Hydraulic breaking hammer change-over valve and manufacturing method thereof

A technology of hydraulic breaker and reversing valve, applied in the field of hydraulic components, can solve the problems of unguaranteed machining accuracy, increased machining difficulty, inconvenient clamping, etc., and achieves the effects of reducing machining cost, low machining cost and convenient machining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

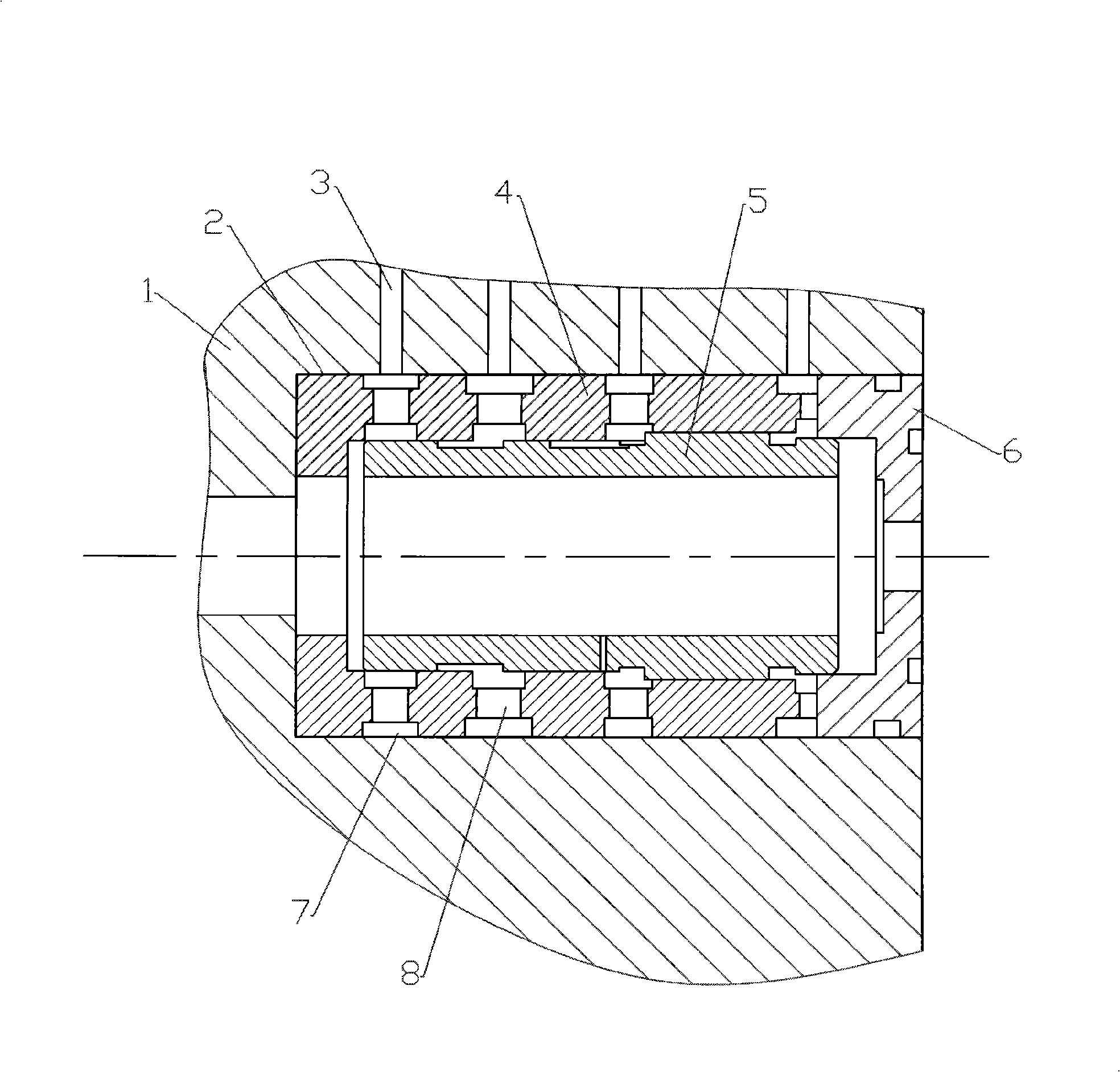

[0011] Such as figure 1 The hydraulic breaker reversing valve shown has a middle cylinder body as a valve body 1, and a valve hole 2 is opened on the valve body. The valve hole 2 is a smooth hole with a smooth inner wall, and the inner wall of the valve hole is connected to the middle cylinder. The oil passage 3 of the oil cylinder and the valve sleeve 4 are located in the valve hole 2 and cooperate with the valve hole. The outer wall of the valve sleeve 4 is provided with an annular groove 7 at the position corresponding to the opening of the oil passage. Between the annular groove 7 and the center hole of the valve sleeve Connected by the oil hole 8, the valve sleeve 4 is provided with a valve core 5 that can move radially in the valve sleeve, and the end of the valve hole 2 is provided with a valve cover 6 that presses the valve sleeve 4.

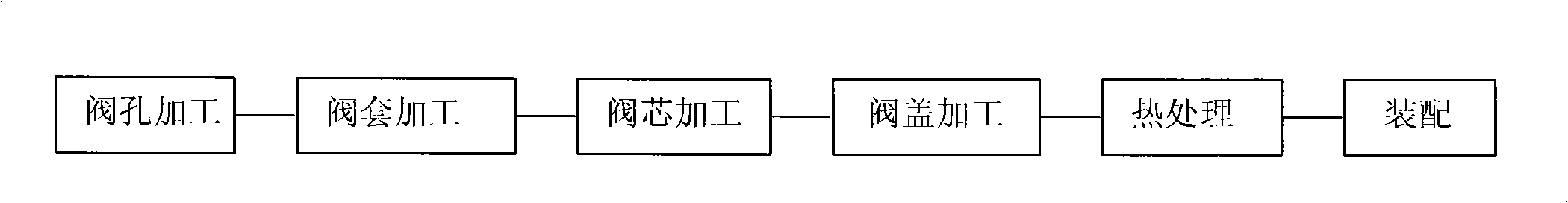

[0012] Such as figure 2 The production method of the hydraulic breaker reversing valve shown in the figure: 1. Valve hole processing:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com