Environment-friendly aqueous film forming foam fire extinguishing agent and preparation method thereof

A foam fire extinguishing agent, water film forming technology, applied in fire protection equipment and other directions, can solve the problems of no improvement of product freezing point, water pollution, poor cold resistance, etc., and achieve the effect of strong product spreading ability, low freezing point temperature, and rapid fire extinguishing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

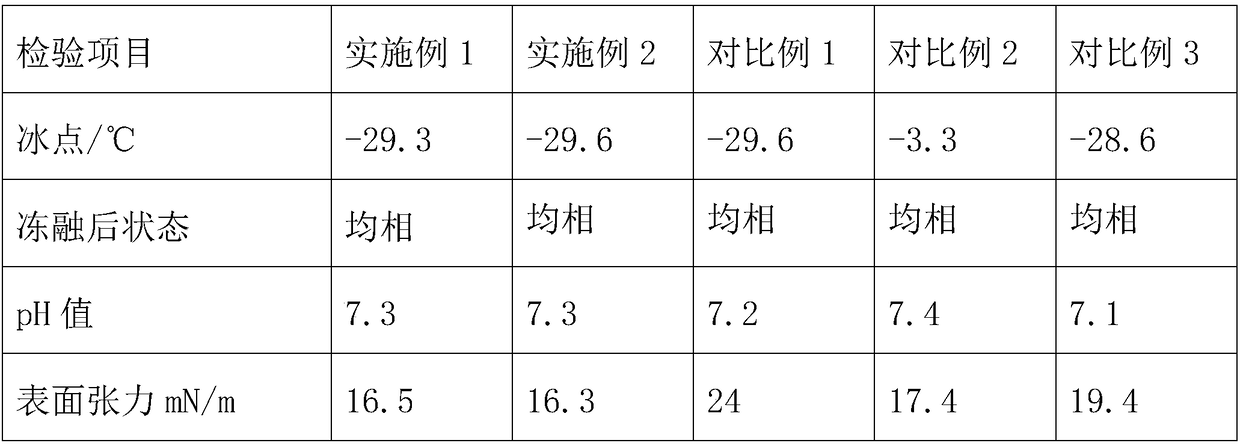

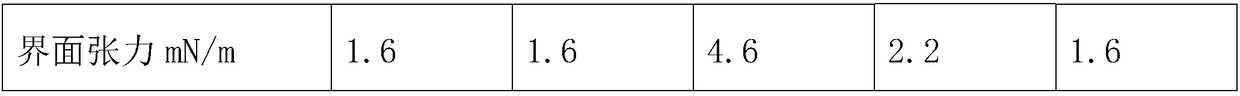

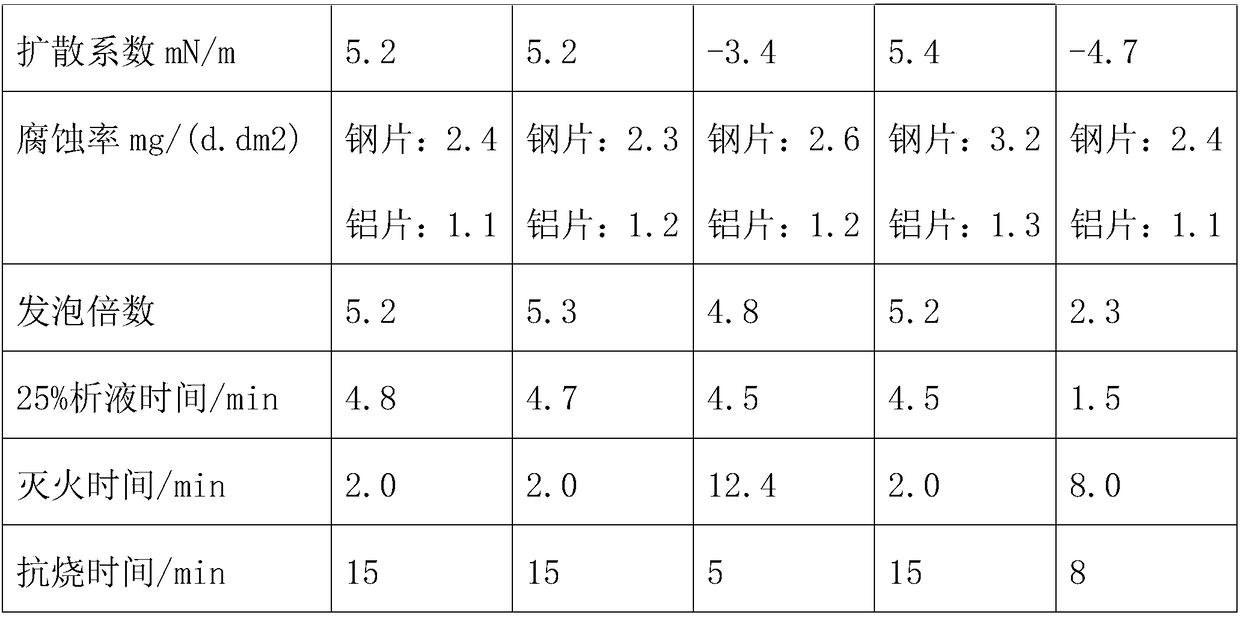

Examples

preparation example Construction

[0018] A preparation method of an environment-friendly aqueous film-forming foam fire extinguishing agent, comprising the steps of:

[0019] Add deionized water to the raw materials according to the formula ratio, start the mixer, add water-soluble ammonium polyphosphate and urea to dissolve them all, add xanthan gum, dissolve them all, stir for 30 minutes, continue stirring and add cocamidopropyl betaine and APG After fully stirring for 1 hour, add modified nanocellulose sodium salt, perfluorohexylsulfonyl betaine, amphoteric fluorinated acrylate emulsion and buffer in sequence, and stir for 30-60 minutes. Adjust the pH value of the material to 7.0-7.5 and stop. Stirring, and then settling, filtering and packaging to obtain the concentrated liquid of the environment-friendly aqueous film-forming foam fire extinguishing agent. The dosage ratio of perfluorohexylsulfonyl betaine to amphoteric fluorinated acrylate emulsion is 1:6.5.

[0020] 1. The concentrated solution of the e...

Embodiment 1

