Patents

Literature

62 results about "Biodegradable product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Product that incorporates a resorbable characteristic that causes it to break down over time; frequently used for surgical materials, implants, vaccine vectors, drug delivery systems, etc.

Biodegradable resin compositions

InactiveUS6669771B2Increase resistanceHigh strengthCosmetic preparationsAntifouling/underwater paintsBiodegradable productDigestion

Owner:NAT INST OF ADVANCED IND SCI & TECH +2

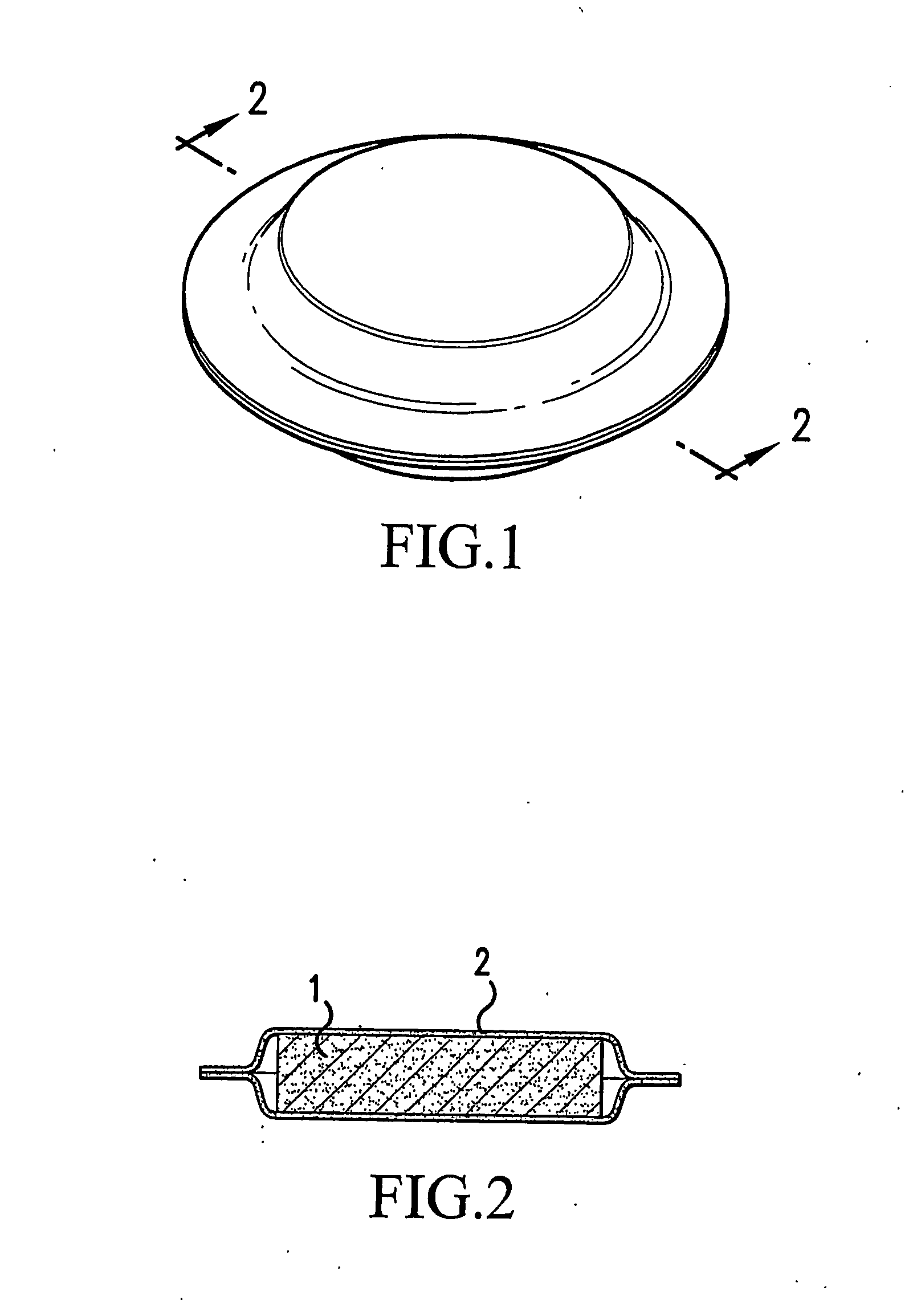

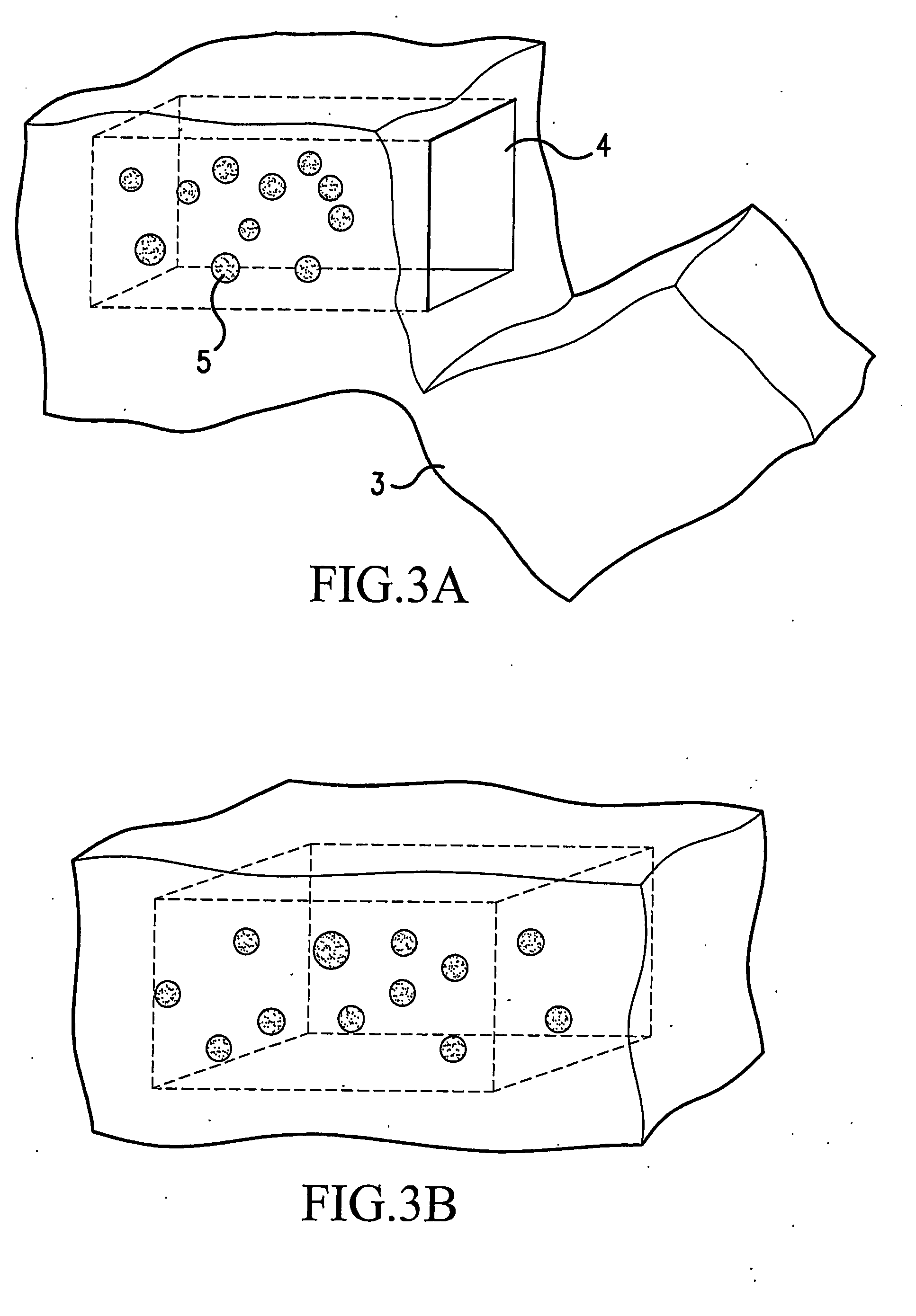

Seedbed for growing vegetation

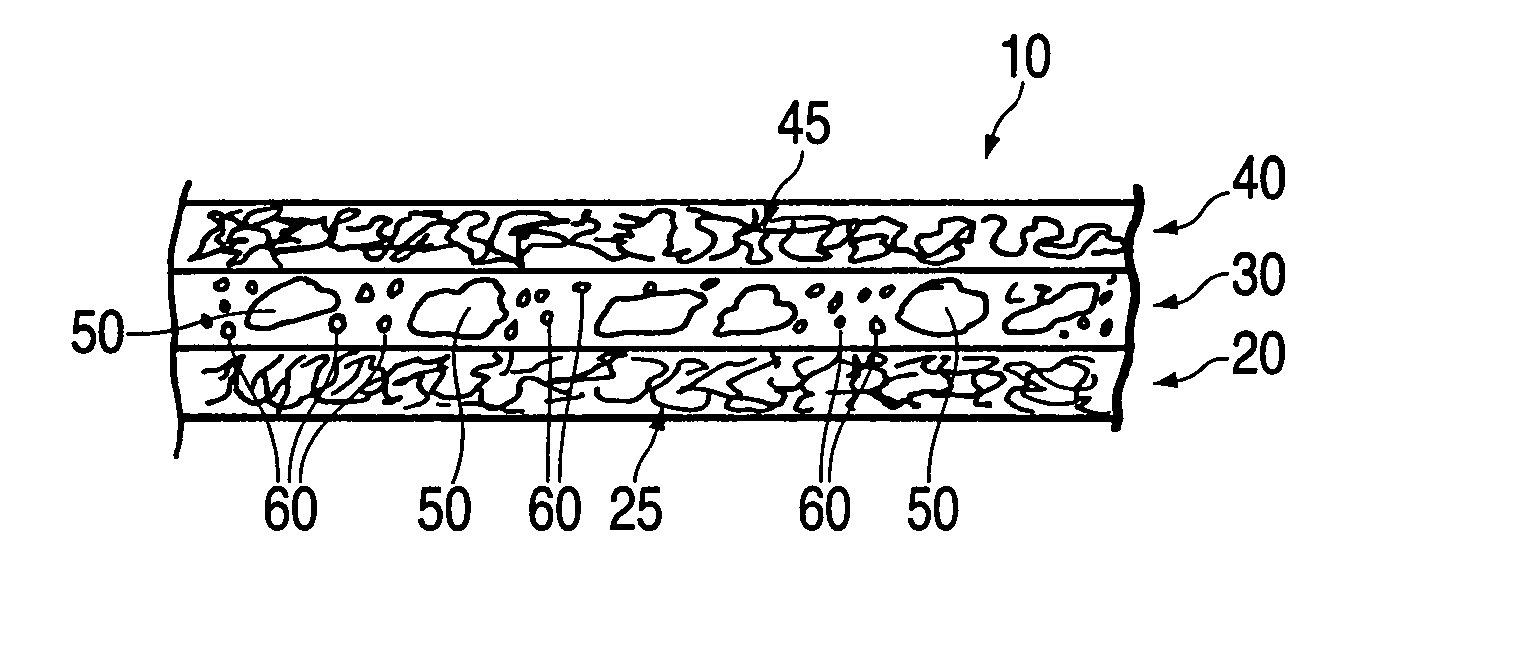

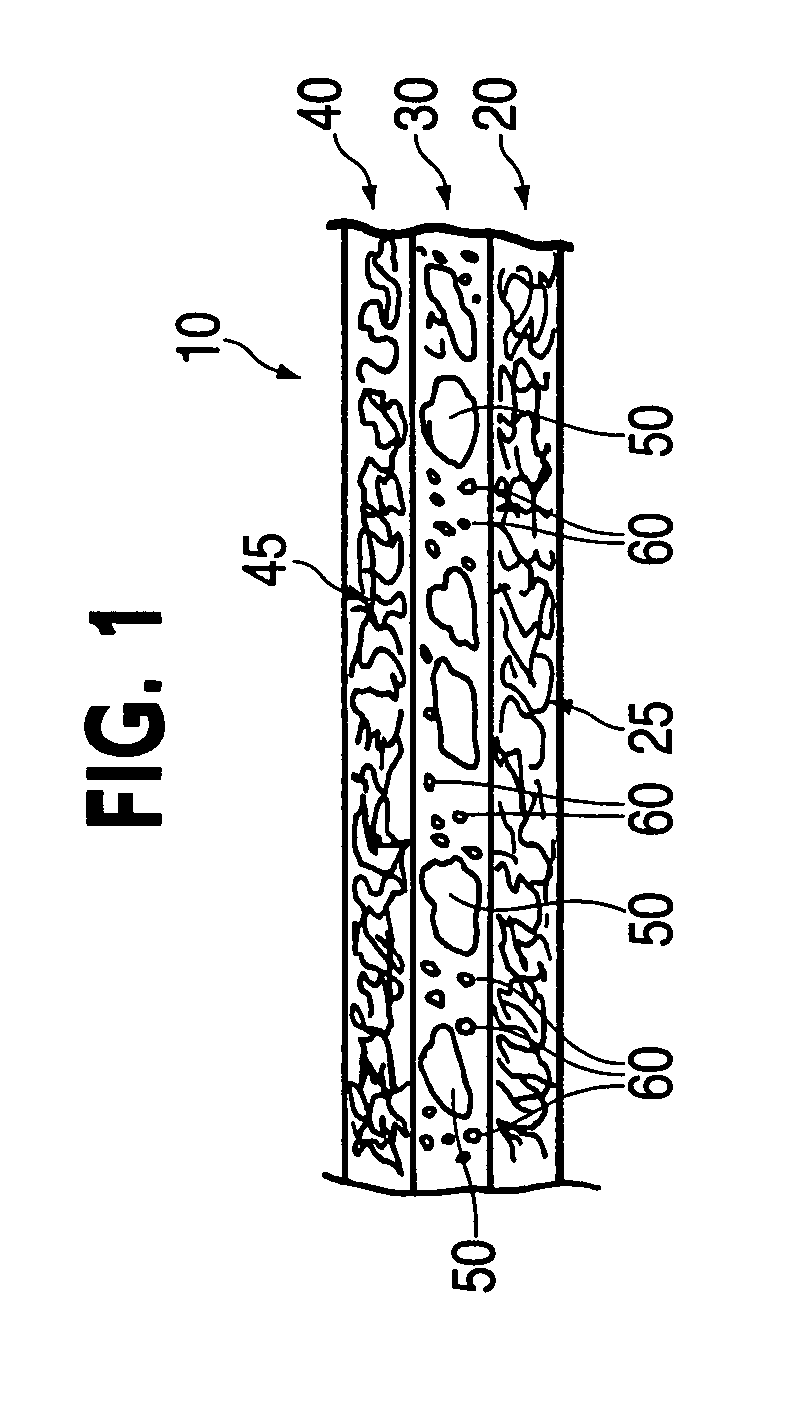

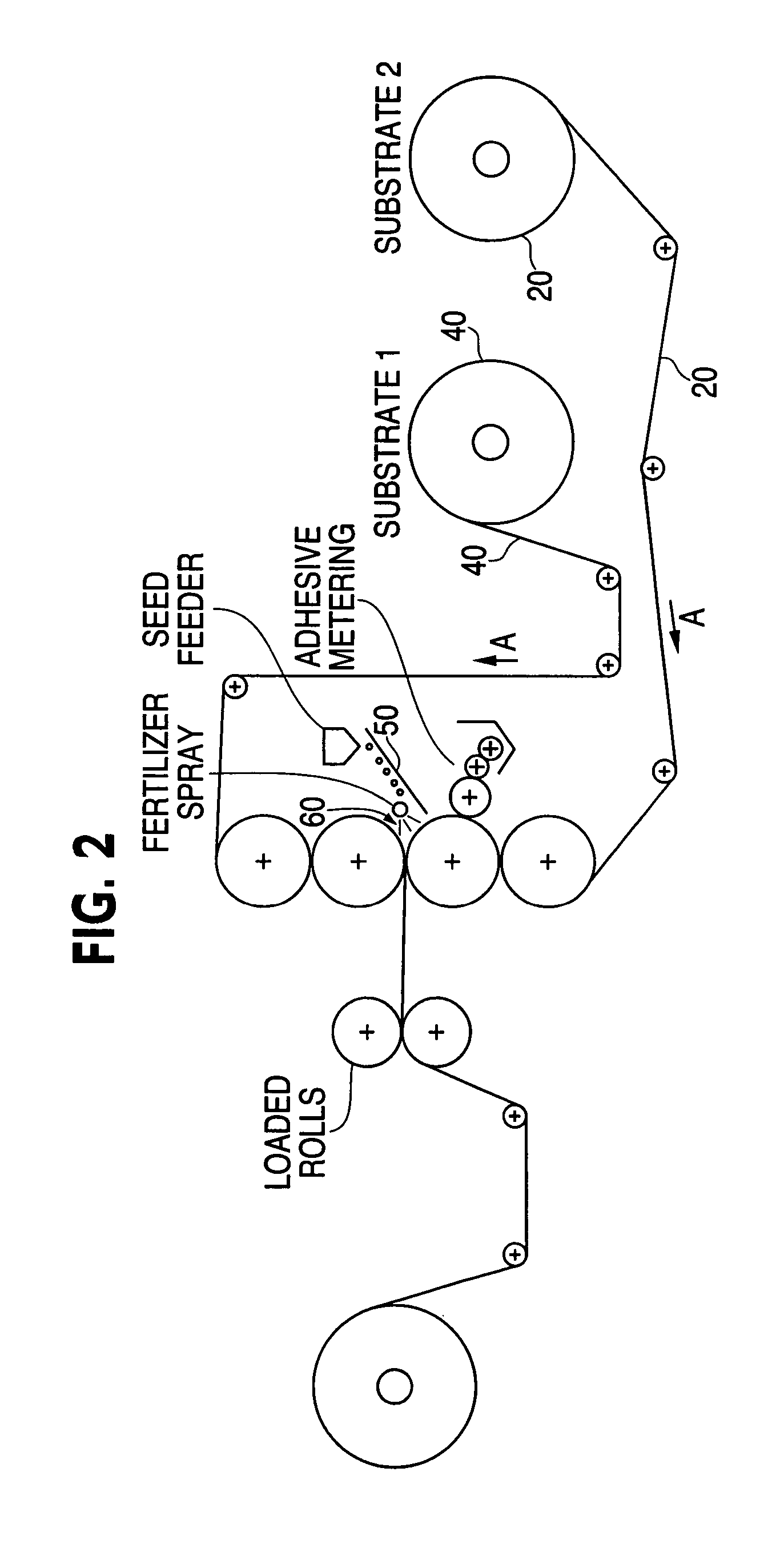

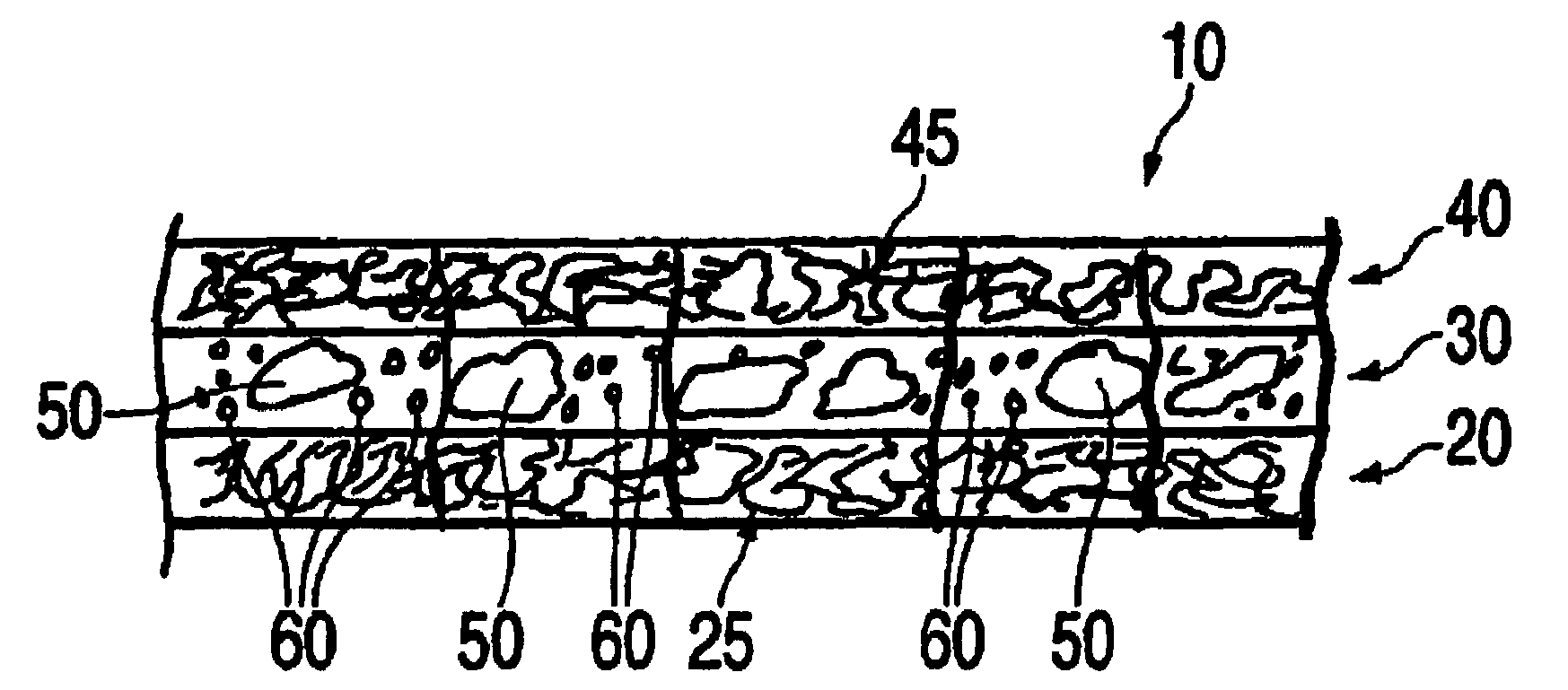

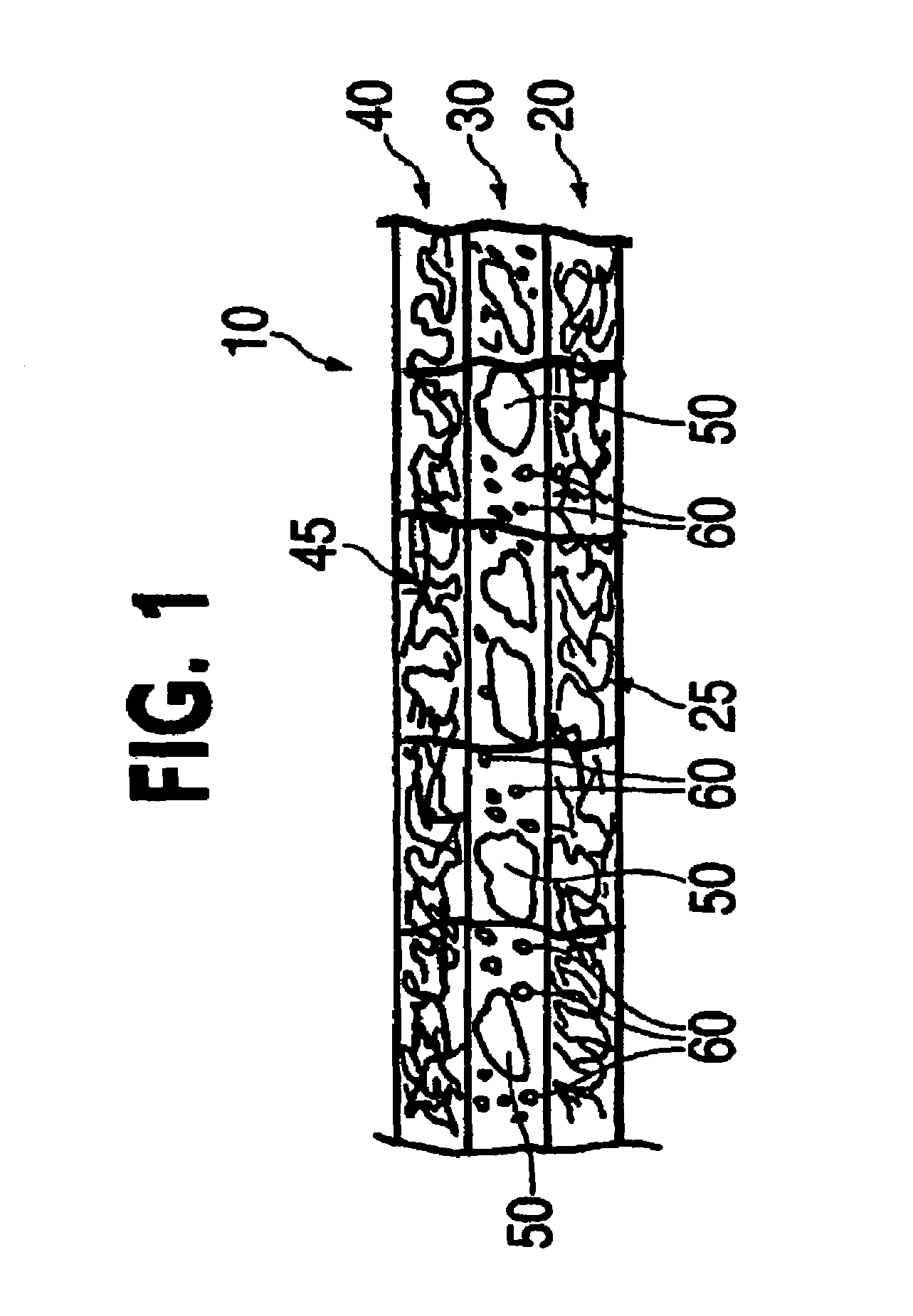

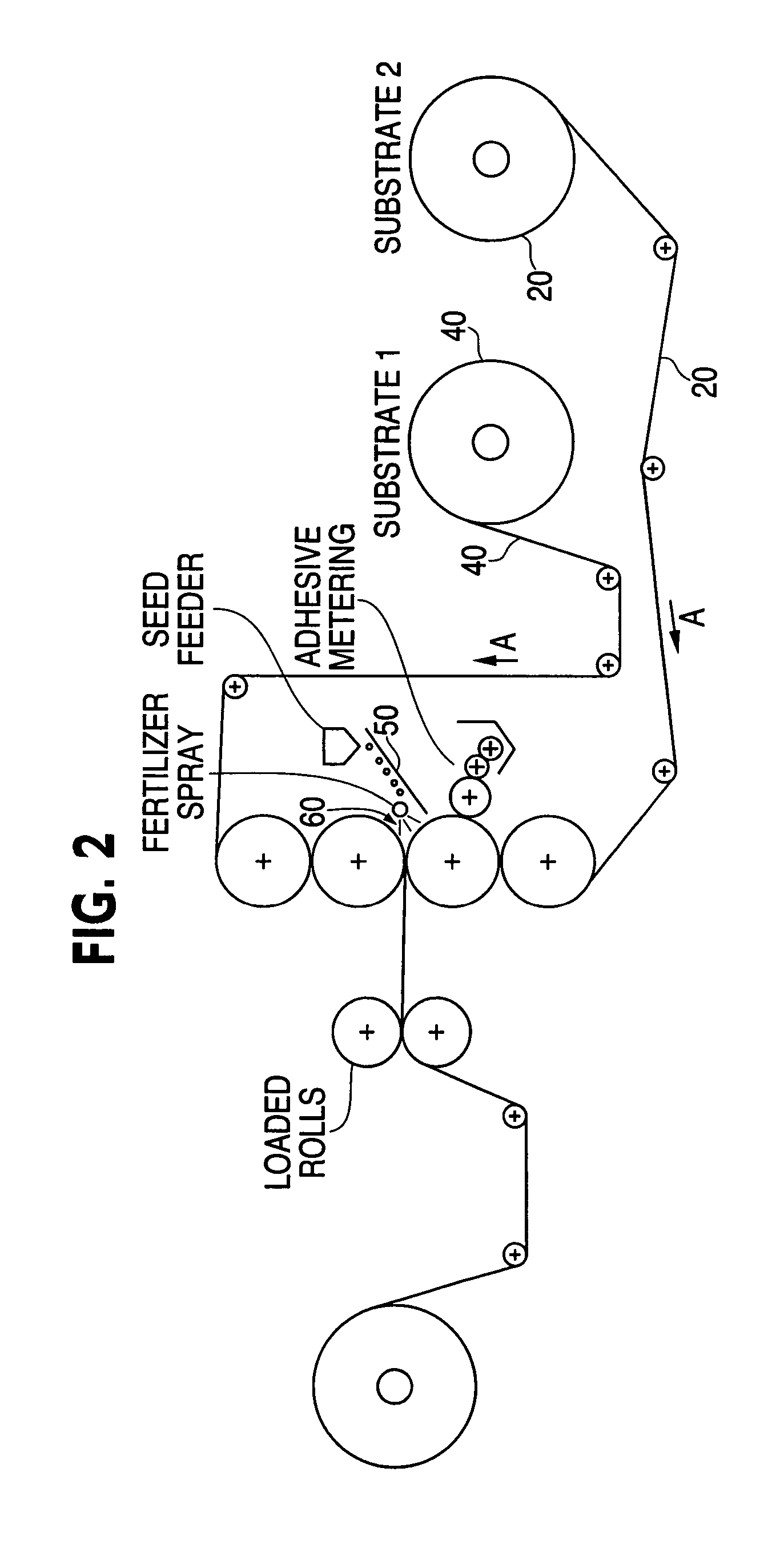

An artificial seedbed used in growing vegetation. The artificial seedbed comprises a base layer formed of a biodegradable product having a porosity and wet density that permit a root of the desired vegetation to penetrate the base layer and establish the vegetation for growing. The artificial seedbed also comprises an intermediate layer comprising a plurality of seeds for use in growing the desired vegetation. A cover layer cooperates with the base layer to form an envelope about the intermediate layer. The cover layer can be coextensive with the base layer and secured to the base layer by a bonding agent. The cover layer is formed of the same or different biodegradable product as the base layer. The material used in the cover layer permits the sprouting vegetation to penetrate it during the growing process.

Owner:GTX TURF FARMS LP

