Patents

Literature

295results about How to "Improve hard water resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid

InactiveCN104498164AImprove the lubrication effectImprove rust resistanceLubricant compositionWater basedCombustion

The invention discloses anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid. The anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid is prepared from the following components in percentage by mass: 5 to 10 parts of base oil, 5 to 15 parts of an oiliness agent, 10 to 25 parts of organic amine, 5 to 15 parts of a synthetic rust inhibitor, 15 to 25 parts of a functional polyether surfactant, 0.2 to 3 parts of an extreme pressure additive, 3 to 8 parts of a solubilizer, 0.1 to 2 parts of a metal corrosion inhibitor, 0.1 to 2 parts of a magnesium alloy anti-fading agent, 0.1 to 2 parts of a bactericide, 0.1 to 1 part of an antifoaming agent, 0.1 to 10 parts of a pH regulator and 15 to 30 parts of water. The nticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid is outstanding in ticorrosive and lubricating and has water resisting performances, and is high in cleaning and cooling effects, and effectively reduces the major technical problems such as corrosion, oxidative combustion, fading of magnesium alloy, demulsification and layering of the cutting fluid in the magnesium alloy processing process; the pH ranges from 9 to 11, and therefore, the demand of magnesium alloy cutting process can be met well.

Owner:苏州禾川化学技术服务有限公司

Water-based fully-synthetic ferrous metal processing liquid with high-hard-water-rust resistance

PendingCN108277077ANo pollution in the processOvercome the disadvantage of poor antirust performance in high hard waterLubricant compositionWater basedHard water

The invention provides a water-based fully-synthetic ferrous metal processing liquid with high-hard-water-rust resistance, wherein the water-based fully-synthetic ferrous metal processing liquid comprises, by weight, 5-25 parts of a composite rust inhibitor, 5-30 parts of a lubricant, 5-30 parts of a pH value stabilizer, 1-9 parts of a coupling agent, 0.1-2 parts of an antifoaming agent, 1-4 partsof a sterilization agent, and 20-50 parts of water. According to the preset invention, the ferrous metal processing liquid has advantages of no environment pollution, excellent rust resistance, excellent cooling performance, excellent hard-water resistance and high biological stability, and can overcome the disadvantage of poor high-hard-water-rust resistance of the traditional water-based fully-synthetic ferrous metal processing liquid.

Owner:超滑科技(佛山)有限责任公司

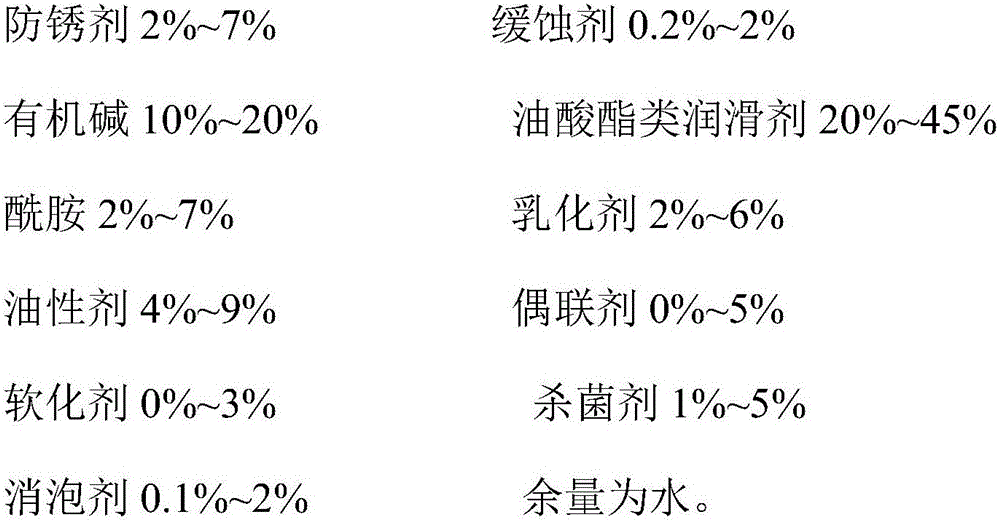

Water-based metal cutting liquid

InactiveCN106479654AGood compatibilityStrong synergistic functionLubricant compositionWater basedSulfur

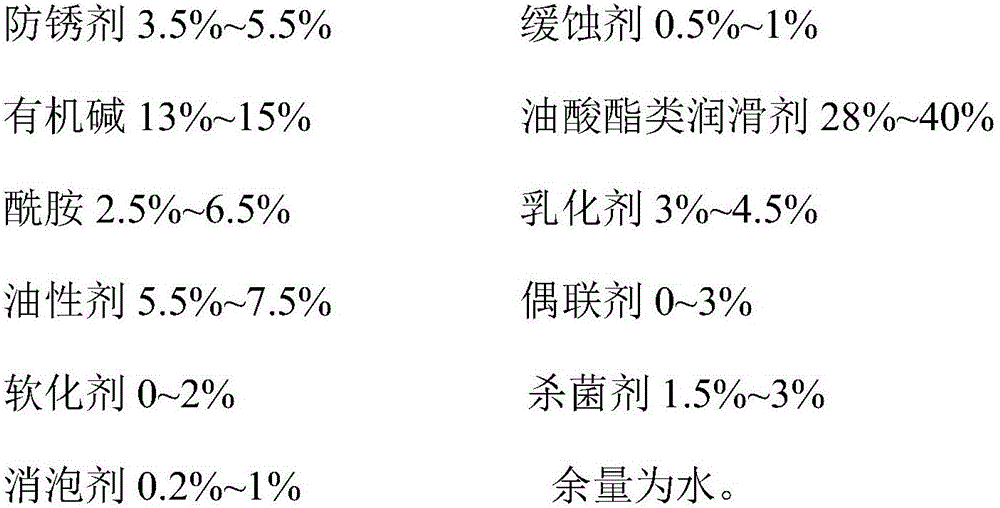

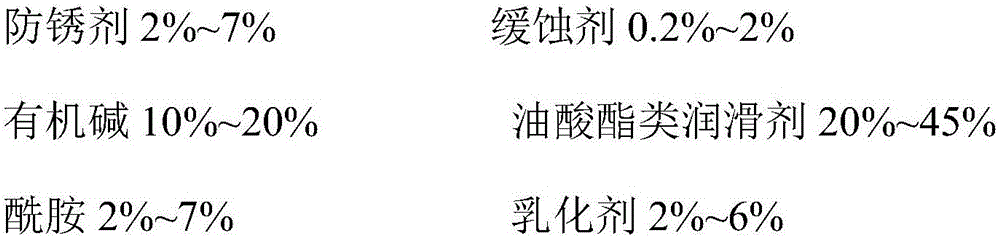

The invention discloses a water-based metal cutting liquid. The water-based metal cutting liquid is prepared from raw materials in percentage by mass as follows: 2%-7% of an antirust agent, 0.2%-2% of a corrosion inhibitor, 10%-20% of organic alkali, 20%-45% of an oleate lubricant, 2%-7% of amide, 2%-6% of an emulsifier, 4%-9% of an oiliness agent, 0%-5% of a coupling agent, 0%-3% of a softener, 1%-5% of a sterilizing agent, 0.1%-2% of a defoaming agent and the balance of water. The water-based metal cutting liquid provided by the invention contains no sulfur, phosphorus, chlorine or boric acid and is efficient, environment-friendly and recyclable.

Owner:深圳市宏达威表面处理技术有限公司

Organic engine cooling liquid

InactiveCN1336410AReduce corrosionImprove corrosion inhibitionHeat-exchange elementsSuccinic acidSebacic acid

The present invention relates to organic cooling liquid for engine, it is composed of ethylene glycol 1000 parts, sebacic acid 2-8 parts, terephthalic acid 2-5 parts, octytic acid 1-12 parts, methylbenezenetriazole 1-4 parts, p-tert-butylbenzoic acid 5-25 parts, succinic acid 1-4 parts, antifoaming agent 0.1-0.2 parts, the invented cooling liquid possesses the advantages of good metal corrosion resistance, good transportation stability, strong hard water resistance, small environmental pollution, no harmful component, small use level etc.

