Water-based fireproof coating suitable for railway vehicle chassis and preparation method thereof

A rail vehicle and fireproof coating technology, applied in fireproof coatings, epoxy resin coatings, coatings, etc., can solve the problems that coatings cannot meet the structural fire resistance requirements, the large amount of harmful substances volatilized, and the construction process is complex, etc., to delay flames and heat transmission, excellent environmental performance, and excellent bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

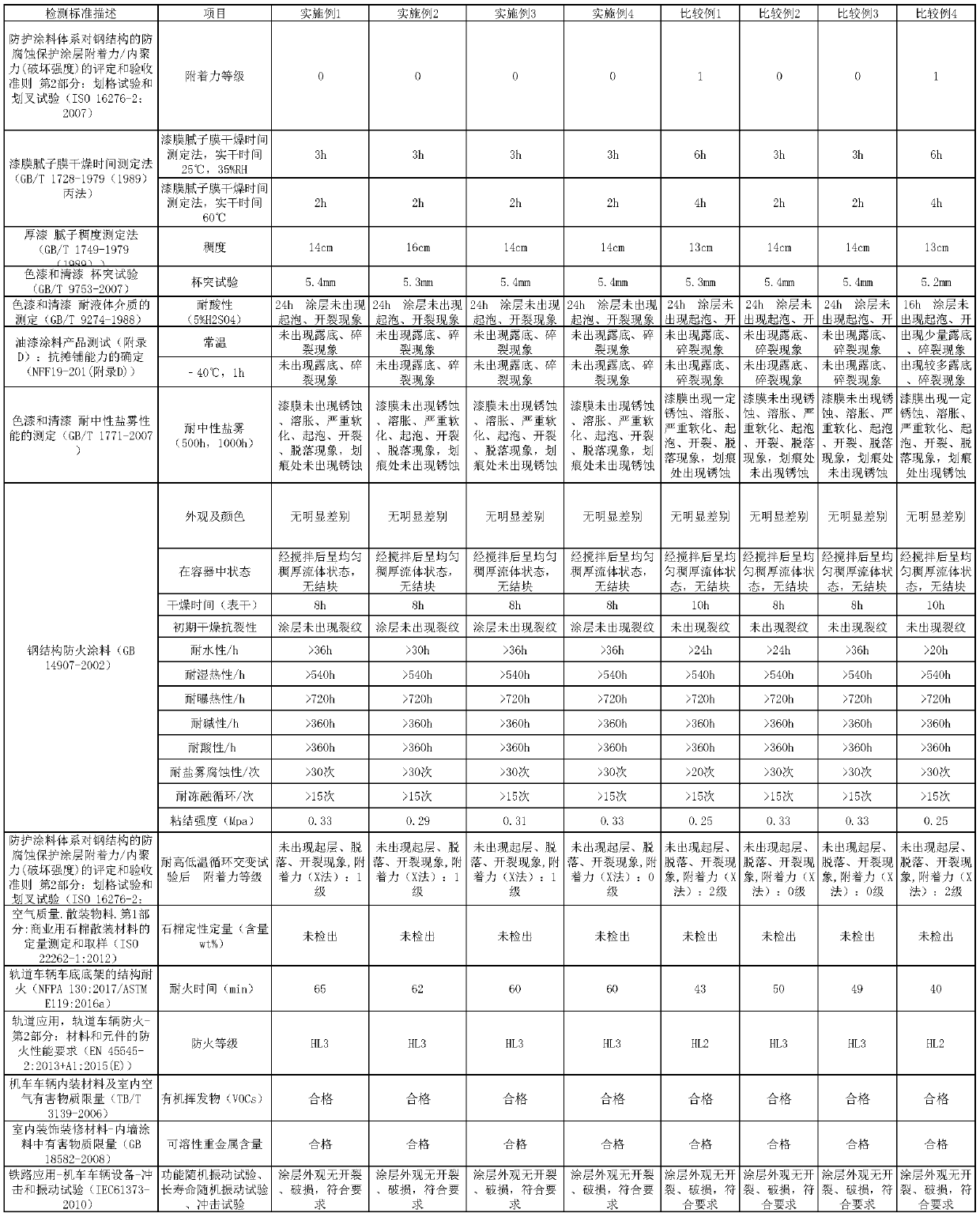

Examples

Embodiment 1

[0026] Step 1: Add 500g of epoxy / acrylic hybrid emulsion and 6g of wetting and dispersing agent into the mixing tank for low-speed dispersion and stirring for 2-5 minutes;

[0027] Step 2: While stirring and dispersing, add 30g organic bentonite, 120g titanium dioxide, 40g expandable graphite, 60g nano-aluminum magnesium hydroxide, 460g melamine phosphate, 220g dipentaerythritol, 260g melamine, 6g wetting defoamer, 20g into Membrane aid, 150g deionized water, disperse at high speed for 20-40 minutes after adding completely;

[0028] Step 3: According to the requirement of expected viscosity of 15000±1000mPa·s, add 128g of deionized water and stir to disperse;

[0029] Step 4: Put the paint obtained in the above steps into a ball mill for grinding, and use a scraper fineness meter to detect the fineness of the paint until the fineness value reaches 90um±15um, then stop grinding;

[0030] Step 5: Use a strainer to filter, separate the grinding beads and paint, put the paint int...

Embodiment 2

[0032] On the basis of Example 1, the content of catalyst melamine phosphate, charring agent dipentaerythritol, blowing agent melamine relatively increased intumescent flame retardant system, reduce the consumption of film-forming material epoxy / acrylic acid hybrid emulsion and deionized water, its The preparation method is the same as in Example 1. For the specific mass ratio of this example, refer to Formulation 2 in Table 1. The properties of the obtained coating are shown in Example 2 in Table 2.

Embodiment 3

[0034]On the basis of Example 1, further increase the content of film-forming material epoxy / acrylic acid hybrid emulsion, and relatively reduce the content of catalyst melamine phosphate, carbonizing agent dipentaerythritol, and foaming agent melamine of the intumescent flame-retardant system, and its preparation method is the same as Example 1, the specific mass ratio of this example is shown in Formulation 3 in Table 1, and the properties of the obtained coating are shown in Example 3 in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com