Biodegradable fat-aromatic copolyester with low carboxyl content and multi-branched chain structure, and preparation method and application thereof

A technology of aromatic copolyester and carboxyl content, applied in the field of biodegradation of fat-aromatic copolyester and its preparation, can solve the problems of destroying the earth's ecological environment, product yellowing, and odor generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

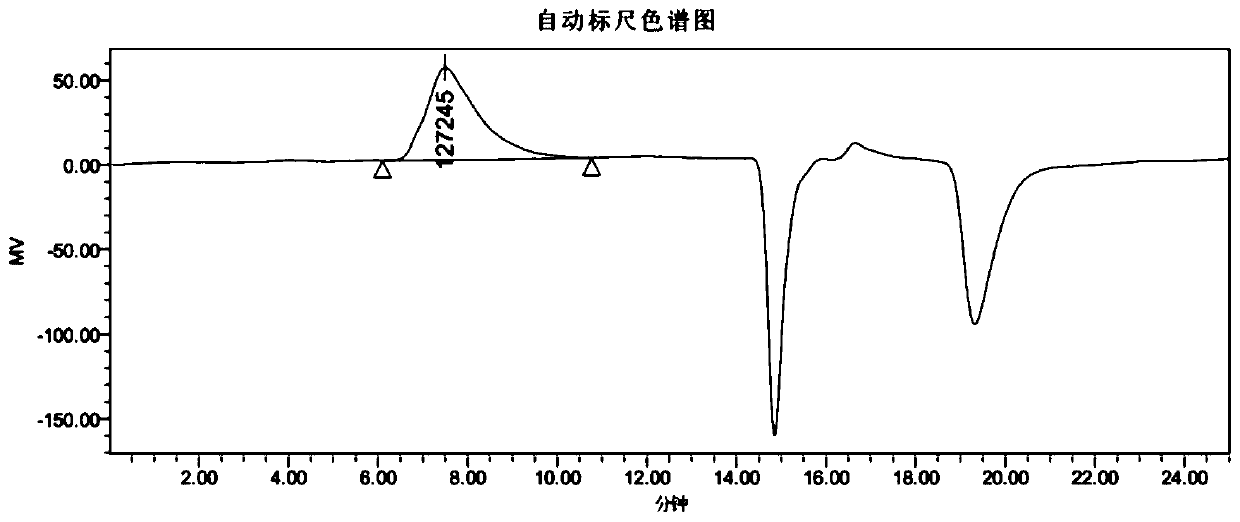

Image

Examples

preparation example Construction

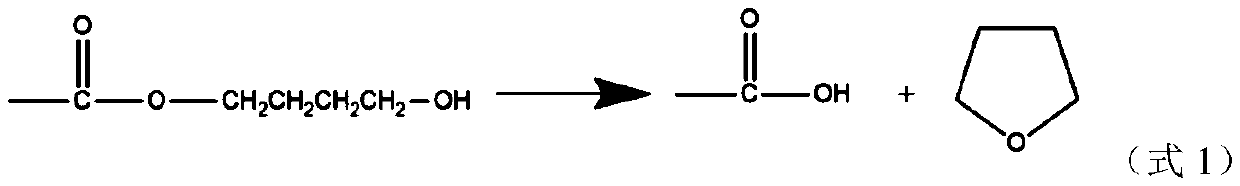

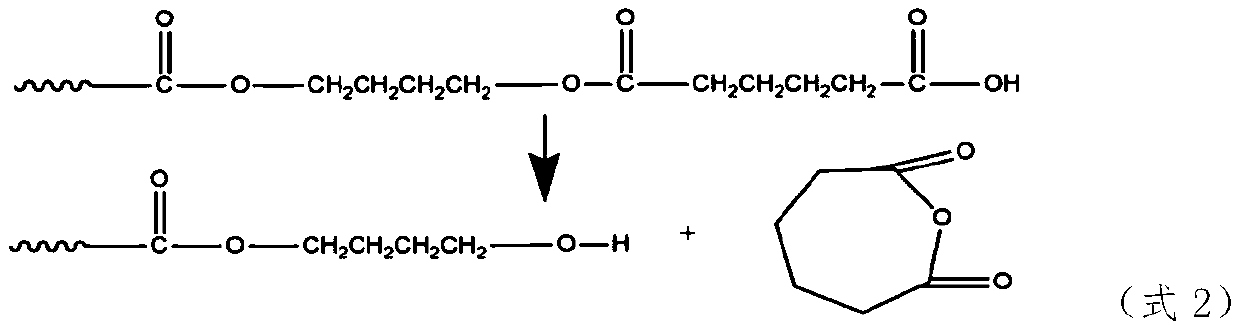

[0045] Another object of the embodiments of the present application is to provide a simple and feasible method for preparing a biodegradable aliphatic-aromatic copolyester with a low carboxyl group content and a multi-branched structure, which comprises the following steps:

[0046] Step 1: First, the polymerized monomer a, the polymerized monomer b, the polymerized monomer c, and the polymerized monomer d are mixed, and then the esterification reaction is carried out under the conditions of an absolute pressure of 0.1 to 0.05 MPa and a temperature of 140 to 260 ° C. When the completion rate of esterification is greater than or equal to 97%, an esterified product with a completion rate of esterification greater than or equal to 97% is obtained, and the polycondensation reaction in the next step is carried out.

[0047] Step 2: The above-mentioned ester compound is subjected to a polycondensation reaction under the conditions of an absolute pressure of 0.1 MPa to 5 Pa and a temp...

Embodiment 1

[0064] The present embodiment provides a kind of aliphatic-aromatic copolyester, which is prepared according to the following preparation method:

[0065] Weigh 4.60 kilograms of adipic acid, 4.30 kilograms of terephthalic acid, 9.30 kilograms of 1,4-butanediol, 60 grams of glycerol, 115 grams of 2-naphthoic acid, and 12 grams of tetrabutyl titanate, and add them to 30 liters of esterified In the reaction kettle, the temperature is raised to 200-250° C. in a temperature-programmed manner, and the reaction is stirred for 2-5 hours until the esterification rate reaches more than 97% to obtain an esterified product.

[0066] Transfer the esterified product to a 30-liter polycondensation kettle with a decompression device, vacuumize to an absolute pressure of 3-5Kpa under stirring, heat up to 200-250°C at the same time, stir and react for 0.5-2 hours, and further reduce the pressure to an absolute pressure of 100 ~200Pa, continue the reaction for 0.5~3 hours, judge the reaction en...

Embodiment 2

[0068] The present embodiment provides a kind of aliphatic-aromatic copolyester, which is prepared according to the following preparation method:

[0069] Weigh 4.10 kilograms of succinic acid, 4.60 kilograms of terephthalic acid, 10.00 kilograms of 1,4-butanediol, 50 grams of pentaerythritol, 90 grams of benzoic acid, 10 grams of tetraisopropyl titanate, and add them to 30 liters of esterification reaction In the kettle, the temperature is raised to 200-250° C. in a temperature-programmed manner, and the reaction is stirred for 2-5 hours until the esterification rate reaches over 97% to obtain an esterified product.

[0070] Transfer the esterified product to a 30-liter polycondensation kettle with a decompression device, vacuumize to an absolute pressure of 3-5Kpa under stirring, heat up to 200-250°C at the same time, stir and react for 0.5-2 hours, and further reduce the pressure to an absolute pressure of 100 ~200Pa, continue the reaction for 0.5~3 hours, judge the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com