Waterborne ultrathin steel structure fireproof coating material and preparation method thereof

A fire-resistant coating, ultra-thin technology, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of damage to the health of construction workers, poor water resistance of coatings, environmental pollution, etc., to overcome easy cracking, excellent water resistance, foaming Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

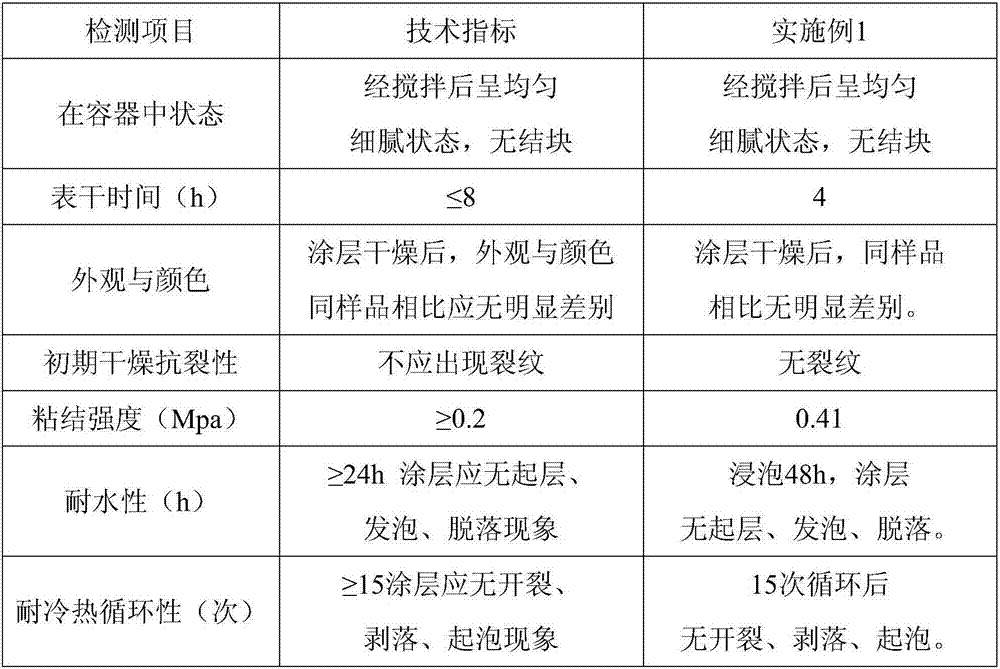

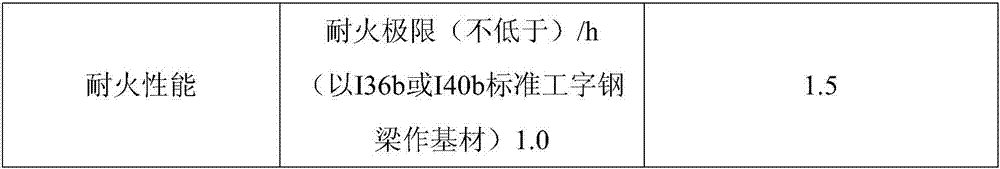

Embodiment 1

[0038] Modified tertiary vinegar emulsion 175g, MF modified ammonium polyphosphate 200g, pentaerythritol 105g, melamine 95g, defoamer TEGO Airex 902W 2g, thickener 5g, pH regulator 5g, film-forming aid alcohol ester-12 10g, Dispersant 4g, preservative 2g, sericite 20g, talcum powder 40g, titanium dioxide 70g, water 270g.

[0039] Preparation process: fully mix 2g of dispersant, 1g of defoamer, pentaerythritol, and water in the batching tank; pump the mixed materials into a sand mill, and disperse them by high-speed sand milling to make a pentaerythritol skeleton slurry of 110-130 μm; Then add MF modified ammonium polyphosphate, melamine, 2g of dispersant, thickener, titanium dioxide, sericite, talcum powder, and pH regulator into the pentaerythritol skeleton slurry, mix well, and pump it into the sand mill for high-speed sand grinding and dispersion , to make a slurry of 110-130 μm; put the slurry into the paint mixing tank, add film-forming aids at a speed of 400r / min and sti...