Owner:CHINA PETROLEUM & CHEM CORP

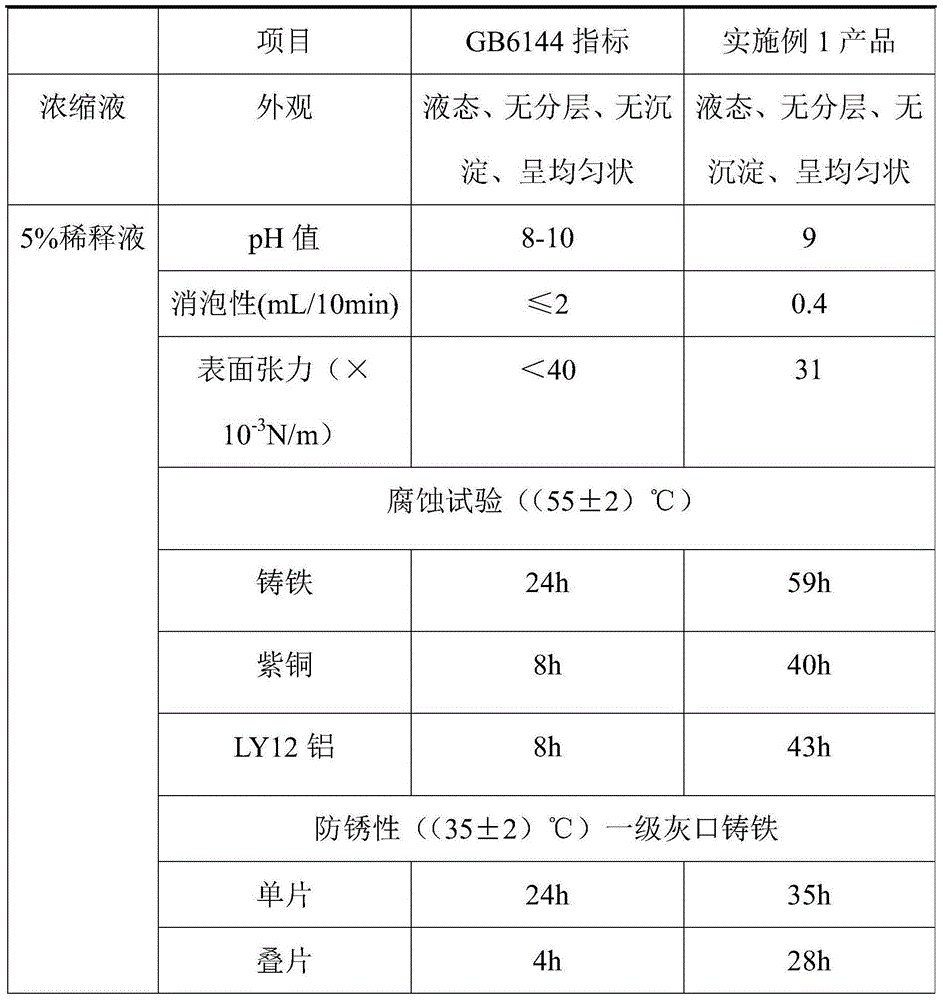

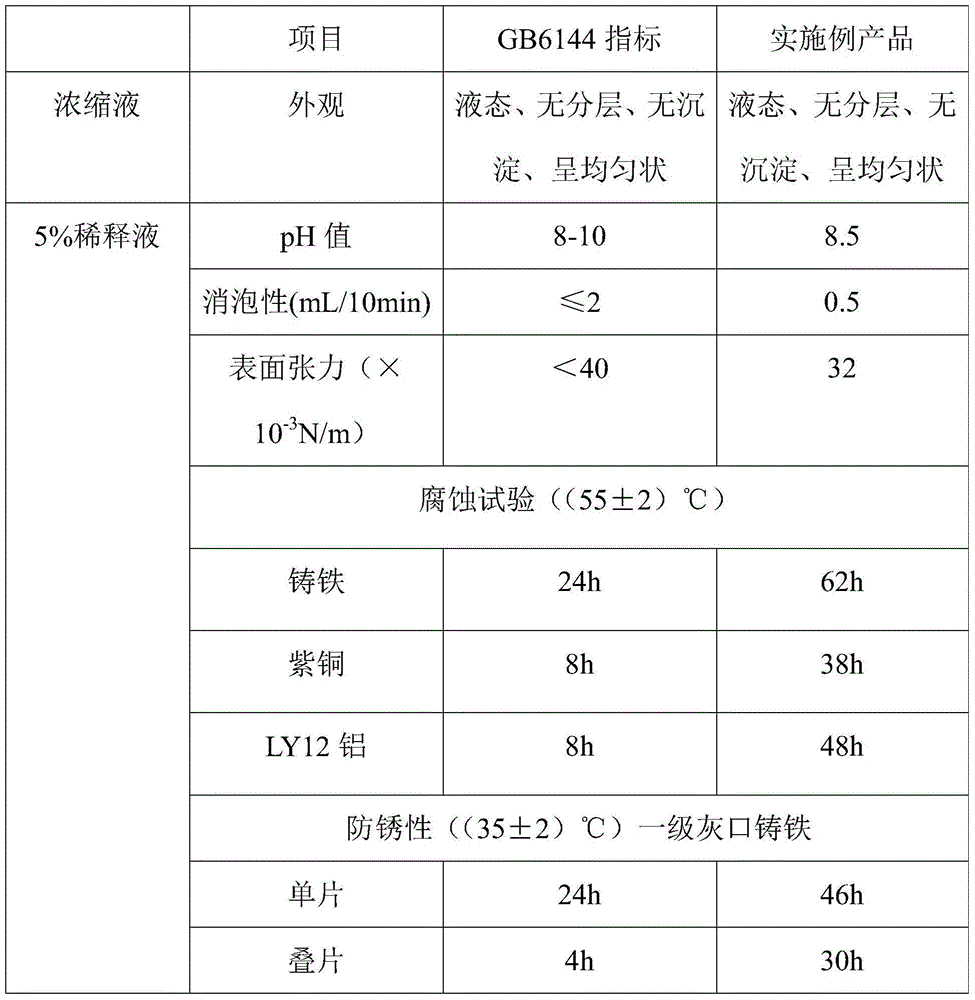

Semi-synthesis cutting fluid for magnesium alloy, preparation method and application method

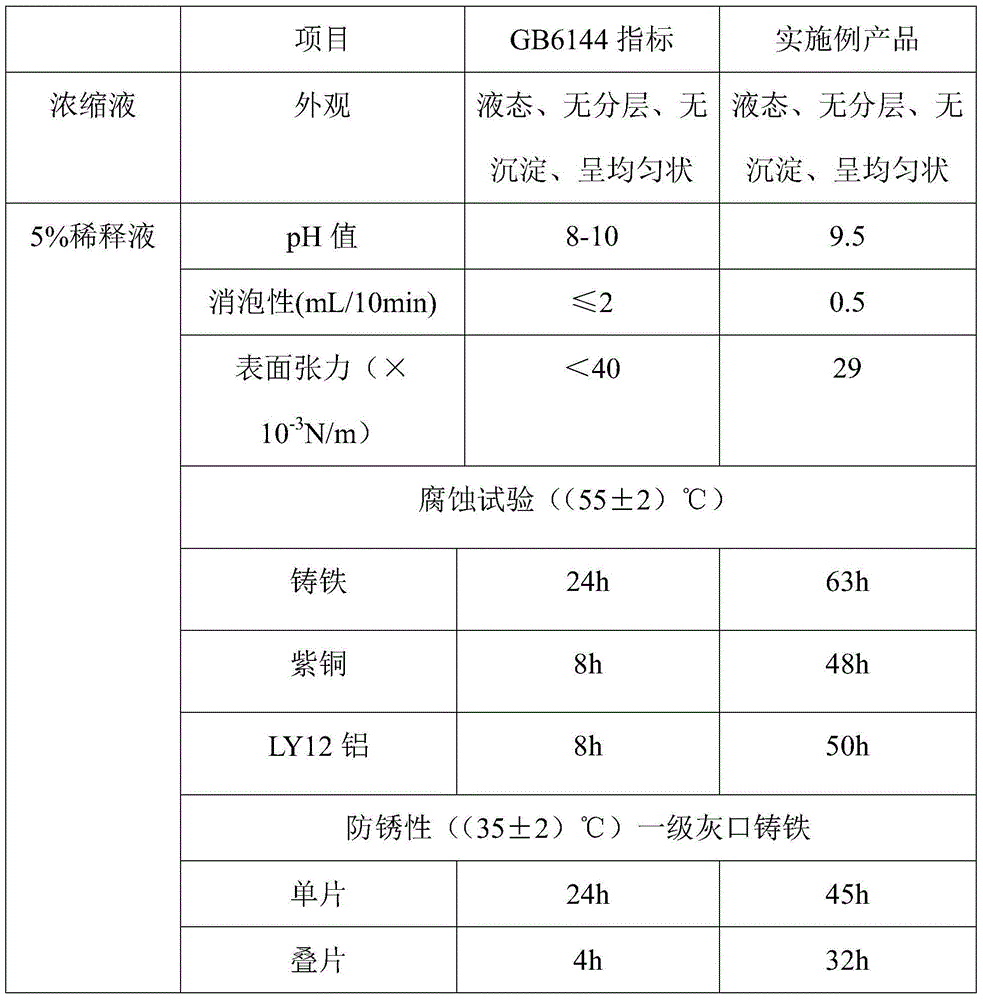

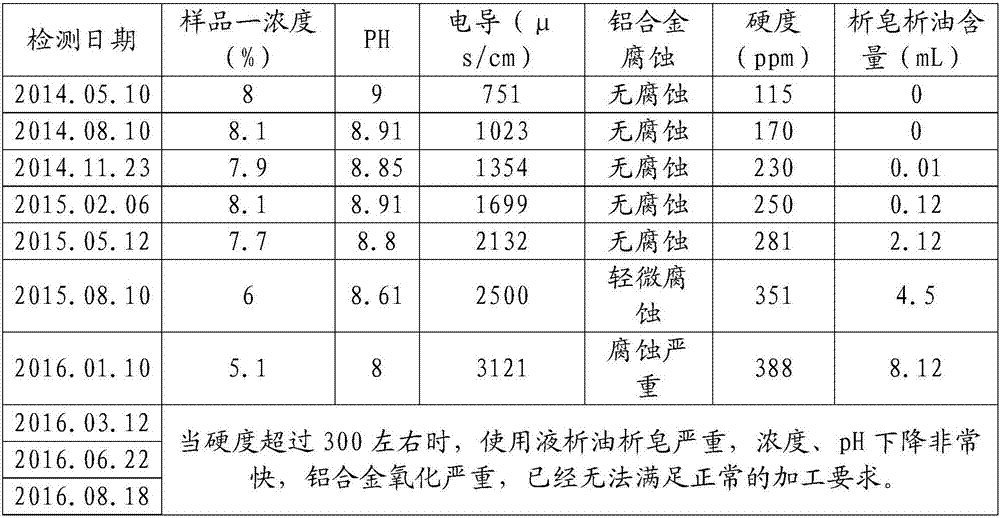

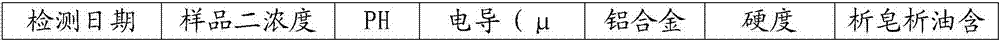

ActiveCN102732363AFire Hazard PreventionAvoid difficult issuesLubricant compositionWater solubleHard water

The invention discloses a semisynthesis cutting fluid for magnesium alloy. According to the invention, the hidden danger of fire hazard in the process of magnesium alloy processing is totally avoided by using an environment-friendly water-soluble system; excellent reasonable proportioning of additives and combined application of corrosion inhibitors effectively prevent the surface of processed magnesium alloy from corrosion and blackening; designing of a low foam type formula enables generation of foam in the cutting fluid for the magnesium alloy to be totally inhibited; application of a delicate low-foam surfactant enables the problem of difficult cleaning of workpiece surface due to excessive oil stains to be overcome; application of an additive with resistance to hard water enables hard water-resistance of the fluid to be effectively improved, the fluid has hard water-resistance of 15000 ppm, allowing the service life of the fluid to be prolonged, all the indexes of the fluid reach or exceed relevant indexes in GB6144-2010, anti-rust performance lasts for more than 72 h per sheet, and the life cycle of the fluid is more than 8 months, 3 to 6 times the life cycle of magnesium alloy cutting fluid on the market; and reasonable design of an environment-friendly formula enables the problems of difficulty in treating waste liquid and the like to be effectively overcome.