Seedbed for growing vegetation

An artificial seedbed used in growing vegetation. The artificial seedbed comprises a base layer formed of a biodegradable product having a porosity and wet density that permit a root of the desired vegetation to penetrate the base layer and establish the vegetation for growing. The artificial seedbed also comprises an intermediate layer comprising a plurality of seeds for use in growing the desired vegetation. A cover layer cooperates with the base layer to form an envelope about the intermediate layer. The cover layer can be coextensive with the base layer and secured to the base layer by a bonding agent. The cover layer is formed of the same or different biodegradable product as the base layer. The material used in the cover layer permits the sprouting vegetation to penetrate it during the growing process.

Owner:GTX TURF FARMS LP

Composition absorbing odorous substances and releasing various active substances

InactiveUS6635344B1Easy to operateGaseous substancesDeodrantsAdditive ingredientBiodegradable product

A new product is described characterized by its qualities to absorb undesirable scents present in the air, while serving at the same time as a carrier for aromas, fragrances, flavorings, repellents, attractants and other active ingredients. The active ingredients are gradually released by the carrier, which is compatible with the environment and current tendencies towards the use of organic and biodegradable products. The composition comprises a carrier and an active ingredient. The carrier is characterized as being particles obtained from the milling, separation, air wash and classification of the different fractions obtained from corncobs.

