carried out.

Owner:上海驭扬投资有限公司

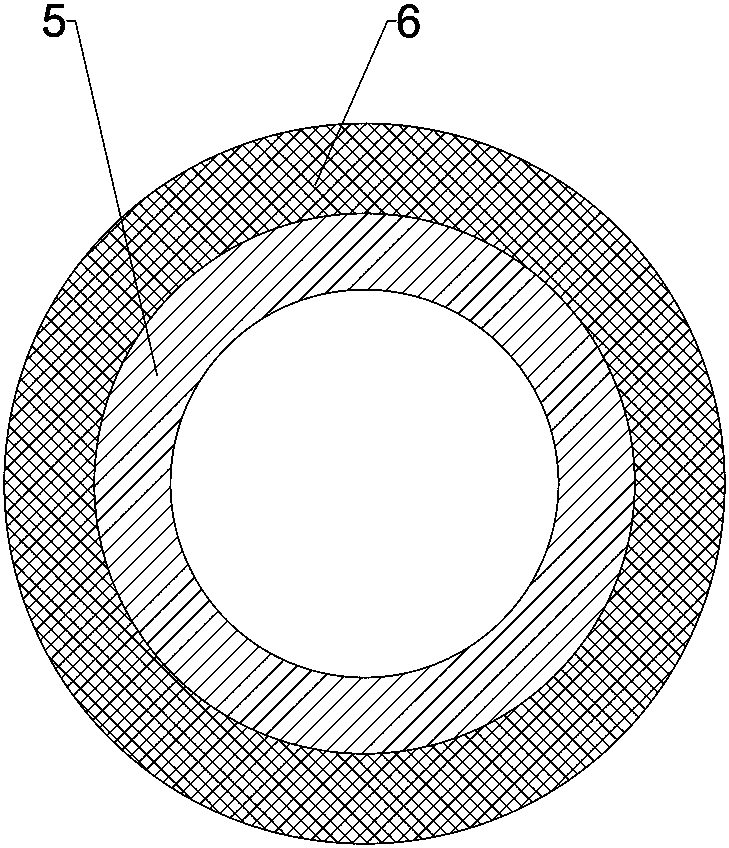

Environment-friendly expanding fireproof synthetic rubber, fireproof cable and rubber coated fireproof pipeline

InactiveCN107674441AImprove fire performanceSocial securityRubber insulatorsPlastic/resin/waxes insulatorsEnvironmental resistanceWater based

The invention relates to the technical field of rubber production, and particularly relates to environment-friendly expanding fireproof synthetic rubber and a fireproof cable and a rubber coated fireproof pipeline using the fireproof synthetic rubber. The environment-friendly expanding fireproof synthetic rubber comprises the following substances in parts by weight: 30-50 parts of water-based resin, 10-20 parts of water, 10-30 parts of expanded graphite, 5-15 parts of ammonium polyphosphate, 8-12 parts of vermiculite, 2-5 parts of perlite, 3-5 parts of tackifier, 3-5 parts of thickener, 1-3 parts of lightning protection agent and 1-3 parts of defoamer. The environment-friendly expanding fireproof synthetic rubber provided by the invention combines the characteristics of environment friendliness, flame retardancy, fire proofness and the like, and can be used instead of traditional toxic synthetic rubber which sends out pungent smell and generates black smoke during combustion; and the product takes the perlite tailing as the raw material, thereby achieving the effects of energy saving and environment friendliness. By using the environment-friendly expanding fireproof synthetic rubber as a coat, the invention also provides the fireproof cable and the rubber coated fireproof pipeline. Fire resistance tests prove that the fireproof cable and the rubber coated fireproof pipeline have the advantages of the environment-friendly expanding fireproof synthetic rubber.

