Castor oil-based quaternary ammonium salt anti-mud agent and preparation method thereof

A castor oil-based, anti-mud agent technology, applied in the field of concrete admixtures and building materials, can solve the problems of toxic and harmful chemical reagents, poor concrete performance, high operation risk, etc., and achieve low synthesis cost and post-processing cost. The effect of adsorption and reduction of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

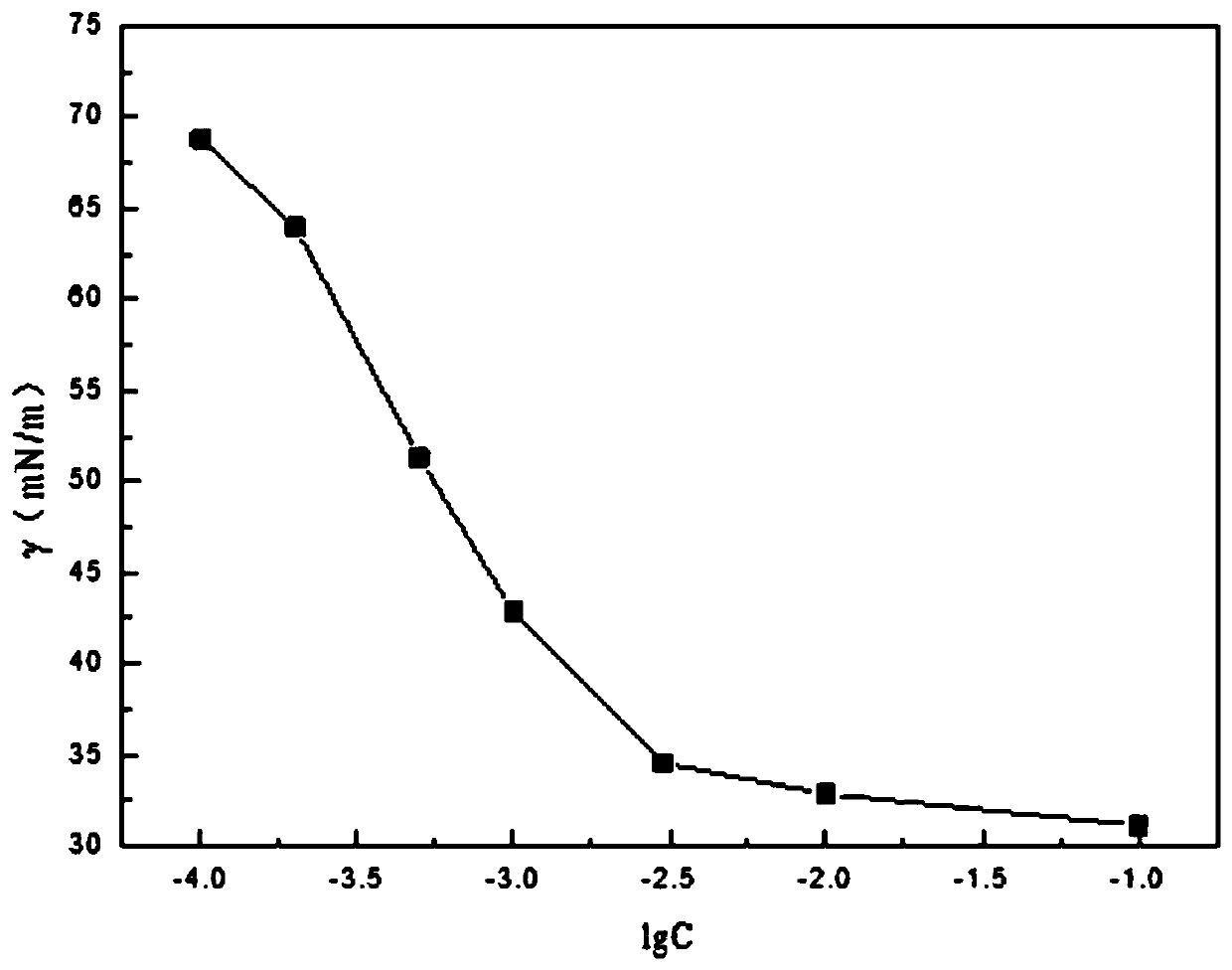

[0030] The preparation reaction of the castor oil-based quaternary ammonium salt anti-mud agent is shown in Reaction Formula II:

[0031]

[0032] The preparation method of described castor oil-based quaternary ammonium salt anti-mud agent, concrete steps are as follows:

[0033] (1) Add castor oil and catalyst NaOH into the reaction vessel, pass nitrogen gas for 5 minutes, add N,N-dimethyl-1,3-propanediamine dropwise while stirring at room temperature, and raise the temperature to 65-90 °C, react for 5-10 hours.