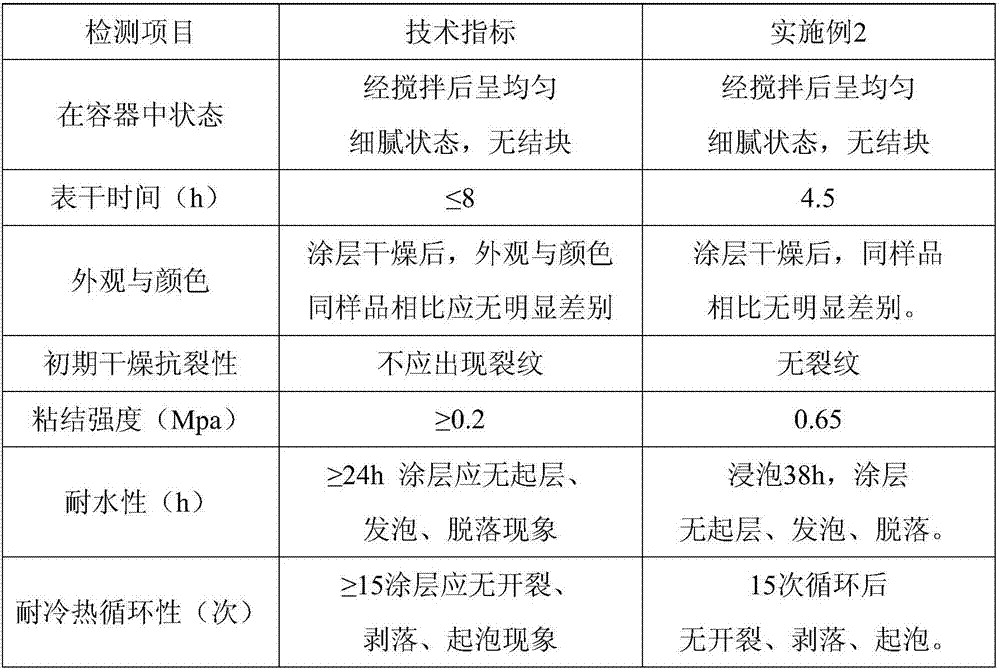

Embodiment 2

[0045] Modified tertiary vinegar emulsion 180g, MF modified ammonium polyphosphate 220g, pentaerythritol 110g, melamine 100g, defoamer TEGO Airex 901W 3g, thickener 4g, pH regulator 2g, film-forming aid alcohol ester-12 10g, Dispersant 3g, preservative 2g, sericite 10g, talcum powder 20g, titanium dioxide 40g, water 296g.

[0046] Preparation process: fully mix 1.5g of dispersant, 1.5g of defoamer, pentaerythritol, and water in the batching tank; pump the mixed material into a sand mill, and disperse it by high-speed sand milling to make a pentaerythritol skeleton of 110-130 μm Then add MF modified ammonium polyphosphate, melamine, dispersant 1.5g, thickener, titanium dioxide, sericite, talcum powder, and pH regulator into the pentaerythritol skeleton slurry, mix evenly, and pump it into a sand mill for high-speed Sand mill and disperse to make a slurry of 110-130μm; put the slurry into the paint mixing tank, add film-forming aids at a speed of 400r / min and stir evenly, then a...

Embodiment 3

[0052] 220g modified tertiary vinegar emulsion, 200g MF modified ammonium polyphosphate, 100g pentaerythritol, 90g melamine, 2g defoamer TEGO Foamex 810, 4g thickener, 3g pH regulator, 12g film-forming aid, 4g dispersant, Preservative 2g, sericite 15g, talcum powder 25g, titanium dioxide 50g, water 272g.

[0053] Preparation process: fully mix 2g of dispersant, 1g of defoamer, pentaerythritol, and water in the batching tank; pump the mixed materials into a sand mill, and disperse them by high-speed sand milling to make a pentaerythritol skeleton slurry of 110-130 μm; Then add MF modified ammonium polyphosphate, melamine, 2g of dispersant, thickener, titanium dioxide, sericite, talcum powder, and pH regulator into the pentaerythritol skeleton slurry, mix well, and pump it into the sand mill for high-speed sand grinding and dispersion , to make a slurry of 110-130 μm; put the slurry into the paint mixing tank, add film-forming aids at a speed of 450r / min and stir evenly, then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com