Owner:APROA ASESORES S C

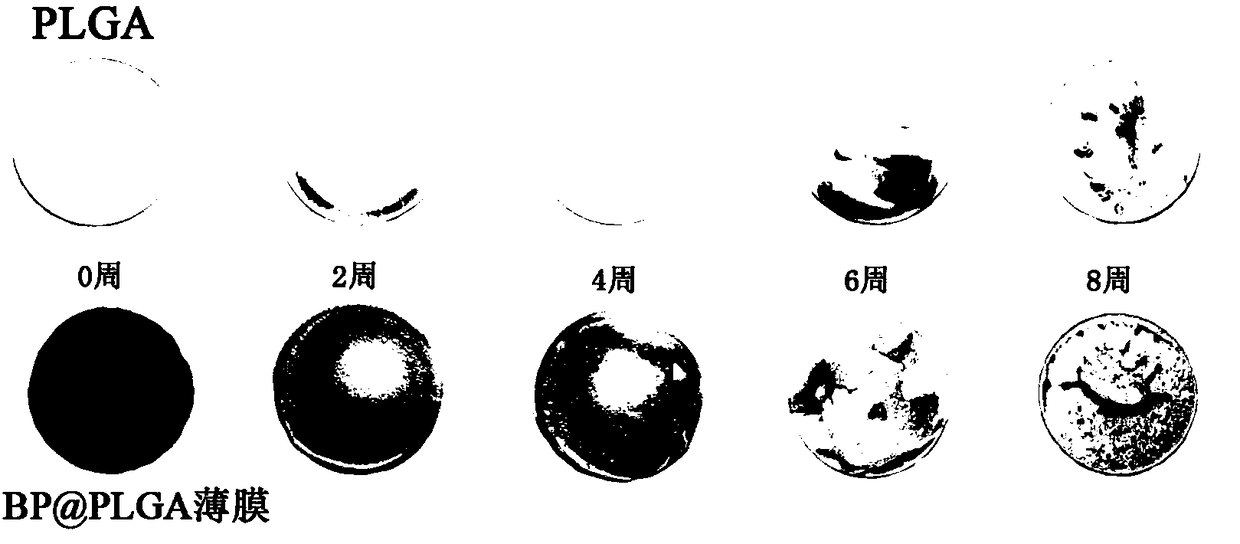

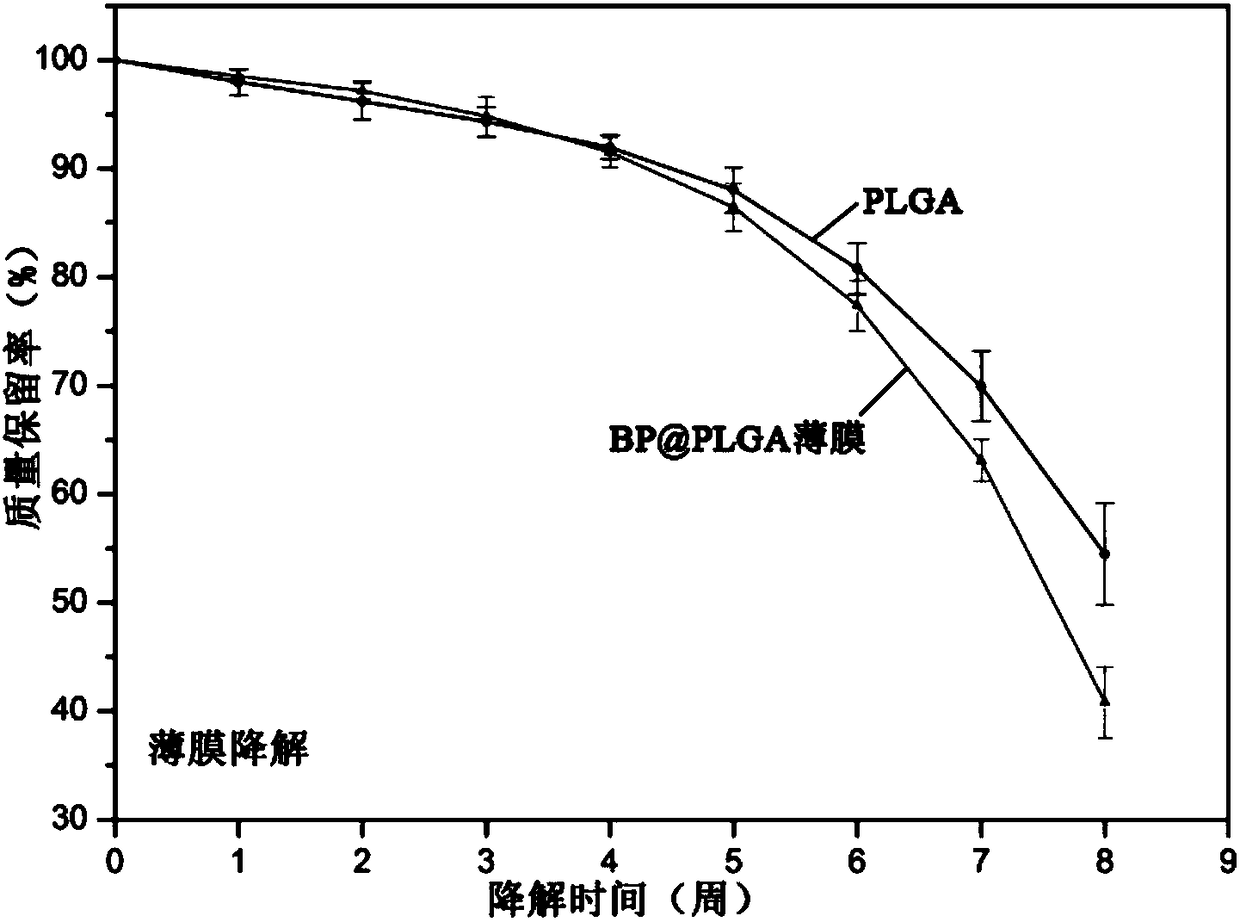

Bone implant material as well as preparation method and application thereof

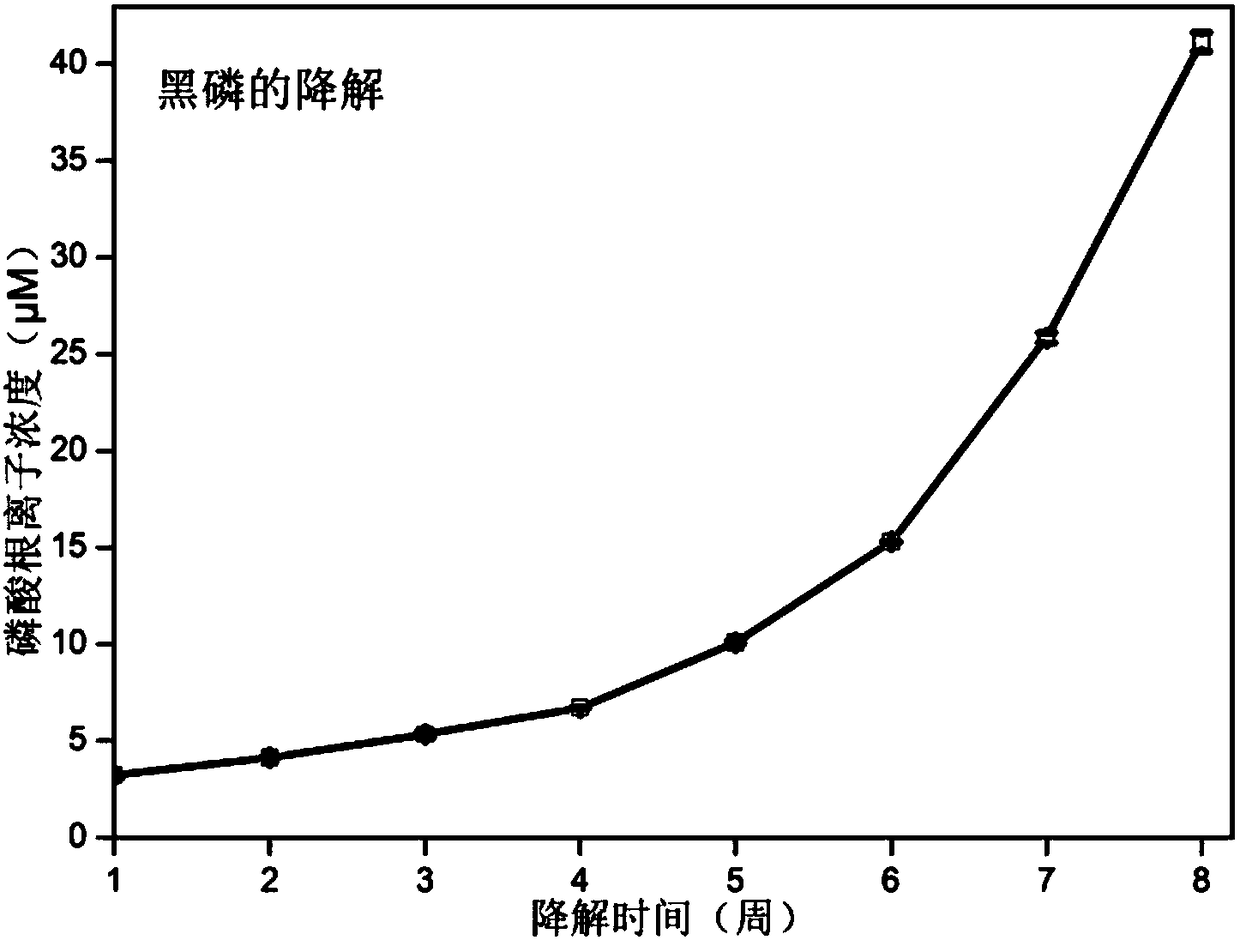

ActiveCN108066815AImprove efficiencyGood curative effectEnergy modified materialsTissue regenerationBone implantBlack phosphorus

The invention provides a bone implant material as well as a preparation method and application thereof. The preparation method of the bone implant material comprises the following steps: carrying outultrasonic dispersion on black phosphorus and dissolving into a first solvent to obtain dispersion liquid A; dissolving a high polymer material into a second solvent to obtain a solution B; mixing thedispersion liquid A with the solution B and carrying out ultrasonic treatment to obtain a solution of a uniformly-dispersed BP@ high polymer material; injecting the solution into a mold for molding or carrying out three-dimensional printing and molding, and volatilizing the solvent to obtain the bone implant material. The bone implant material has photothermal osteogenesis promoting function andcan be degraded in the physiological environment; when the bone implant material as an implant for a bone defect filling part is applied to clinical treatment of bone defect, the efficiency of promoting osteogenesis with heat by penetrating through biological tissues through near infrared can be improved; besides, the bone implant material also can be combined with clinical physiotherapy so as tobetter promote the healing effect of the bone defect; meanwhile, a biodegradable product of the bone implant material is essential for a human body and can participate in bone healing and regenerationprocess.

Owner:SHENZHEN INST OF ADVANCED TECH

Foaming agent for shield

The invention discloses a foaming agent for a shield. The foaming agent contains the components in percentage by weight: 1.0-10.0% of alpha-olefin sulfonate (AOS), 1.0-8.0% of sodium fatty alcohol -polyoxyethyleneether sulfate (AES), 1.0-6.0% of ammonium lauryl sulfate (K12 ammonium), 1.0-6.0% of cocoanut fatty acid diethanolamide (6501), 1.0-5.0% of dodecyl dimethyl betaine (BS-12), 0.005-0.1% of fluorocarbon surfactant (FS), 0.2-5.0% of sodium nitrilo triacetate (A92R), 0.2-5.0% of ethylene diamine tetraacetic acid disodium salt (EDTA) and the balance of water. The foaming agent for the shield provided by the invention realizes high multiple foaming rate, long foam stabilizing time, nontoxicity and innocuity and is an environment friendly biodegradable product which does not contain phosphorus.

Owner:GUANGZHOU TAISHENG BIOTECH

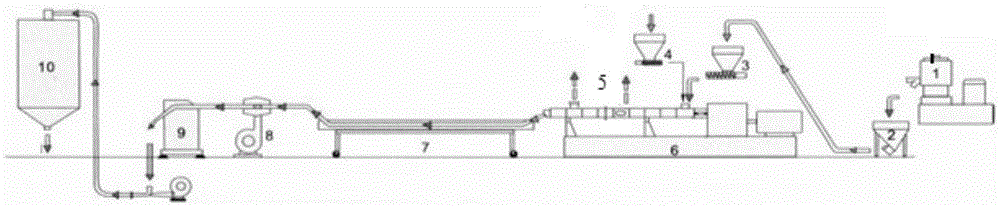

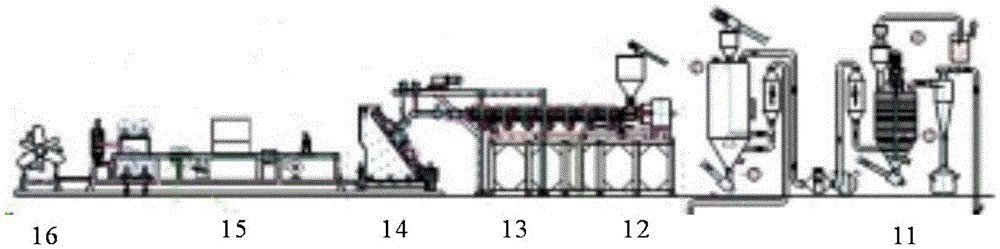

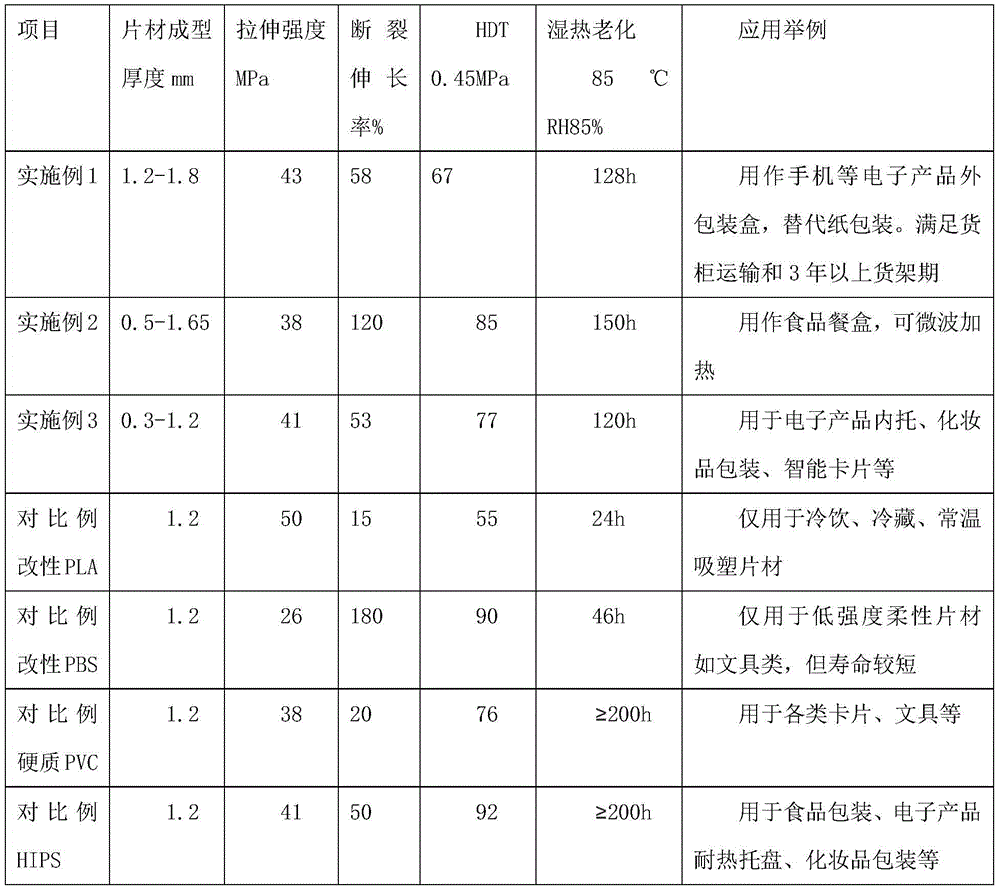

Biodegradable heat-resistant sheet and preparation method thereof

The invention provides a biodegradable heat-resistant sheet and a preparation method thereof. The biodegradable heat-resistant sheet is prepared from, by weight, 20-50% of polylactic acid, 35-55% of PBS, 0-10% of polyester, 1-25% of nucleation enhancer, 0.5-5% of an auxiliary and 0-0.5% of an anti-UV agent. The biodegradable heat-resistant sheet and the preparation method solve the problems that existing polylactic acid sheets are high in brittleness, not resistant to heat, high in sheet rolling cost, narrow in application range and the like. The biodegradable sheet is low in cost, can be efficiently produced, has good physical and mechanical properties, machinability and heat resistance, and can be widely applied to the fields such as electronic products, cosmetics and disposable heat-resistance articles. The application range of biodegradable products is widened.

Owner:SHENZHEN GREENNATURE BIODEGRADABLE TECH LTD

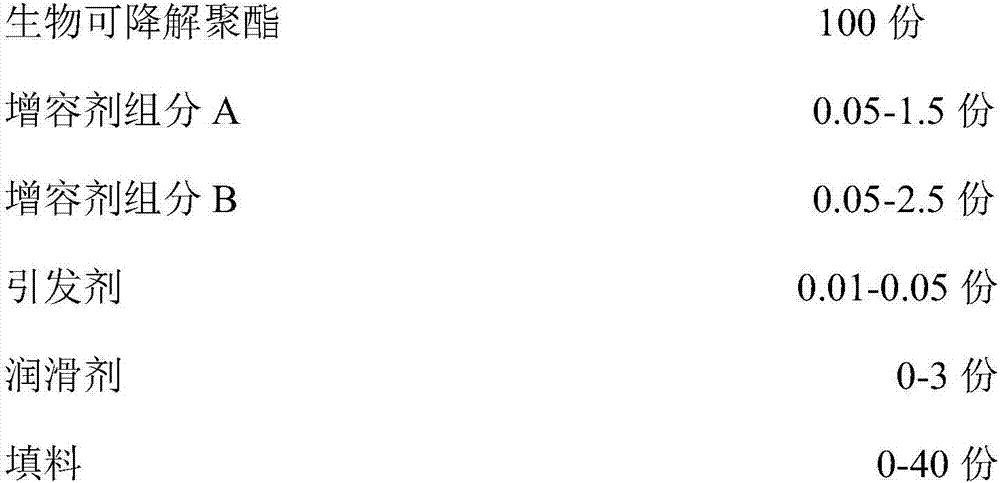

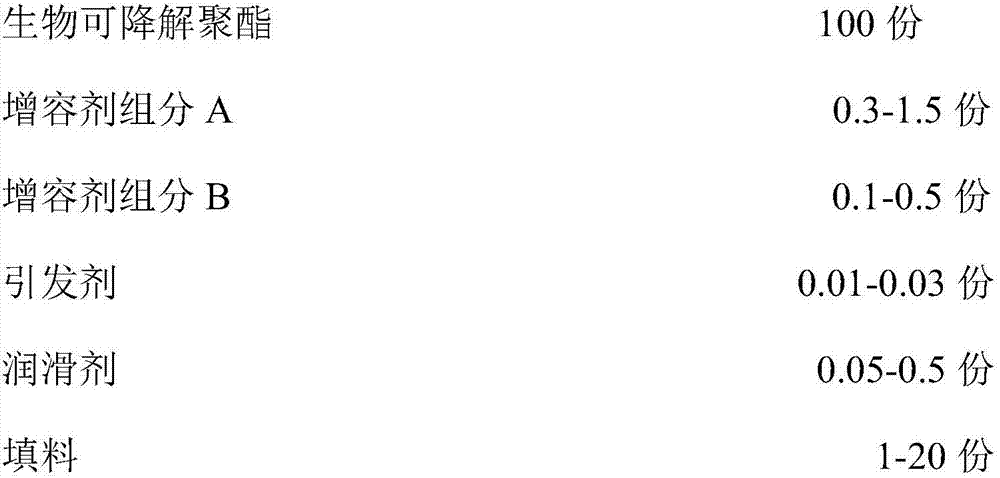

Biodegradable polyester alloy and preparation method thereof

The invention relates to a method for conveniently and economically realizing the preparation of an alloy by compounding two and more biodegradable polyesters. According to the invention, on the basis of a reaction extruding technique, a one-step method is adopted for charging, bifunctional small molecules and an initiator are directly mixed with the biodegradable polyester component, the polymerization of vinyl and the reaction of epoxy group and polyester molecule are realized in the twin-screw extruding process and the chain extension and compatibility are realized. A biodegradable polyester alloy comprises the following components in parts by weight: 100 parts of biodegradable polyester, 0.05-1.5 parts of compatibilizer component A, 0.05-2.5 parts of compatibilizer component B, 0.01-0.05 part of initiator, 0-3 parts of lubricant and 0-40 parts of filler. The polyester alloy provided by the invention has the advantages of adjustable performance, full biodegradable product, no small molecule residue and application in various fields, such as, films, wires and panels.

