Low-temperature thermal expansion micro-sphere

A technology of expanding microspheres and low-temperature heat, applied in the field of chemical products, can solve the problems of increasing production costs, not meeting the sustainable development of environment-friendly economy, increasing risks, etc., and achieving the effect of good foaming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

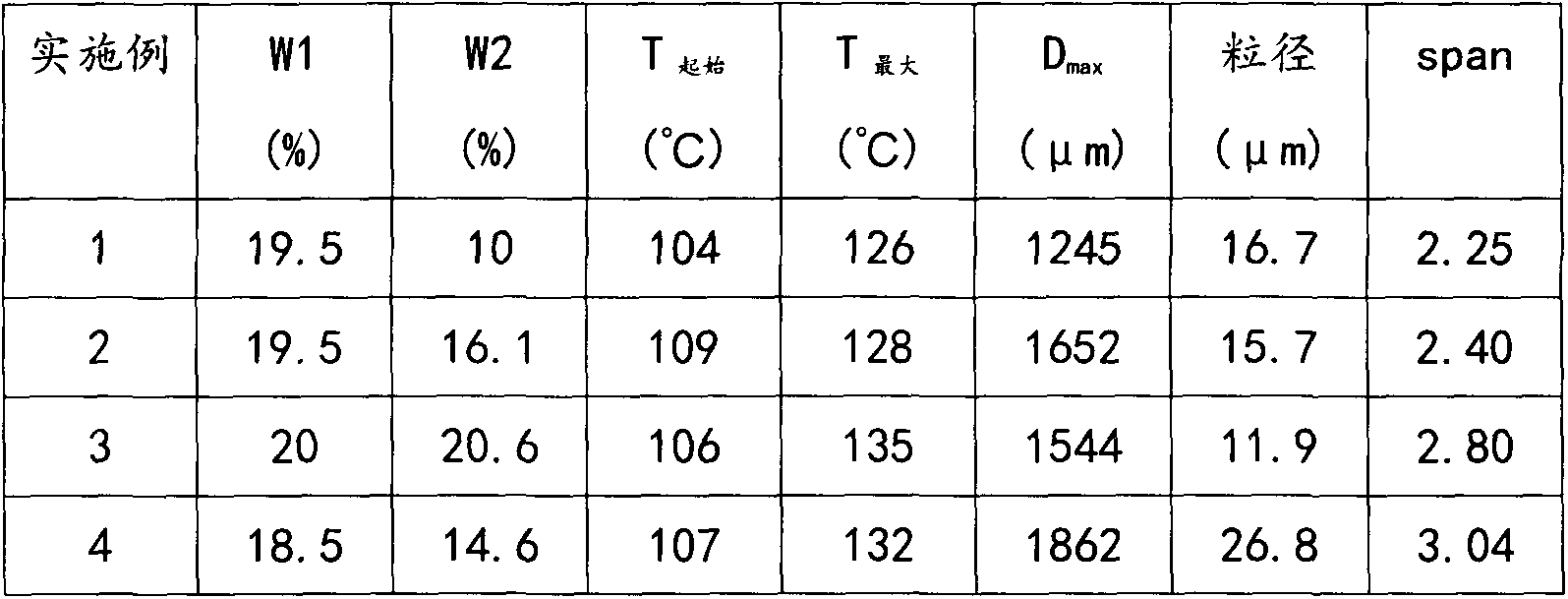

Examples

Embodiment 1

[0034] Add 270g of deionized water, 10g of sodium hydroxide, 30g of magnesium chloride hexahydrate, 4g of 1wt% sodium lauryl sulfate-water solution, 35g of sodium chloride into a 500ml three-neck flask, and stir vigorously at 1000r / min for half an hour to obtain a water phase protection solution.

[0035] Add 60g of acrylonitrile, 2g of methyl methacrylate, 30g of methyl acrylate, 1g of butyl acrylate, 10g of vinyl acetate, 25g of n-hexane, 1.8g of azobisisobutyronitrile, ethylene glycol diformic acid acrylate into the beaker 0.42g, mixed evenly to obtain an oil phase.

[0036] Add the oil phase to the water phase protection solution, stir at 1000r / min for 20 minutes to obtain stable droplets with a particle size of 10-50μm, raise the temperature to 60°C-70°C, replace the air with nitrogen, seal, and react at normal pressure for 20 hours , to obtain a suspension, wash with hydrochloric acid, filter with suction, and dry at 50°C to obtain heat-expandable microspheres.

Embodiment 2

[0038] On the basis of Example 1, the oil phase was replaced with 60g of acrylonitrile, 2g of methyl methacrylate, 10g of methyl acrylate, 1g of butyl acrylate, 30g of vinyl acetate, 25g of n-hexane, and 1.8 g of azobisisobutyronitrile. g, 0.42 g of ethylene glycol dicarboxylic acid acrylate.

Embodiment 3

[0040] On the basis of Example 1, the oil phase was replaced with 60g of acrylonitrile, 30g of methyl acrylate, 10g of vinyl acetate, 15g of n-hexane, 10g of isooctane, 1.8g of azobisisobutyronitrile, ethylene glycol di Formic acid acrylate 0.42g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com