Waterborne ultra-thin steel structure fire retardant coating and preparation method thereof

A fire retardant coating, ultra-thin technology, applied in fire retardant coatings, coatings, etc., can solve the problems of easy separation of the carbonized layer from the steel, poor strength of the carbonized layer, and poor expansion effect of the fireproof coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

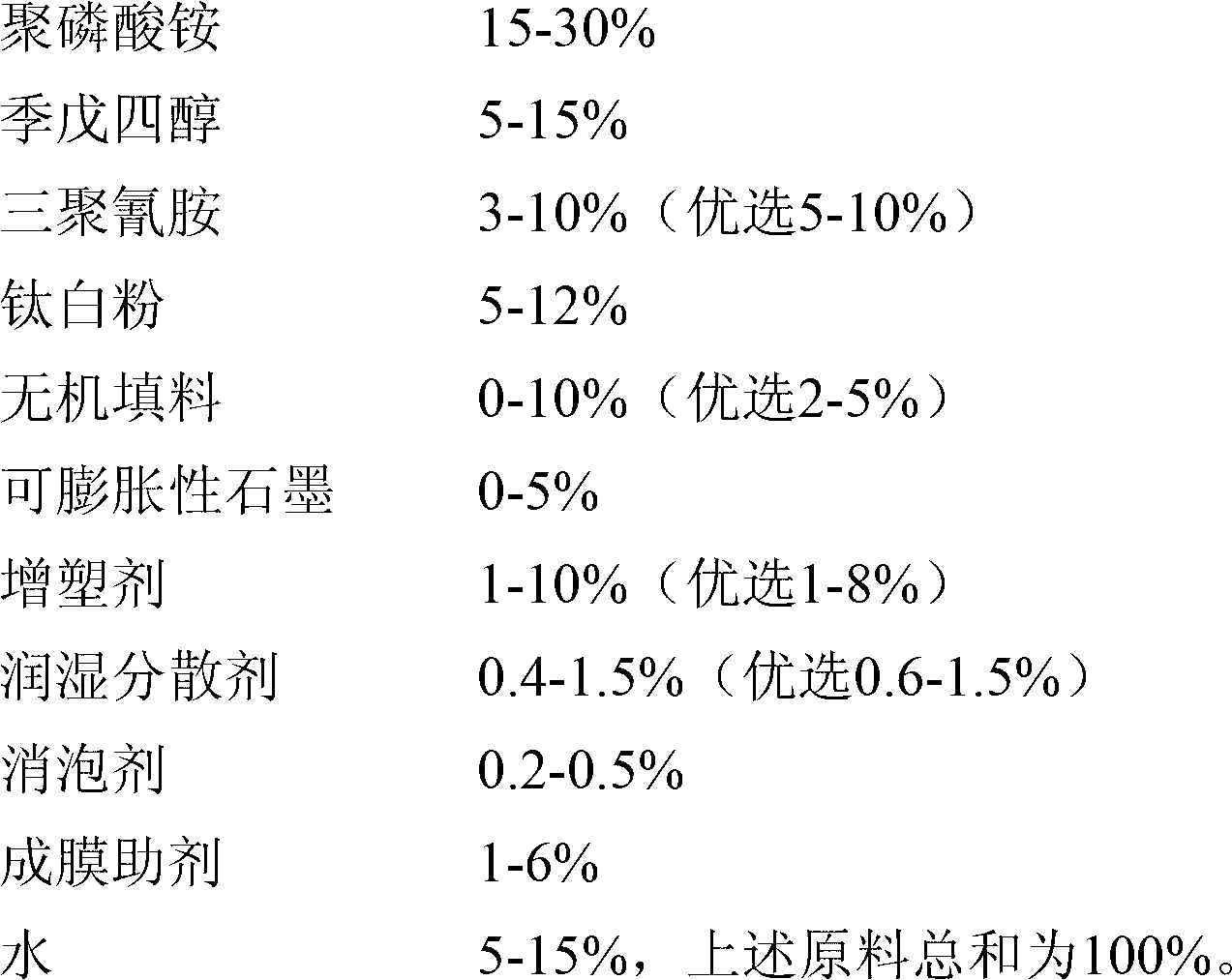

Method used

Image

Examples

Embodiment 1

[0046] Acrylic polymer emulsion 250g, ammonium polyphosphate (polymerization degree 600) 250g, pentaerythritol 100g, melamine 50g, titanium dioxide (rutile titanium dioxide) 120g, sepiolite 20g, plasticizer (chlorinated paraffin) 60g, wetting and dispersing agent 12g (the mass ratio of wetting agent to dispersant is 1:2), coalescent (2,2,4-trimethyl-1,3-pentanediol-monomethyl acrylate) 10g, silicone Defoamer 2g, water 126g.

[0047] Specific preparation method: Disperse wetting and dispersing agent and 1g defoamer in water at a speed of 1000r / min for 20min, add acrylic polymer emulsion and mix evenly, then add ammonium polyphosphate, pentaerythritol, melamine, titanium dioxide and sepiolite Into the above liquid, disperse on a high-speed disperser at a speed of 2000r / rin for 15 minutes, and finally add plasticizer, film-forming aid, and 1g of defoamer, and stir evenly to obtain the product.