Owner:AMER TECH CO LTD

Plant nutrient solution with high bioactivity

InactiveCN101723757ASmall molecular weightImprove biological activityFertilizer mixturesSolubilityRare earth

The invention discloses plant nutrient solution with high bioactivity, which is prepared by uniformly mixing, stirring and dissolving the following raw materials in percentage by weight: 8 to 12 percent of nitro-fulvic acid, 10 to 15 percent of chelating protein, 8 to 15 percent of nitrogen, phosphorus and potassium, 2 to 4 percent of microelement and rare earth, 0.8 to 1.0 percent of compound microbe and the balance of water. The nutrient solution has the advantages of having comprehensive nutrition, low molecular weight of oxides, high bioactivity, good water-solubility, strong anti-hard water capacity, high stability in natural environment, and difficult reduction when mixed with reductive substances, well promoting the growth of root system of the plant, helping the absorption of nutritive elements, stimulating the crop growth, improving the content of chlorophyll, promoting the crop photosynthesis, particularly properly controlling the opening degree of leaf stomas of crop, reducing moisture transpiration, increasing antivirus capacity of the crop, also strengthening drought resistance and resilience capacity of the crop, effectively improving the quality of farm products, and having remarkable output increasing effect.

Owner:唐荣敏

Environment-friendly water-soluble cutting fluid for magnesium alloy cutting

InactiveCN105038942AExtended service lifeImprove wear resistanceLubricant compositionOrganic acidHydrogen

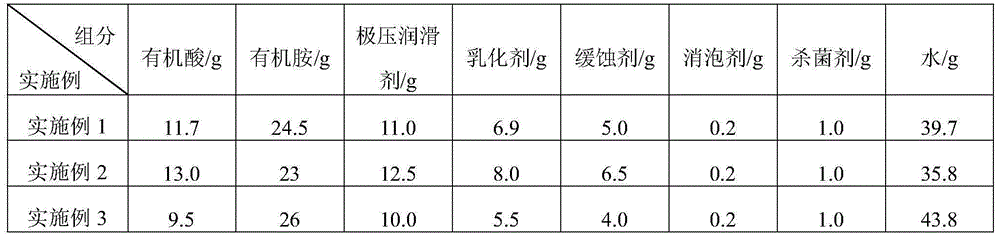

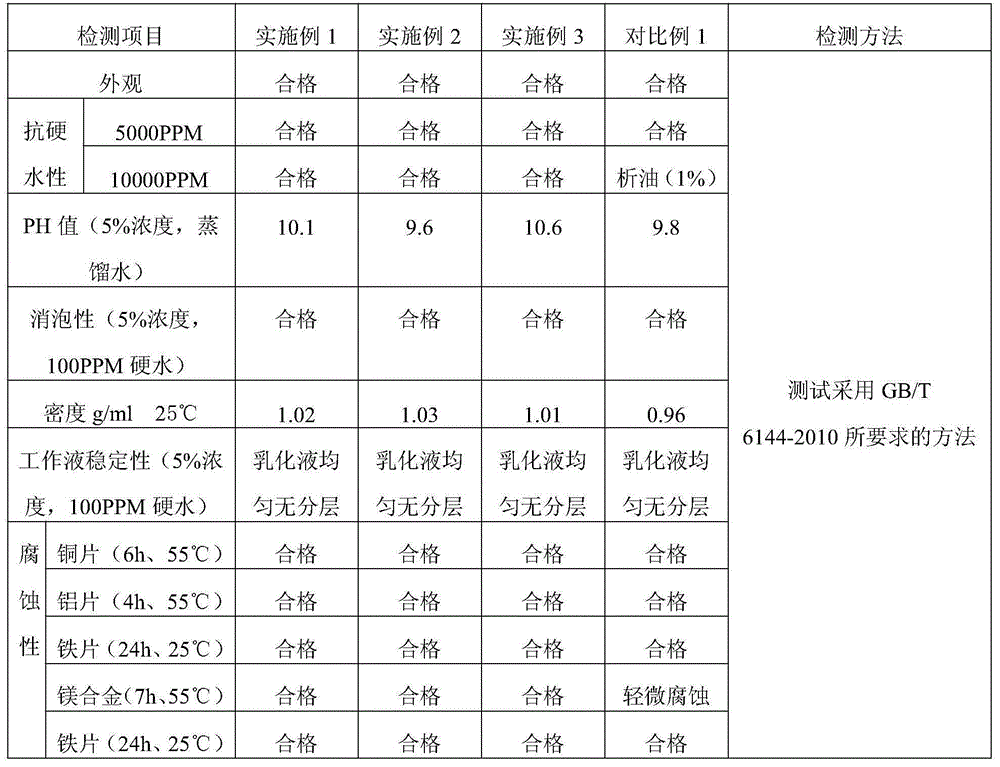

The invention relates to an environment-friendly water-soluble cutting fluid for magnesium alloy cutting, which comprises the following components in parts by weight: 5-20 parts of organic acid, 15-30 parts of organic amine, 5-16 parts of lubricant, 3-11 parts of emulsifier, 1-6 parts of corrosion inhibitor, 0.1-0.5 part of defoaming agent, 0.1-3.5 parts of bactericide and 15-70 parts of water. The magnesium alloy cutting fluid has the advantages of favorable abrasion resistance, favorable hard water resistance, favorable rust and corrosion resistance, and is capable of effectively protecting the cutter and prolonging the service life of the cutter. The water-soluble cutting fluid can quickly take away the heat generated in the machining process, lower the temperature of the machined surface and effectively avoid the defect of high flammability of the magnesium chips due to high temperature. The aluminum-magnesium alloy cutting fluid provided by the embodiment of the invention does not release hydrogen when being used for magnesium alloy cutting, thereby ensuring the safe proceeding of the production process.

Owner:深圳市奥科宝特种油剂有限公司

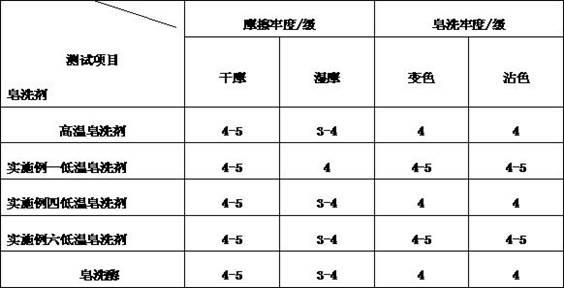

Low-temperature soaping agent as well as preparation method and application thereof

ActiveCN102660404AAvoid stainsHas anti-scaling effectOrganic non-surface-active detergent compositionsDyeing processTextile printerSodium acetate

The invention relates to the technical field of textile printing and dyeing and provides a low-temperature soaping agent. The low-temperature soaping agent can soap surface dyeing of a dyed object at a lower temperature (60 DEG C), is not easy to foam, can chelate metal ions, has stronger combined dyeing capability and effectively prevents from staining. Meanwhile, the invention further provides a method for preparing the low-temperature soaping agent and an application of the low-temperature soaping agent. The low-temperature soaping agent is prepared from the following components in percentage by weight: 50-75% of maleic-acrylic copolymer, 5-15% of a surfactant, 0.1-0.5% of a de-foaming agent, 1-5% of ethanediamine di-o-hydroxyphenyl sodium acetate and the balance of de-ionized water.

Owner:冠宏股份有限公司

Medical liquid multienzyme detergent

InactiveCN102453631AHigh activityImprove performanceNon-ionic surface-active compoundsDetergent compounding agentsPhosphateRaw material

The invention belongs to a detergent, in particular relates to a medical liquid multienzyme detergent containing multiple biological enzymes. The medical liquid multienzyme detergent is prepared from the following raw materials in parts by weight: 1-3 parts of antiseptic, 50-98 parts of enzyme stabilizer, 30-80 parts of sodium alcohol ether sulphate, 180-250 parts of non-ionic surface active agent, 30-80 parts of propylene glycol, 35-90 parts of triethanolamine, 10-60 parts of sodium citrate, 10-90 parts of citric acid, 0.1-2 parts of defoaming agent, 16-50 parts of multienzyme mixture and 197-627.9 parts of deionized water. The medical liquid multienzyme detergent provided by the invention has stable product performance, long storage life, strong organic matter multienzyme decomposition capacity and good cleaning effect for surgical equipment and hospital-polluted fabrics; the medical liquid multienzyme detergent provided by the invention is neutral in pH, has natural ingredients, is mild, does not hurt skin and is applicable to hand washing; and the medical liquid multienzyme detergent provided by the invention has good hard water resistance, is non-toxic and harmless and has antistatic and shrinkproof performances. The medical liquid multienzyme detergent provided by the invention adopts a phosphate-free formula and is highly environmentally friendly and has biodegradability more than 90%; and the detergent is only required to be diluted when in use, is convenient to operate and easy to rinse.

