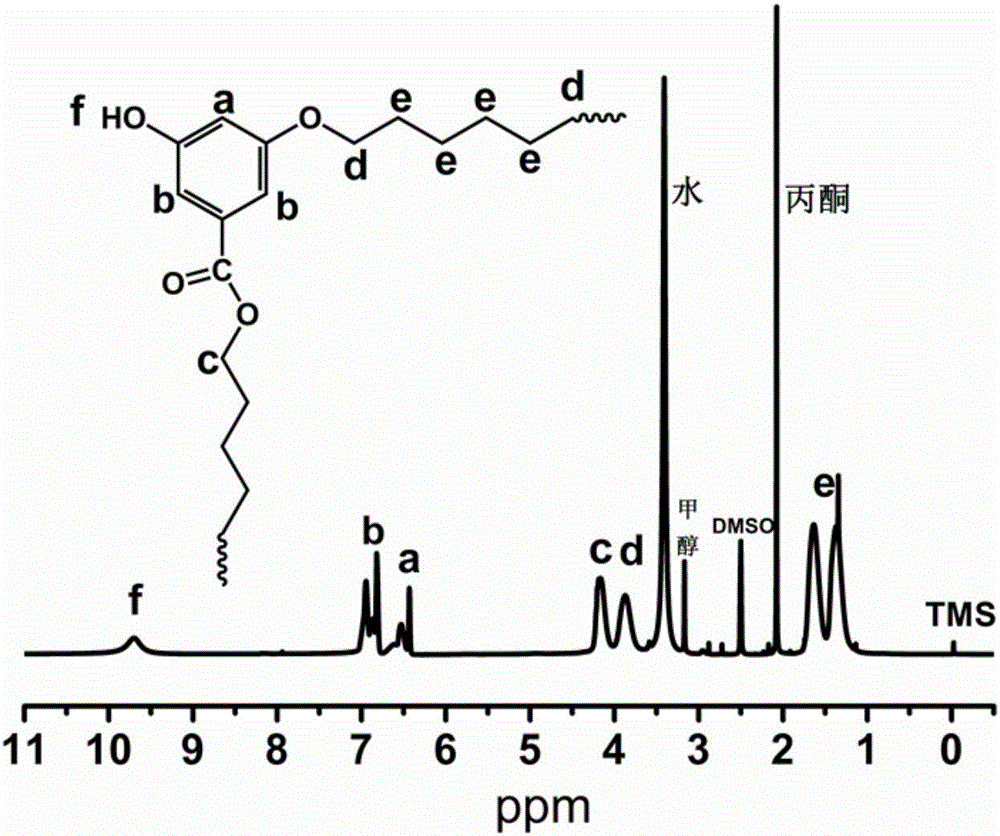

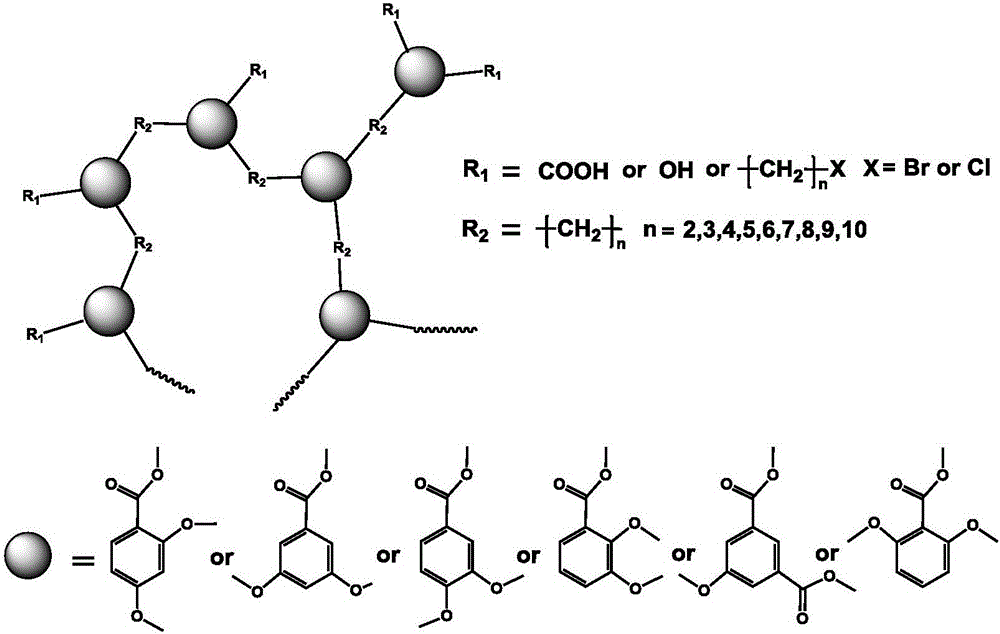

Hyperbranched polyether ester preparation method

The technology of a polyetherester and a polymerization method is applied in the field of preparation of hyperbranched polyetherester, which can solve the problems of lowering performance and achieve the effects of high controllability, easy availability of synthetic raw materials, and high selective activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