Owner:ZHEJIANG HISEA TECH CO LTD

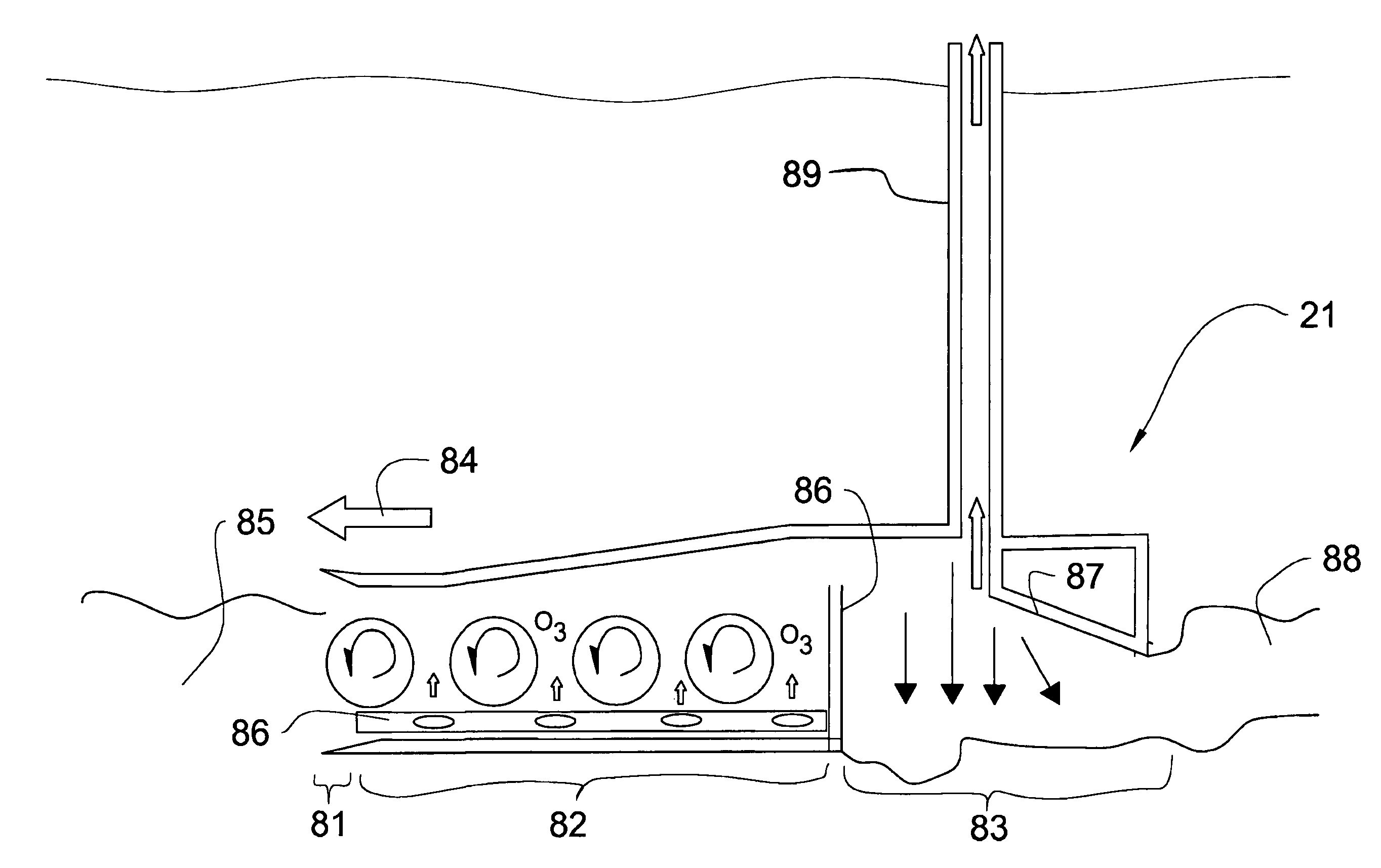

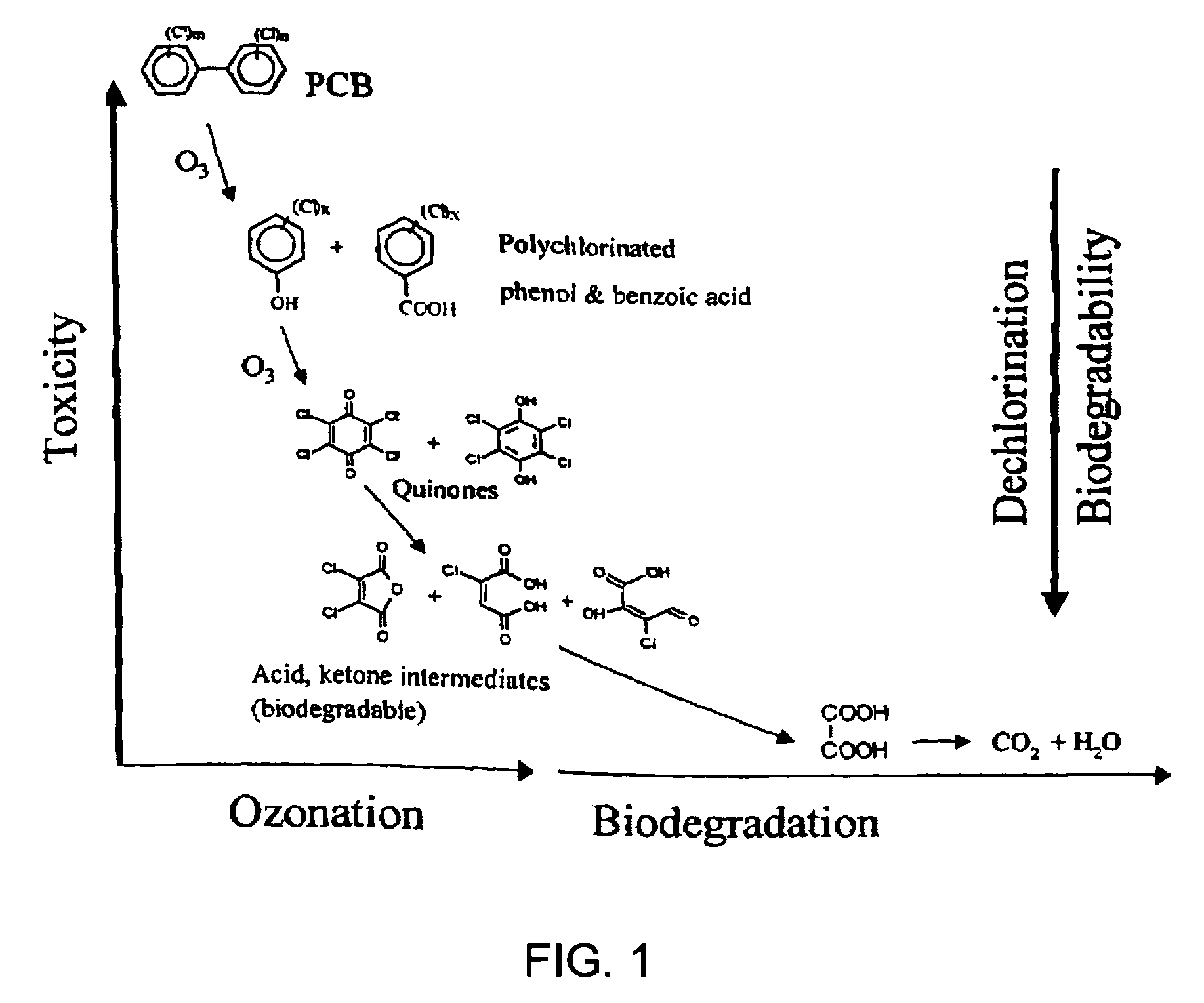

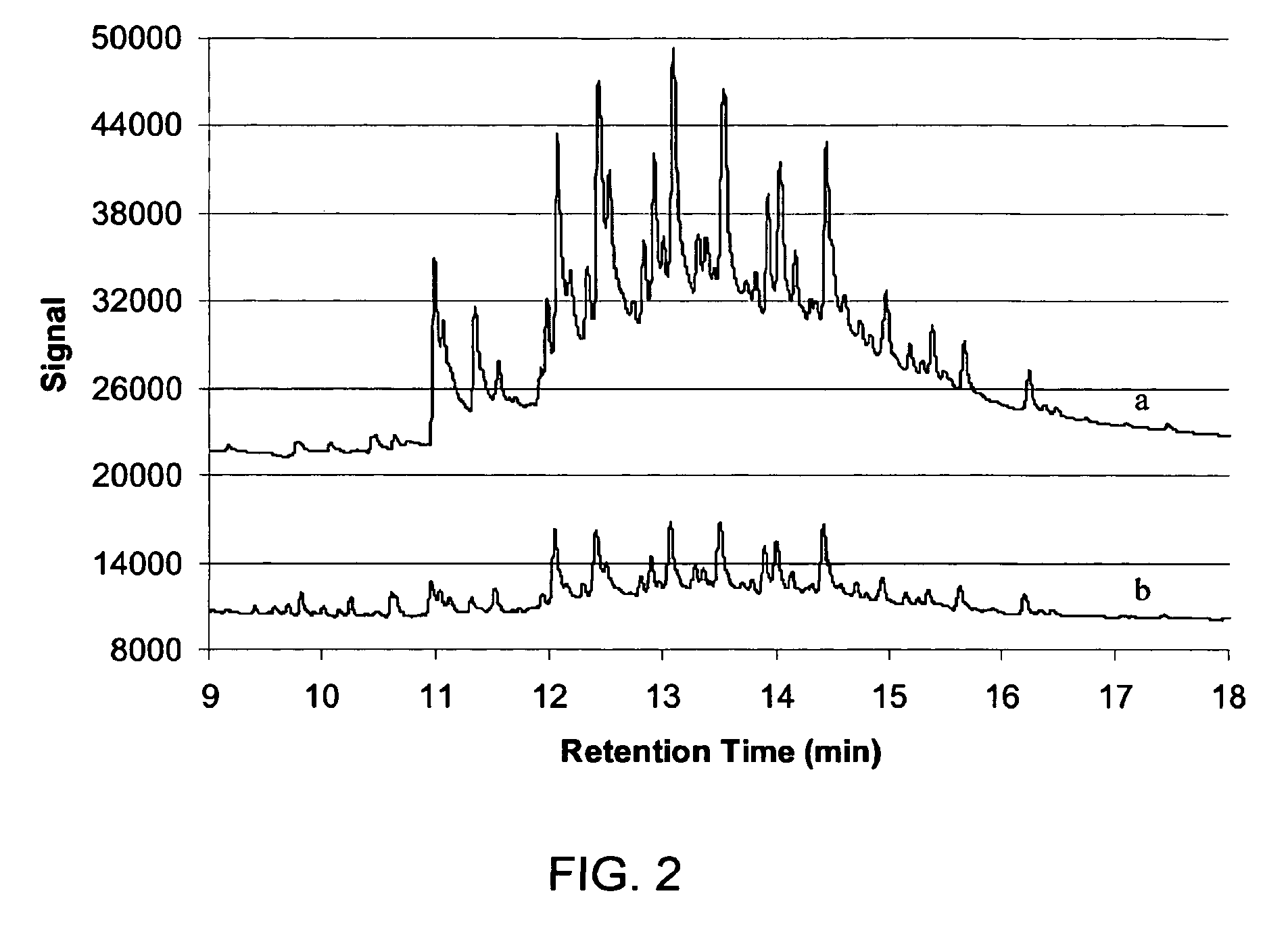

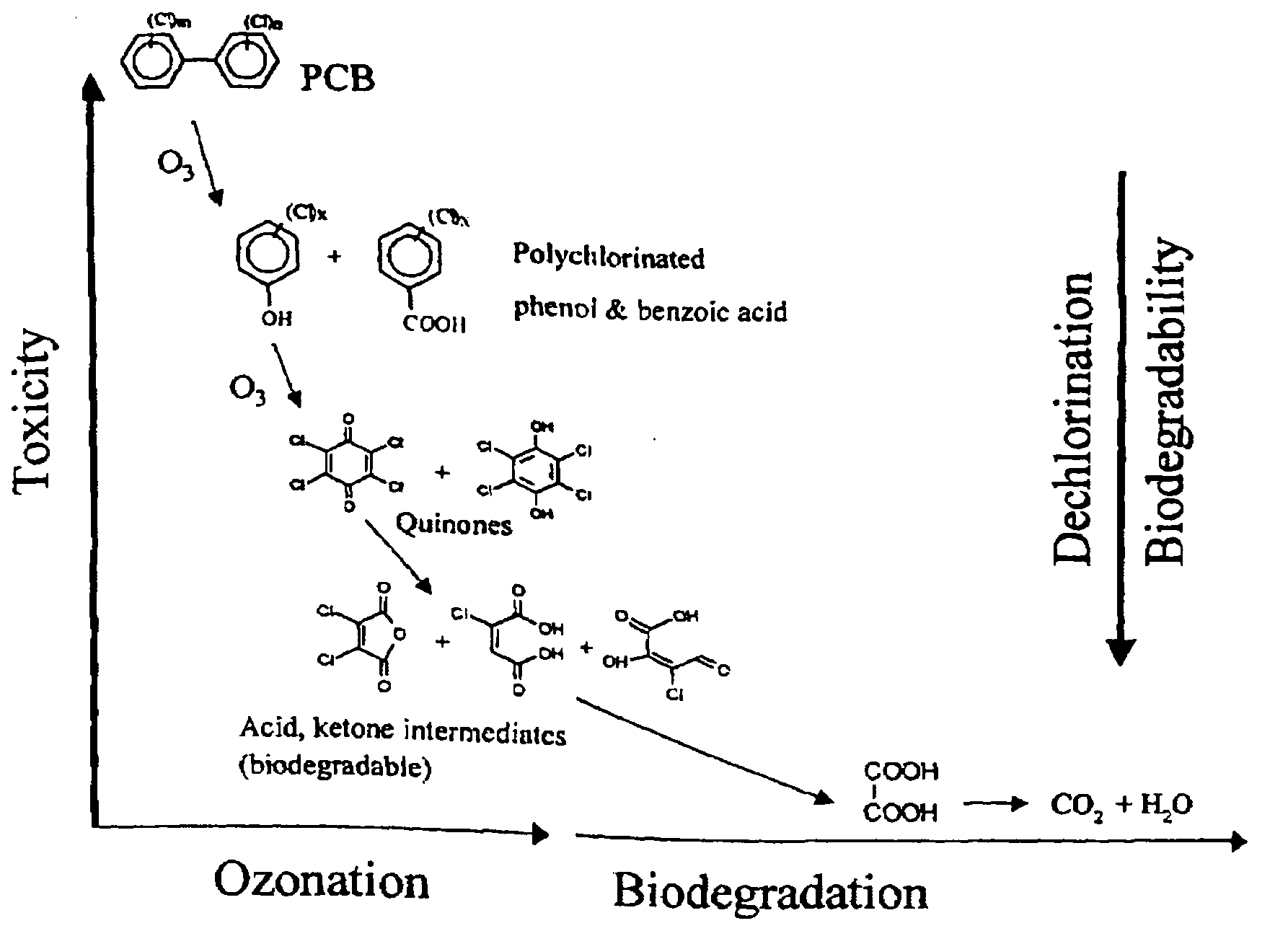

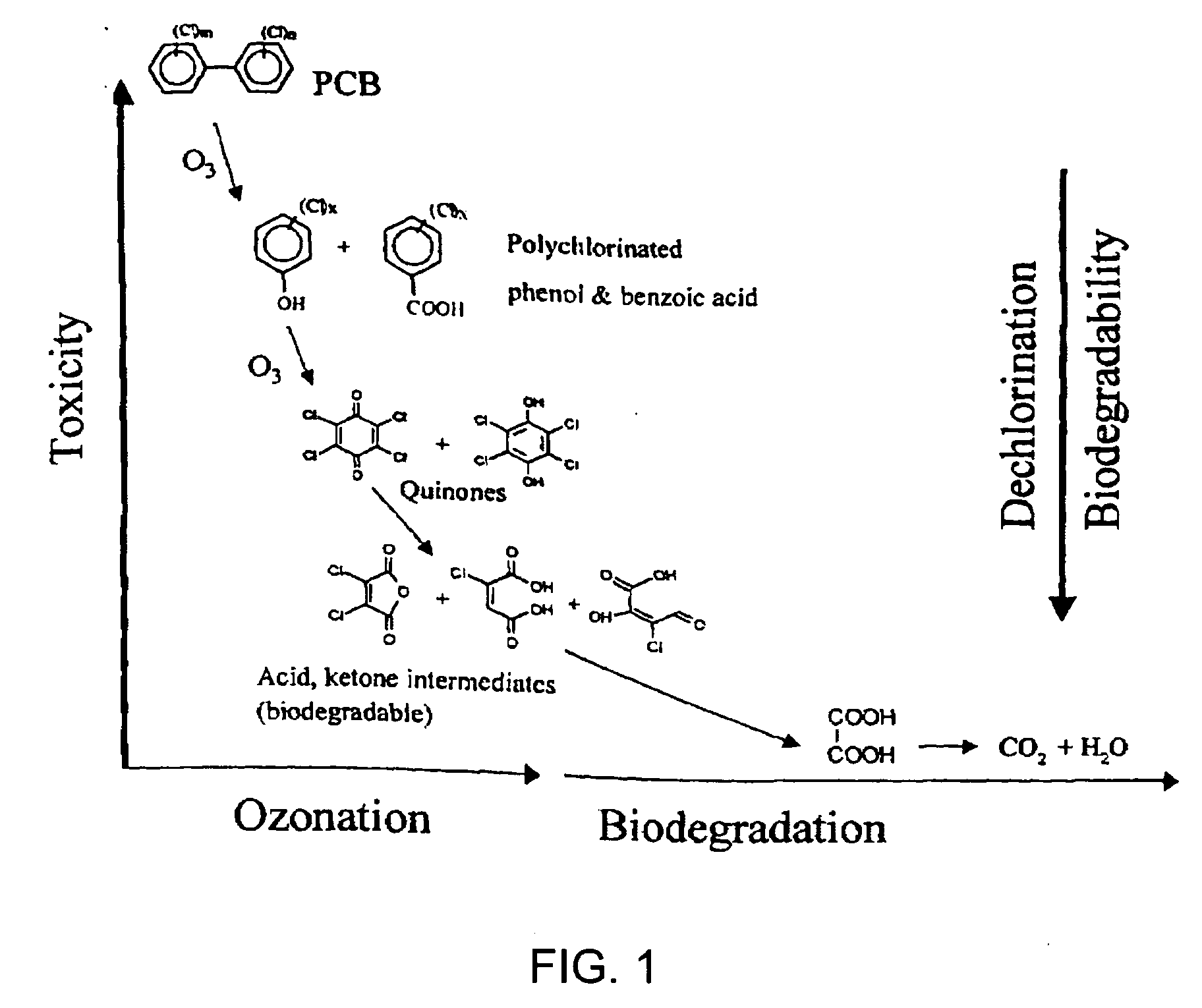

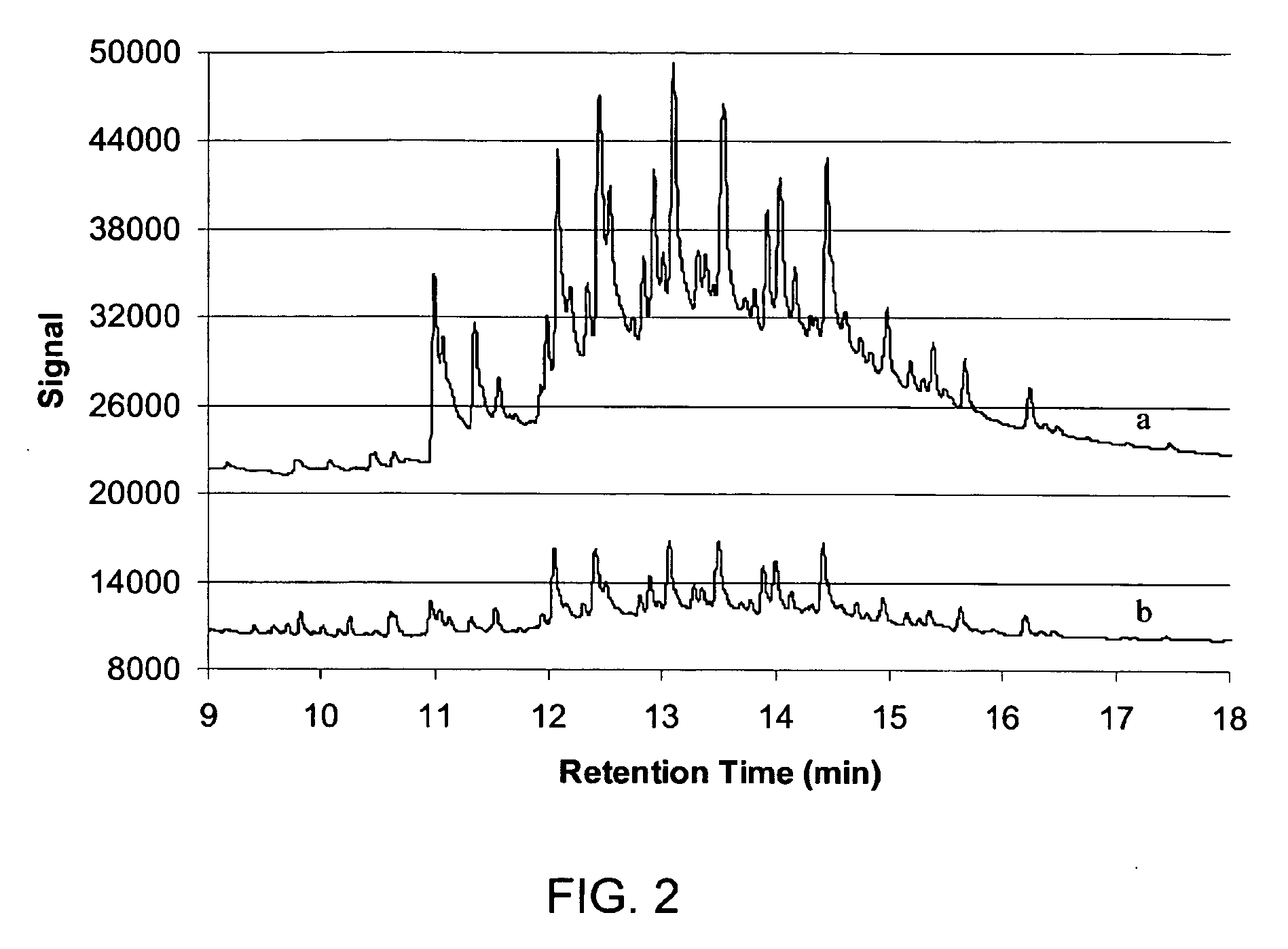

Remediation with ozone of sediments containing organic contaminants

InactiveUS20060027505A1Machines/dredgers working methodsTreatment using aerobic processesPolychlorinated biphenylBiodegradable product

A system for treating sediments contaminated with organic contaminants, such as polychlorinated biphenyls (PCBs) and other contaminants polyaromatic hydrocarbons (PAHs) and dichlorodiphenyltrichloroethane (DDT) includes treating the sediments with ozone to react the contaminants. The system is particularly effective for remediation of PCBs. In an in-situ system for remediating sediments in underwater sediment beds that are contaminated with (PCBs) and other contaminants, the contaminated sediments are treated with ozone with an ozonator conveyed over the sediment bed to mix the sediment with the ozone. The ozone reacts with the PCBs to form more reactive and biodegradable products. The treated sediment is then redeposited upon the sediment bed.

Owner:UNIV OF UTAH RES FOUND

Biodegradable resin compositions

InactiveUS20030079654A1Suitable for useLow costCosmetic preparationsAntifouling/underwater paintsBiodegradable productDigestion

The present invention provides a biodegradable resin composition with improved biodegradability or with an additional useful function (antibacterial properties), while maintaining the mechanical properties of the biodegradable resin. More specifically, the present invention provides a biodegradable resin composition containing a biodegradable resin such as a polylactic acid polymer and a mamman digestion product such as a mannooligosaccharide. The present invention further provides various biodegradable products produced by molding this biodegradable resin composition into desired shapes.