[0023] a. Add 44.5kg of water into the 500L reactor, start stirring, set the stirring speed to 100rpm, then slowly add 10kg of water-soluble ammonium polyphosphate and 5kg of urea into the reactor.

[0024] b. After fully dissolving, slowly add 0.7kg xanthan gum into the reaction kettle.

[0025] c. After the xanthan gum is fully dissolved and mixed, add 10kg of cocamidopropyl betaine and 10kg of APG.

[0026] d. After fully dissolving, slowly add 0.75 kg of perfluorohexylsulfonyl betaine, 5 kg of amphoteric fluorinated acrylate emulsion and 12 kg of modified nanocellulose sodium salt successively.

[0027] e. After fully mixing and dissolving, add an appropriate amount of sodium bicarbonate to adjust the pH value of the material to 7.0-7.5, stop stirring, and then settle, filter and pack.

Embodiment 2

[0029] a. Add 40kg of water into the 500L reactor, start stirring, set the stirring speed to 100rpm, then slowly add 10kg of water-soluble ammonium polyphosphate, 5kg of urea and 4.5kg of sodium dodecylsulfonate into the reactor.

[0030] b. After fully dissolving, slowly add 0.7kg xanthan gum into the reaction kettle.

[0031] c. After the xanthan gum is fully dissolved and mixed, add 10kg of cocamidopropyl betaine and 10kg of APG.

[0032] d. After fully dissolving, slowly add 0.75 kg of perfluorohexylsulfonyl betaine, 5 kg of amphoteric fluorinated acrylate emulsion and 12 kg of modified nanocellulose sodium salt successively.

[0033] e. After fully mixing and dissolving, add an appropriate amount of sodium bicarbonate to adjust the pH value of the material to 7.0-7.5, stop stirring, and then settle, filter and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com