Expandable graphite plugging agent system for deep channel blocking of heavy oil reservoir steam flooding and injection method

A technology for expanded graphite and heavy oil reservoirs, applied in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve the problems of short validity period, short consolidation time, complicated high-temperature foam construction, etc., to save economic costs, The effect of improving mining efficiency and facilitating deep migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned expandable graphite plugging agent system for steam flooding deep channeling of heavy oil reservoirs, the steps are as follows:

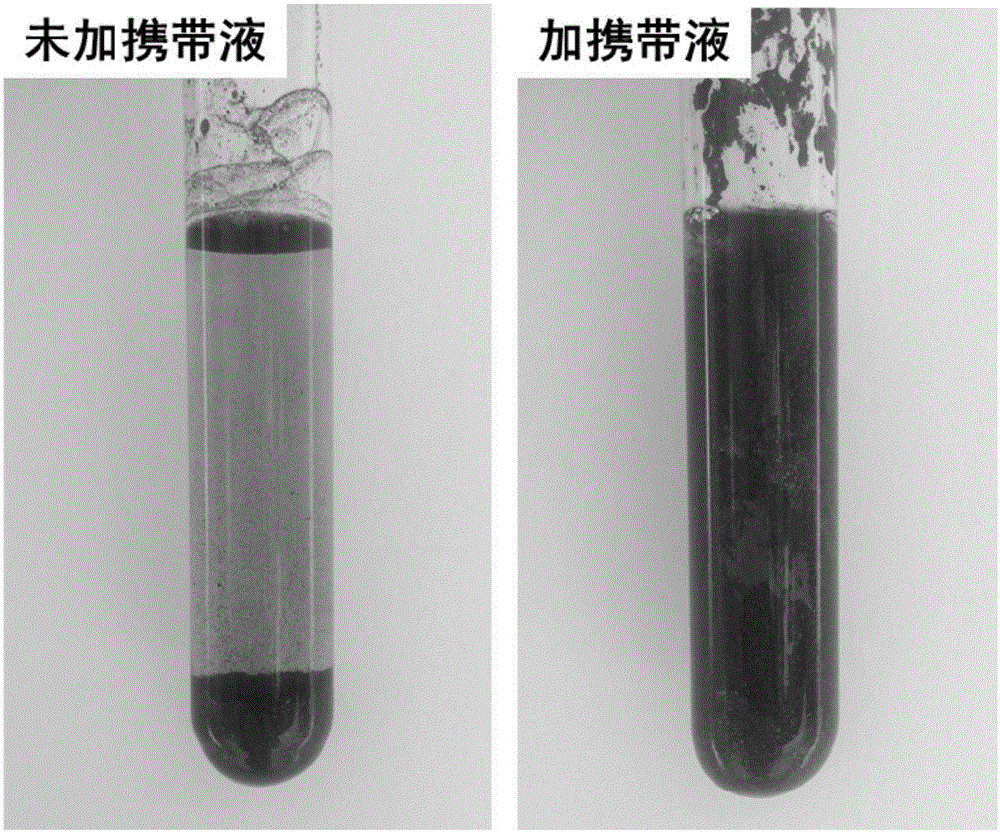

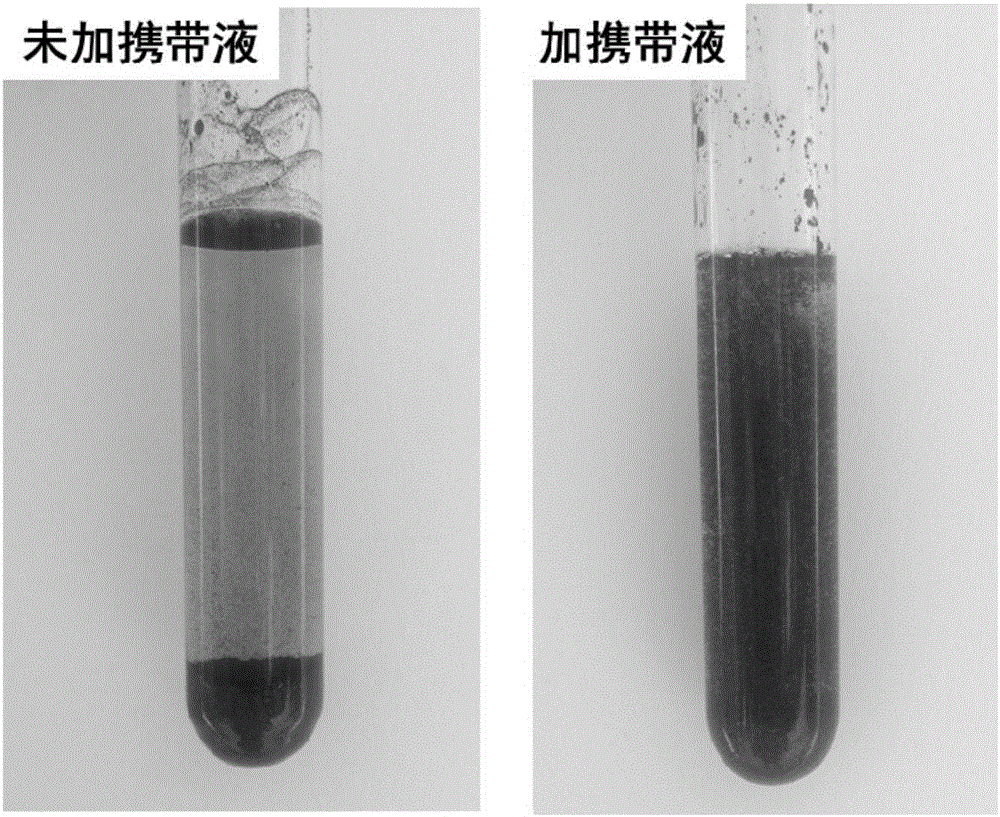

[0039] At room temperature (20±5°C), first add non-ionic polymer to the liquid preparation water to prepare the carrier liquid, stir for 60 minutes until it is fully dissolved; then add low-temperature expandable graphite particles, stir for 10 minutes until it is fully dispersed to prepare Obtain a low-temperature expansion particle plugging agent system for steam flooding deep channeling in heavy oil reservoirs; at room temperature (20±5°C), add non-ionic polymers to the liquid preparation water to prepare the carrier fluid, stir for 60 minutes until it is fully dissolved Then add medium-temperature expandable graphite particles, stir for 10 minutes and wait for it to fully disperse to obtain a medium-temperature expandable particle plugging agent system for steam flooding deep channeling in heav...

Embodiment 1

[0054] This example provides the preparation method and injection method of the expandable graphite plugging agent system for steam flooding deep channeling in heavy oil reservoirs.

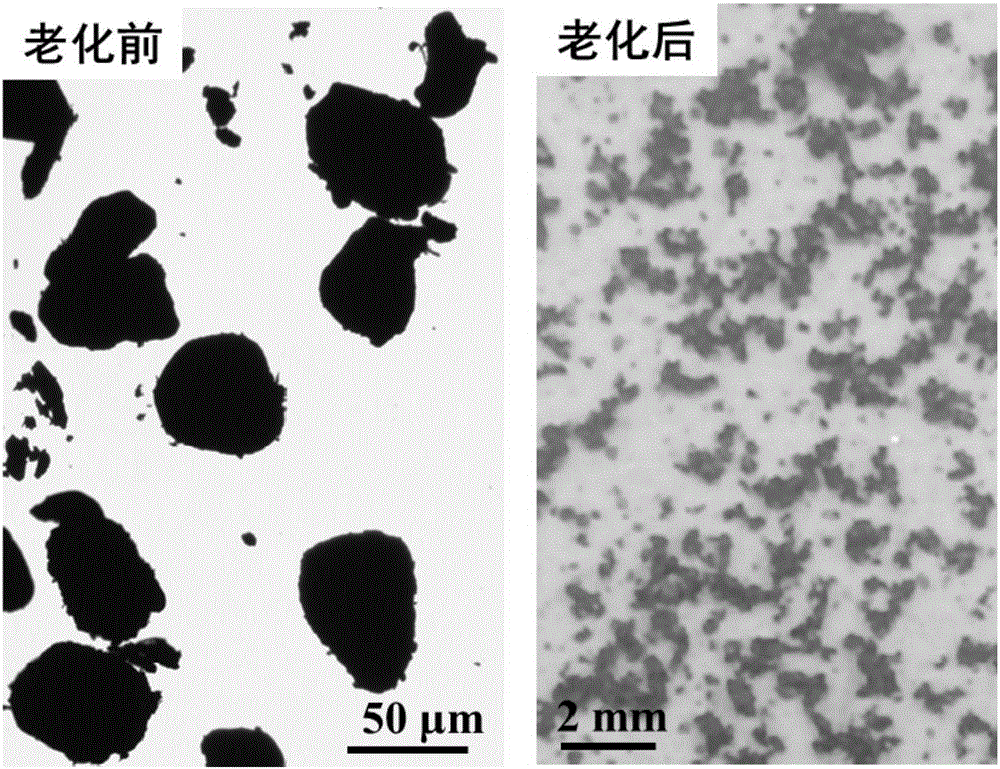