[0034] (2) The reaction product obtained in (1) is washed with distilled water, then left standstill, removes the turbid liquid of the lower floor, and washes repeatedly like this, until the lower floor is clarified, removes the lower floor, and retains the ricinoleic acid amide crude product of the upper floor.

[0035] (3) Vacuum drying the crude ricinoleic acid amide to remove excess water to obtain ricinoleic acid amide.

[0036] (4) Weigh the ricinoleic ac...

Embodiment 1

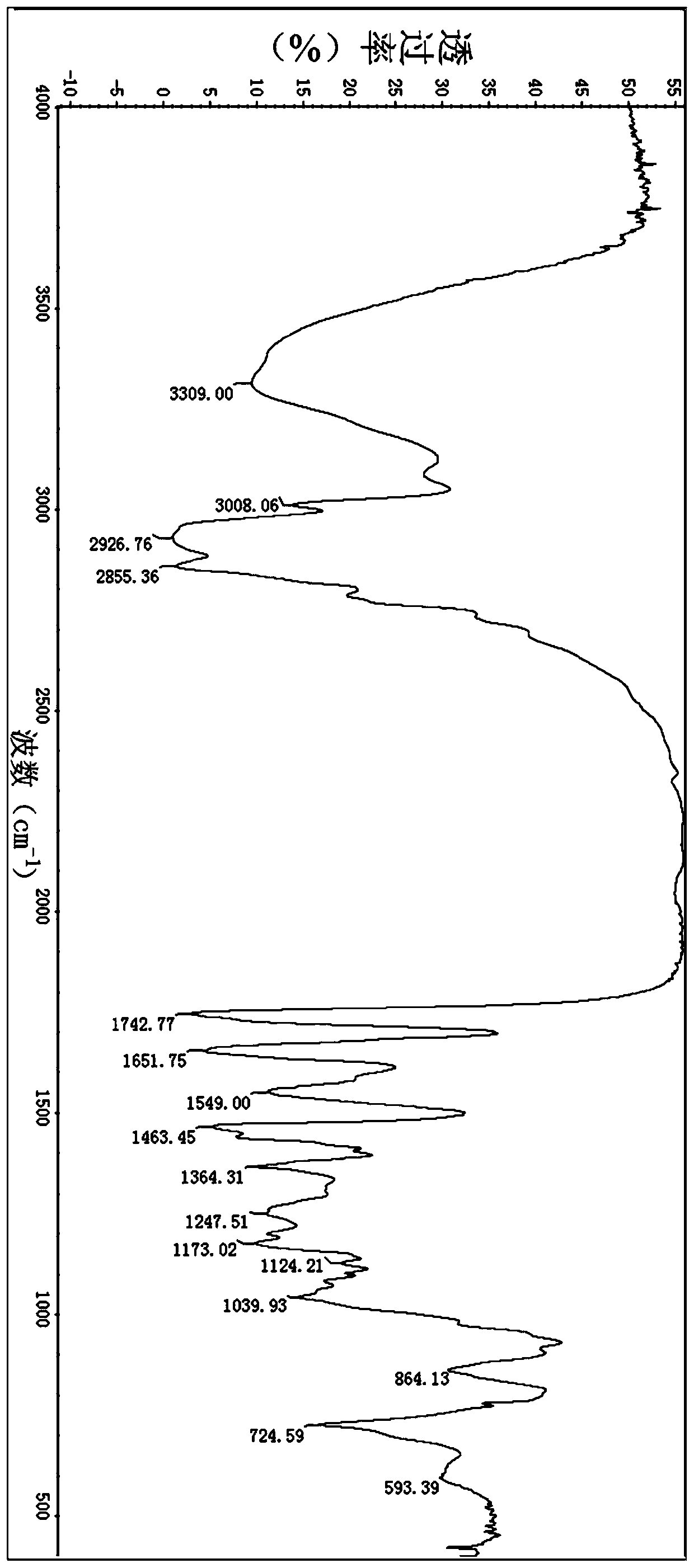

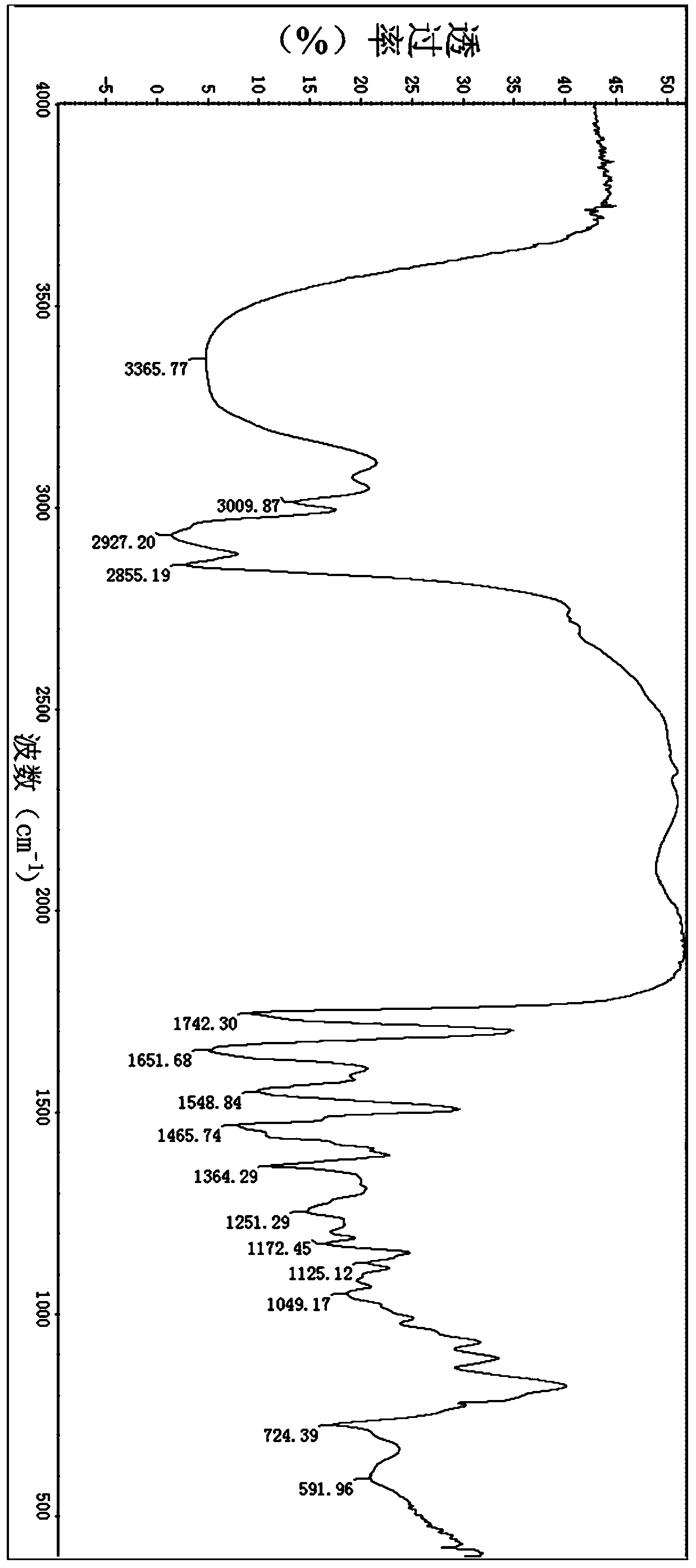

[0038] The preparation of embodiment 1 castor oil base amide

[0039] 10g castor oil is subjected to vacuum distillation to remove water and other solvents in the castor oil, then the treated castor oil is added to a four-necked flask with a mechanical stirring device, N,N-dimethyl-1, 3-Propylenediamine was reacted with catalyst NaOH at 80°C for 8 hours under stirring conditions to obtain ricinoleic acid amide.

[0040] Wherein, the molar ratio of N,N-dimethyl-1,3-propanediamine to castor oil is 3:1, and the amount of the catalyst is 6% of the weight of the reactant castor oil.

[0041] The yield of the product ricinoleyl amide was 68.38%.

Embodiment 2

[0042] The preparation of embodiment 2 castor oil base amides

[0043] 10g castor oil is subjected to vacuum distillation to remove water and other solvents in the castor oil, then the treated castor oil is added to a four-necked flask with a mechanical stirring device, N,N-dimethyl-1, 3-Propylenediamine was reacted with catalyst NaOH at 80°C for 8 hours under stirring conditions to obtain ricinoleic acid amide.

[0044] Wherein, the molar ratio of N,N-dimethyl-1,3-propanediamine to castor oil is 4:1, and the amount of catalyst used is 6% of the weight of reactant castor oil.

[0045] The yield of the product ricinoleylamide was 72.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com