Telescopic anti-freezing full-physical crosslinked hydrogel material for multi-mode flexible sensor and preparation method thereof

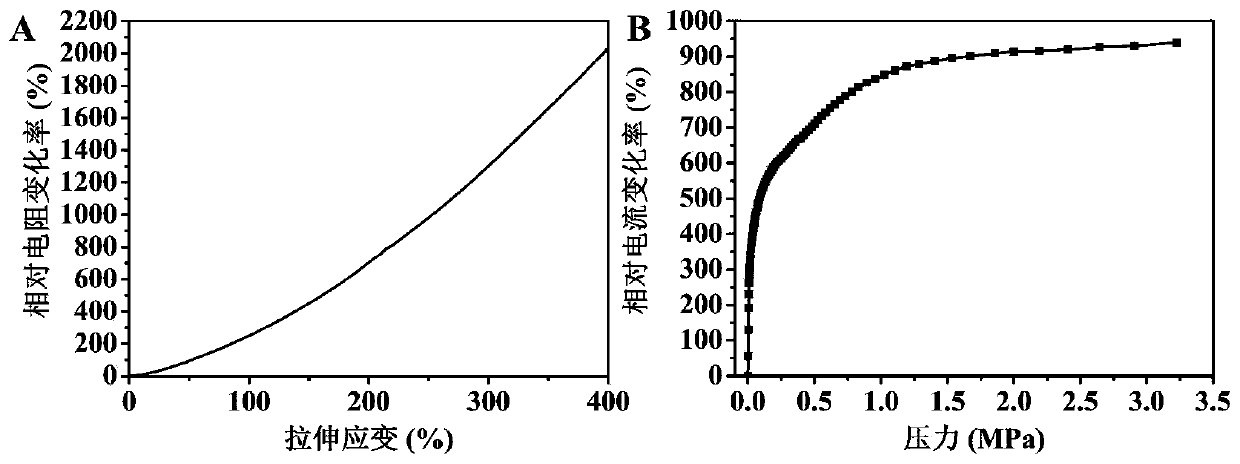

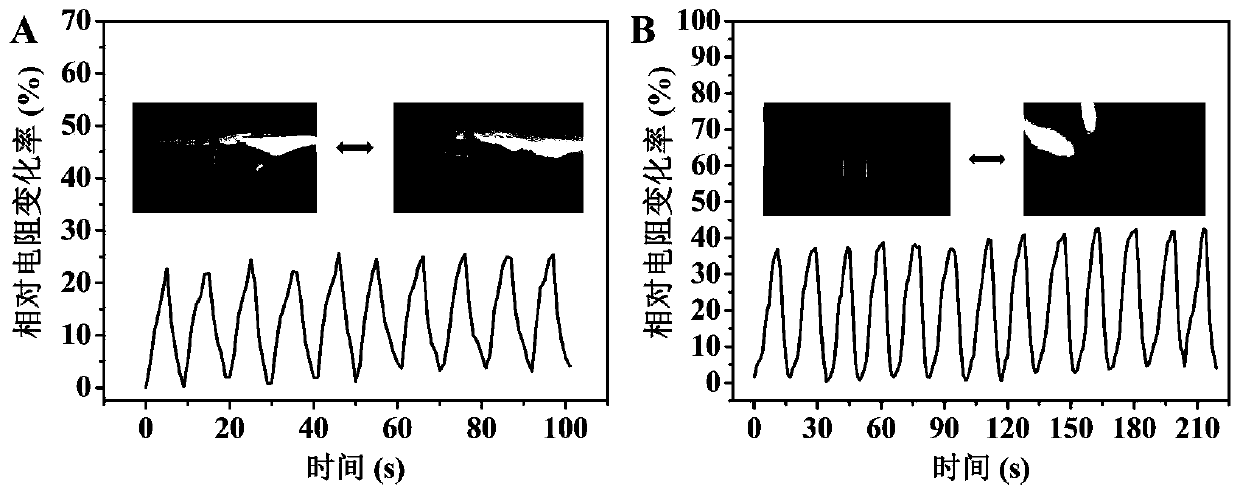

A flexible sensor and cross-linked hydrogel technology, applied in the field of flexible sensing, can solve the problems of low ductility, large material rigidity, and small pressure monitoring range, achieve good mechanical properties and electrical conductivity, and enhance hydrogen bond force. , the effect of reducing electrostatic repulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A stretchable antifreeze fully physically cross-linked hydrogel material for multimodal flexible sensors, comprising the following steps:

[0053] (1) Weigh 0.5g chitosan and add it to 10mL water, then add 3g N-hydroxyethylacrylamide, 50mg 2-hydroxy-4-(2-hydroxyethoxy)-2-methylpropiophenone, stir Uniformly, a mixed solution is obtained;

[0054] (2) Pour the mixed solution into a glass mold, cover the surface of the solution with a layer of polyethylene terephthalate film with a thickness of 0.03mm, and use 100W and a wavelength of 365nm UV lamps to irradiate for 30min to cure, to obtain Hydrogel intermediate;

[0055] (3) The hydrogel intermediate was soaked in a saturated sodium sulfate solution for 20 minutes for cross-linking to obtain a stretchable antifreeze fully physically cross-linked hydrogel material. The fully physically cross-linked hydrogel material has high ductility (1200%), supercompressibility (~98%), self-healing (strength recovery 98%), self-healin...

Embodiment 2

[0061] A stretchable antifreeze fully physically cross-linked hydrogel material for multimodal flexible sensors, comprising the following steps:

[0062] (1) Weigh 1g chitosan into 10mL water, then add 4g N-hydroxyethylacrylamide, 40mg 2-hydroxy-4-(2-hydroxyethoxy)-2-methylpropiophenone, stir well , to obtain a mixed solution;

[0063] (2) Pour the mixed solution into a glass mold, cover the surface of the solution with a layer of polyethylene terephthalate film with a thickness of 0.05mm, and use 60W and a wavelength of 256nm UV lamps to irradiate for 40min to cure, and obtain Hydrogel intermediate;

[0064] (3) Soak the hydrogel intermediate in a saturated sodium citrate solution for 15 minutes for cross-linking to obtain a stretchable antifreeze fully physically cross-linked hydrogel material. The fully physically cross-linked hydrogel material has high ductility (925%), supercompressibility (~98%), self-healing (strength recovery 93%), self-healing (strength healing 78%)...

Embodiment 3

[0066] A stretchable antifreeze fully physically cross-linked hydrogel material for multimodal flexible sensors, comprising the following steps:

[0067] (1) Weigh 1.5g chitosan and add it to 10mL water, then add 4g N-hydroxyethylacrylamide, 25mg 2-hydroxy-4-(2-hydroxyethoxy)-2-methylpropiophenone, stir Uniformly, a mixed solution is obtained;

[0068] (2) Pour the mixed solution into a glass mold, cover the surface of the solution with a layer of polyethylene terephthalate film with a thickness of 0.02mm, and use 70W and a wavelength of 365nm ultraviolet lamps to irradiate for 30min to cure, and obtain Hydrogel intermediate;

[0069] (3) Soak the hydrogel intermediate in 2mol / L sodium citrate solution for 25min for cross-linking to obtain a stretchable antifreeze fully physically cross-linked hydrogel material. The fully physically cross-linked hydrogel material has high ductility (910%), supercompressibility (~98%), self-healing (strength recovery 95%), self-healing (stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com