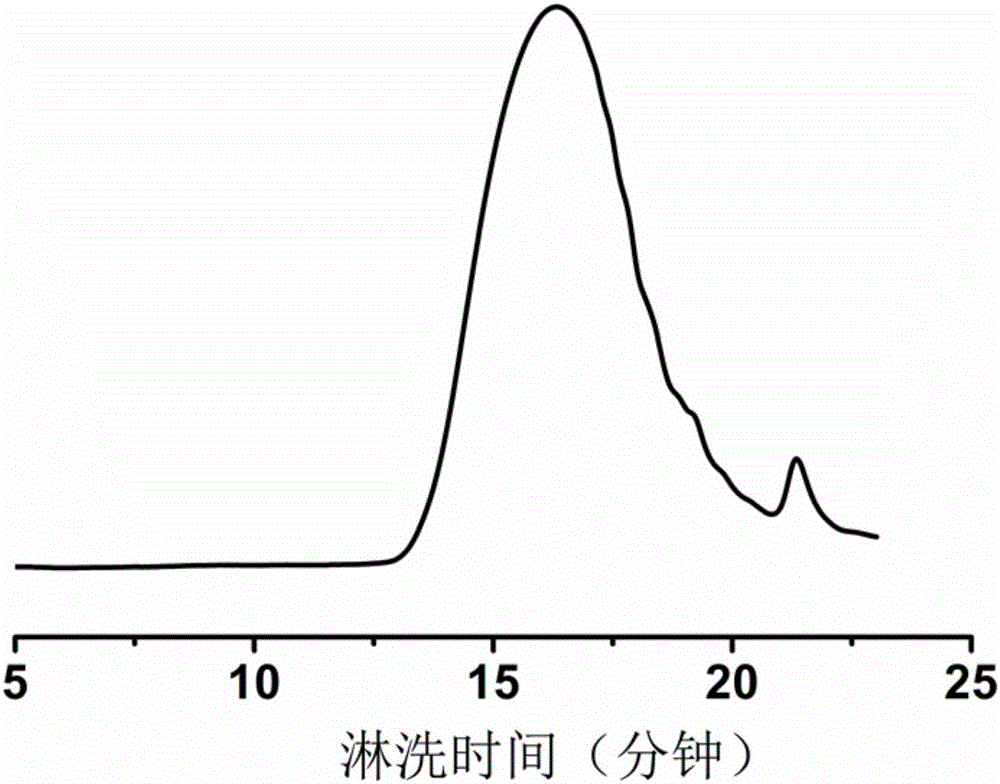

Method used

Image

Examples

Embodiment example 1

[0026] Add 10.0g (0.065mol) of 2,3-dihydroxybenzoic acid, 53.9g (0.39mol) of acid-binding agent potassium carbonate, and 31.6g (0.13mol) of 1,6-dibromohexane into the reactor at the same time and dissolved in 83.2mL of N,N′-dimethylformamide; the temperature was raised to 20°C for 96 hours; after the reaction was completed, acidified with inorganic acid, and the precipitate was filtered to obtain the filtrate; the filtrate was mixed with equal volumes of ethanol and deionized water Precipitated in the dissolved precipitant, dried for 24 hours, and obtained 8.6 g of light yellow solid with a yield of 86%.

Embodiment example 2

[0028] In this embodiment, in the preparation process of hyperbranched polyether ester by the seedless one-pot method, the raw material 10.0g (0.065mol) 3,5-dihydroxybenzoic acid is replaced by 10.0g (0.065mol) 3,4-dihydroxybenzene Formic acid, others are identical with embodiment case 1.

Embodiment example 3

[0030] In this embodiment, in the preparation process of hyperbranched polyether ester by the seedless one-pot method, the raw material 10.0g (0.065mol) of 3,5-dihydroxybenzoic acid is replaced by 10.0g (0.065mol) of 2,6-dihydroxybenzene Formic acid, others are identical with embodiment case 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com