Owner:ZHENGZHOU UNIV

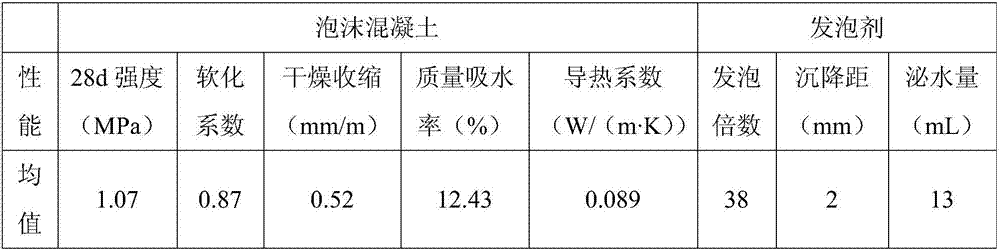

Foaming concrete for foam agent

The invention discloses a foaming agent for foam concrete. The foaming agent is prepared by uniformly mixing and stirring the following raw materials at room temperature, by weight : 5-10 parts of sodium dodecyl benzene sulfonate, 2-4 parts of sodium alcohol ether sulphate, 1-2 parts of sodium lauroyl sarcosinate, 1-2 parts of cocamidopropyl betaine, 0.2-0.6 part of polyethylene glycol (120) methyl glucoside dioleate, 0.3-0.5 part of triethanolamine, 0.5-1 part of polyacrylamide, 1-2 parts of hydroxyethyl cellulose, and 60-70 parts of water. The invention has advantages of easily available raw materials, low cost and simple preparation process; and the produced foaming agent has advantages of good stability, no deterioration, easiness for long-term preservation, prolonged shelf-life, good foaming power, good peaceability with various foam concrete substrates, no defoaming and unrestricted range of usage.

Owner:安徽艾柯泡塑股份有限公司

Foaming agent for shield

The invention discloses a foaming agent for a shield. The foaming agent contains the components in percentage by weight: 1.0-10.0% of alpha-olefin sulfonate (AOS), 1.0-8.0% of sodium fatty alcohol -polyoxyethyleneether sulfate (AES), 1.0-6.0% of ammonium lauryl sulfate (K12 ammonium), 1.0-6.0% of cocoanut fatty acid diethanolamide (6501), 1.0-5.0% of dodecyl dimethyl betaine (BS-12), 0.005-0.1% of fluorocarbon surfactant (FS), 0.2-5.0% of sodium nitrilo triacetate (A92R), 0.2-5.0% of ethylene diamine tetraacetic acid disodium salt (EDTA) and the balance of water. The foaming agent for the shield provided by the invention realizes high multiple foaming rate, long foam stabilizing time, nontoxicity and innocuity and is an environment friendly biodegradable product which does not contain phosphorus.

Owner:GUANGZHOU TAISHENG BIOTECH

High-performance and environment-friendly water-based cleaning agent

The invention discloses a high-performance and environment-friendly water-based cleaning agent, which comprises macromolecular carboxylic acid, organic amine, alcohol, a surfactant, a hard water softening agent, a corrosion inhibitor, other additives and pure water. The cleaning agent is good in biodegradability, good in hard water resistance, applicable to high-pressure cleaning, and safe to people and environment, and can realize short-term rust prevention.

Owner:SHANGHAI YUSHIRO CHEM IND +1

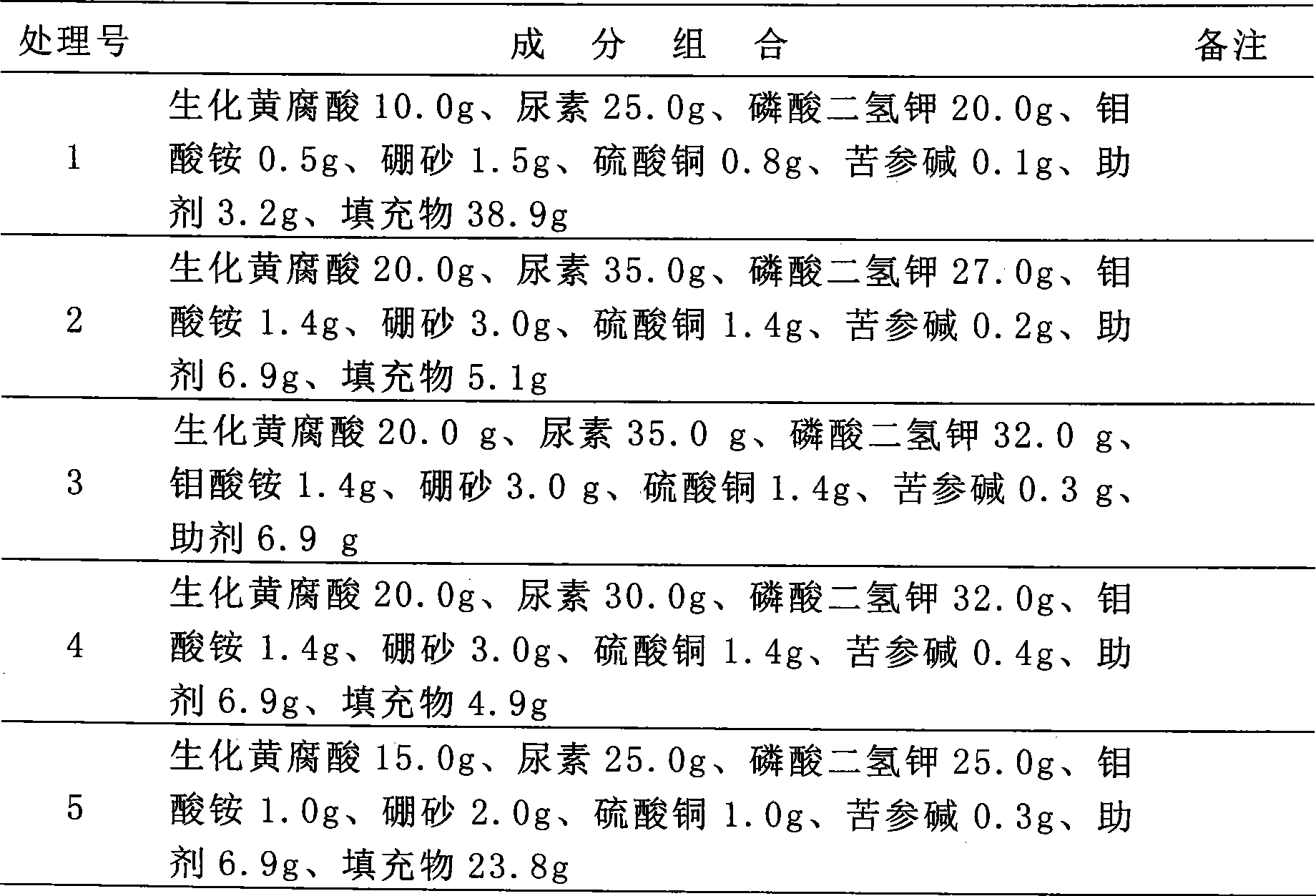

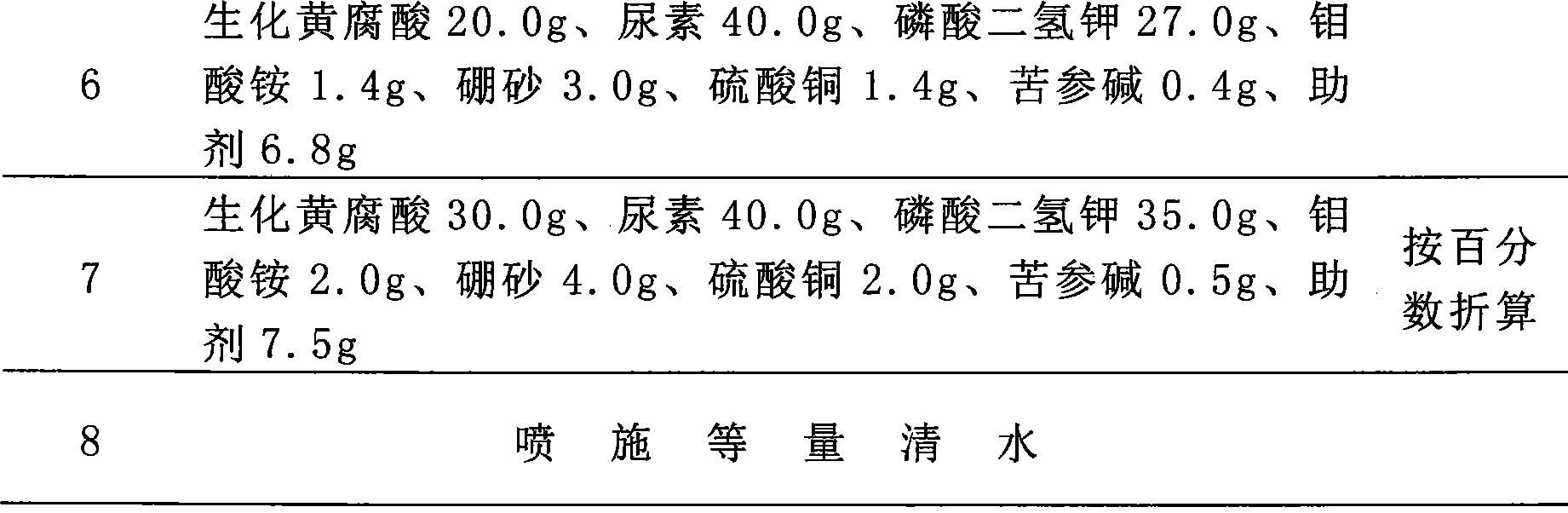

Novel non-pollution foliar medical fertilizer and preparation thereof

InactiveCN101503323APromote absorptionImprove fertilizer efficiencyAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSocial benefitsFilling materials

The invention discloses a novel nuisanceless foliage fertilizer which is characterized in that every 100 parts by weight of the novel nuisanceless foliage fertilizer comprises the components according to the parts by weight: 10.0-30.0 parts of biochemical fulvic acid, 25.0-40.0 parts of urea, 20.0-35.0 parts of monopotassium phosphate, 0.5-2.0 parts of ammonium molybdate, 1.5-4.0 parts of borax, 0.8-2.0 parts of bluestone, 0.1-0.5 part of matrine, 3.2-7.5 parts of auxiliary agent and the rest of filling material. A method for preparing the novel nuisanceless foliage fertilizer comprises: all the components are mixed according to the measurement, fully stirred by a stirrer and ground, and packed according to the measurement. The foliage fertilizer has multiple effects of promoting the growing development of crops, increasing both production and income, improving the quality, increasing nutrient utilization rate, controlling pests, no pollution and the like, and is especially suitable for the production of nuisanceless agricultural products. The foliage fertilizer has remarkable application effect, simple manufacturing technique, great market potential, obvious economic and social benefits and very wide application prospect.

