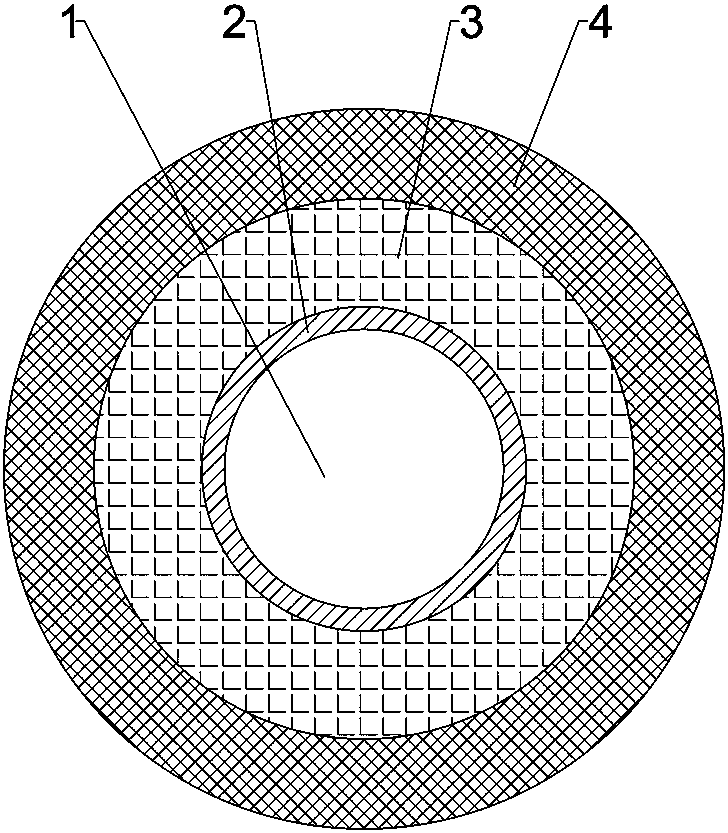

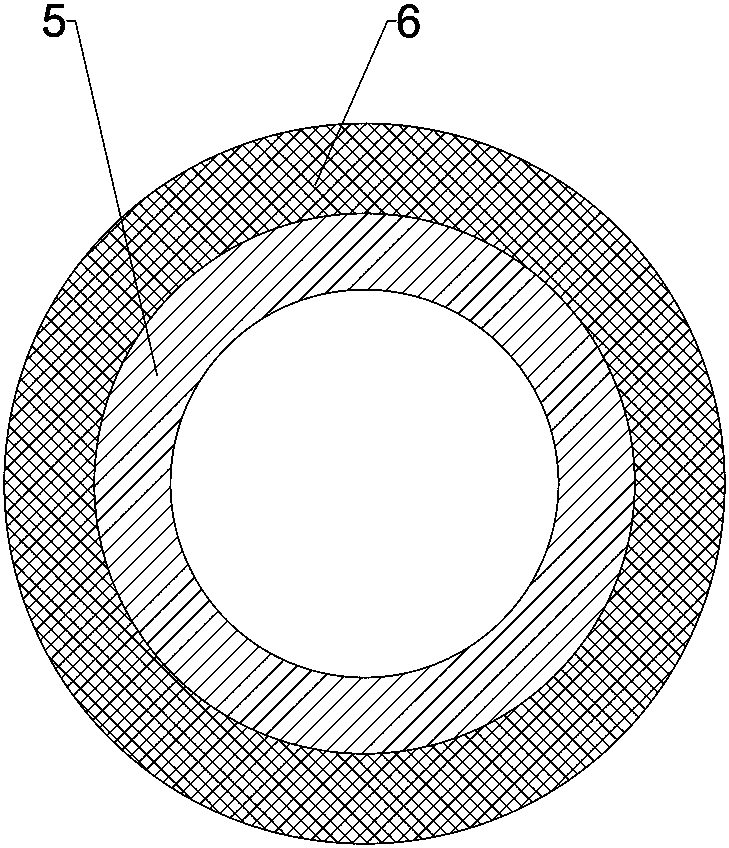

Environment-friendly expanding fireproof synthetic rubber, fireproof cable and rubber coated fireproof pipeline

A synthetic rubber, environmentally friendly technology, used in rubber insulators, plastic/resin/wax insulators, organic insulators, etc., can solve problems such as fire, filler and sheath damage, danger, and achieve social safety and environmental protection, saving The effect of resource consumption and superior fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides an environmentally friendly expanded fireproof synthetic rubber, including the following parts by weight: 30 parts of water-based resin, 10 parts of water, 10 parts of expanded graphite, 5 parts of ammonium polyphosphate, 8 parts of vermiculite, and 2 parts of perlite , 3 parts of tackifier, 3 parts of thickener, 1 part of lightning protection agent, 1 part of defoamer.

Embodiment 2

[0027] This embodiment provides an environmentally friendly expanded fireproof synthetic rubber, including the following parts by weight: 50 parts of water-based resin, 20 parts of water, 30 parts of expanded graphite, 15 parts of ammonium polyphosphate, 12 parts of vermiculite, and 5 parts of perlite , 5 parts of tackifier, 5 parts of thickener, 3 parts of lightning protection agent, 3 parts of defoamer.

Embodiment 3

[0029] This embodiment provides an environmentally friendly expanded fireproof synthetic rubber, including the following parts by weight: 40 parts of water-based resin, 15 parts of water, 20 parts of expanded graphite, 10 parts of ammonium polyphosphate, 10 parts of vermiculite, and 3 parts of perlite , 3 parts of tackifier, 3 parts of thickener, 2 parts of lightning protection agent, 2 parts of defoamer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com