[0055] Expandable graphite plugging agent system for steam flooding deep channeling in heavy oil reservoirs, including: carrier fluid, low temperature expandable graphite particles (initial expansion temperature 150°C), medium temperature expandable graphite particles (initial expansion temperature 220°C), high temperature expandable graphite particles Expanded graphite particles (initial expansion temperature 300°C), mixed with water.

[0056] At room temperature (20±5°C), add 0.1 g of non-ionic polymer to 99.4 g of clear water while stirring and stir for 60 minutes. After it is fully dissolved, the carrier liquid is prepared, and then 0.5 g of low-temperature expandable graphite particles are added. Stir for 10 minutes and wait for it to fully disperse to obtain a low-temperature expandable gra...

Embodiment 2

[0065] This example provides the preparation method and injection method of the expandable graphite plugging agent system for steam flooding deep channeling in heavy oil reservoirs.

[0066] Expandable graphite plugging agent system for steam flooding deep channeling in heavy oil reservoirs, including: carrier fluid, low temperature expandable graphite particles (initial expansion temperature 150°C), medium temperature expandable graphite particles (initial expansion temperature 220°C), high temperature expandable graphite particles Expanded graphite particles (initial expansion temperature 300°C), mixed with water.

[0067] At room temperature (20±5°C), add 0.15 g of polymer in turn to 98.85 g of clear water while stirring and stir for 60 minutes. After it is fully dissolved, a carrier liquid is obtained, then add 1.0 g of low-temperature expandable graphite particles, and stir After 10 minutes of being fully dispersed, a low-temperature expandable graphite plugging agent sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com