Self-expanding inorganic foam foaming filling material for mines

A technology of inorganic powder and filling material, which is used in filling materials, applications, household appliances, etc., can solve the problems of excessive pressure, large unilateral specific gravity, low foaming ratio, etc., to prevent gas leakage/accumulation, and suitable pumping. Mobility, reducing stress or burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

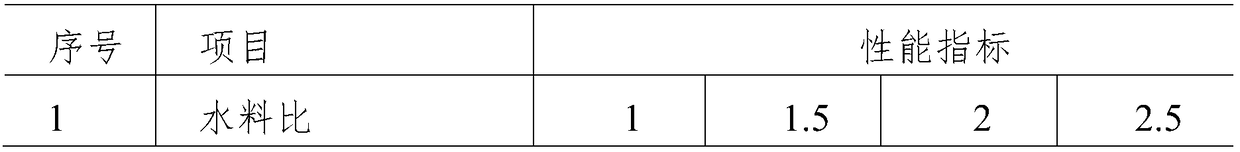

Embodiment 1

[0035] Weigh 88 parts by weight of sulphoaluminate cement, 1 part by weight of reactive chemical foaming agent aluminum powder, 0.7 parts by weight of air-entraining vegetable protein foaming agent, and 0.3 parts by weight of air-entraining animal protein foaming agent powder; In the accelerator, 0.5 parts by weight of sodium silicate powder, 1.1 parts by weight of slaked lime powder, 0.3 parts by weight of sodium carbonate powder, 0.1 parts by weight of lithium carbonate powder, and 3 parts by weight of aluminum hydroxide powder; Weigh the sodium nitrite in the early strength agent 0.4 parts by weight of powder and 0.8 parts by weight of sodium fluoride powder; weighed 2.7 parts by weight of silica fume in the thickener and 0.6 part by weight of redispersible latex powder; weighed 0.4 parts by weight of gum arabic powder in the foam stabilizer, 0.1 parts by weight of sodium dodecylbenzene sulfonate. Add the weighed powders into the dry powder mortar mixing chamber one by one, ...

Embodiment 2

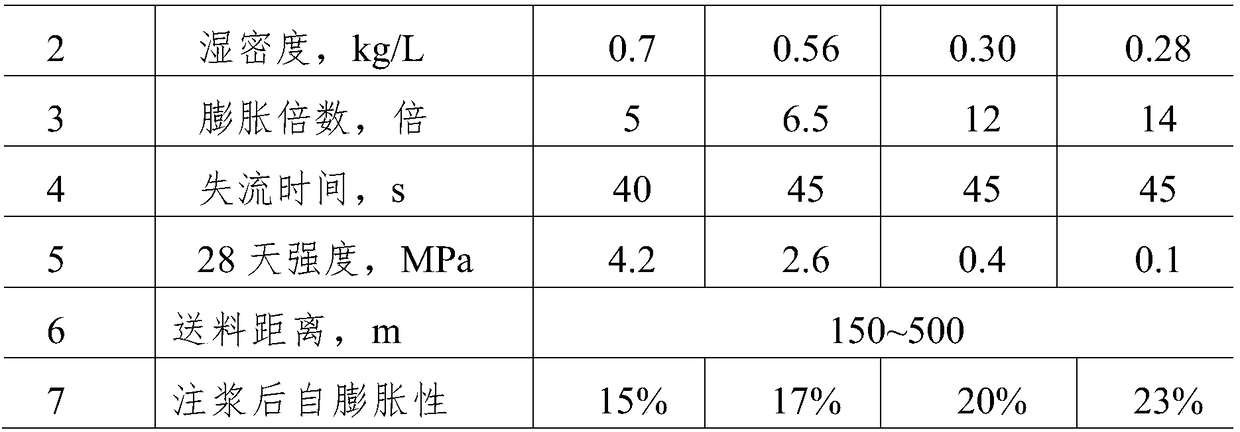

[0041] Weigh 21 parts by weight of Portland cement, 33 parts by weight of ordinary Portland cement, 11 parts by weight of sulphoaluminate cement, and 23 parts by weight of gypsum powder in the hydraulic cementitious material; weigh the reactive chemical foaming agent aluminum 1.5 parts by weight of powder, 1.2 parts by weight of air-entraining vegetable protein foaming agent powder, 0.3 parts by weight of air-entraining animal protein foaming agent powder; 0.5 parts by weight of sodium silicate powder and 1.1 parts by weight of slaked lime powder in the coagulant Parts, 0.3 parts by weight of sodium carbonate powder, 0.1 parts by weight of lithium carbonate powder, 3 parts by weight of aluminum hydroxide powder; weighing 0.2 parts by weight of calcium oxalate powder, 0.2 parts by weight of sodium nitrite powder, and sodium fluoride powder in the early strength agent 0.8 parts by weight; weigh 2.4 parts by weight of silica fume in the thickener, 0.3 parts by weight of hydroxyprop...

Embodiment 3

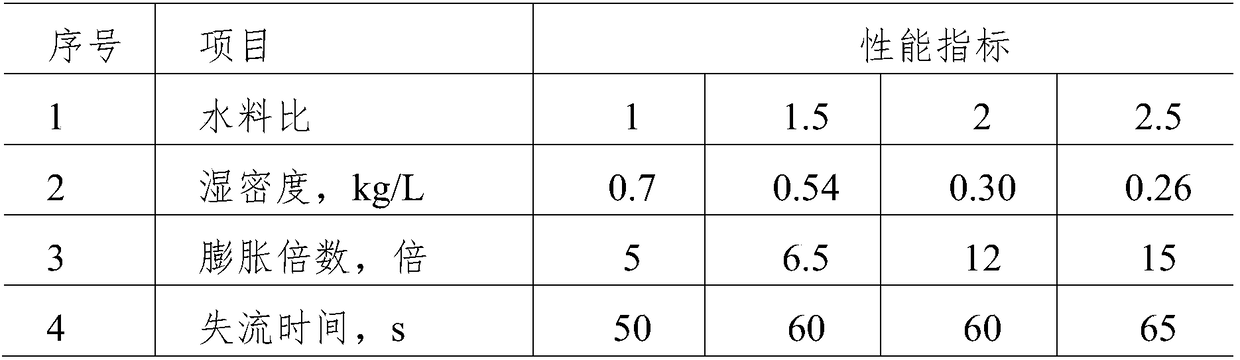

[0047] Weigh 32 parts by weight of Portland cement, 24 parts by weight of sulfoaluminate cement, 10 parts by weight of aluminate cement, and 20 parts by weight of gypsum powder in the hydraulic cementitious material; weigh the aluminum powder as a reactive chemical blowing agent 2.5 parts by weight, 1.5 parts by weight of air-entraining plant protein foaming agent powder, 1 part by weight of air-entraining animal protein foaming agent powder; 0.6 parts by weight of sodium silicate powder and 2.8 parts by weight of slaked lime powder in the coagulant , 0.2 parts by weight of sodium carbonate powder, 0.1 parts by weight of lithium carbonate powder, 1.3 parts by weight of aluminum hydroxide powder; weighing 0.3 parts by weight of sodium nitrite powder, 0.1 parts by weight of aluminum sulfate powder and 1.1 parts by weight of sodium fluoride powder in the early strength agent Parts by weight; weigh 2.8 parts by weight of silica fume in the thickener, 0.7 parts by weight of hydroxypr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com