Nanometer wax-removal degreasing cleaning agent and preparation method thereof

A cleaning agent and nanotechnology, applied in the field of cleaning agents, can solve the problems of corrosion of stainless steel tank body of ultrasonic equipment, difficult biodegradation of surfactants, unsatisfactory cleaning effect, etc., to achieve good economic and social benefits, wax removal Strong ability and the effect of enhancing cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

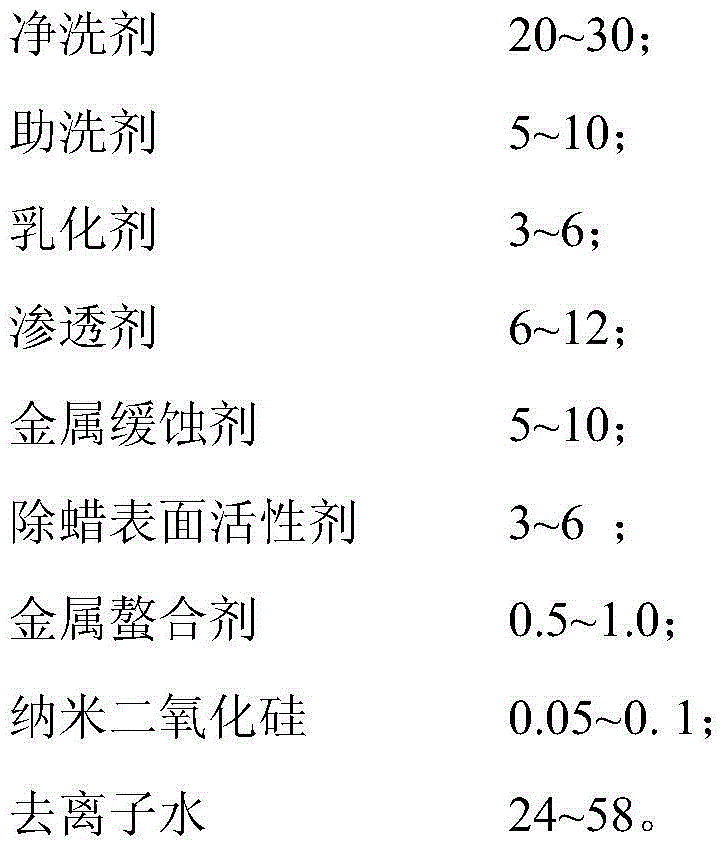

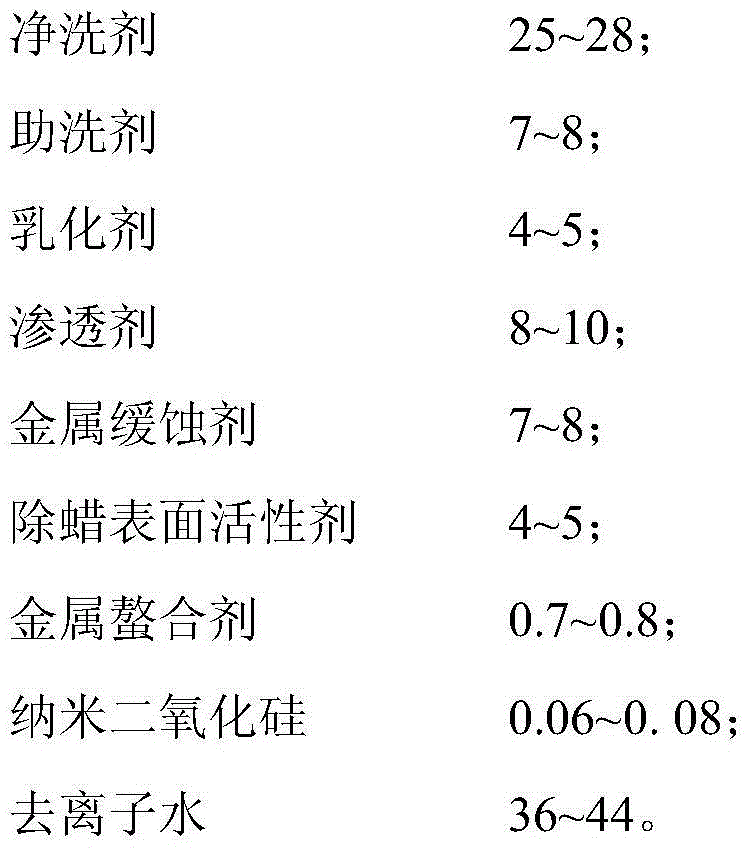

Method used

Image

Examples

Embodiment 1

[0032] A nano wax and degreasing cleaning agent, its composition and quality are respectively: coconut oil diethanolamide (6501) 4kg, coconut oil alkanolamide phosphate (6503) 26kg; Linear alkylbenzene sulfonic acid 6kg; 5kg of chypre oleic acid; 10kg of fatty alcohol polyoxyethylene ether (JFC); 8kg of triethanolamine; 3kg of YT-61 special surfactant for wax removal; 0.5kg of tetrasodium ethylenediaminetetraacetic acid (ETDA tetrasodium); MPA-500 Nano silica airgel powder 0.05kg, deionized water 37.45kg.

[0033] The preparation method of described nanometer dewaxing degreasing cleaning agent, its steps are:

[0034] (1) take each component by mass parts;

[0035] (2) Add the metal chelating agent tetrasodium ethylenediaminetetraacetic acid (ETDA tetrasodium) into an appropriate amount of deionized water, then stir to make it completely dissolve, and obtain an aqueous solution of tetrasodium ethylenediaminetetraacetic acid (ETDA tetrasodium) for later use.

[0036] (3) Add ...

Embodiment 2

