Anti-flaming inhaul cable

A technology of cable body and thermal insulation layer, applied in the field of bridge cables, can solve the problems of inability to protect the anti-corrosion effect of steel cable body, poor flame retardant performance, cable stress failure, etc., to achieve good fire protection effect and increase fire protection function , The effect of reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

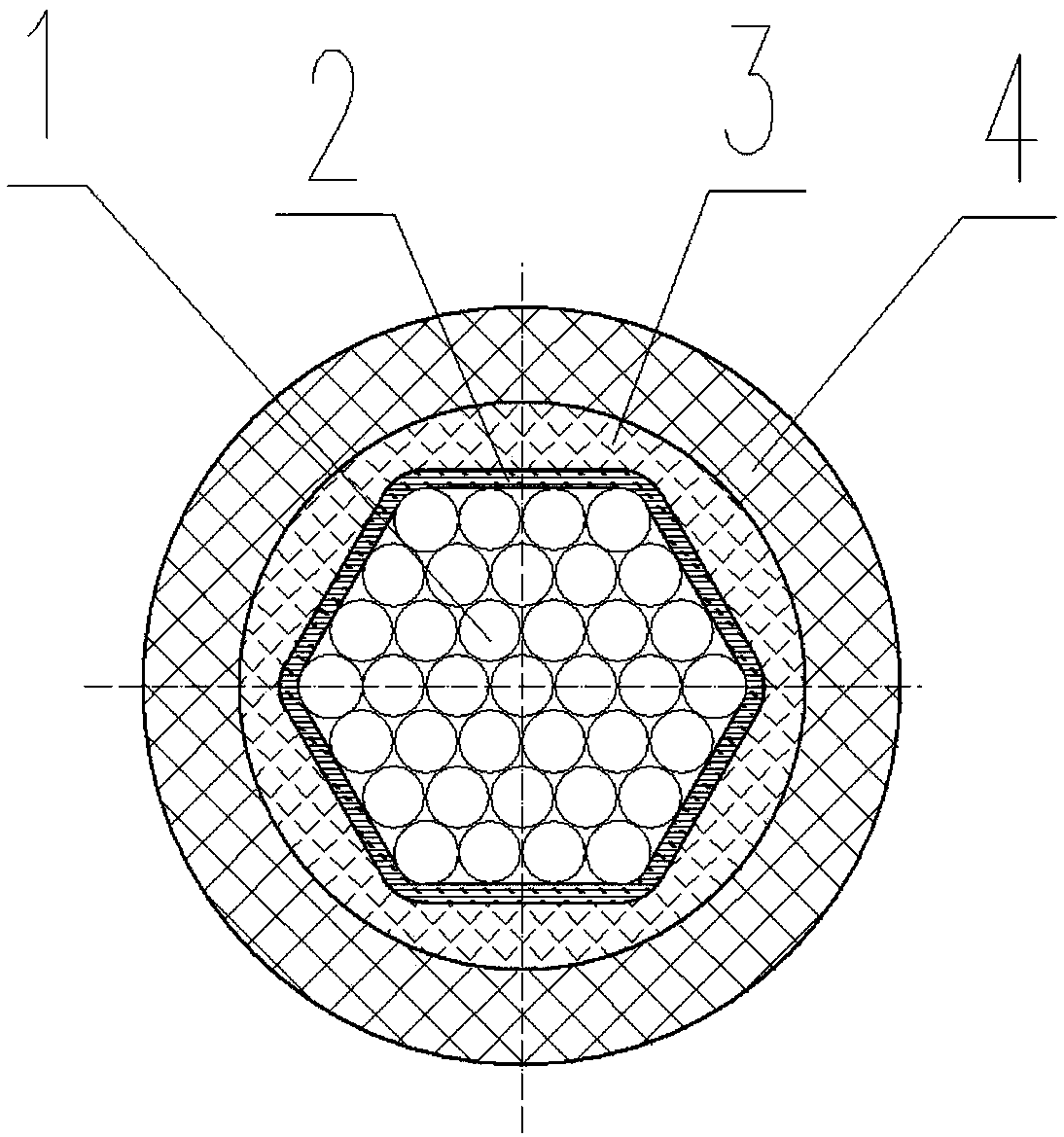

[0016] A flame retardant cable, comprising a cable body 1, a polyurethane wrapping tape 2, a heat insulation layer 3 and a fireproof rubber layer 4, the polyurethane wrapping tape 2 is coated on the outer surface of the cable body 1, and the polyurethane wrapping The wrapping tape 2 wraps and fixes the steel strands of the cable body 1, the heat insulation layer 3 is covered on the outer surface of the polyurethane wrapping tape 2, and the fireproof rubber layer 4 is covered on the outside of the heat insulation layer 3 On the surface, the fireproof rubber layer 4 is formed by polymerizing under the action of an initiator and a catalyst according to a certain ratio of a raw material composition including water-based resin, ammonium polyphosphate, vermiculite, expanded graphite, perlite and water, and an auxiliary agent. The auxiliary agents are plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com