Horizontal well seam forming method and method for extracting oil gas from underground oil shale

A horizontal well and oil shale technology, applied in the field of oil exploitation, can solve the problems of slow heating speed, high cost, low energy utilization rate, etc., and achieve the effects of increasing oil drainage area, improving utilization rate, and improving seepage channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

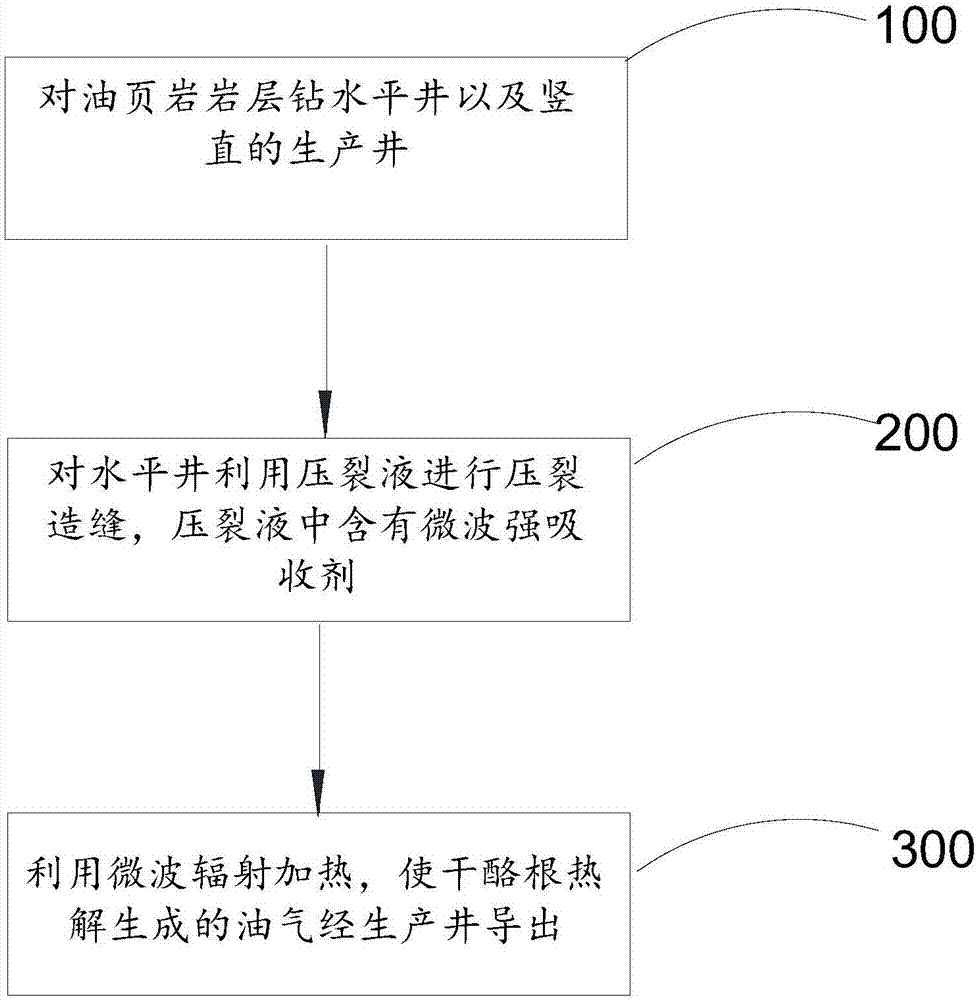

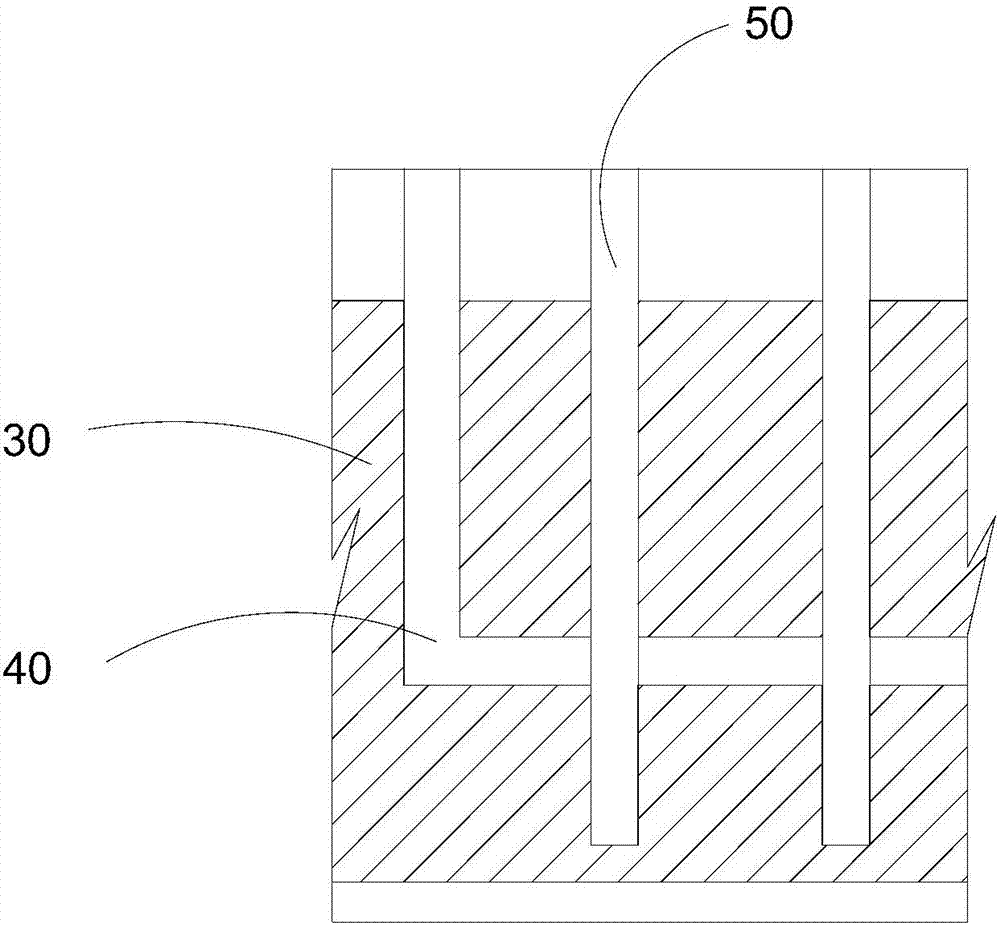

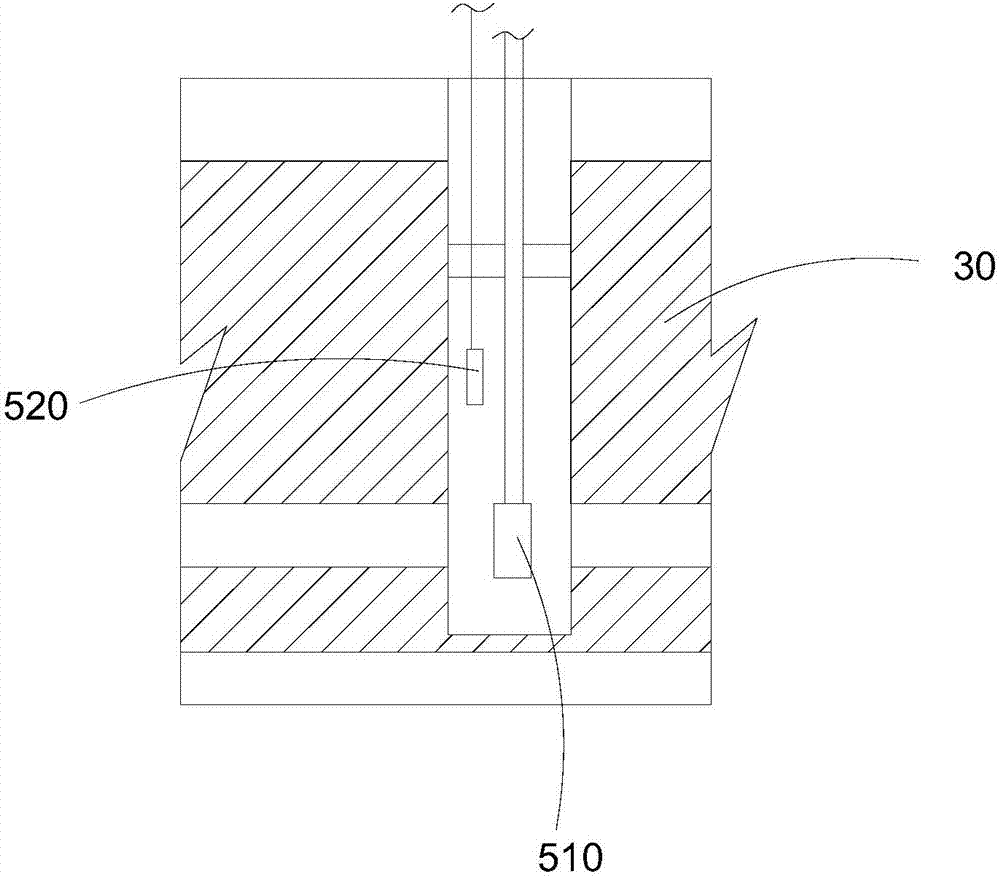

[0024] Please also refer to figure 1 and figure 2 , the present embodiment provides a method for extracting oil and gas from underground oil shale, which includes a method for creating fractures in horizontal wells 40, specifically, the method for extracting oil and gas from underground oil shale includes the following steps:

[0025] Step 100 , drilling a horizontal well 40 and a vertical production well 50 on the oil shale formation 30 .

[0026] Step 200, use fracturing fluid to fracture the horizontal well 40, and the fracturing fluid contains a strong microwave absorber.

[0027] Step 300 , using microwave radiation to heat, so that the oil and gas generated by kerogen pyrolysis are exported through the production well 50 .

[0028] The details will be described below.

[0029] In step 100, due to the extremely poor oil permeability of the oil shale formation 30, the oil and gas formed after in-situ heating must have sufficient oil and gas passages to ensure that it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com