Owner:TAIAN ACAD OF AGRI SCI

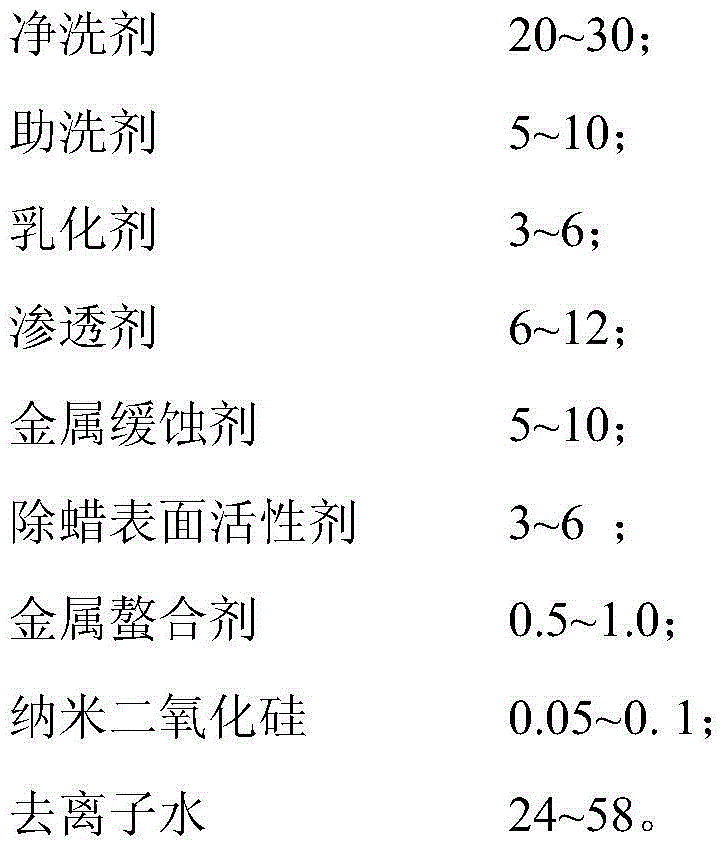

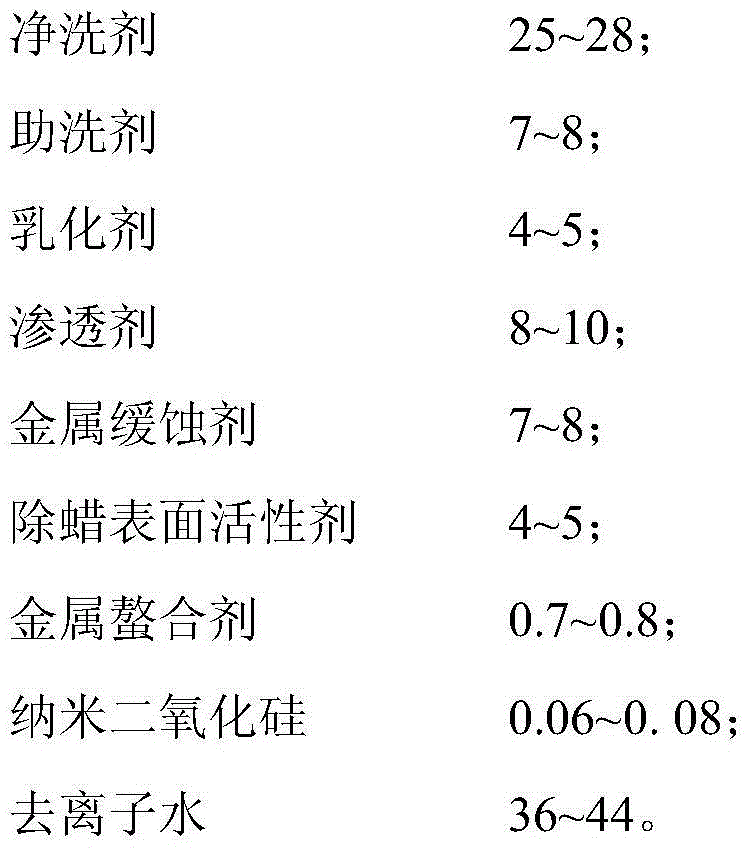

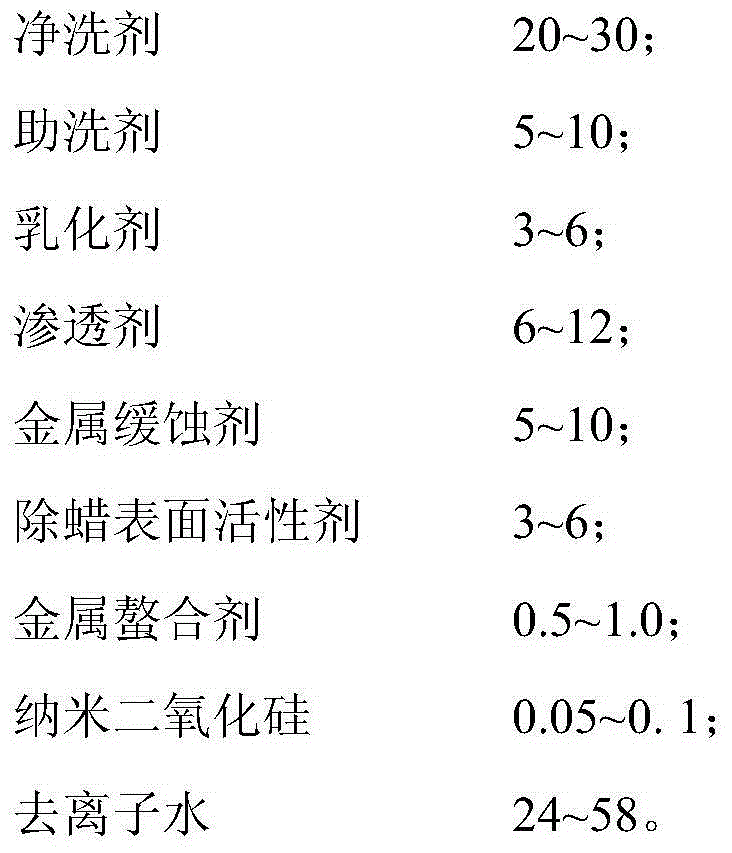

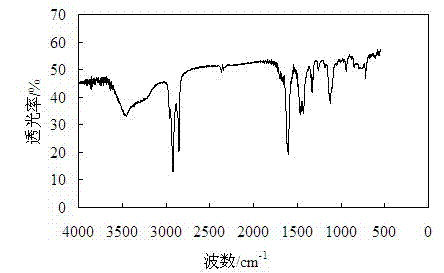

Nanometer wax-removal degreasing cleaning agent and preparation method thereof

InactiveCN104560447AEasy to cleanUnique nanoporous structureOrganic detergent compounding agentsSurface-active detergent compositionsSilicon oxideLotion

The invention relates to a nanometer wax-removal degreasing cleaning agent and a preparation method thereof and relates to cleaning agents. The nanometer wax-removal degreasing cleaning agent is prepared from the following raw materials in mass ratio: 20-30 of detergent, 5-10 of a builder, 3-6 of an emulsifier, 6-12 of a penetrating agent, 5-10 of a metal corrosion inhibitor, 3-6 of a wax-removal surfactant, 0.5-1.0 of a metal chelating agent, 0.05-0.1 of nanometer silicon oxide and 24-58 of deionized water. The preparation method comprises the following steps of (1) adding the metal chelating agent in deionized water to obtain an aqueous solution of the metal chelating agent; and 2) adding the emulsifier, the metal corrosion inhibitor and the nanometer silicon oxide into a reactor, adding deionized water and the detergent, adding the penetrating agent, the wax-removal surfactant and nanometer silicon oxide, stirring and adding the aqueous solution of the metal chelating agent obtained in the step (1), supplementing the residual deionized water and further stirring to obtain the nanometer wax-removal degreasing cleaning agent. The cleaning agent has the advantages of high wax-removal and degreasing speeds, long application period, good cleaning effect and environmental friendliness.