[0038] A nano wax and oil removal cleaning agent, its composition and quality are respectively: coconut oil diethanolamide (6501) 4kg, coconut oil alkanolamide phosphate (6503) 20kg; linear alkylbenzene sulfonic acid 7kg; 4kg of chypre oleic acid; 8kg of fatty alcohol polyoxyethylene ether (JFC); 6kg of triethanolamine; 4kg of YT-61 special surfactant for wax removal; 0.5kg of tetrasodium ethylenediaminetetraacetic acid (ETDA tetrasodium); MPA-500 Nano silica airgel powder 0.07kg, deionized water 46.43kg.

[0039] The preparation method of described nanometer dewaxing degreasing cleaning agent, its steps are:

[0040] (1) take each component by mass parts;

[0041] (2) Add the metal chelating agent tetrasodium ethylenediaminetetraacetic acid (ETDA tetrasodium) into an appropriate amount of deionized water, then stir to make it completely dissolve, and obtain an aqueous solution of tetrasodium ethylenediaminetetraacetic acid (ETDA tetrasodium) for later use.

[0042] (3) Add ...

Embodiment 3

[0044] A nano wax and oil removal cleaning agent, its composition and quality are respectively: coconut oil diethanolamide (6501) 3kg, coconut oil alkanolamide phosphate (6503) 22kg; linear alkylbenzene sulfonic acid 9kg; 6kg of chypre oleic acid; 7kg of fatty alcohol polyoxyethylene ether (JFC); 8kg of triethanolamine; 2.5kg of YT-61 special surfactant for wax removal; 0.1kg of 500nm silica airgel powder, 41.4kg of deionized water.

[0045] The preparation method of described nanometer dewaxing degreasing cleaning agent, its steps are:

[0046] (1) take each component by mass parts;

[0047] (2) Add the metal chelating agent tetrasodium ethylenediaminetetraacetic acid (ETDA tetrasodium) into an appropriate amount of deionized water, then stir to make it completely dissolve, and obtain an aqueous solution of tetrasodium ethylenediaminetetraacetic acid (ETDA tetrasodium) for later use.

[0048] (3) Add emulsifier chypre oleic acid, corrosion inhibitor triethanolamine and builde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com