Owner:NAT INST OF ADVANCED IND SCI & TECH +2

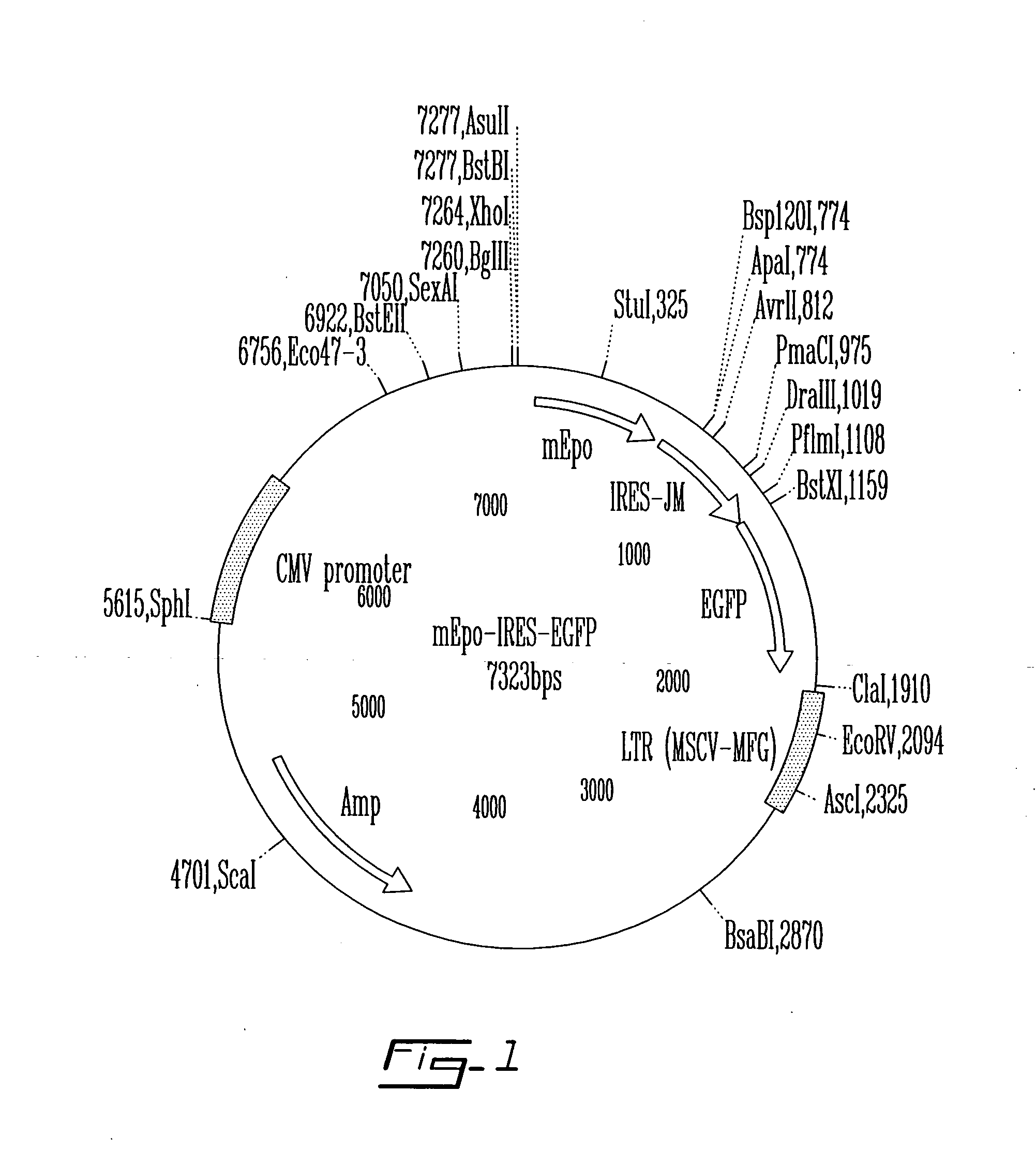

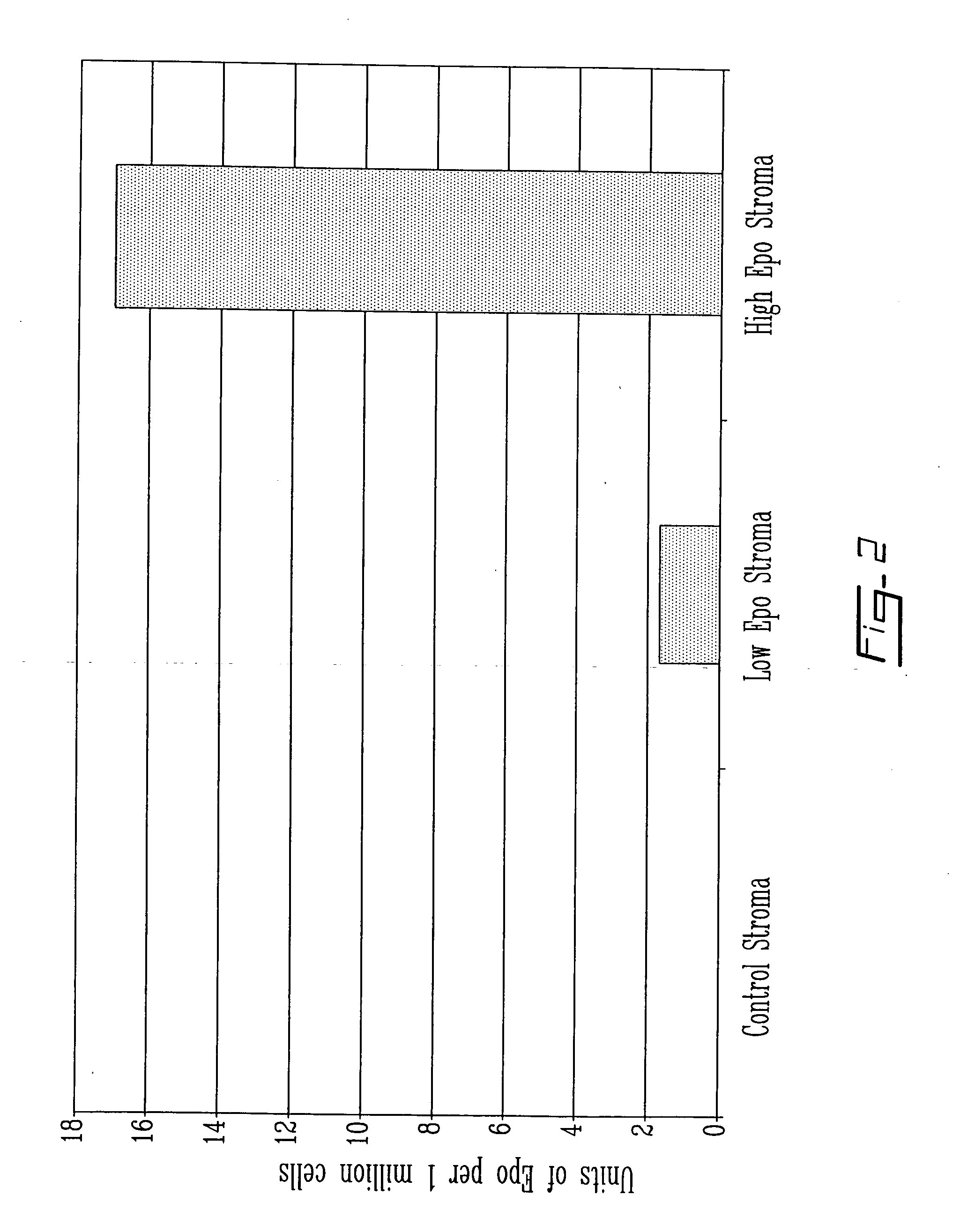

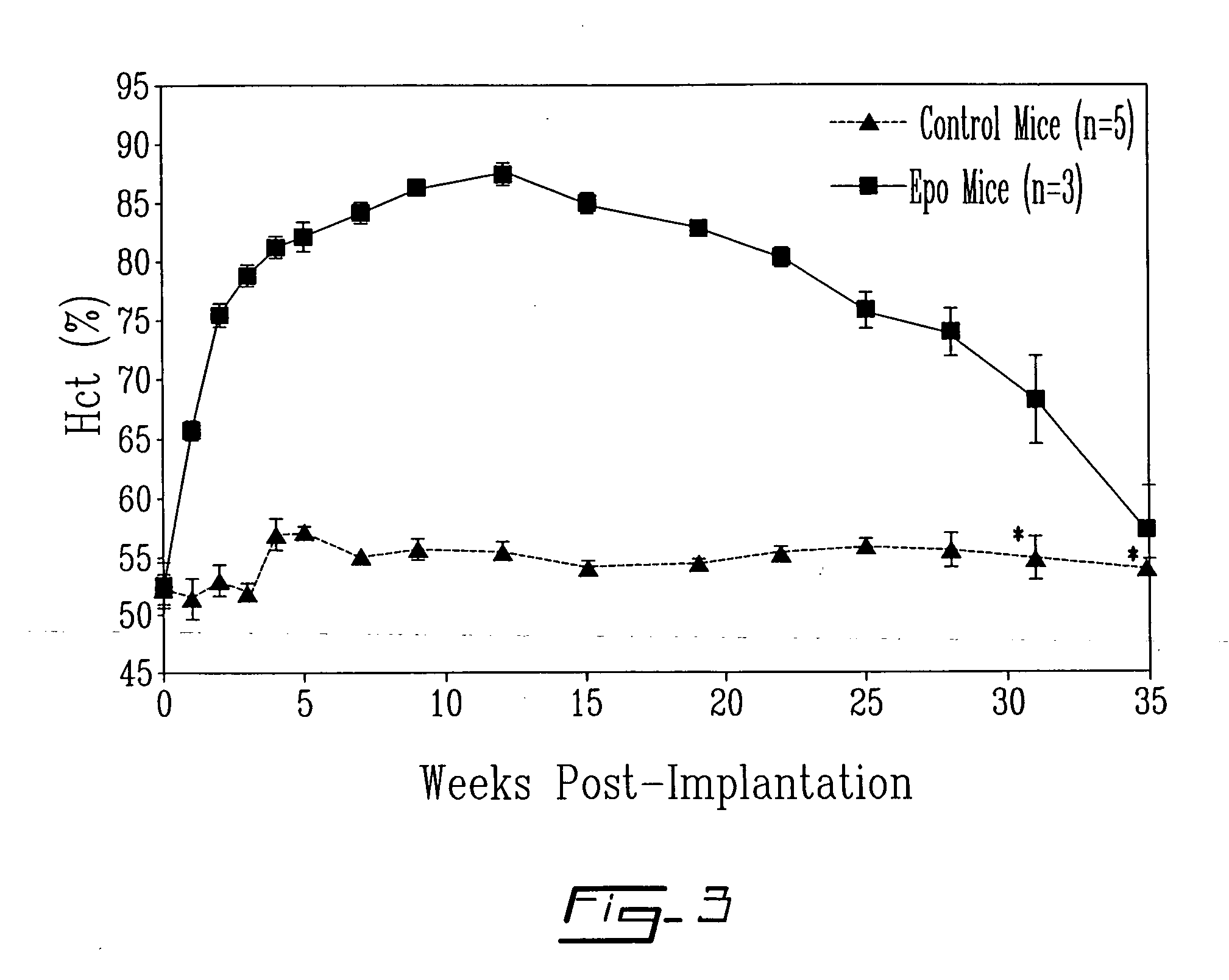

Cultured stromal cells and uses thereof

The present invention relates to genetically-engineered bone marrow stromal cells and method of preparation thereof for ex vivo delivery of protein and peptides of interest into human or animals. The method includes forming a bone marrow stromal cell expression system in vitro and administering the expression system to a human or animal recipient. The invention relates also to implants colonized by bone marrow stromal cells. In accordance with the invention, the implants comprise a matrix which can be composed of a large variety of biocompatible and biodegradable products, and stromal cells which are integrated into the matrix as such or under genetically-engineered forms. Genetically-engineered bone marrow stromal cells or cell colonized implant are also useful for tissue repair and tissue synthesis, as for angiogenesis.

Owner:CENT FOR TRANSLATIONAL RES & CANCER

Absorbent composition of matter for controlled release of essential oils

InactiveUS7247377B2Cosmetic preparationsSoap detergents with other compounding agentsAdditive ingredientControl manner

Owner:JASSAN GENARO CASAS +1

Biodegradable film and preparation method thereof

The invention provides a biodegradable film and a preparation method thereof, which belongs to the field of biodegradable polymer materials. The biodegradable film takes terephthalic acid, oxalic acid and 1,4 butanediol copolyester as base materials, and after thermoplastic starch, modified nano-silica and other raw materials are added, a blown film produced is a fully biodegradable product and can be decomposed by microorganisms in a specific environment. The biodegradable film also has moisture resistance as well as high tensile strength, toughness and hardness, and can resist oil, moisture and temperature change. The biodegradable film can be widely used in a plurality of industries as a daily packaging film, a vest bag, a food packaging bag and the like, and plays an extremely important role in protecting environment and resources. Tests prove that packing materials made from the base materials or blends containing the base materials can be completely decomposed and only need four weeks to be thoroughly decomposed under composting conditions with no residue. The preparation method of the biodegradable film has the advantages of simple process, easy control and suitability for industrial production.

Owner:林存革

Absorbent composition of matter for odoriferouse substances and releaser of diverse active ingredients and articles incorporating same

InactiveUS7163737B2Efficiently and economicallyEasily disposableCosmetic preparationsLayered productsBiodegradable productBULK ACTIVE INGREDIENT

A new product is described characterized by its qualities to absorb undesirable scents present in the air, while serving at the same time as a carrier for aromas, fragrances, flavorings, repellents, attractants and other active ingredients. The active ingredients are gradually released by the carrier, which is compatible with the environment and current tendencies towards the use of organic and biodegradable products. The composition comprises a carrier and an active ingredient. The carrier is characterized as being particles obtained from the milling, separation, air wash and classification of the different fractions obtained from corncobs. An article of manufacture and a method of making the article containing the absorbent composition of matter is also disclosed.

Owner:APROA ASESORES S C

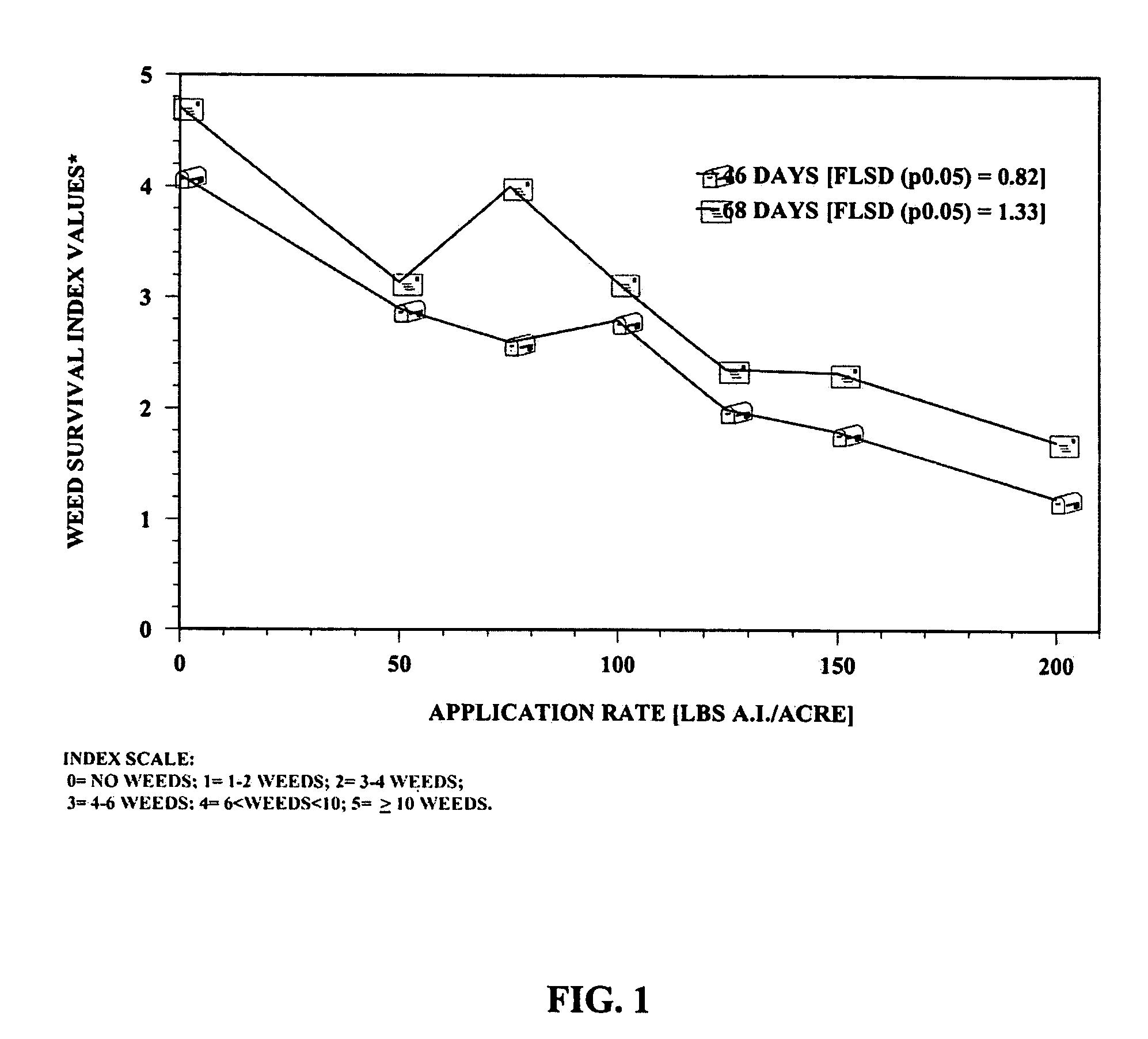

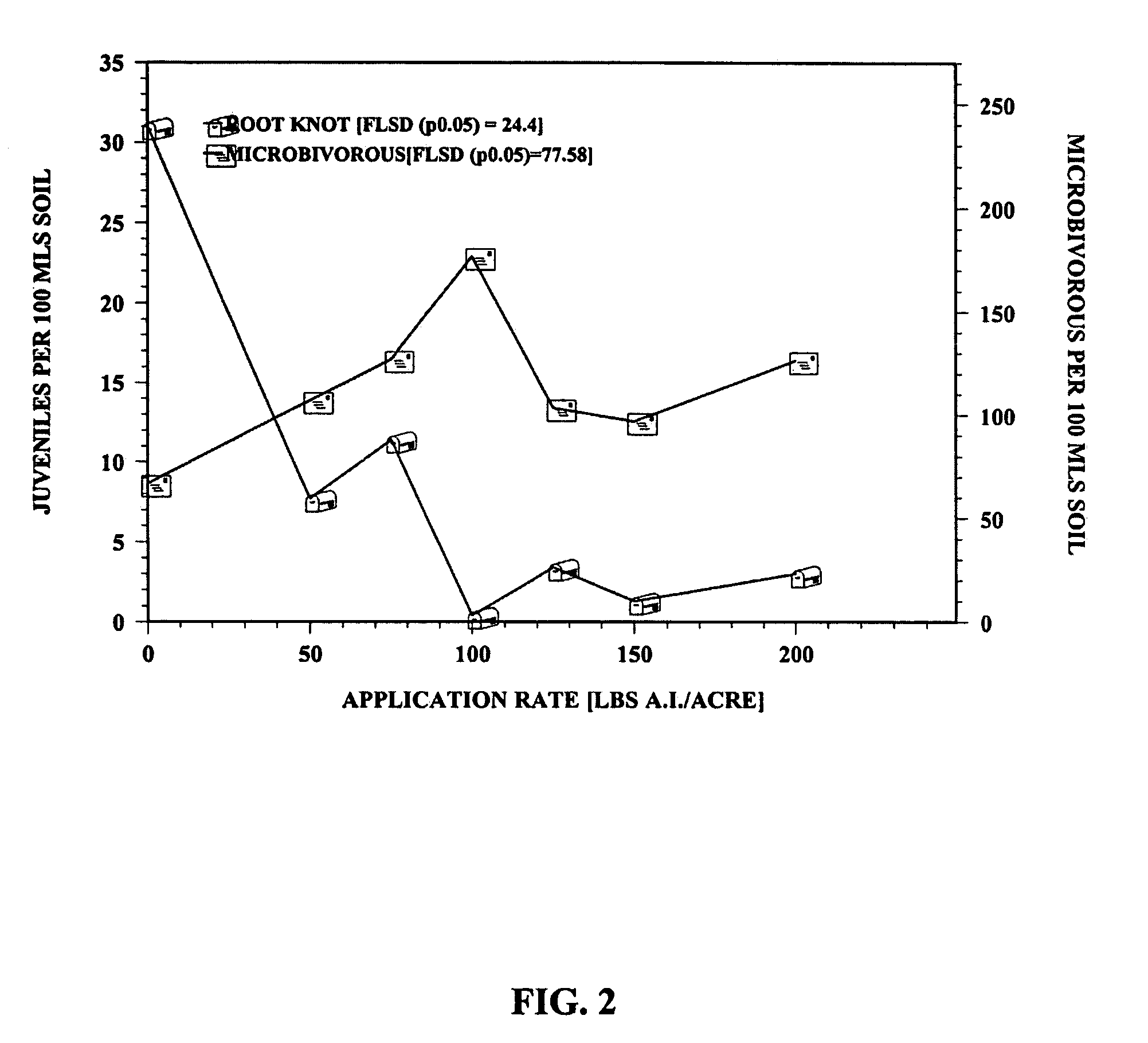

Absorbent composition of matter for controlled release of essential oils

InactiveUS20060078733A1Increase the scope of applicationPromote resultsSoap detergents with organic compounding agentsCosmetic preparationsAdditive ingredientControl manner

An absorbent composition of matter acts as a carrier for an active ingredient. The active ingredient is gradually released by the carrier in a controlled manner, which is compatible with the environment and current tendencies towards the use of organic and biodegradable products. The carrier is characterized as being particles obtained from the milling, separation, air wash and classification of the different fractions obtained from corncobs. The active ingredient is, for example, an essential oil, such as garlic oil or extract that may be combined with other essential oils for a synergistic effect that results in an improved insecticide / fungicide that is natural and contains no chemical additives. Alternatively, an artificially obtained substitute, for example, allyl isothiocyanate (AITC), can be used as a substitute for mustard seed oil.