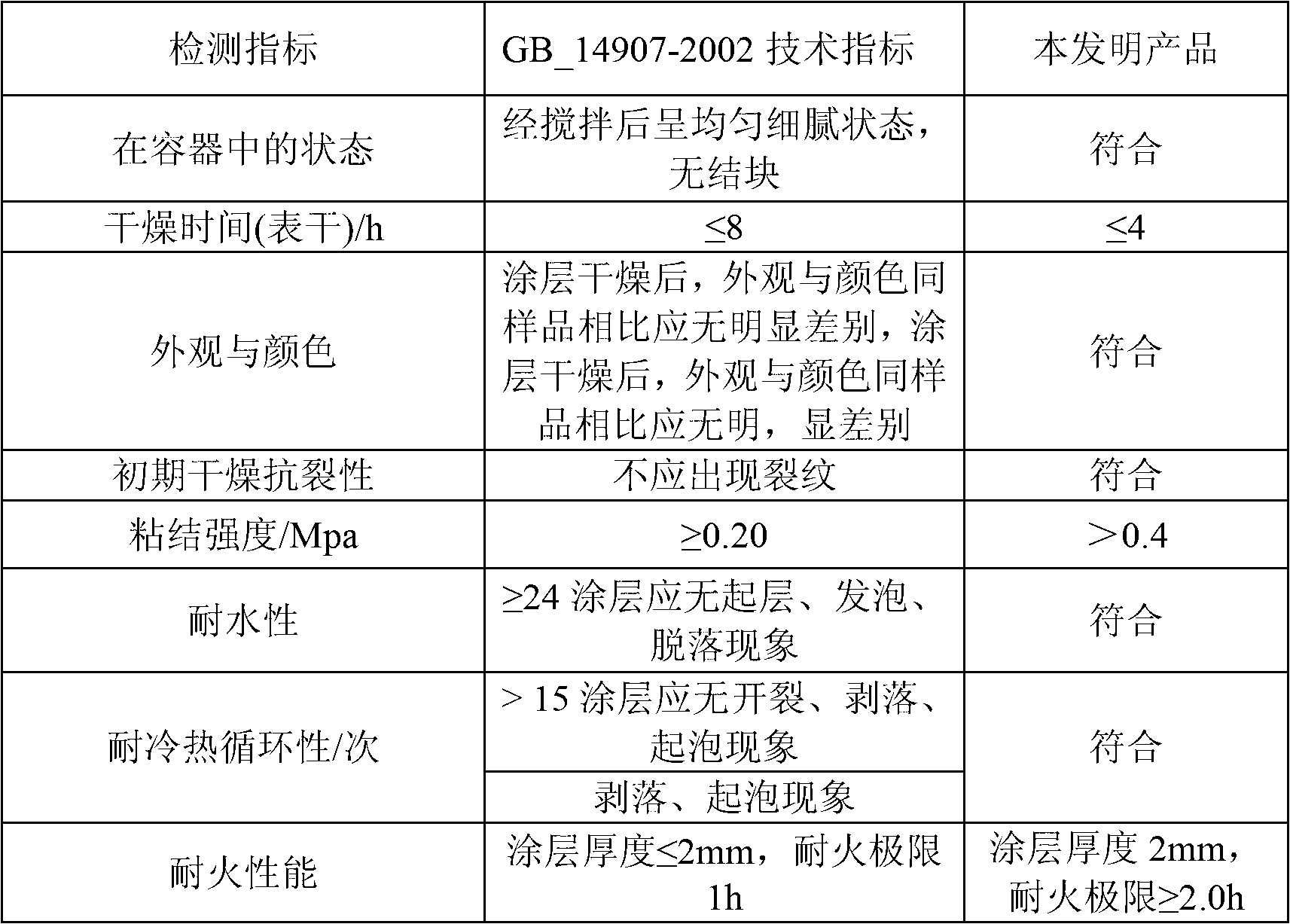

[0048] Fire-resistant performance test results: when the dry film thickness is 2.0mm...

Embodiment 2

[0050] Vinyl acetate-vinyl tertiary carbonate emulsion 400g, ammonium polyphosphate (polymerization degree 1000) 200g, pentaerythritol 50g, melamine 100g, titanium dioxide 50g, sepiolite 20g, scaly expandable graphite (80 mesh) 50g, plasticizer ( Chlorinated paraffin) 10g, wetting and dispersing agent 12g (the mass ratio of wetting agent to dispersing agent is 1:3), film-forming aid (dipropylene glycol methyl ether) 20g, mineral oil defoamer 3g, water 85g.

[0051] Preparation method: Disperse wetting agent, dispersant, and 1.5g defoamer in water at a speed of 1000r / min for 20min, add vinyl acetate-vinyl tertiary carbonate emulsion and mix evenly, then mix ammonium polyphosphate, pentaerythritol, melamine and titanium dioxide Add sepiolite and expandable graphite to the above solution, disperse on a high-speed disperser at a speed of 2000r / min for 20min, and finally add plasticizer, film-forming aid, and 1.5g defoamer and stir evenly to obtain a fire-resistant coating.

[0052...

Embodiment 3

[0054] Vinyl acetate-vinyl tertiary carbonate emulsion 200g, ammonium polyphosphate (polymerization degree 1000) 200g, pentaerythritol 150g, melamine 50g, titanium dioxide 50g, hydrotalcite 60g, fiber filler 50g, plasticizer (chlorinated paraffin) 80g, wet dispersion 12g of agent (the mass ratio of wetting agent to dispersant is 1:2) 40g of film-forming aid (of which 2,2,4-trimethyl-1,3-pentanediol-monomethyl acrylate and dipropylene glycol The mass ratio of methyl ether is 2:1), silicone defoamer 2g, water 106g.

[0055] Preparation method: disperse wetting agent, dispersant, 1g defoamer in water for 20min, then add vinyl acetate-vinyl tertiary carbonate emulsion and mix evenly, then add ammonium polyphosphate, pentaerythritol, melamine, titanium dioxide and hydrotalcite to the above Disperse the solution in a high-speed disperser at a speed of 2000r / min for 20 minutes, and finally add plasticizer, 1g of defoamer, and film-forming aid and stir evenly to obtain a fire-resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fire resistance time | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fire resistance time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com