Preparation method of nanometer iron oxide particle/expanded microcrystalline graphite composite material used for lithium ion batteries

A technology of nano-iron oxide and lithium-ion batteries, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc. Excellent electrical properties, discounts on the electrical properties of composite materials, etc., to achieve the effects of tight combination, improved corrosion resistance, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

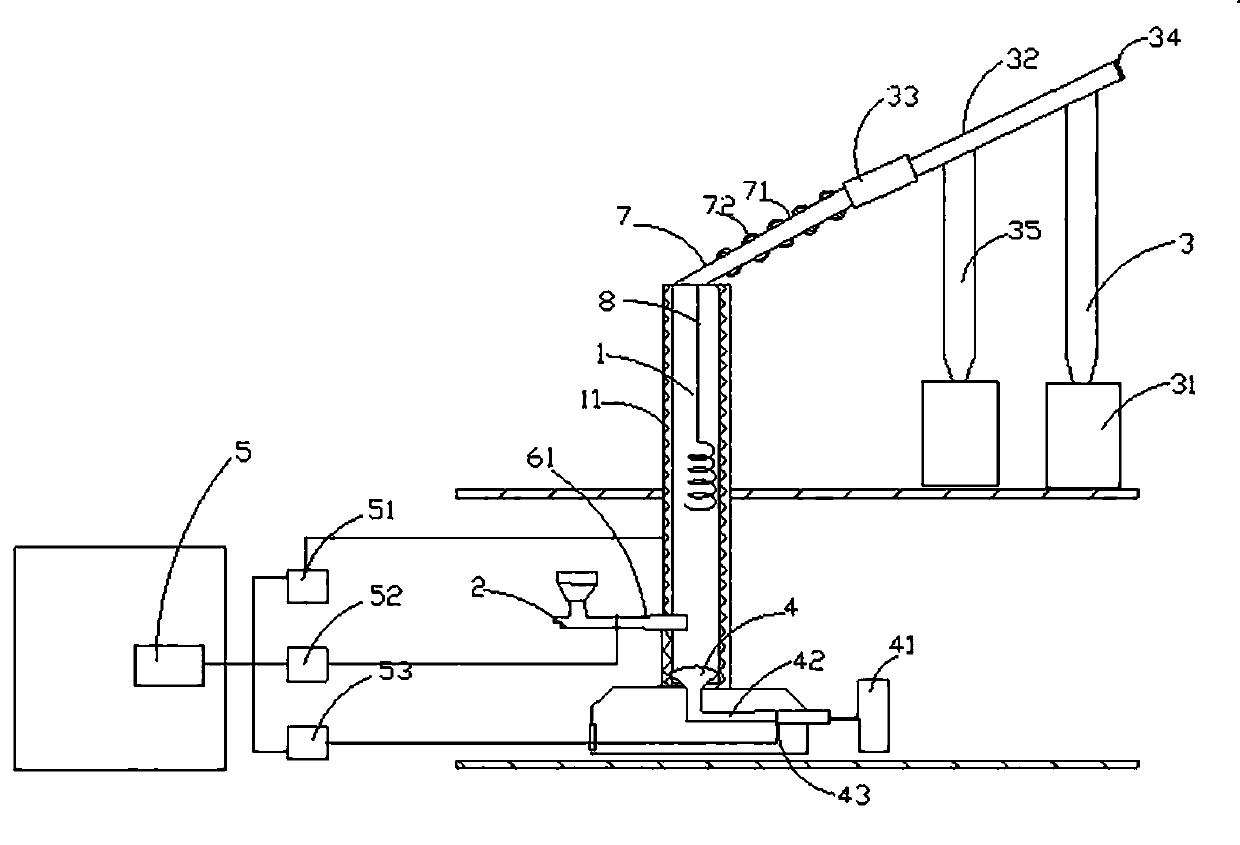

Image

Examples

Embodiment 1

[0045] The present invention prepares the method for expanded microcrystalline graphite material with microcrystalline graphite, comprises steps as follows: comprises graphite expansion furnace, adopts high-temperature expansion method, comprises the following steps:

[0046] S1. Get the microcrystalline graphite raw material, the carbon content is 70%, crushing and grinding, until the particle size is 300 mesh microcrystalline graphite powder;

[0047] S2. the microcrystalline graphite powder obtained in step S1, perchloric acid and potassium permanganate are placed in the reaction device for the first chemical intercalation treatment to obtain an acidic suspension of expandable microcrystalline graphite, and the resulting expandable microcrystalline graphite Filtrate the acidic suspension, keep the filtrate for later use, then wash and dry the filtrate to obtain an expandable microcrystalline graphite; wherein, the specific steps of the first chemical intercalation are: S21. Co...

Embodiment 2

[0054] The steps of this embodiment are basically the same as in Embodiment 1, the difference is that:

[0055] S1. Get the microcrystalline graphite raw material, the carbon content is 70%, crushing and grinding, until the particle size is 300 mesh microcrystalline graphite powder;

[0056] S2. The specific steps of chemical intercalation for the first time are: S21. Mix perchloric acid and microcrystalline graphite powder at a liquid-solid ratio of 15:1L / Kg and stir evenly; S22. Press microcrystalline graphite powder and high manganese The mass ratio of potassium permanganate is 4:1. Add potassium permanganate, stir evenly at room temperature, raise the temperature to 40°C and continue to stir for 2 hours; S23. Add deionized water to raise the temperature in the reaction device to 70°C, and then Continue to stir and react for 2h;

[0057] S4. The primary expanded graphite obtained in step S3 is mixed with ferrocene in a mass ratio of 1:2, and the ball-to-material ratio is 3...

Embodiment 3

[0061] The steps of this embodiment are basically the same as in Embodiment 1, the difference is that:

[0062] S1. Get the microcrystalline graphite raw material, the carbon content is 75%, crushing and grinding, until the particle size is 350 mesh microcrystalline graphite powder;

[0063] S2. The specific steps of chemical intercalation for the first time are: S21. Mix perchloric acid and microcrystalline graphite powder at a liquid-solid ratio of 20:1L / Kg and stir evenly; S22. Press microcrystalline graphite powder and high manganese The mass ratio of potassium permanganate is 6:1. Add potassium permanganate, stir evenly at room temperature, raise the temperature to 50°C and continue to stir for 2 hours; S23. Add deionized water to raise the temperature in the reaction device to 80°C, and then Continue to stir and react for 2h;

[0064] S4. The primary expanded graphite obtained in step S3 is mixed with ferrocene in a mass ratio of 1:3, and the ball-to-material ratio is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com