Owner:XIAMEN UNIV

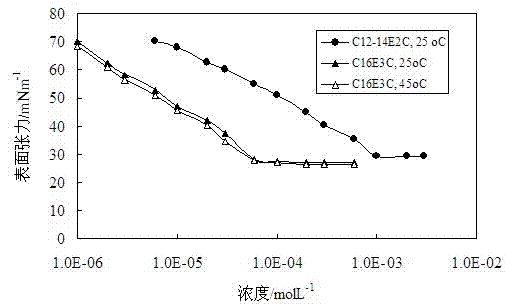

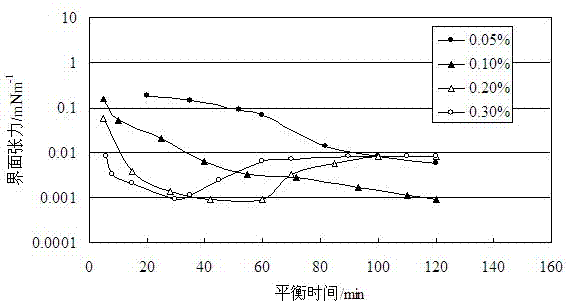

Preparation method of nonionic-anionic compound type surfactant and application thereof

InactiveCN102516064AThe synthesis process is simpleImprove performanceCarboxylic acid salt preparationDrilling compositionAlcoholEthylene oxide

The invention relates to a preparation method of a nonionic-anionic compound type surfactant and an application thereof, which belongs to the technical field of colloid and surface chemistry. The nonionic-anionic compound type surfactant is obtained by the addition of straight-chain saturated fatty alcohol and ethylene oxide and then carboxymethylation, and is called alcohol ether carboxylate for short. The atomic number of alkyl carbon of the fatty alcohol is 12-18, and the number n of added ethylene oxide is 2-5. The nonionic-anionic compound type surfactant is compounded with a betaine type amphoteric surfactant, wherein the mole faction of the alcohol ether carboxylate is 0.10-0.50, the mixed surfactant is solved in Daqing oilfield formation water or simulated formation water, and under the conditions that the total surfactant mass concentration is 0.05%-0.4%, 1000mg / L polyacrylamide is added, alkali is not added and the temperature is 45 DEG C, the interfacial tension of Daqing crude oil / formation water is reduced to 10-3mN / m orders of magnitude.

Owner:JIANGNAN UNIV

High-performance metal cutting fluid

InactiveCN104403772AEasy to cleanImprove anti-corrosion performanceLubricant compositionPhosphateChemistry

The invention discloses a high-performance metal cutting fluid including following raw materials, by weight: 3-15 parts of an oleamide-based nonionic surfactant, 5-12 parts of twain, 10-25 parts of dodecyl aminopropionic acid, 5-10 parts of a betaine-typed ampholytic surfactant, 10-20 parts of sodium alkyl benzene sulfonate, 1-10 parts of sophorolipid, 10-25 parts of a water-soluble lubricant, 5-18 parts of triethanolamine oleate, 5-15 parts of sodium borate, 1-5 parts of benzotriazole, 5-20 parts of cyclohexanehexol phosphate, 8-25 parts of an organic borate, 5-15 parts of a molybdate, 3-8 parts of copper citrate, 3-10 parts of a chelating agent, 3-10 parts of sodium citrate, 4-15 parts of citric acid and 80-150 parts of water. The high-performance metal cutting fluid is excellent in cleaning performance, corrosion-resistant performance, cooling performance, lubricating performance and anti-hard-water performance, is stable when being stored and is suitable for various materials.

Owner:CHAOHU GUANGFENG METAL PROD

Ether carboxylic acid compound of water-based cutting solution,preparation method and water-based cutting solution

ActiveCN106893622ALow costImprove hard water resistanceLubricant compositionWater basedCarboxylic salt

The invention provides an ether carboxylic acid compound ofa water-based cutting solution. The ether carboxylic acid compound is prepared from, by weight, 32.14-39.28% of ether carboxylic acid,19.29%-23.57%short-chain ether carboxylate and 38.57-47.15% of long-chain ether carboxylat, wherein the brand of ether carboxylic acid is Emulsogen COL100, the brand of the short-chain ether carboxylic acid is AkypoLF4, and the brand of the long-chain ether carboxylic acid is Akypo RO 90 VG. The invention further provides a preparation method of the ether carboxylic acid compound ofthe water-based cutting solution and the water-based cutting solution. Compared with the prior art, the ether carboxylic acid compound has the following advantages that the cost is low, the anti-hard water performance is excellent, the compound is chelated with Ca<2+> and Mg<2+>in water, a generated chelate has a good dispersion effect and low bubble performance, the used solution does not produce a large amount of foam, and the ether carboxylic acid compound is environmentally friendly and low in toxicity and has good biodegradability.

Owner:富兰克润滑科技(太仓)有限公司

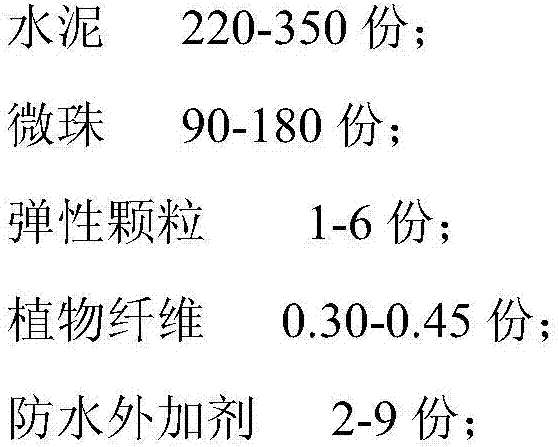

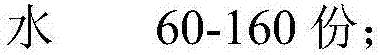

Waterproof crack-resistant foam concrete and manufacture method

The invention discloses waterproof crack-resistant foam concrete and a manufacture method thereof. The waterproof crack-resistant foam concrete is formed by mixing and stirring of raw materials including, by weight, 220-350 parts of cement, 90-180 parts of microspheres, 1-6 parts of elastic particles, 0.30-0.45 parts of palm filaments, 60-160 parts of water, 2-9 parts of waterproof admixtures and foam. The waterproof crack-resistant foam concrete and the manufacture method thereof have the advantages that the raw materials such as industrial by-products, tailings powder or waste rubber powder and the palm filaments are adopted, and the multi-scale toughening principle on compounding of the elastic particles and fibers is followed, so that strength and crack resistance of the foam concrete are improved, and waste resource utilization is benefited; the adopted waterproof admixtures are highly compatible with other materials, and accordingly, water resistance and durability of the foam concrete are improved effectively; by the prepared foam which is fine, uniform and high in stability, anti-permeability and thermal performance of the foam concrete are improved; the foam concrete is applicable to heat insulation of building walls and roofs and roadbed refilling materials for highways in regions with soft soil and high water level.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Compound foaming agent used for depositing dust and preparation method thereof

InactiveCN103361035AGood acid and alkali resistanceImprove hard water resistanceOther chemical processesDust removalRespirable dustAlkyl polyglycoside

The invention discloses a compound foaming agent used for depositing dust and a preparation method thereof. The compound foaming agent is prepared from following materials by weight: 5-8 parts of an alkyl polyglucoside, 20-25 parts of a fatty alcohol-polyoxyethylene ether, 9-14 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 1-2 parts of 2-ethyl hexyl succinate sodium sulfonate and 51-65 parts of water. The compound foaming agent has advantages of good acid and alkali resistance and hard-water resistance, strong foaming capability, fine and rich foams, small bubble sizes, moderate stability, large dust contacting area, good adhesiveness and wettability, enhanced dust depositing effects, enhanced capturing capability for respirable dust in particular, no toxicity, no harm, no skin irritation, rapid and complete biodegradation, selection of raw materials common in market and low cost. The compound foaming agent has wide applicability in the field of dust deposition using foams.

Owner:CHINA UNIV OF MINING & TECH +1

High-efficiency safe environment-friendly all-synthetic cutting fluid and preparation method thereof

InactiveCN104479833AImprove the lubrication effectExcellent rust and corrosion inhibition performanceLubricant compositionEnvironmental resistanceWork in process

The invention discloses a high-efficiency safe environment-friendly all-synthetic cutting fluid and a preparation method thereof. The cutting fluid consists of the following components in percentage by weight: 20-30% of synthetic ester, 4-8% of surfactant, 5-15% of antirust agent, 2-10% of pH regulator, 0-3% of corrosion inhibitor and the balance of deionized water. The preparation method comprises the following specific steps: adding the pH regulator into part of the deionized water and stirring uniformly; adding the corrosion inhibitor and the antirust agent in turn and stirring until solid powder is completely dissolved; after uniformly mixing and stirring the synthetic ester, adding the surfactant of the proportion and stirring for 15 minutes till uniformity; pouring a semi-finished product into the reaction system and stirring uniformly; repeatedly flushing the preparation container with the rest deionized water, and completely beating the flushing liquid back into the reaction system; and continuously stirring the reaction system until the solution is uniform and transparent to obtain a finished product. In the invention, the prepared all-synthetic cutting fluid has excellent lubricating and antirust and corrosion inhibition properties as well as good stability at high and low temperature to avoid color change, and avoids stimulation to the skin of a human body; and moreover, the all-synthetic cutting fluid has good biological stability and is safe, environment-friendly and non-irritant.

Owner:JIANGSU XINLU NEW MATERIALS CO LTD

Phosphorylated polymerization polymer dispersant and its preparation method

ActiveCN103084119AImprove completenessImprove hard water resistanceBiocideTransportation and packagingPhosphoric acidPolymer chemistry

The invention belongs to the polymer synthesis field and concretely relates to a phosphorylated polymerization polymer dispersant and its preparation method. The dispersant is characterized in that the dispersant comprises 5.0-100.0% by mole of a phosphorylated polymerization monomer and 0-95.0% by mole of other unsaturated copolymerization monomers, and the preparation method of the dispersant comprises a step of the synthesis of the phosphorylated polymerization monomer and a step of the copolymerization of the phosphorylated polymerization monomer with the other monomers. The introduction of phosphate radicals in the dispersant improves the hard water resistance and the dispersion suspension performance of the dispersant.