Owner:信阳市华盈矿业有限公司

Fireproof material taking gypsum as base material and construction method thereof

The invention relates to a fireproof material taking gypsum as a base material and a construction method thereof, and belongs to the technical field of building materials. The fireproof material taking gypsum as a base material is a two-component system, wherein the component A is prepared from the following materials in parts by weight: 30-80 parts of gypsum, 0-30 parts of polystyrene particles,0-30 parts of vermiculite, 1-15 parts of fiber, 50-100 parts of sodium carbonate, 1-5 parts of graphite, 1-5 parts of alpha-olefin sodium sulfonate, 1-10 parts of gypsum retarder, 1-3 parts of fillerand 1-3 parts of dicalcium silicate; and the component B is modified aluminum hydroxide and accounts for 5-30% of the weight of the component A. By means of the fireproof material, the one-time spraying thickness of a base material can reach 50 mm, and the problem caused by the fact that the thickness requirement is met only when workers conduct spraying on the base material many times is avoided.

Owner:河南中柏防火涂料科技有限公司

Method for preparing expanded graphite through chemical oxidation

A disclosed method for preparing expanded graphite through chemical oxidation comprises: putting natural flake graphite into a container, adding sulfuric acid with stirring, adding potassium permanganate after the mixture is stirred uniformly, continuing to stir for 5-10 min, then reacting under the temperature condition of 60 DEG C for 30 min, wherein the diameter of natural flake graphite is less than 2 mu m, the mass ratio of natural flake graphite, sulfuric acid and potassium permanganate is 1:6:(1.2-1.5); and washing the reacted product with water to be neutral, then dewatering and airing, and expanding under the temperature condition of 850-950 DEG C, so as to prepare the expanded graphite. By taking natural graphite as the raw material and potassium permanganate as an oxidant for preparing expanded graphite, graphite flake is embedded with sulfuric acid and an interlaminar compound is formed, the expanded graphite prepared after expanding is high in expansion multiple, the preparation method is simple, and the output is high.

Owner:QINGDAO TAIHAODA CARBON MATERIAL

A kind of preparation method of nano-scale organic bentonite

ActiveCN104760968BUndamagedHigh expansion factorMaterial nanotechnologySilicon compoundsSodium BentoniteMass ratio

The invention discloses a preparation method of nanoscale organobentonite, which comprises the following six steps: (1) bentonite raw ore processing, (2) sodium modification, (3) centrifugation purification, (4) inorganic acid modification, (5) organic coating reaction, and (6) a post treatment stage. The preparation method has the characteristics that through substep purification, a mass ratio of a sodium agent to suspending liquid is kept at 0.3%; in an inorganic acid modification process, improvements are performed by adjustment of a PH value to subacid and a charging mode in the organic coating reaction stage; the bentonite is subjected to delaminating dispersion, centrifugation purification and superfine grading to prepare pure montmorillonite with the content greater than 95%; then, double octadecyl dimethyl ammonium chloride is used for performing the organic coating reaction; finally crushing to a nanoscale particle size is performed, that is, the average lamellar thickness is less than 25 nanometers; and the preparation method ensures the product quality, shortens the production cycle greatly, lowers the production cost, and is suitable for large-scale popularization and application.

Owner:HUANGSHAN BAIYUE ACTIVATED CLAY

Acidified bentonite

ActiveCN103979559APromotes natural weatheringImprove the disintegration effectAluminium silicatesFiberAviation

The invention discloses an acidified bentonite. The technical scheme is as follows: the acidified bentonite is composed of bentonite, sulfuric acid, instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium carbonate. The production method of the acidified bentonite comprises the following steps: inputting acidified bentonite materials into a mill, and milling into powder, thereby obtaining the acidified bentonite. The composite proportioning is performed after acidification, thereby avoiding the chemical reaction between the sulfuric acid and the instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium carbonate, fully displaying the respective characteristics of the raw materials in the formula, and ensuring the inherent quality of the acidified bentonite. The acidified bentonite has favorable adsorbability, high-temperature stability and lubricating property, and the water absorptivity, colloid index, plasticity, expansion coefficient, colloid viscosity and thixotropy are greatly enhanced. The acidified bentonite is suitable for producing products in the fields of paints, aviation, metallurgy, chemical fibers, petroleum, firefighting and the like.

Owner:江苏世澳非金属应用科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com