Low-temperature soaping agent as well as preparation method and application thereof

A low-temperature soap and lotion technology, applied in detergent compositions, chemical instruments and methods, non-surface active detergent compositions, etc., can solve the problems of hard water resistance, increased washing burden, and large molecular structure, etc., and achieve good Hard water resistance, excellent soaping performance, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

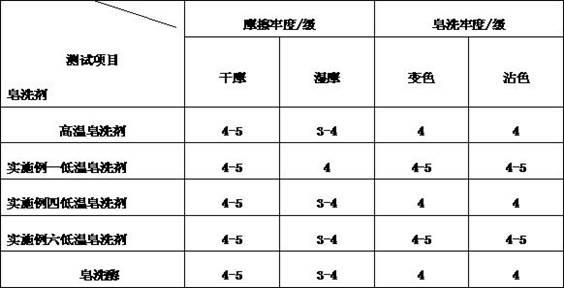

Examples

Embodiment 1

[0051] A kind of preparation method of low-temperature soaping agent, comprises the steps:

[0052](1) Preparation of the maleic anhydride copolymer: Add 30 parts by weight of maleic anhydride and 39 parts by weight of deionized water into the reaction kettle, raise the temperature to 60°C, and after the maleic anhydride is completely dissolved, add the dissolved 30 Parts by weight of acrylamide and 1 part by weight of sodium persulfate are heated to 70°C, kept for 4 hours, and then cooled to below 40°C to adjust the pH to 7-8 with ammonia water, and then discharge;

[0053] (2) Compounding: Add 55 parts by weight of the horse-propylene copolymer prepared in step (1), 5 parts by weight of fatty alcohol ether sulfate, and 1 part by weight of ethylenediamine di-o-hydroxyphenyl bismuth Sodium acetate, 0.3 parts by weight of an antifoaming agent and 38.7 parts by weight of deionized water are stirred evenly and discharged to obtain a low-temperature soaping agent.

Embodiment 2

[0055] A kind of preparation method of low-temperature soaping agent, comprises the steps:

[0056] (1) Preparation of the maleic anhydride copolymer: add 40 parts by weight of maleic anhydride and 38 parts by weight of deionized water into the reaction kettle, raise the temperature to 70°C, after the maleic anhydride is completely dissolved, add the dissolved 20 Parts by weight of acrylamide and 2 parts by weight of sodium persulfate are heated up to 90°C, kept for 3 hours, then cooled to below 40°C to adjust the pH to 7-8 with ammonia water, and discharged.

[0057] (2) Compounding: Add 65 parts by weight of the horse-propylene copolymer prepared in step (1), 8 parts by weight of fatty alcohol ether sulfate, and 2 parts by weight of ethylenediamine di-o-hydroxyphenyl bismuth Sodium acetate, 0.4 parts by weight of an antifoaming agent and 24.6 parts by weight of deionized water are stirred evenly and discharged to obtain a low-temperature soaping agent.

Embodiment 3

[0059] A kind of preparation method of low-temperature soaping agent, comprises the steps:

[0060] (1) Preparation of the maleic anhydride copolymer: Add 40 parts by weight of maleic anhydride and 27 parts by weight of deionized water into the reaction kettle, raise the temperature to 70°C, after the maleic anhydride is completely dissolved, add dropwise 30 parts by weight of the dissolved Acrylamide and 3 parts by weight of sodium persulfate are used as an initiator, the temperature is raised to 80°C, and the temperature is kept for 3 hours, and then the temperature is lowered to below 40°C to adjust the pH to 7-8 with ammonia water, and the material is discharged.

[0061] (2) Compounding: Add 50 parts by weight of the horse-propylene copolymer prepared in step (1), 12 parts by weight of fatty alcohol ether sulfate, and 3 parts by weight of ethylenediamine di-o-hydroxyphenyl bismuth Sodium acetate, 0.4 parts by weight of an antifoaming agent and 34.6 parts by weight of deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com