Owner:JASSAN GENARO CASAS +1

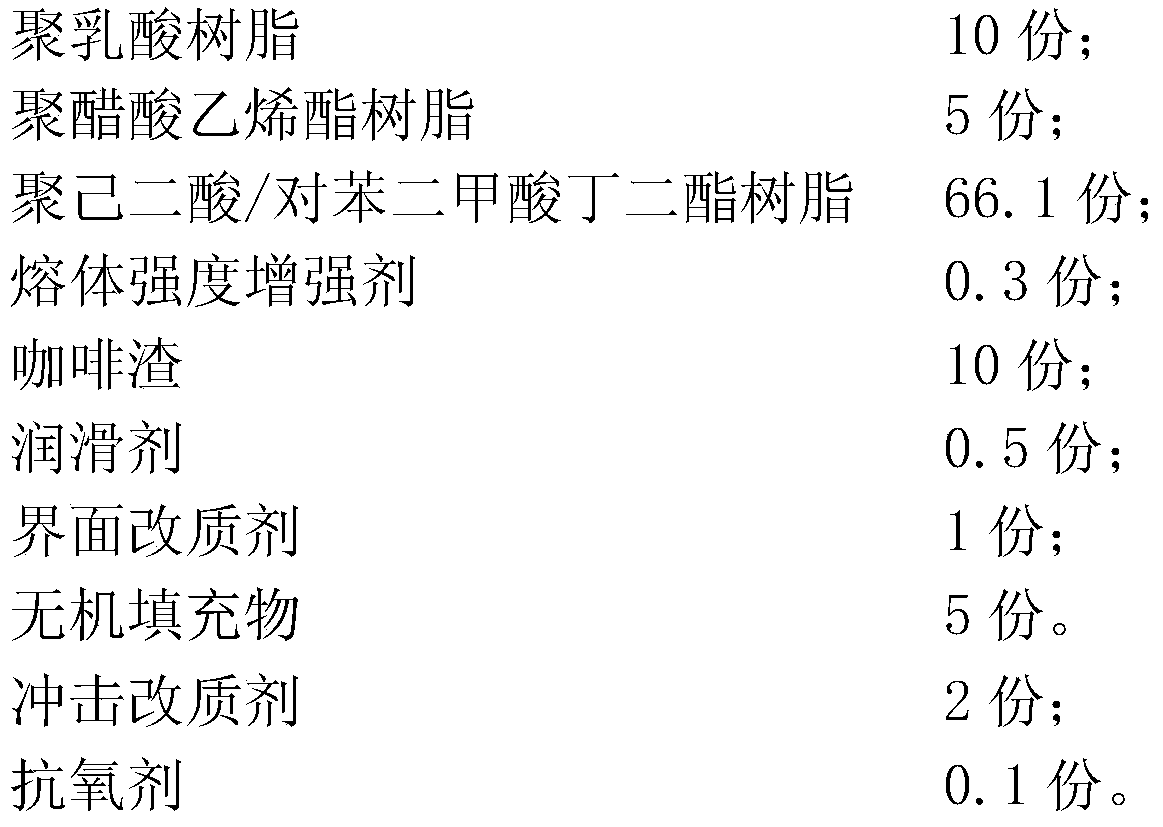

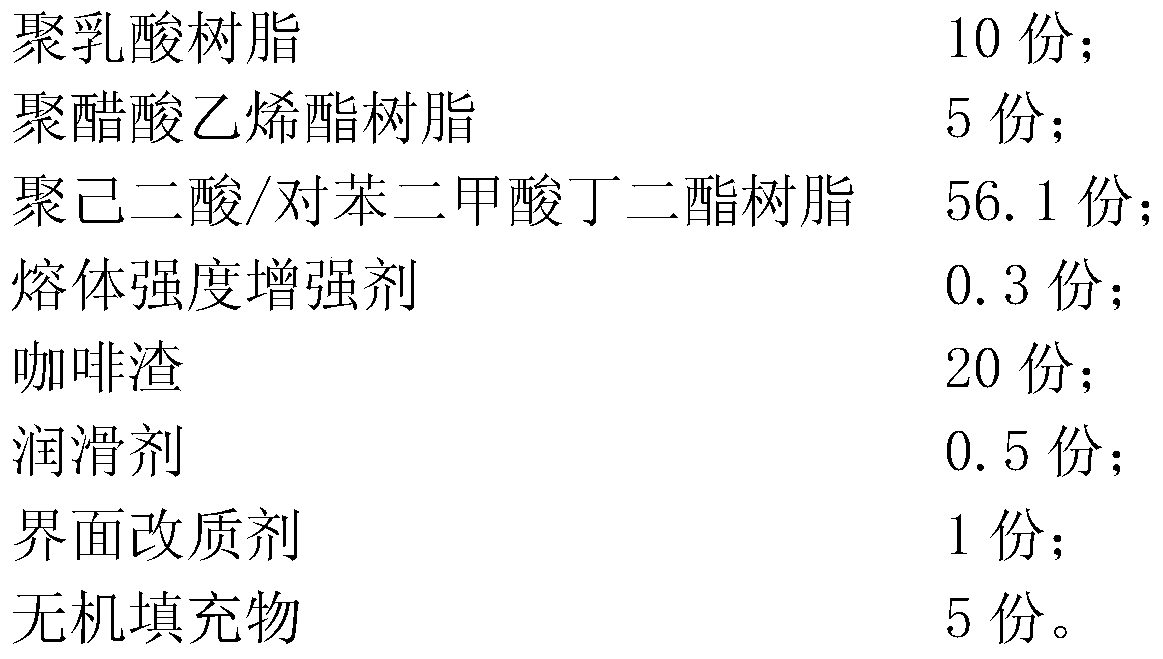

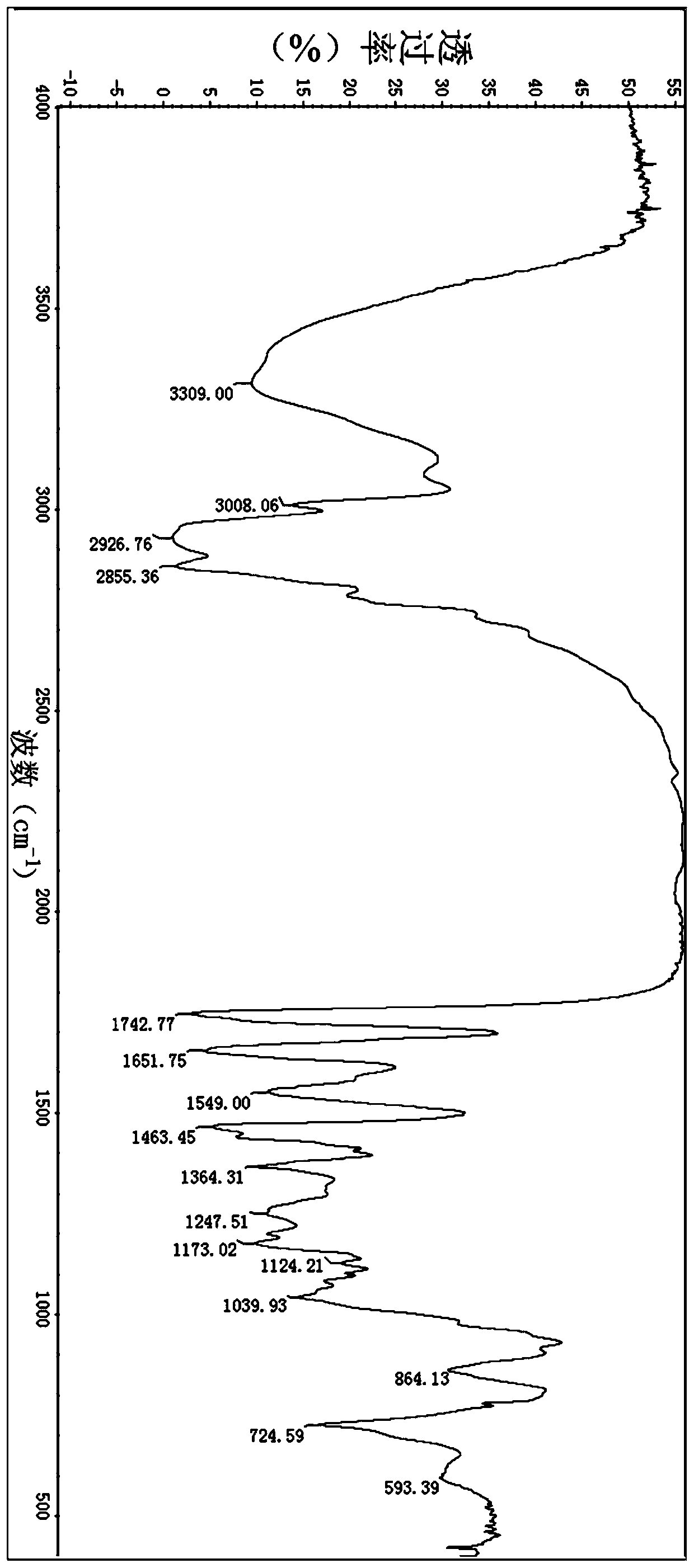

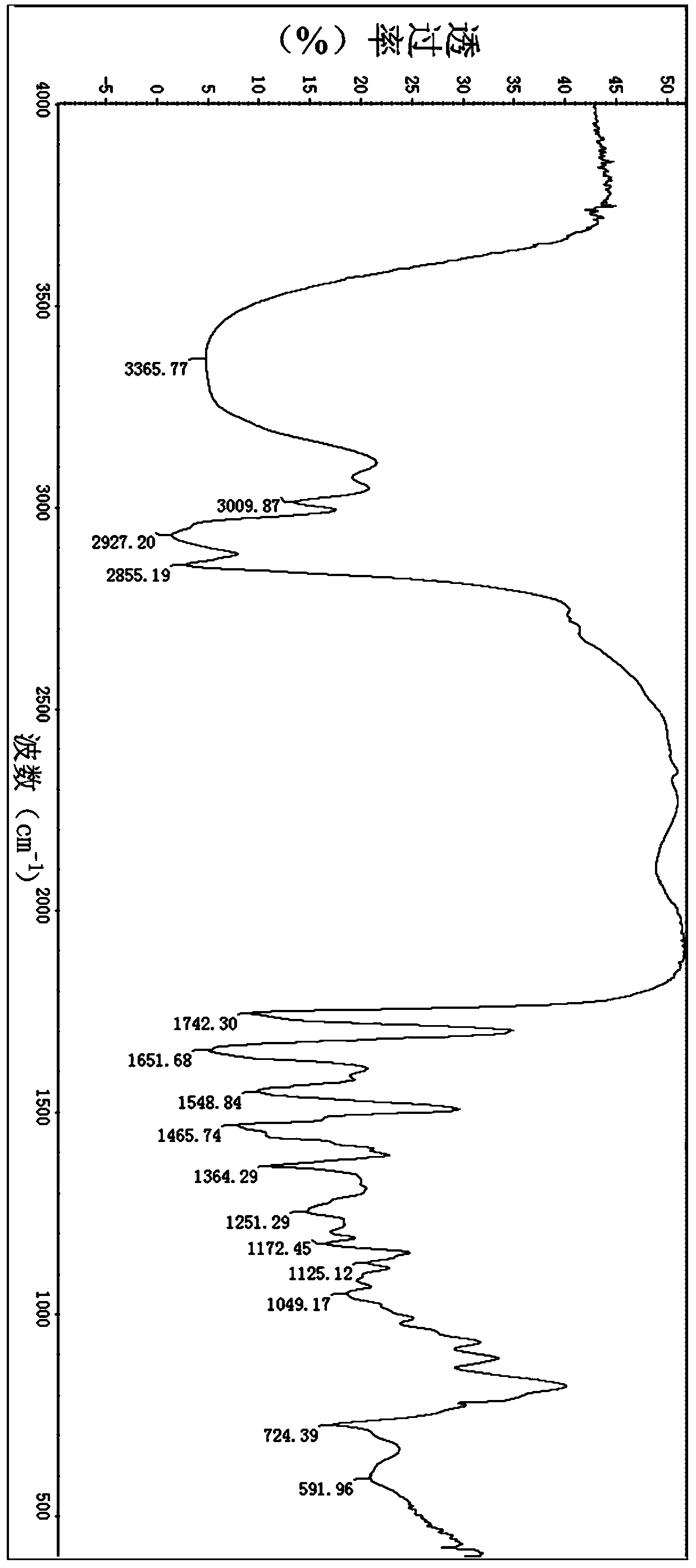

Biodegradable product and preparation method thereof

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

Grain protein-based formulations and methods of using same

Shelf stabilizing agents including hydrolyzed protein, hydrolyzed protein derivatives, and hydrolyzed protein-emulsifier complexes improve the shelf life of a pelletized grain protein-based resin formulation. The pellets may be prepared well in advance of further processing, such as by injection molding and extrusion, which provides shaped articles of the edible or biodegradable variety.

Owner:MGP INGREDIENTS

Slurry of agricultural fibres and its products

Environmental friendliness and biodegradability are important considerations of disposable materials, be it packaging or paper, in order to minimize environmental damage. The present invention relates to a method of producing environmental friendly and biodegradable products using mechanically processed agricultural fibres and rightly formulated adhesive. In particular, mechanical treatment takes place in a pressure vessel under hydrothermal conditions using superheated steam. Treated agricultural fibres are mixed with stoichemtric amount of adhesive, through vigorous agitation, a well furnished agricultural fibre slurry is obtained and ready to be fed into manufacturing process to produce, in this invention, moulded shape bodies and paper liners. Unlike synthetic resin, the said adhesive formulation is biodegradable and made of natural renewable resources. The said adhesive has self-retention property. The agricultural fibre slurry can be easily made into moulded products and paper liners using commonly available processes.

Owner:GRENIDEA TECH PTE

Absorbent composition of matter for odoriferouse substances and releaser of diverse active ingredients and articles incorporating same

InactiveUS20040078048A1Cosmetic preparationsToilet preparationsBiodegradable productBULK ACTIVE INGREDIENT

A new product is described characterized by its qualities to absorb undesirable scents present in the air, while serving at the same time as a carrier for aromas, fragrances, flavorings, repellents, attractants and other active ingredients. The active ingredients are gradually released by the carrier, which is compatible with the environment and current tendencies towards the use of organic and biodegradable products. The composition comprises a carrier and an active ingredient. The carrier is characterized as being particles obtained from the milling, separation, air wash and classification of the different fractions obtained from corncobs. An article of manufacture and a method of making the article containing the absorbent composition of matter is also disclosed.

Owner:APROA ASESORES S C

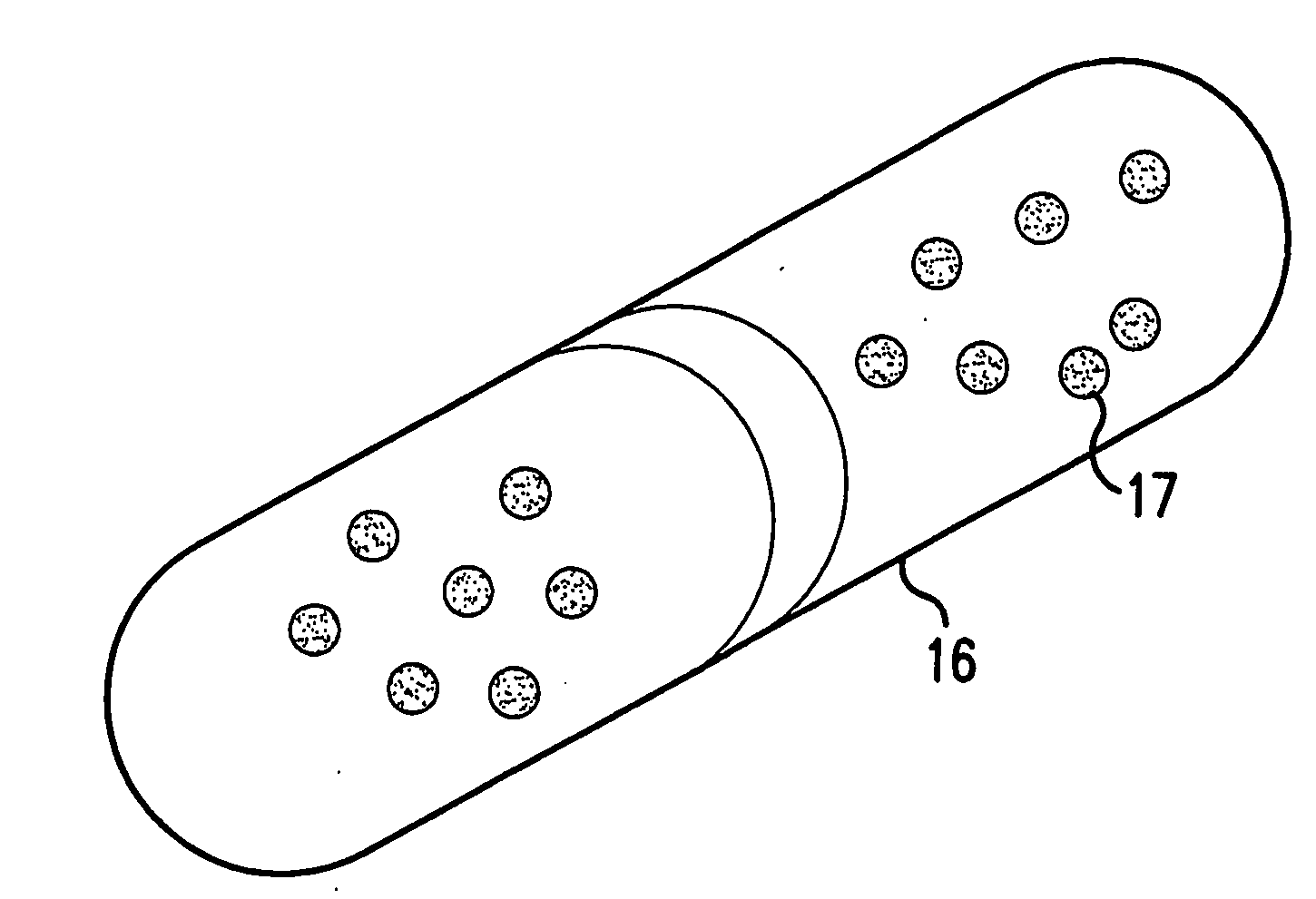

Method for Bioremediation and Biodegradable Product Therefor

A product for bioremediation, comprising a biodegradable carrier and a tablet or powder consisting essentially of microorganisms capable of digesting hydrocarbons, an inert material, and optionally trace oil in an amount sufficient to maintain the microorganisms in a dormant state, said microorganisms located entirely within said biodegradable carrier, and wherein the biodegradable carrier is directly in contact with the microorganisms.

Owner:YOUNG WILLIAM I

Remediation with ozone of sediments containing organic contaminants

InactiveUS20050087499A1Machines/dredgers working methodsMechanical machines/dredgersBiodegradable productDDT (Insecticide)

A system for treating sediments contaminated with organic contaminants, such as polychlorinated biphenyls (PCBs) and other contaminants polyaromatic hydrocarbons (PAHs) and dichlorodiphenyltrichloroethane (DDT) includes treating the sediments with ozone to react the contaminants. The system is particularly effective for remediation of PCBs. In an in-situ system for remediating sediments in underwater sediment beds that are contaminated with (PCBs) and other contaminants, the contaminated sediments are treated with ozone with an ozonator conveyed over the sediment bed to mix the sediment with the ozone. The ozone reacts with the PCBs to form more reactive and biodegradable products. The treated sediment is then redeposited upon the sediment bed.

