Pellet ore binder

A technology of binder and pellets, which is applied in the field of pellet binder formula, can solve the problems of increasing or decreasing blast furnace ironmaking costs, reducing production efficiency, and poor quality of bentonite, so as to ensure strength, improve utilization rate, and strengthen cohesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 is a mixture of hydroxymethyl cellulose and sodium silicate with a particle size of about 220 meshes, and the weight percentage of the mixture is: hydroxymethyl cellulose: sodium silicate=10%: 90%.

[0024] This embodiment is applied in the production process of pellets with a particle size of iron concentrate powder of about 220 meshes, and its effects are compared as shown in Table 1,

[0025] Table 2 shows:

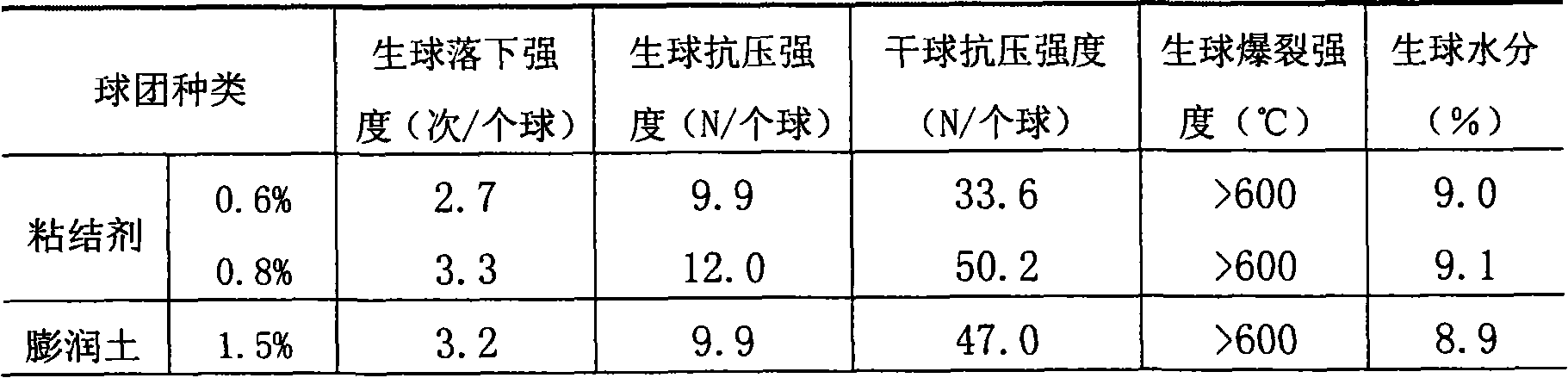

[0026] Table 1 Comparison of pelletizing and raw pellet performance

[0027]

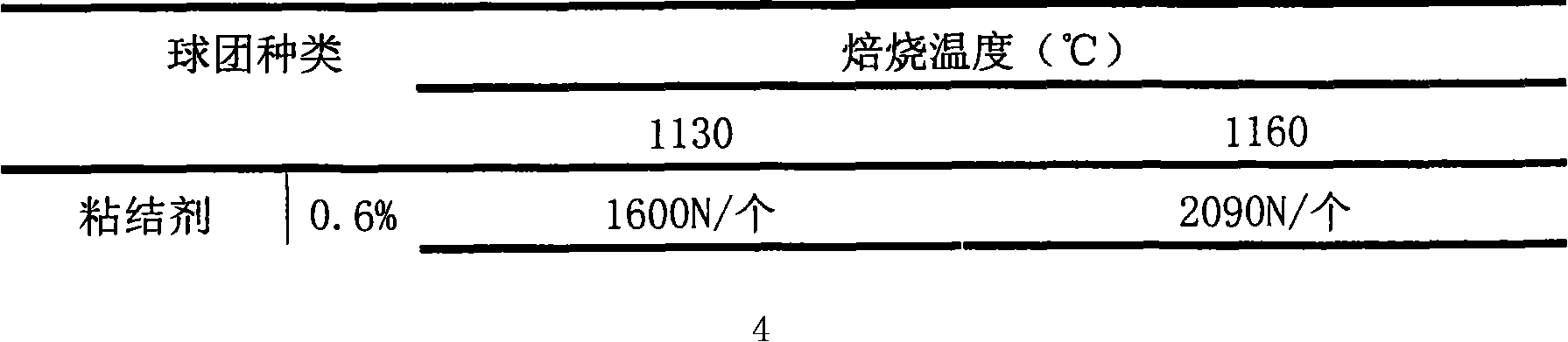

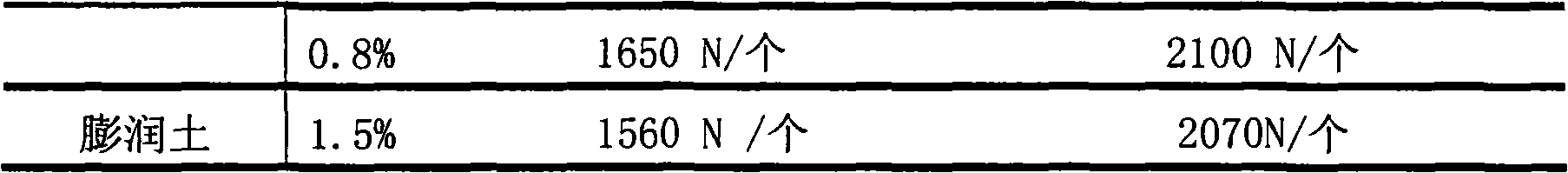

[0028] Table 2 Final Ball Performance Comparison

[0029]

[0030]

Embodiment 2

[0031] Example 2 is a mixture of hydroxypropyl methylcellulose and potassium silicate with a particle size of about 180 meshes, and the weight percentage of the mixture is: hydroxypropyl methylcellulose: potassium silicate=50%: 50%.

[0032] This embodiment is applied in the production process of pellets with a particle size of iron fine powder of about 180 meshes, and its effects are compared as shown in Table 3 and Table 4:

[0033] Table 3 Comparison of pelletizing and raw pellet performance

[0034]

[0035] Table 4 Final Ball Performance Comparison

[0036]

Embodiment 3

[0037] Embodiment 3 is the mixture of carboxymethyl cellulose, sodium silicate, potassium silicate of particle size about 120 orders, and the percentage by weight of this mixture is: carboxypropyl methylcellulose: sodium silicate: potassium silicate=50% : 30%: 20%, it is applied in the pellet production process of about 150 meshes in iron fine powder particle size, and its effect contrast is as shown in Table 5 and Table 6:

[0038] Table 5 Comparison of pelletizing and raw pellet performance

[0039]

[0040] Table 6 Final Ball Performance Comparison

[0041]

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com