Owner:中化化工科学技术研究总院有限公司 +1

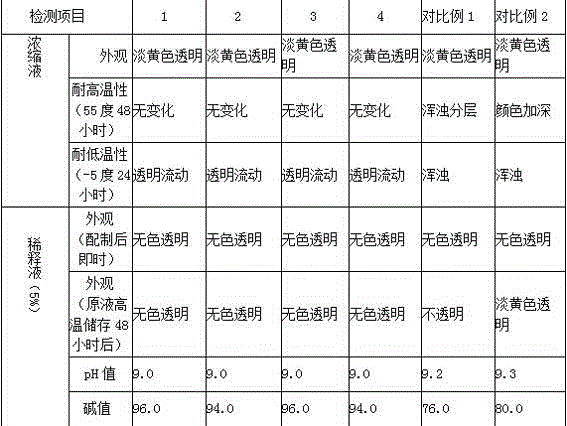

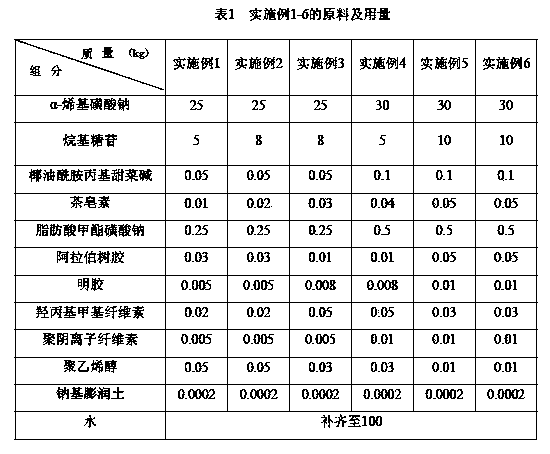

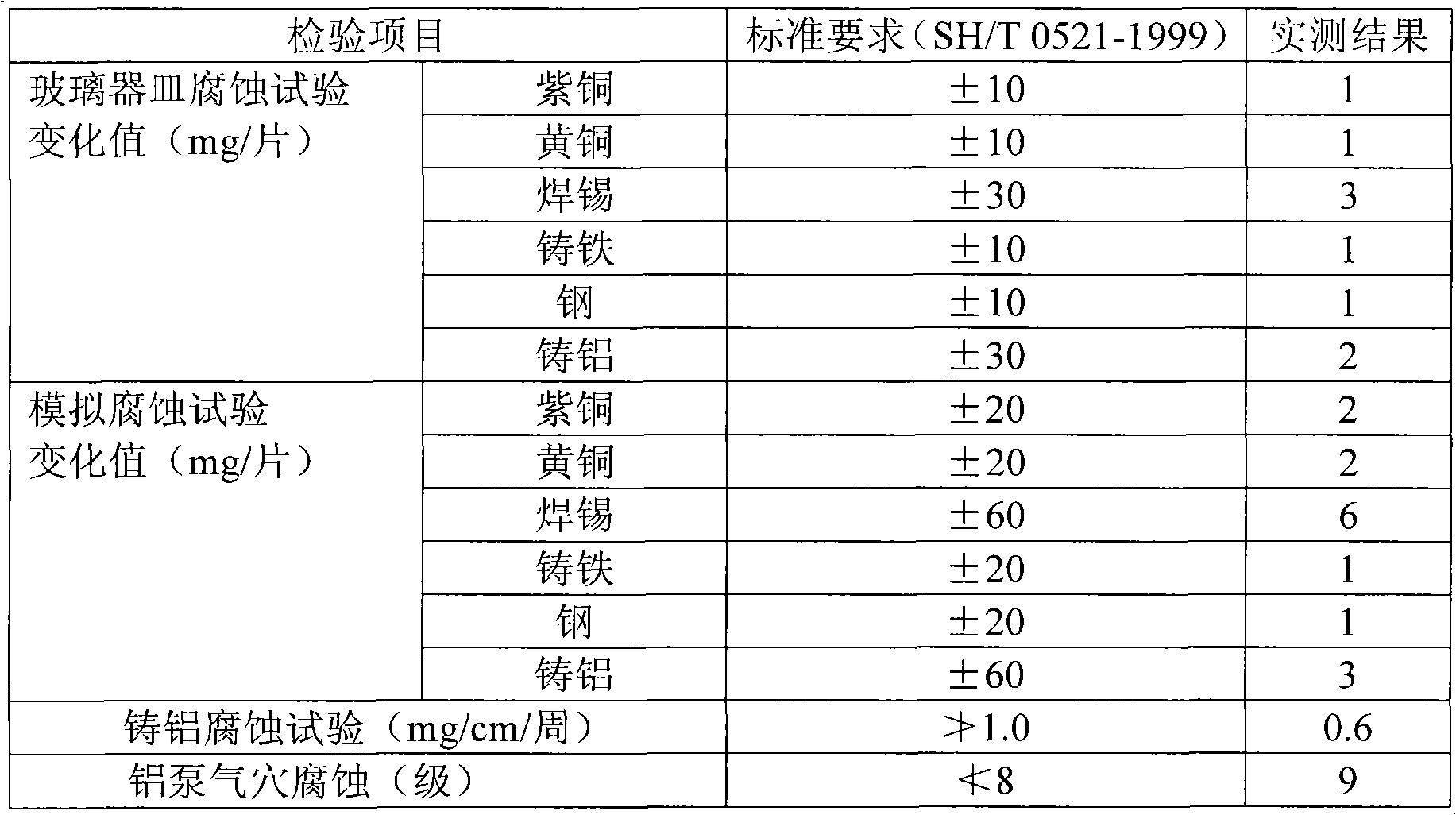

Environment-friendly compound concrete foaming agent and preparation method thereof

The invention discloses an environment-friendly compound concrete foaming agent and a preparation method thereof. The environment-friendly compound concrete foaming agent comprises the following components: sodium alpha-olefin sulfonate, alkyl glycoside, methyl ester sulfonate, cocamidopropyl betaine, tea saponin, arabic gum, hydroxypropyl methyl cellulose, gelatin, polyanionic cellulose, polyvinyl alcohol and sodium bentonite. The environment-friendly compound concrete foaming agent disclosed by the invention is alkalescent, achieves the pH value of 7-9, has the advantages of high foaming power, large foam expansion, fine uniform and tough foam, durability, stability, long foam stabilizing time, small bleeding amount, small deposition amount, good hard water resistance and suitability for water with various rigidities.

Owner:深圳市中天元实业有限公司

All-organic engine coolant

InactiveCN101955756AIncrease reservesImprove the stability of useHeat-exchange elementsOrganic compoundDefoamer

The invention relates to an all-organic engine coolant, comprising the following components by parts by weight: 1000 parts of glycol, 16-20 parts of dodecanedioic acid, 5-9 parts of undecanedioic acid, 1-5 parts of benzotriazole, 3-6 parts of 2-ethylhexoic acid, 0.5-3 parts of hydroxybenzoic acid, 0.05-0.1 part of hydrolytic polymaleic anhydride and 0.1-0.3 part of antifoaming agent. The engine coolant takes all-organic compounds as raw materials, synergistic effect is good, and anti-corrosion property to multiple metals, especially aluminium, is good; hard water resistance is good; storage and use stability of coolant can be greatly improved; the service life of antifreezing solution can be effectively prolonged; and no influence to the environment is produced as nitrous, amine, phosphorus and chromium components are not contained.

Owner:兰州蓝星有限公司

Neutral fancy soap for moistening skin

ActiveCN1760354APromote degradationLow degreasing powerCosmetic preparationsNon-ionic surface-active compoundsIrritationWhite powder

A neutral skin-moistening toilet soap is proportionally prepared from anionic surfactant, ampholytic surfactant, fatty acid, titanium white powder, chelating agent, and deionized water. Its advantages are low irritation to skin, high foaming power and good biodegradability.

Owner:克劳丽化妆品股份有限公司

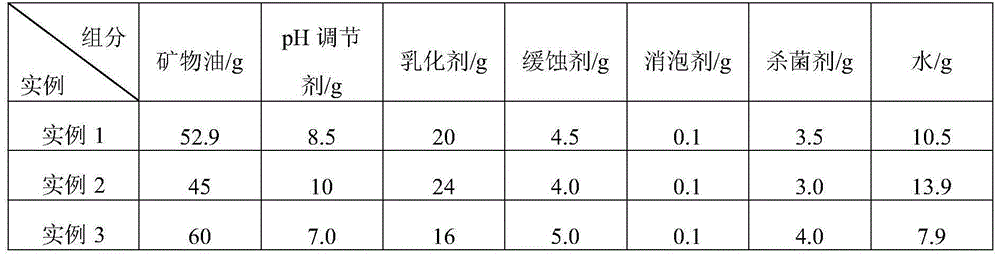

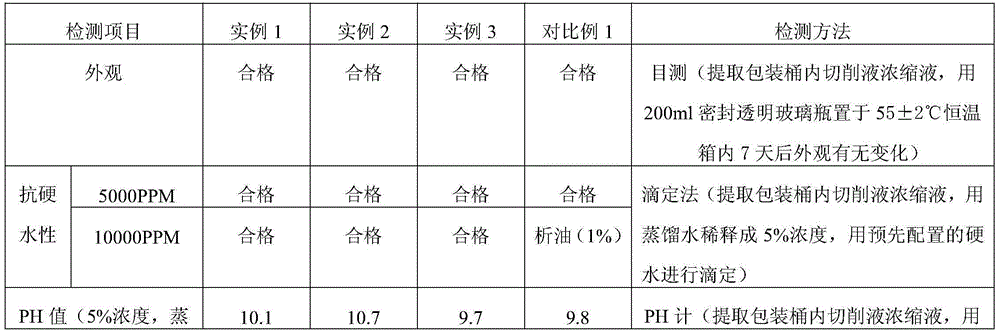

Semisynthetic micro-emulsified cutting fluid for magnesium alloy cutting

InactiveCN105087129AImprove wear resistanceImprove hard water resistanceLubricant compositionHard waterSemi synthetic

The invention relates to semisynthetic micro-emulsified cutting fluid for magnesium alloy cutting, comprising, by weight, 40 to 60 parts of mineral oil, 4 to 13 parts of pH regulator, 12 to 30 parts of emulsifier, 2.5 to 5 parts of corrosion inhibitor, 0.5 to 1.5 parts of stabilizer, 0.01 to 0.2 part of defoamer, 2 to 4 parts of sterilizing agent, and 5 to 20 parts of water. The semisynthetic micro-emulsified cutting fluid is good in abrasion resistance, hard water resistance and magnesium alloy corrosion resistance, is super-long in service life; adding the semisynthetic micro-emulsified cutting fluid for magnesium alloy cutting is required only, while replacing is not required.