Owner:THE UNIV OF UTAH

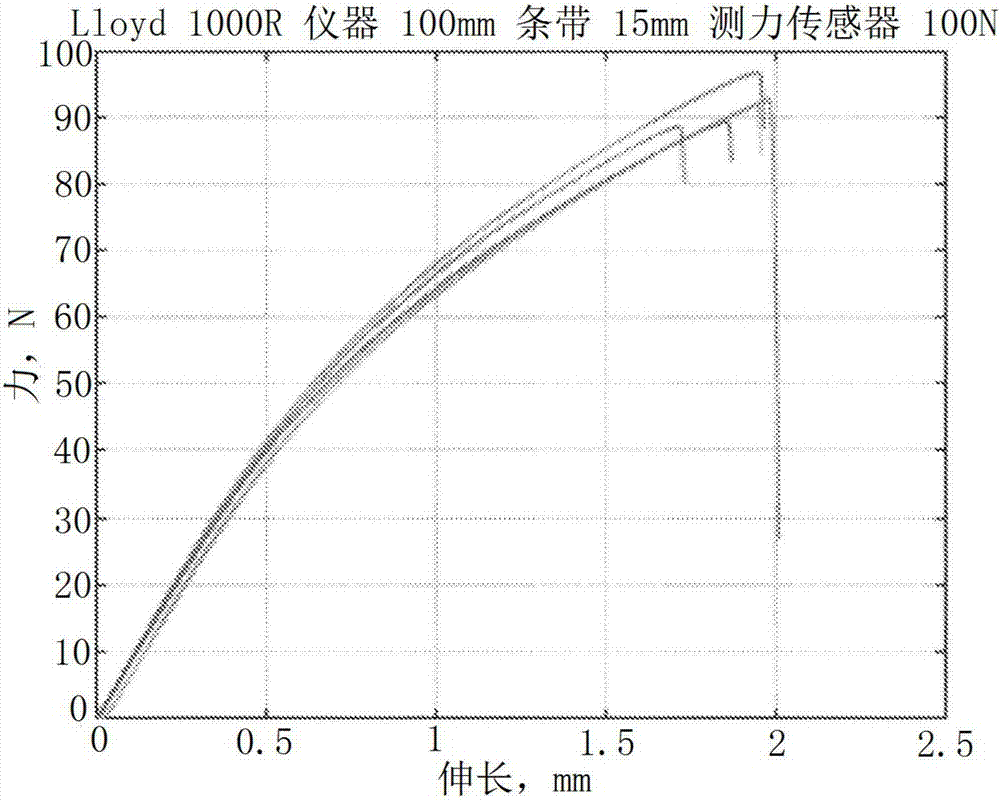

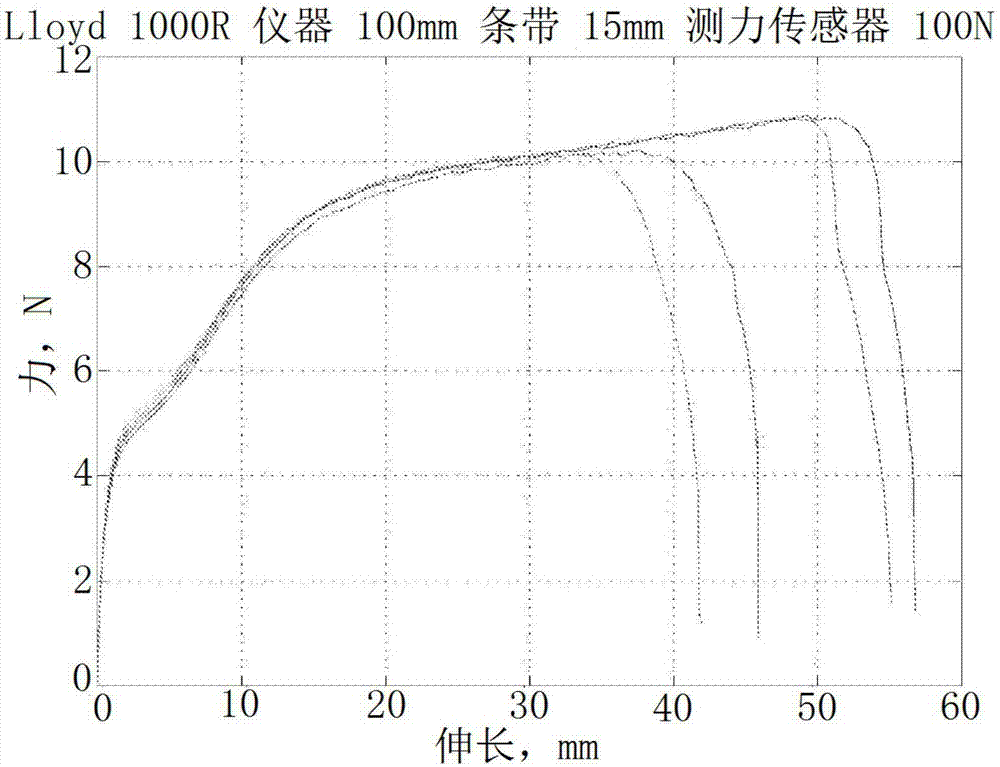

Biodegradable fat-aromatic copolyester with low carboxyl content and multi-branched chain structure, and preparation method and application thereof

The embodiment of the invention provides a biodegradable fat-aromatic copolyester with low carboxyl content and a multi-branched-chain structure, and a preparation method and an application thereof, and relates to the technical field of high polymer materials. Polymeric monomers comprise: at least one selected from C2-C36 aliphatic dibasic acids and derivatives thereof; at least one selected fromC6-C20 aromatic diacids and derivatives thereof, and heterocyclic diacids and derivatives thereof; at least one selected from C2-C20 diols; at least one selected from polyols, polybasic organic acidsand derivatives thereof; and at least one selected from organic single acids with a boiling point of not less than 200 DEG C under normal pressure. The biodegradable fat-aromatic copolyester is prepared by mixing the polymerization monomers and then carrying out esterification or ester exchange and condensation polymerization reactions, the carboxyl content of the copolymer is less than or equal to 15 mmol / kg, and the weight-average molecular weight is greater than or equal to 100,000; and the production cost is low, and the product has good biodegradability, aging resistance, excellent mechanical properties and processability and can be used for preparing various biodegradable products.

Owner:戴清文

Preparation method of oxidation-biodegradable shopping bag

PendingCN107353481APerformance is not affectedSimple preparation processBag making operationsFlexible containers manufactureFiller ExcipientBiodegradable product

The invention belongs to the technical field of degradable plastic and in particular relates to a preparation method of an oxidation-biodegradable shopping bag. The oxidation-biodegradable shopping bag is prepared from the following raw material components: a resin additive, a degradable master batch and a filling agent; the oxidation-biodegradable shopping bag is prepared from the raw material components in percentage by mass: 87 percent to 96 percent of the resin additive, 3.0 percent to 10 percent of the degradable master batch and 1.0 percent to 3.0 percent of the filling agent; a preparation process is simple, and production equipment and a production process do not need to be changed; the oxidation-biodegradable shopping bag can be recycled and waste materials are not generated; toxic substances are not generated in production, storage, utilization and degradation processes; original performance of a product is not influenced; the productivity is improved; especially, the productivity of thin film and sheet material products is improved; the thickness can be properly reduced when mechanical properties are the same; the raw materials adopt conventional materials and a natural modifier; compared with energy source investment of competitive products or directly-biodegradable products, the energy source investment of the oxidation-biodegradable shopping bag is the lowest and the energy consumption of other products is 3 times as much as that of the oxidation-biodegradable shopping bag; few polymers are used so that natural resources are ensured; the waste materials are reduced; in a composting process, nutrients are easily supplemented and the value of useful humus soil is not influenced.

Owner:昆明鑫鑫大壮降解塑料技术有限公司

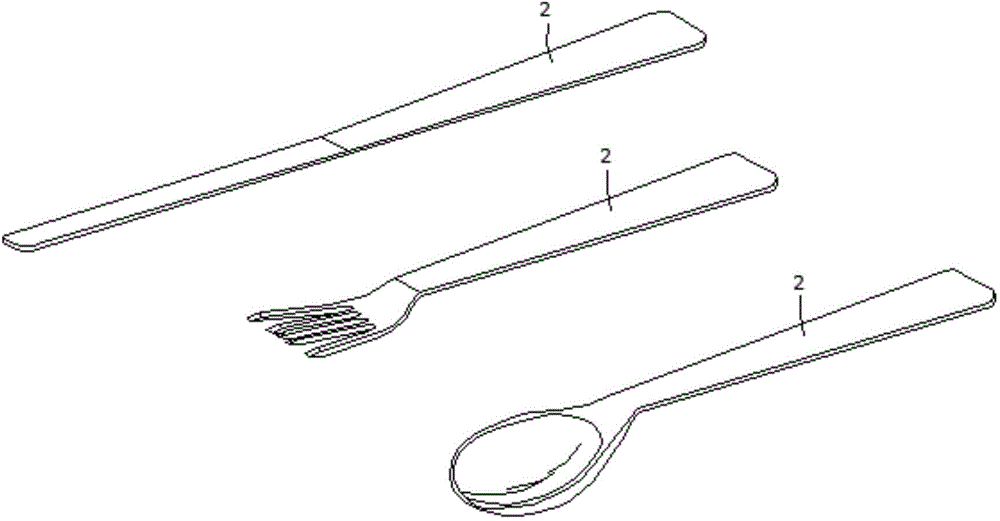

Product prepared from additive type biodegradable composition

The invention provides a product prepared from an additive type biodegradable composition. The product is prepared by the following steps: grinding sodium sulfate or a starch material until powder with a size over 1000 meshes is obtained, then adding synthesized biodegradable resin as the main raw material and other additives, mixing, stirring the mixture in a high-low temperature boiler in a high speed until the mixture becomes paste, then kneading the paste in a kneading machine, cooling to obtain blocks, transferring the blocks to a granulating machine to carry out mixing and granulating, cooling the granules by water, cutting and forming to obtain biodegradable composition particles, and finally making the biodegradable composition particles into biodegradable products such as bags, tableware, and the like. The product has the advantages of high heat resistant temperature, high transparency, low cost, and easy degradation, can be degraded in nature, and will not pollute the environment.

Owner:刘增平 +1

Biodegradable molded products

InactiveCN102686803AIncrease elasticityAvoid lossNon-fibrous pulp additionFlexible coversChemistryBiodegradable product

The invention relates to a process of manufacturing 100% biodegradable molded products. The process includes the use of materials such as starch, and corn wastes such as corncobs, cornstem, corn roots and cornleaves. Accordingly, the corn wastes are pulverized and added to a determined ratio of water and starch to produce a pulp mixture. The pulp mixture is then molded into desired shape of products using determined amount of pulp mixture to prevent wastage. The biodegradable molded products require no coating for water resistance or trimming unlike previous products which are produced using conventional processes. These biodegradable molded products can be molded into various uses such as food catering utensils, packaging and containers for various industries. The resulting biodegradable product is inexpensive, 100% biodegradable and useful.

Owner:R·默罕萨斯·纳拉亚纳萨梅

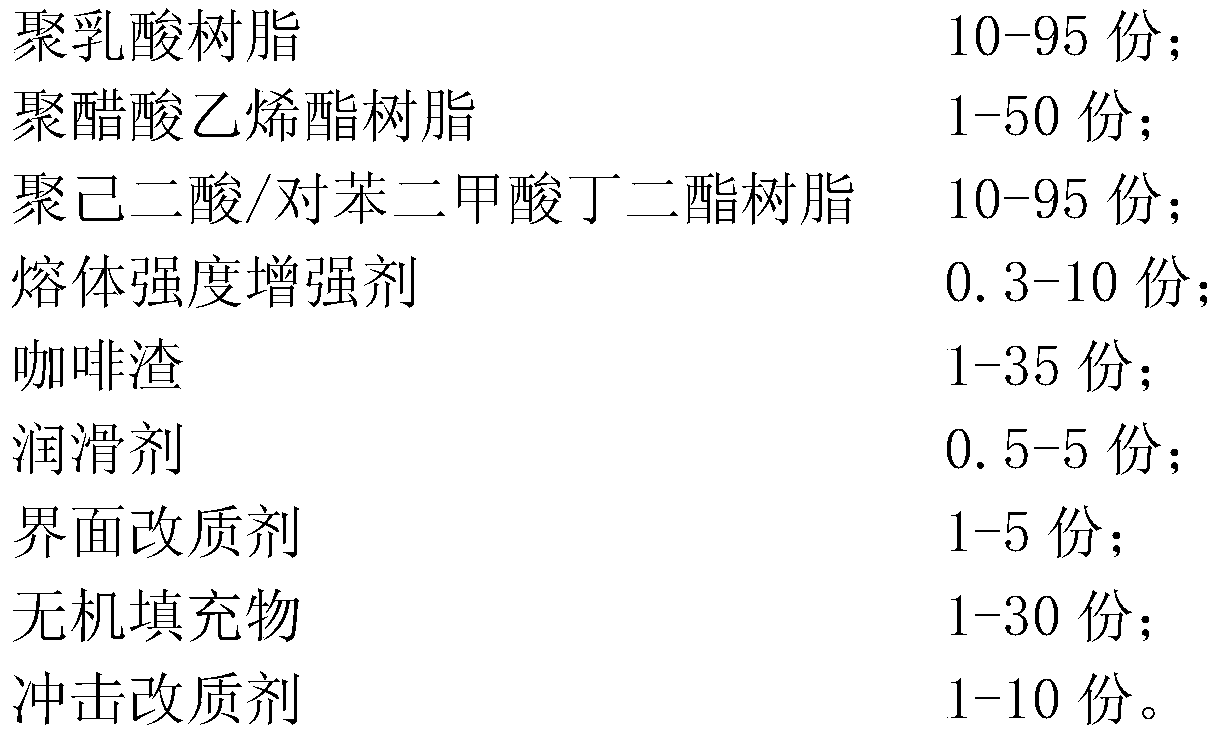

Biodegradable coffee grounds composite material and its products

ActiveCN105985616BSolve problems that can only be used in low-level applicationsBiodegradable productFood packaging

The invention provides a biodegradable coffee grounds composite material and its products. The composite material is directly made of coffee grounds through surface treatment and then added with biodegradable materials, and then modified to make biodegradable coffee grounds composite materials. Material. The molded products of the composite material are widely used in the film industry, such as disposable garbage bags, food packaging bags or films used in agriculture, thus solving the problem that coffee grounds can only be used in low-level applications.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Castor oil-based quaternary ammonium salt anti-mud agent and preparation method thereof

ActiveCN110627746ASynthetic raw materials are readily availableMild reaction conditionsOrganic chemistryChemical recyclingBiodegradable productSuperplasticizer

The invention discloses a castor oil-based quaternary ammonium salt anti-mud agent and a preparation method thereof. The anti-mud agent is prepared from ricinoleic acid, N, N-dimethyl-1, 3-propane diamine and epoxy chloropropane; and the specific preparation method comprises the following steps: putting castor oil and a catalyst into a reaction container, introducing nitrogen, dropwise adding N, N-dimethyl-1, 3-propane diamine while stirring at room temperature, heating for reaction after dropwise adding is finished, and treating to obtain ricinoleic acid amide; and putting ricinoleic acid amide into a reaction container, introducing nitrogen, slowly dropwise adding epoxy chloropropane while stirring, controlling the temperature at 48 DEG C, heating to 50 DEG C after dropwise adding is finished, carrying out heat preservation reaction for 1 hour, removing excessive epoxy chloropropane with n-hexane, and carrying out vacuum drying to obtain a finished product. The anti-mud agent can quickly adsorb mud, reduce the mixing amount of polycarboxylate superplasticizers and ensure the performance of concrete, and the preparation method has the advantages of easily available synthesis raw materials, mild reaction conditions, biodegradable product, no influence on the environment, and low synthesis cost and post-treatment cost.

Owner:YANCHENG INST OF TECH

Strategies for reducing leaching of water-soluble metal biocides from treated wood products

InactiveUS20110091575A1Reduce leachingImprove metal resistanceBiocideInorganic active ingredientsBiodegradable productOxygen

Strategies that dramatically reduce leaching of water-soluble metal-containing biocides from treated biodegradable products. Aqueous, preservative compositions of the present invention incorporate one or more water-soluble metal species having biocidal activity and one or more agents that increase the leaching resistance of these metal species when impregnated into biodegradable products. Using one or more of these agents allows usage rates of the biocide impregnants to be dramatically lowered at the time of impregnation of the products. Because less of the metal biocide leaches in the presence of these agent(s), less biocide has to be added in order to meet desired loading goals. Generally, an agent of the present invention that reduces leaching of metal biocides is water soluble, is substantially nonionic in aqueous media, has a molecular weight greater than about 100, and has a vapor pressure less than that of water at standard temperature. Preferred agents are those including at least 10 weight percent, more preferably at least 16 weight percent, and even more preferably at least 20 weight percent oxygen. Examples of these preferred agents include (poly)ethers and / or nonionic surfactants including one or more oxyalkylene units in the backbone and / or as substituents of the molecule.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

Preparation method of oxidized biodegradable mulching film

InactiveCN107383544APerformance is not affectedSimple preparation processPolymer scienceBiodegradable product

The invention belongs to the technical field of degradable plastics, and specifically relates to a preparation method of an oxidized biodegradable mulching film. The oxidized biodegradable mulching film is prepared from a resin additive and a degradable master batch, wherein the raw material components in mass percent are as follows: 98-99.8% of the resin additive and 0.2-2.0% of the degradable master batch. According to the preparation method of the oxidized biodegradable mulching film, the preparation process is simple without the need of changing the production equipment and process; the mulching film can be recovered without generating waste; no toxic substance is generated in the processes of production, storage, use and degradation; the inherent properties of the products are unaffected; the productivity is increased especially for film and sheet products; the thickness of the film can be appropriately reduced under the condition of the same mechanics properties; the raw materials adopt general materials and natural modifiers; the energy source investment is the lowest compared with compatible products or directly biodegradable products, because the energy consumption of other products is as high as 3 times of the oxidized biodegradable mulching film; less polymers are used and natural resources are guaranteed; waste is reduced; and supplement nutrition is benefited in composting without influencing the value of available humus soil.

Owner:昆明鑫鑫大壮降解塑料技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com