Owner:深圳市奥科宝特种油剂有限公司

Polyethylene glycol monooleate fully-synthetic cutting fluid and preparation method thereof

ActiveCN102776060AComprehensive lubricationExtend the life cycleLubricant compositionPolyethylene glycolMaterials science

The invention relates to a cutting fluid for metal processing, and particularly relates to a polyethylene glycol monooleate fully-synthetic cutting fluid and a preparation method thereof. Polyethylene glycol monooleate is used as a lubricating agent, and borate generated by boric acid and monoethanolamine and triazine amino-acid ester are combined to form an anti-rust component which has better anti-rust property, thus solving the defects of poor lubricating property, easy deterioration and smelliness and short service life of polyethylene glycol lubricating agents, polyether lubricating agents, oleic acid soap lubricating agents and sulfonated caster oil lubricating agents, and further achieving a corrosion inhibition and synergy function by adding a proper amount of benzotriazole copper corrosion inhibitor and other anti-rust agents. The fully-synthetic cutting fluid prepared from the raw materials is complete in property, has excellent hard water resistance, can be used under a high hard water environment, is high in pH buffer capacity, is stable in quality, has excellent lubricating, anti-rust and anti-corrosion functions, belongs to an environment-friendly product, can be biodegraded, is suitable for various kinds of machining, and is especially suitable for various machining processes of a grinder.

Owner:温州宝罗润滑材料有限公司

Low-foam green CIP bactericidal concentrated cleaning agent

ActiveCN107937171APromote degradationEfficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsProduction lineFood industry

The invention discloses a low-foam green CIP bactericidal concentrated cleaning agent, and relates to the field of CIP engineering cleaning agents. The cleaning agent aims to solve the technical problems that the time of a cleaning process is long, industrial wastewater is easy to cause environmental pollution, and green cleaning standards are not met in the existing food industry. The cleaning agent is prepared from an active component, an assistant, a chelating agent, a penetrating agent, an antifoaming agent, a bactericide, a pH regulator and residual deionized water. The cleaning agent isapplicable to the cleaning of food production line CIP, has excellent hard water resistance and dirt-removing power, adopts a nonionic / anionic surfactant with excellent biological degradability, belongs to an efficient CIP green cleaning agent integrating low foam and bactericidal activity, and can effectively remove various food dirt.

Owner:HEILONGJIANG HEIKE TECH CO LTD

Process for preparing modified fatty alcohol polyethenoxy ether

This invention relates to a preparation method for modified fatty alcohol polyoxyethylene ether. The said method includes carrying out a glucosidation reaction of glucose with fatty alcohol ether in the presence of acid catalyst and under vacuum condition, adding NaOH to pH of 8~9, filtrating and precipitating to remove unreacted sugar to obtain modified alcohol ether glucoside, preparing chloroacetic acid modified ether solution of modified alcohol ether glucoside and chloroacetic acid at a molar ratio of 1~2:1, stirring and adding sodium hydroxide into the remaining modified alcohol ether glucoside, heating to 100-110degreeC under vacuum condition and hydrating for 1~2 hours, cooling and adding chloroacetic acid modified alcohol ether solution, maintaining the reaction temperature at 40~90degreeC, and reacting for 2~4 hours to obtain carboxymethylated modified fatty alcohol polyoxyethylene ether. The method has the advantages of easy operation and low cost.

Owner:CHINA RES INST OF DAILY CHEM IND

Stable foaming agent for shield construction of complex stratum and preparation method and application of stable foaming agent

InactiveCN106929023AGood thickening effectExtended half-lifeBuilding constructionsOrganic fertilisersSulfonateFoaming agent

The invention discloses a stable foaming agent for shield construction of a complex stratum and a preparation method and an application of the stable foaming agent, and solves the problems that the foaming agent for an earth pressure balance shield is low in foaming capacity, poor in foaming stability performance and poor in hard water resistance, and is not green or environmentally friendly in the prior art. The stable foaming agent has the advantages of high foaming expansion, long half foam life period and good biodegradability, and comprises the following components of 8-14% of foaming agent, 0.2-0.5% of thickener, 0.1-0.5% of foam stabilizer and the balance of water, wherein % refers to mass percent, and the foaming agent comprises alpha-olefin sulfonate, alpha-sulfonated fatty acid methyl ester and alkyl polyglucosides.

Owner:SHANDONG UNIV

Washing powder and soap powder viscosity reduction synergist

ActiveCN102002445AGood viscosity reduction effectImprove cleanlinessOrganic detergent compounding agentsSlurryWater soluble

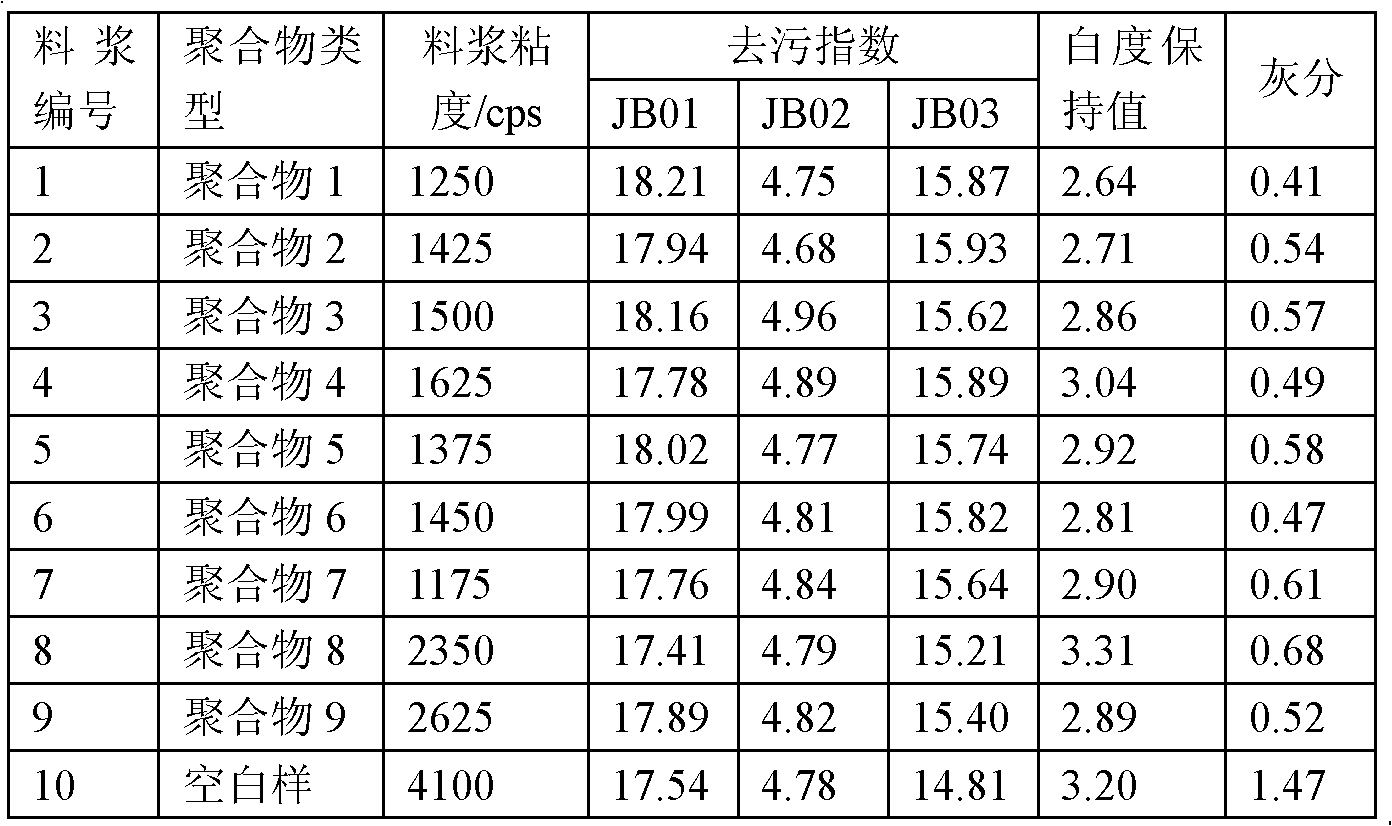

The invention discloses washing powder and a soap powder viscosity reduction synergist. The soap powder viscosity reduction synergist is characterized by being an amphipathic polymer copolymerized by the following monomers under the action of assistants: (a) 10-90 percent of carbpxyl-containing unsaturated monomer and / or salts thereof; (b) 1-80 percent of polyether-containing chain segment unsaturated monomers; (c) 0-70 percent of hydrophobic group-containing unsaturated monomer; and (d) 0-50 percent of acid diffluent water-soluble unsaturated monomer, wherein the weight percentage summation of all monomers is 100 percent. The invention also discloses a detergent addictive and a detergent with the washing powder and the soap powder viscosity reduction synergist. The soap powder viscosity reduction synergist can play roles of reducing the viscosities of the washing powder and soap powder dusting slurry and improving the washing effect and the synergism, thereby meeting the demand of the current market.

Owner:广州星业科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com